Changing the power steering pump with your own hands

Power steering problems begin to manifest themselves in the form of heaviness when the steering wheel is turned, especially at low speeds; a hum may appear and a whistle may appear. When the device finally broke down, it stopped helping to steer even when not warmed up.

Since the venerable age of the car left no hope for official warranty service, I decided that the replacement of the power steering would be done on my own.

Looking ahead, I would like to note that replacing parts yourself in order to save money on repairs showed the excessive optimism of such an idea. The work of replacing it turned out to be quite labor-intensive.

However, for those for whom working with a car is a kind of vacation, repairing a hydraulic drive will not seem like anything special.

It is worth assessing the need to purchase a pump, pulley, oil seal, Teflon ring for high-pressure pipes and a belt. I get to work by removing the protection and the mudguard on the belts. Next, the coolant tanks are removed. I remove the power steering belt or simply cut it, depending on its condition. Next comes the disconnection of the power steering tubes, both inlet and outlet, attached to the nuts.

On the right side of the radiator, I remove the oil seal, the supply tube, which is held in place by a simple clamp, and then drain the liquid from the tube. To completely remove fluid from the system, it is advisable to have someone spin the car's wheels.

After this operation, I disconnect the flange of the power steering high pressure pipe. The next step is to unscrew the clamp securing the supply tube. The pump mount is held in place by four bolts. I unscrew three of them at once, and access to the fourth opens after unscrewing the timing belt housing bolts.

Now you can remove all four bolts holding the pump in place.

How to change the pump

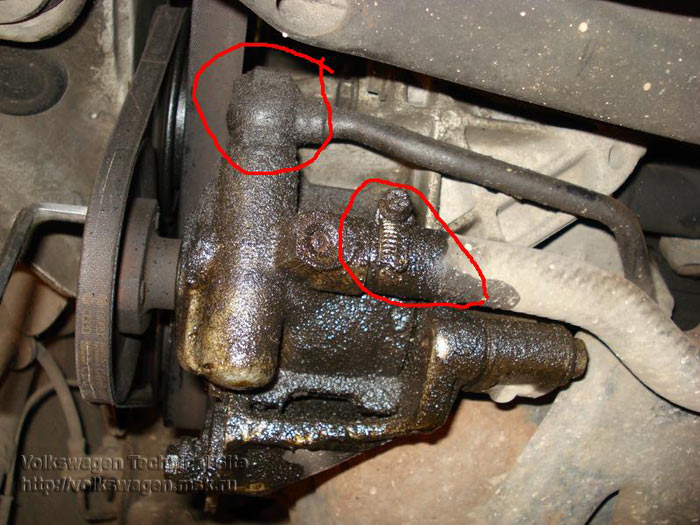

Disassembly of the pump and dismantling of the power steering must be carried out according to the instructions. Next, I recommend cleaning it from dirt and inspecting it to identify the causes of the malfunction.

Often the cause of failure is wear in the internal cavity of the pump housing. Visually it is perceived as a step. You can deal with the defect using a drill with an attachment.

However, difficulties may arise if you come across a non-dismountable pump model that has neither retaining rings nor covers.

I broke the clamps securing the pipes to the tank, since in my case the clamps turned out to be disposable. After which I drained the remaining fluid from the tank. When using it again, you should definitely look inside and check the cleanliness of the mesh located there.

If necessary, the tank should be washed or bought a new one, since its cost is low. Cleaning the system does not end there. It is advisable to clean all the insides with compressed air under a pressure of eight atmospheres.

After this, the pump pipe clamp is disconnected.

Teflon gaskets are durable, but on high-pressure pipe flanges they should be replaced with new ones. Even in comfortable conditions - a garage, a pit - replacing the pump took me about three hours of work. In general, replacing the pump takes about six hours of careful work.

If the design of the pump allows it to be repaired, then pressing out the pulley and oil seal takes a special place. But in order to save time and effort, it is better to replace it with a new one. If replacement is not possible, you will have to press a new pulley onto the shaft of the new pump. The structure is secured with a screw and nut. The pump shaft has an M6 thread inside.

In order to place a flange on the shaft, it must be preheated. After cooling, it will sit tightly on the shaft. Inside the pump, the power steering bearing is secured with a curved edge.

Installation of the power steering is carried out in the reverse order. I tensioned the belt using a cone. Sometimes a special tin device is used for these purposes. Or another option is possible, when the power steering mount is not fully tightened and the belt is loosely put on the pulley. Only after this is the entire structure secured with the required degree of belt tension.

Bleeding the pump after installation

The power steering pump is assembled in reverse order . After assembly, the power steering may make a buzzing noise, but you should not be afraid of this, since the parts will wear in after 300-500 kilometers. Some car owners keep the power steering fluid, but I would recommend adding new fluid.

Usually it is filled until the tank is completely filled. The system is filled with the engine running. It is important to prevent air from entering the system. If this could not be avoided, as happened to me, then after the fluid had foamed, I stood for about thirty minutes with the reservoir open, constantly adding it to the power steering.

And even after that, for two hours the power steering jerked at times.

Video “Replacing the power steering pump at home”

In the video below you will learn how to replace the power steering pump at home.

Source: http://MineAvto.ru/remont/rulevoe-upravlenie/menyaem-nasos-gura-2067.html

Do-it-yourself replacement and repair of power steering (power steering)

Modern cars are equipped with power steering - this simplifies any maneuvers. Such a system must be maintained, sometimes changing components. Consider a situation when the amplifier needs to be replaced. To ensure that the mechanism operates correctly, promptly correct any errors.

Modern cars are equipped with power steering - this simplifies any maneuvers. Such a system must be maintained, sometimes changing components. Consider a situation when the amplifier needs to be replaced. To ensure that the mechanism operates correctly, promptly correct any errors.

❶ When turning the steering wheel, more effort is required or the manipulation is very easy. Apparently the pump was faulty. You need to look at the composition of the filling tank. Without fluid, the power steering stops functioning.

❷ When holding the steering wheel, you feel shocks, and it has become more difficult to turn corners. This is due to insufficient tension on the drive belt.

If there is insufficient idle speed, a similar effect is possible.

❸ When driving, noises are heard from the steering unit. It happens that the rod ends are set incorrectly, so the fasteners remain weak. Damage can be caused by incorrect placement of power steering pipes on the body.

❹ The steering wheel turns - the valve pump that controls the flow has become jammed. If there is insufficient pressure, the situation becomes identical.

❺ The effect of “airing” the control system will not allow you to control the machine. Evaluate the functionality of ball joints.

❻ Occurred by unscrewing a pump pulley that was installed incorrectly.

❼ When the steering wheel turns with varying success (difficulty and smoothly), it is worth considering the fasteners on the turn switches. Even poor alignment of the flow control valve element will reflect this defect.

❶ Clean the engine compartment and remove accumulated dirt.

❷ We drain the liquid by turning the steering wheel.

❸ Unscrew the clamp that secures the supply tube.

❹ Remove the screws holding the installation shaft.

❺ Disconnect the rods on the bipod.

❻ Raise the vehicle to remove the left wheel.

❼ Unscrew the bolts that hold the pump.

❽ We place the container under the fittings, then disconnect the hoses one by one.

➒ To remove the power steering, remove the bolt and remove the unit.

❶ Having placed the pump, we start the equipment from the crankshaft pulley.

❷ Tighten the front bolt, fixing the pulley.

❸ We will fix the connections on the equipment.

❹ We connect the pipelines, paying attention to the joints of the components. We install the seal rings.

❺ Fasten the nut to the pressure pipe.

❻ Place the steam exhaust hose on the pump fitting.

❼ Tighten the hose clamp.

❽ Fix the drive belt of the auxiliary elements.

➒ Bleed the amplifier system.

When all activities have been completed, double-check and test the equipment.

Source: https://vseautomobile.ru/obzory/1586-zamena-i-remont-gidrousilitelya-rulya-gur-svoimi-rukami.html

Do-it-yourself diagnostics and repair of the power steering pump

We will repair the main unit of the car's control system, the power steering pump.

We will repair the main unit of the car's control system, the power steering pump.

Those who have already encountered car breakdowns know for sure that repairs at service centers will be a little expensive.

It’s much easier than ever, the most important thing is cheap - to do it yourself. At the same time, putting a little knowledge and effort into this process. The inherent content of the material will allow you to get acquainted with the independent repair of the power steering pump.

You can also carry out diagnostics to identify malfunctions in the operation of the pump itself.

The process of removing the power steering pump:

The elements that make up the pump.

The most difficult part of dismantling is to free the pump from disconnecting the supply hoses with tubes and draining the hydraulic fluid. Initially, we loosen the belt or unhook the gear drive, then unscrew it from its attachment to the engine block. We flush the housing to remove dirt accumulation.

Next, we disassemble the pump housing itself. Very carefully remembering this moment how everything is attached (or otherwise there will be a problem during assembly), then we carefully clean all the component elements from dirt from the inside.

We visually determine the cause of the malfunction, it could be:

With a detailed inspection of the internal parts of the pump, we determine their working condition.

1. Burr.

2. Worn bearing.

3. Rubber gasket.

4. Uneven surface of the inner part of the cylinder (stator).

We inspect the rotor, paying attention to the grooves: their edges should be smooth and sharp, without chips or nicks.

Next, we look at the inner working surface of the stator; it often happens that its wear is the cause of problems with the power steering pump.

We remove the found faults:

All we may need in the upcoming work is this!

- alcohol (White Spirit is best, also known as gasoline solvent or a can of WD40);

- sandpaper (from P2000 to P1000);

- cloth or soft paint brush;

- small needle file or file;

- electric drill;

We use sandpaper to clean the seats of the rotor blades.

Cleaning the rotor comes down to eliminating irregularities and burrs of the grooves, as well as grinding the rotor surface.

It is better to work with gloves, as the edges of the rotor are very sharp. Try to keep the movements smooth and uniform for smoother grinding.

There is no consensus on the method of grinding the inner surface of the stator. If you have enough patience and time, you can try leveling it manually.

The algorithm is like this:

First, we do a rough cleaning with a file, then smooth it with coarse sandpaper and polish it with sandpaper.

It is easier to adapt an electric drill using a drill and sandpaper.

You will get something like a mini-grinding machine by screwing sandpaper onto a drill with a diameter of at least 12 mm (against the rotation of the drill).

When sanding with a home-made unit, you should try to evenly distribute the load over the entire surface, without being too zealous and remembering to change the sandpaper from coarse to fine.

Using a drill and sandpaper, we eliminate uneven surfaces of the stator.

Having finished with grinding, we will return the power steering pump to its original working condition. When performing the assembly process in the reverse order, it would be useful to first check whether the shaft rotates easily inside the pump itself.

The final touch will be to install the cover in place, with the preliminary installation of a new sealing gasket. During the assembly process itself, the cover is easily tightened with four bolts, which are best pulled crosswise, thereby achieving a uniform, precise fit of the cover plane to the stator.

Watch a video tutorial on how to repair a power steering pump yourself.

Watch a video lesson on how the power steering system works.

Source: http://remcars.info/neispravnosti-i-sposoby-ih-ustroneniya/remont-nasosa-gur-svoimi-rukami.html

Do-it-yourself power steering pump repair: to add to the motorist’s knowledge base

Home page » Electronics » ECU » Do-it-yourself power steering pump repair: adding to the motorist’s knowledge base

The hydraulic booster is a closed hydraulic system, the main elements of which are as follows:

- power steering pump;

- expansion tank containing consumables;

- controller that regulates pump pressure;

- control element;

- power cylinder.

The power steering pump is the main component in the design of the steering system. Thanks to this unit, hydraulic oil is pumped from the expansion tank through the lines, which subsequently disperses around the ring.

Depending on the vehicle, the main types of units used are plate or gate mechanisms. As reviews show, this principle of operation allows for minimal wear of parts and surfaces.

However, units of this type also have a drawback - the bearing elements wear out more often, as a result of which the car owner has to repair the power steering with his own hands.

Design and designation of pump elements

The pressure level in such systems is quite high - it is about 150 bar maximum. According to the principle of operation, this unit begins to work as a result of the influence of a belt on it, turning the generator device, as well as the pump.

It should be noted that the design of the power steering pump, whether it is an MSG system or any other, requires clearances in the design as determined by the manufacturer. Typically these gaps should be around 0.005-0.01mm.

If the gap begins to increase, this may lead to a decrease in the pressure level at low speeds, that is, the steering wheel may become tight.

The main elements that determine the normal operating principle of the system are the power steering pump pulley, as well as the power steering pump pressure reducing valve.

Signs and causes of malfunctions

For what reasons can a MSG or another brand system hum and whistle, and how can I check the unit? In general, plate systems represent a unit with a long service life. But if mistakes were made in using the unit, this can lead to buzzing and other damage.

The main malfunctions of the MSG pump or any other are as follows:

- an oil leak occurred, its level in the lines decreased;

- the oil has been changed quite a long time ago and has already lost all its features and characteristics;

- foreign objects or impurities have entered the lines or mechanisms of the system;

- the oil stops moving through the system, and the mechanism may overheat (the author of the video is the Do-It-Yourself channel).

To avoid having to repair your power steering, you should always monitor the level of consumables in the system. In addition, repair of the power steering pump can be avoided by regularly diagnosing the lines for integrity.

So, we figured out why the system is humming, now let’s look at the main signs of a malfunction:

- When driving at low speeds, you have to put more effort into turning the steering wheel. When the speed increases, this need disappears.

- When turning the steering wheel, extraneous sounds appear.

- Under the bottom of the car and on the elements of the power unit, leaks from hydraulic oil may appear.

- While driving, the bearing device may whistle.

Before repairing, you need to check the pump. If external diagnostics show a faulty unit, it needs to be replaced or repaired.

Sorry, there are no surveys available at this time.

Instructions for replacing and repairing the pump

The mechanism can be checked at home. It is possible that repairing the power steering pump yourself will only involve replacing the worn-out bearing element. Often the cause of breakdowns is the formation of air jams in the lines of the unit, so first of all it is necessary to pump the hydraulics and get rid of the plugs.

So, how to overhaul and replace the power steering pump at home:

- First you need to slightly loosen the bolt that secures the pump itself to the bracket; for this, use the hole located on the pulley. It is necessary to completely unscrew the lock nut of the tensioner device and dismantle the strap.

- Using a syringe and tube, you need to pump out the consumables from the expansion tank. To ensure that the fluid leaves the system as much as possible, you can turn the steering wheel in different directions during the process.

- Then you need to slightly loosen the clamp on the pipe coming from the tank; this section of the line can be dismantled.

- After these steps, unscrew the bolt securing the high-pressure pipe that goes from the device to the system. Then you can remove the axial screw that secures the assembly to the bracket and install a screwdriver in its place. Having done this, you can unscrew the nut securing the device pulley.

- Next, you need to pull the pump itself up, then remove it and place it in a place prepared for this. All dust and smudges should be removed from the mechanism body. Using a special puller, it is necessary to dismantle the retaining ring of the bearing element.

- Then you can unscrew the bolts securing the back cover. Carefully and effortlessly pry it up with a screwdriver and remove it, being careful not to let the rotor blades fall out. Remove the blades themselves and place them on paper; it is advisable to number the pieces of paper in advance, otherwise you may make mistakes during assembly.

- Then remove the plate and all the components that are underneath it. Now you need to knock out the shaft; to do this, gently tap it with a hammer or screwdriver.

- The bearing element must be pressed out from the assembly shaft. If it is worn out, replace it with a new one.

- Diagnostics of system elements for defects and damage, clean all surfaces from dust. According to experts, such cleaning will reduce gaps and increase the service life of the unit as a whole. The assembly procedure is carried out in the reverse order of dismantling. Before assembly, check the oil seal and rubber seals; if the washers are in poor condition, replace them.

1. Pump out all consumables with a syringe.2. Unscrew the bolts securing the back cover and remove it.3. Replace the worn bearing with a new one.

Video “Do-it-yourself repair of the power steering pump on a Chevrolet Aveo”

Using the Chevrolet Aveo as an example, you can familiarize yourself with the procedure for repairing the power steering system pump (the author of the video is the Chevrolet Aveo channel).

Do you have any questions? Specialists and readers of the LABAVTO website will help you ask a question

Source: https://labavto.com/elektronika/eby/nasos-gidrousilitelya-rulya/

Do-it-yourself power steering pump repair

x

x

Check Also

The reduction in emissions of volatile organic compounds in the 70s was achieved as a result of tightening control over vehicle exhaust gases, the use of engines with ...

The suspension spring is a structural element of the shock absorber and has a direct impact on driving comfort and safety by maintaining ground clearance...

A car breakdown is always an unpleasant situation for the driver, which wastes money and time. Failures can be divided according to external signs, and...

Each part of the car (as well as the car itself) has its own resource, and nothing will always work. This …

They say that a car's dashboard is its inner face. Throughout the entire journey, the driver looks at the panel, and at night...

For the installation of mufflers on AvtoS towbars, we remove the particulate filter - programmatically and physically. Removing the particulate filter is accompanied by the necessary...

Vibration of the steering wheel and brake pedal when braking One of the biggest troubles in the braking system of a car is the vibration and...

Athermal auto glass. Green, blue, violet glasses Athermal glasses become after specific treatment. Glass of this type has an increased level of protection...

Restoring the transparency of headlights without polishing, by applying varnish How much we haven’t talked about restoring and preserving plastic headlights so that...

The Ford Kuga 2 crossover has appeared on the domestic market since the beginning of 2013 and during this time has gained sufficient popularity and ...

As you know, after the adoption of the traffic rules law in 2010, all vehicles must drive with daytime running lights during the daytime...

Changing engine oil yourself - nuances. How to change the oil correctly Changing the oil yourself - the procedure itself is very simple, but...

Have you ever had this happen to your car? You're driving along the highway and suddenly there are jerks while it's moving? ...

The Lifan Solano car, according to most car enthusiasts, behaves quite well on the road, but sometimes when driving this car there are problems...

The main reasons for high engine oil consumption. Why does he eat more than normal? List of complex and easy faults Engine oil is...

How and with what to reupholster the ceiling in a car without turning to professionals? The upholstery of a car's interior wears out quite intensively during use. ...

Source: http://xn--b1altabgdr.org/avtoremont-i-tyuning/remont-nasosa-gidrousilitelya-rulya-gur-svoimi-rukami

Instructions for replacing and repairing power steering with your own hands

The main malfunctions, their causes and troubleshooting tips are given in the table.

| Problem | Causes | Repair recommendations |

| When driving, you feel a kickback, there are shocks coming from the steering wheel | With such incorrect operation of the power steering, the problem may be wear or poor tightening of the drive belt of the pumping device. | The product needs to be replaced or its tension adjusted. |

| The steering wheel turns hard, you have to make an effort | Causes:

|

To fix the problem:

|

| When turning the steering wheel in the middle position, you have to apply more effort | The malfunction must be looked for in a mechanical breakdown of the pumping device. | A complete diagnosis of the pump is performed. Depending on the problem, it is repaired or replaced. You also need to diagnose the entire steering system. |

| When turning the steering wheel to one side, more effort is required | Problems with the pump. | The pumping device is diagnosed and repaired. Often the reason is related to the seals and requires replacement. |

| The driver has to exert more effort when the steering wheel is turned quickly | Causes of malfunction:

|

The repair principle is as follows:

|

| The power steering system as a whole does not function correctly | Possible causes of the malfunction:

|

Recommendations to fix the problem:

|

| Increased noise during power steering operation | The problem may be a low level of lubricant in the reservoir. Also, oil is sometimes released through the safety valve device. With the latter problem, a whistle will appear when the steering wheel goes to the extreme right or left position. | Oil is added to the system and all elements, especially the valve, are checked for leaks. It is necessary to determine the cause of the problem and remove the air lock, if any. The pumping mechanism is being checked. It is also necessary to test the pump pressure. |

| Vibration | An air lock has formed in the hydraulic system. The problem may also be damage or unsatisfactory condition of the rubber. | All elements of the power steering system are diagnosed. The cause of airing is determined and the plug is removed. If the tires are worn out, they must be replaced. |

Pavel Kovalev spoke about the power steering design, as well as the typical malfunctions inherent in these systems.

Diagnostics

Schematic structure of the power steering system

Power steering repair begins with testing it. When checking the system, the quality and level of lubricant in the reservoir under the hood are first tested.

If the oil has not reached the end of its service life, it will not have a waste smell, and dark shades of the liquid are not allowed. Ideally, the power steering lubricant should be transparent, and if its color is gray or brown, then the fluid must be replaced.

Service manuals for modern cars indicate that oil is filled once, but in practice, lack of maintenance will lead to pump failure.

To diagnose the operability of the system, the power unit is started. It is necessary to determine by ear the presence of noise in the area where the pumping device is located. If the mechanism functions without interruption, there will be no extraneous sounds. The pump itself is used to pump working fluid into the mechanism.

Further verification steps are performed as follows:

- The steering wheel turns to the right and left until the end. If the steering wheel turns and this is accompanied by a howling or buzzing sound in the pump area, the sound intensifies as the angle of rotation increases, the mechanism is broken. These signs may indicate wear on the shaft bearing device. If this part breaks, this leads to a violation of the tightness of the amplifier system, then foam forms in the expansion tank. The liquid may bubble and overflow from the reservoir; if this problem occurs, it will usually have a brown tint.

- When turning the steering wheel, pay attention to the idle speed of the engine. If the pump unit fails, then when you turn the steering wheel, the engine speed will drop. If additional effort is required, the problem may be wear of the ball joints or failure of the rotary bearing elements. We are talking about parts located on the front pillars. Failure of the pumping mechanism can be indicated by a change in the forces on the steering wheel with increasing engine speed.

- If vibration or wobbling occurs when you turn the steering wheel, the problem may be that the pump drive belt is slipping. In particular, if it increases when the steering wheel is rotated to a greater angle. Perhaps the strap itself is worn out or the bearing element is defective. With such a problem, a squeal will appear.

- The lubricant in the reservoir may be of high quality, and the fluid level may be within normal limits. At the same time, no extraneous sounds appear in the pump area. With such symptoms, the steering wheel could become stiff if the bypass valve is jammed or sticks.

- Diagnostics of the pressure switching mechanism is performed in the case when there is a difference in the applied force when turning the steering wheel. In particular, when the steering wheel is turned in different directions. The pressure switch mechanism may be worn. The presence of defects can lead to the appearance of intermittent forces.

After installing new wide tires on a vehicle, stress may be placed on the steering wheel.

The VseSam channel spoke in detail about the procedure for diagnosing the hydraulic power steering system on a car.

Trouble-shooting

If the steering wheel has become stiff and does not turn well, you can try to solve the problem yourself. To do this, you must follow the repair instructions.

Preparation

Before performing the task, you need to prepare the power steering:

- Dirt is removed from the system. All contaminants are removed to prevent them from getting inside the device when the pipes are turned off.

- Lubricant is pumped out of the expansion tank. It will not be possible to completely remove it from the system, but you need to remove as much as possible. To do this, you can use a syringe with a hose connected.

- Using a 6-point hex wrench, the steering shaft coupling bolts are unscrewed; they can be accessed from under the bottom of the car. Before performing the task, it is necessary to mark the position of the device relative to the power steering shaft with a roll.

- Then you need to move the elastic coupling from the splines; a pry bar is used for this.

- The steering rods with the puller should be disconnected from the bipod.

- The car is placed on a jack, the bolts on the left front wheel are unscrewed using a wheel wrench, which is then removed.

- Using a 15mm socket tool, you need to loosen the three screws securing the power steering to the side member. They are located on the side of the wheel arch. After loosening, the two screws must be removed.

- A container is placed under the fittings of the pipes into which the oil will be drained. The lines are disconnected one by one. After this, the hoses must be sealed; for this you can use a clean rag.

- Then, supporting the power steering from under the bottom of the car, you need to unscrew the remaining bolt. The gear unit cannot be missed. Before carrying out repairs, the device must be washed to remove dirt.

User Misha B talked about the procedure for dismantling the power steering using the example of a Mercedes car.

Stages of power steering repair

The power steering restoration procedure must be performed taking into account the characteristics of a specific car brand.

Some pump models can be disassembled almost completely, while others are better replaced assembled. It all depends on the specific system model.

Algorithm of actions for power steering repair:

- To disassemble the device, you will need a 6-point hex key and a container to collect old lubricant. The plug is disconnected from the fitting. The power steering is raised above the container. To drain the lubricant, you must rotate the bipod.

- Then the shaft is dismantled, four screws installed on the fixing mastic are unscrewed. You'll have to make an effort.

- The locknut of the adjusting bolt is turned out. After this, it must be rotated to install it in the gearbox. This will allow you to push out the shaft with the device cover itself and the bipod. If there is no gap and the cuff does not need to be changed, then this element can be left and not dismantled. The check valve plug is unscrewed.

- The spring element is removed. The valve part itself is shaken out.

- The cover screws are unscrewed. Then carefully, turning the shaft, you need to ensure that it pushes the upper part out of the housing a little. When performing this task, you must be careful to prevent the pulley from being completely unscrewed from the ball nut.

- Then you need to pry up the gap that appears and remove the shaft with the cover and piston from the gearbox. The nut is being removed. To do this, you need to unscrew the shaft and collect the balls.

- The locknut is released and the bearing element is completely unscrewed.

- The nut and parts are removed from the piston body. Then the first one is disassembled; to do this, you need to bend the locking screws. The fastening elements are unscrewed, and the bracket is dismantled along with the two parts of the ball guide channel.

- The cause of the malfunction is diagnosed. The presence of a gap may be due to play in the shaft-ball nut pair or in the bearing mechanism directly in the cover. Also sometimes this is due to malfunctions of the device in the piston body.

- The gaps are being adjusted. They appeared as a result of weakening of the threaded components that secure the bearing mechanisms. If there is play in the cover, then you need to loosen the lock nut and tighten it until the play disappears. But you can’t overtighten it so as not to damage the device. All actions are carried out on a clean surface to prevent dirt from getting inside.

- Then the gear unit is assembled in the reverse order. The rubbing elements must be treated with a lubricant.

Disassembly of the amplification deviceDisassembled power steering mechanismAdjusting the power steering play on the machine

Replacing power steering

If it was not possible to repair the pumping device, you will have to replace the device (the removal procedure is described above):

- The power steering pump is mounted on the left side of the power unit. Here it will be driven by a V-belt from the crankshaft pulley.

- Use a wrench to tighten the second mounting screw located at the front. The pulley is fixed. Then the fastener is installed through the hole on the shaft. Finally, you need to fix the element located at the back.

- The highways are being connected. When carrying out the task, you must ensure that the tube openings are free of air pockets and foreign objects. It is important that the working fluid can pass freely through the hoses. It is necessary to ensure that the junction of the pressure line and the pumping mechanism is reliably sealed with a sealant. When disassembling the tip of the pipe, it is recommended to use new rubber bands.

- The nut securing the pressure line is tightened. A steam outlet pipe is placed on the fitting of the pump mechanism. Then the self-tapping screw tightens the clamp, which secures this hose.

- The drive belt of the auxiliary units is being fastened.

- Working fluid is poured into the system. It is recommended to use fresh oil. At the first stage, liquid is poured into the expansion tank up to half of the total volume. Then, while monitoring the level of consumables, you need to slowly turn the steering wheel until it stops in the extreme left and right positions. This action is repeated until bubbles stop forming in the tank.

- Air may enter the system as a result of a sudden drop of the lubricant down the lines. Then you need to wait about thirty minutes and repeat the process of turning the steering wheel. When performing a task, you need to check the lubricant level.

- The power unit is started; the front part of the car does not need to be removed from the jack. The pumping procedure by turning the steering wheel to extreme positions is repeated. Air in the system should stop escaping after about three cycles. If this is not the case, then you need to wait and repeat the procedure.

- The power unit stops and the car is removed from the jack. Then the engine starts again and at idle the power steering pumping procedure is repeated. It is important to ensure that no bubbles form in the system. The pumping process must be repeated when the oil level drops by more than 3 mm, as well as when the pump mechanism creaks.

- At the final stage, you need to start the power unit and turn the steering wheel all the way. While performing the task, you need to simultaneously monitor the condition of the fitting connections. This will allow timely detection of leaks in the system. If the elements are worn out, they need to be replaced or the nuts tightened. After the air has been removed from the lines, all connections are diagnosed again.

Video “Replacing the power steering pump with your own hands”

The “Garage Region 51” channel talked about the step-by-step change of the pumping device and the nuances of installing racks using the example of a Volkswagen car.

Source: http://AvtoZam.com/elektronika/eby/remont-i-zamena-gidrousilitelya-rulya/

The principle of replacing the power steering pump

In this article we will talk about the power steering system and structure, discuss the issue of replacing the power steering pump and modernization.

Those car enthusiasts who have driven a car for a long time without this device, and then switched to a foreign car with this function, will immediately notice a significant difference in control. Power steering helps solve several problems at once: the steering process no longer requires much effort, maneuverability increases and the turning trajectory is reduced.

As it turned out, the presence of a hydraulic booster in a car is a very positive thing, however, like other functions, there comes a time when the amplifier fails. The most common problems are: unpleasant noise when turning the steering wheel, leakage of hydraulic fluid, problems with the amplitude of the steering wheel and a significant deterioration in controllability.

How does power steering work?

It is worth noting that each car model may have a different structure, however, there is still a common “basis” for all. For example, this is a pump that sets hydraulic fluid in motion and maintains optimal pressure within the system.

Next comes the distributor, which, as the name suggests, distributes hydraulic fluid. A hydraulic cylinder, which acts as an intermediary between the steering wheel mechanism and the piston, which is responsible for turning the wheels.

Don’t forget about the connecting hoses through which hydraulic fluid circulates.

After any malfunction or breakdown has been discovered, it is recommended to carry out repairs immediately, because in the future the situation can only get worse.

Even in domestic cars, for repair or replacement you need to remove the engine and some elements of the car's chassis. What can we say about foreign cars, the design of which is much more complex, so sometimes it is better to turn to specialists.

Typically, the minimum replacement cost is $30, but the price may vary depending on the vehicle model.

In the next paragraph of the article we will discuss in detail the replacement of the pump, since it is with it that problems often arise.

Replacing the power steering pump

At the initial stage of the replacement process, you need to remove the belt. It is advisable to remember the force of its tension in order to set the optimal value again later. You can simply put a mark at the desired level before you start shooting.

To make the process of removing the belt easier, you need to lower the tensioner roller slightly, and then loosen the belt with this same tensioner. Next, you need to remove the protection above the belt by unscrewing one bolt and partially releasing the second. After performing these simple manipulations, removing the belt should not cause difficulties.

It would not be a bad idea to carefully inspect the tensioner system, because you may often not immediately notice that the roller is slightly “eight-shaped,” and this has a very negative effect on belt wear and on the system as a whole.

Now we follow all safety recommendations when repairing a car - turn off the power to the car by disconnecting the battery terminals. Next, you should also disconnect the terminals, or rather its sensor, and unscrew the return hoses.

It is worth noting that hydraulic fluid will most likely leak from these tubes, so you should place a container under them in advance. But this does not mean that all the liquid must be allowed to leak. It is advisable to minimize losses by using a plug.

After this, you need to start unscrewing the main tube, using the greatest pressure.

To make it easier to remove this tube, you should move it in different directions, but this must be done very carefully, because the aluminum tip is very delicate.

Now the turn comes to the final stage - removing the pump itself. This is very easy to do - you need to carefully unscrew all the bolts and turn the pulley of each.

In order to reassemble the system, you need to repeat the disassembly algorithm in a mirror order. Important to remember! When tightening bolts, it is not recommended to use excessive physical force because in this case the risk of stripping the threads or damaging the bolts themselves increases. The belt tension level must be set according to the previously set mark, or according to the previous tension indicator.

In addition to simply unscrewing the pump and then installing a new one, there are several other required processes. First of all, this is the creation of a vacuum in the hydraulic system, because otherwise it will function intermittently or not work at all.

Also, it is imperative to restore the loss of hydraulic fluid, some of which leaked out while unscrewing the hoses.

Of course, it is more efficient to pour liquid into a running car, but in this case this is impossible, since the battery is disconnected when changing the pump.

In order to increase the temperature of the hydraulic system, you can use a regular hair dryer. However, you should also be careful here, because there is a risk of burning the tubes.

In the same way, you can increase the temperature of the hydraulic fluid.

When choosing a fluid, you need to carefully study the markings on the label in order to choose the best option for your car.

As noted above, after disconnecting the hose from the power steering, it must be lowered into a container. The easiest way is to use a regular bottle as a container.

Next, we pour the leaked liquid back into the tank, and place the tube back into the bottle. Then you need to crank the starter so that the hydraulic fluid is driven through the system and poured back into the bottle. We perform this operation several times.

After this, we attach the tube with the reservoir, turn the starter again so that the liquid is again circulated through the system, it is advisable to move the steering wheel parallel to the left and right in order to develop the hydraulics after stagnation. It is strictly not recommended to start the engine because most likely due to high pressure the hydraulic tube will break and a complete leak of fluid will occur.

This completes the process of replacing and upgrading the power steering pump. You need to put the entire system back together and make sure that the barrel of hydraulic fluid is filled to the maximum. Next, you should start the engine and drive the car for several laps.

While driving, it is advisable to turn the steering wheel as much as possible when turning to make sure there are no problems. You can also ask another person to watch the front wheels while turning the steering wheel, because system malfunctions are more visible from the side.

Bottom line

In this article, we discussed the process of replacing and improving a car's hydraulic system pump. As it turned out, this is not very difficult, however, if you are not confident in your abilities, then it is better to turn to specialists.

We hope that our article has become as useful as possible for you.

Video

Source: http://autoiwc.ru/other/zamena-nasosa-gidrousilitelya-rulya.html