Where is the engine temperature sensor located? :

Automotive problems are an issue that comes up more and more often today. The point here is that there are more cars, and accordingly there are more drivers, and their problems do not increase, but simply begin, figuratively speaking, to hit the area.

There is nothing particularly sad about technical problems, especially if you are able to tighten a few nuts yourself. If there is more experience, for example, five to ten years of regular maintenance with your own hands, then there is nothing to talk about.

But for novice car enthusiasts, even the most obvious things become serious problems that need to be solved somehow. One of these is monitoring the temperature of the coolant in the engine.

Why do you need an engine temperature sensor at all?

In fact, the device is very simple, and there should be no problems with it at all. But it can indicate a lot. The catch is that an internal combustion engine is a complex mechanism that is assembled from many parts. The latter must work in unison, and most importantly, in strict sequence.

High or, conversely, too low engine temperatures can lead to really serious problems.

So large that you won’t be able to cope on your own and will have to contact a repair shop, which is fraught with large expenses that no one needs.

In addition, if you drive a car with a cold engine, the service life of the latter will be greatly reduced. This is how a small engine temperature sensor becomes an indispensable part of a car.

What are they?

Most often, when it comes to such measuring instruments, we are talking about coolant. This is the main way of application, but there are also slightly others. For example, an engine temperature sensor can measure the heat of the oil. Some car models, mainly intended for racing, have devices to monitor transmission and differential oil heat.

Why is new better than old?

Generally speaking, the principle of operation has not changed. Actually, it cannot change - after all, the same parameter is being measured, and nothing can be done about it. But there is a certain point in which the engine coolant temperature sensor in a modern unit differs - this is the dynamics of the indicators.

Old models are designed to measure temperature in a specific place, usually this is the container into which the liquid is poured. That is, the information you receive is quite static, which can be interpreted in completely different ways.

Modern models are designed differently - there is a whole galaxy of different meters that literally intertwine the cooling (and in some cases oil) channels. This way you can see which part of the engine is overheating the most and do something specific. However, the same evolution of cars allows you to not really care about this right on the road.

The on-board computer, having read the data provided by the engine temperature sensor, will independently make changes to the operating mode or display optimization suggestions on the screen.

How does such a device work?

The answer to this question is quite simple, because, despite the multiplicity of design details, it all comes down to three main parts.

First of all, this is, of course, the device itself, which takes readings. It is also necessary to note the sensor unit, which simultaneously controls the operation of the first one and transmits the received information.

The third and final element is a simple wire connecting the first two.

No matter how funny it sounds, the problem often lies precisely there. That is, both parts of the structure work normally, but everything does not happen smoothly, since there is no connection between them.

Types of sensors

At the moment, two main types of meters are produced. They can be magnetic or bimetallic. This information does not particularly affect the work, since the principle is different, but the result remains the same.

It’s easy to determine which one is installed in your car - when you turn on the engine, follow the indicator arrow. If it immediately takes off, then the magnetic sensor is working here. In the same case, when some time passes, after which slow movement begins, this is a bimetallic device.

Magnetic sensor

Here everything is arranged according to a very simple principle - there are several coils that are located on different sides of the rotary armature, where the arrow is fixed. All this is connected directly to the machine’s electrical network - one is grounded directly, but the other passes through the control unit, the resistance of which will give the temperature indicator.

The work is based on the current flowing through the coils. This creates a magnetic field, which causes the armature to move when the temperature changes. Why it moves is a slightly different question - due to the difference in magnetic fields. The coils are located on different sides of the armature, outside and inside.

Bimetallic devices

As a matter of fact, the principle of operation here is based on both physics and chemistry. All substances can change in size depending on the environment, in this case temperature plays the role of an irritant.

In the device itself, the function of reading the indicator falls on a metal rod, which expands and contracts by amounts invisible to the human eye. But this is quite enough to change the indicators on the dashboard.

Also, precisely because of this rather complex operating principle, reading indicators is a little slower when compared with magnetic sensors.

Capillary devices

Old cars are often equipped with a third type, which is almost never used today. For example, the temperature sensor of a VAZ engine may well be exactly like this if the car is seven to ten years old.

The device here is quite complex and fragile, which is why it was discontinued. The point is that a meter tube runs through the entire engine, from the dashboard to the coolant tank. Damaging it is a piece of cake, but the entire system will have to be replaced.

There is no point in describing the operating principle, since encountering such a device in “field conditions” is quite difficult. In addition, it would be better to contact a professional, since during replacement it is quite possible to damage something.

Where is the engine temperature sensor located in a car?

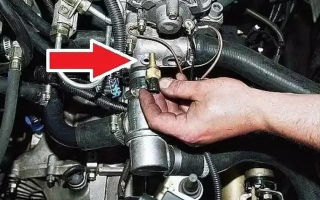

The most common option is installation directly in the motor housing. The block, in turn, can be located in one of three places. This can be the thermostat housing, the cylinder head, or the upper radiator hose.

So you won’t have to search for long, you just need to inspect the upper part of the engine body. The appearance is also not unique. The photo of the engine temperature sensor shown here is suitable for most cars. Simply because they are made the same. There will be no problems identifying and finding a replacement.

Some features of the national automotive industry

Problems do not arise very often with this device. But for some engine models this can be a sad habit. For example, the temperature sensor that the 406 engine is equipped with breaks down quite often. There are even specialized reference books on the topic, so information is easy to find.

The most common proposals are to simply change the model to the 402. Then there will be much fewer problems, and life will become much easier. However, you already know where the engine temperature sensor is located, and therefore you will be able to figure out the simplest diagnostics.

In any case, the on-board computer will display an error in the event of a malfunction, for example, a lit “check engine” message will appear. Or you yourself may notice that the indicator is acting up, always showing the same temperature, or it may start jumping back and forth.

It is also likely that the instrument will completely “die”, so that the needle will remain at zero.

Source: https://www.syl.ru/article/210304/new_gde-nahoditsya-datchik-temperaturyi-dvigatelya

Where is the coolant temperature sensor located and how to replace it?

DTOZH should not be confused with an antifreeze level controller. If the first is intended to detect the temperature of the power unit, then the second is used to control the volume of consumables - refrigerant.

Based on the DTOZH readings, the control unit detects temperature changes and transmits data to the on-board computer about the state in which the engine is operating. Using the controller, engine warm-up, overheating, and the optimal temperature of the operating internal combustion engine are determined.

Pulses transmitted to the control module determine the functionality of the internal combustion engine control system as a whole.

The engine temperature determines the following nuances:

- fuel consumption per 100 km;

- volume and quality of gases;

- ignition of the air-fuel mixture;

- optimal operation of the gearbox.

All these factors are controlled by a control device, which, based on the information received, determines the optimal operating mode of the engine. Therefore, the performance of the temperature sensor is important for the vehicle. If the device is faulty and sends incorrect pulses to the control module, this can lead to problems.

How does DTOZh affect the operation of the internal combustion engine?

Based on the parameters supplied to the control device, the module performs the following functions:

- Enrichment of the air-fuel mixture or its depletion. If the controller detects that the temperature is too low, it will begin to increase the duration of the signal sent to the injectors, which helps to enrich the fuel mixture. In accordance with the normalization of the temperature regime, the fuel is gradually depleted, which prevents possible excessive consumption of gasoline and reduces the volume of exhaust gases. If the sensor breaks down, it can regularly lower the temperature in the engine, which will lead to fuel contamination and increased consumption.

- The control unit sets the ignition. It can be early or late. If the temperature increases, the control module adjusts the ignition timing to reduce exhaust toxicity.

- Thanks to DTOZH, proper recirculation of gases is performed during warming up. The recirculation valve closes tightly when the power unit warms up. If the car’s engine is still cold, then recirculation will cause fluctuations in idle speed and random engine stops.

- With the help of DTOZH, the control unit purges the filtration system, which traps fuel vapors. To achieve better machine controllability, the carbon filter element is not purged until the engine is completely warmed up.

- Locking of the gearbox torque converter when the internal combustion engine warms up. The control module should not limit the operation of the device until the machine warms up.

- The ECU controls the operation of the unit's cooling fan. Based on the temperature controller readings, the module activates and deactivates the ventilation device to correctly select the temperature of the unit. If the DTOZ gives incorrect impulses, there is a possibility of the motor overheating.

Overview of types of DTOZH: design and principle of operation

Let's take a closer look at the operating principle and types of controllers.

Magnetic

Such controllers consist of coils located on the sides of a steel armature. The arrow of the controller located on the instrument panel in the cabin is connected to the latter.

The first coil is connected to the vehicle's on-board network, and the second to a cable with varying resistance. This parameter changes according to the temperature values in the engine.

The voltage passing through the coils creates a magnetic field that controls the armature. The element displacement parameter is determined by the field difference depending on the current value.

User Irimiya Evgeniy showed in his video how unstable the DTOZh is.

Bimetallic

The operating principle of bimetallic controllers is based on the expansion of elements during heating. The device is equipped with a rod that changes size as the temperature of the internal combustion engine increases. The stripes in the coil rotate the arrow on the control panel in the car's interior in accordance with the current value.

Modern antifreeze temperature sensors can use two types of sensors:

- semiconductor;

- bimetallic.

The latter are practically not used today. The strip in such controllers moves to the coil and opens the contacts, helping to change the amount of current flowing to the dashboard. And semiconductors are used everywhere.

The control unit supplies a signal to the device thermistor with a negative coefficient through a resistive element with constant resistance. As the temperature increases, the resistance in this circuit drops. Accordingly, the voltage level decreases.

The control module detects a decrease in this parameter and determines the temperature of the consumable material, displaying it on the control panel with an indicator.

Capillary

It is considered the oldest and irrelevant type of sensor for use today. The arrow on the device is directly connected to the device. The controller is made in a housing in the form of a container with consumables, which has a low boiling point. The reservoir is connected to a pointer as well as a steel tube.

When the power unit warms up, the refrigerant in the container begins to boil and evaporate, resulting in an increase in pressure in the flask. This parameter is sent to the pointer where the Bourdon tube is located. This element begins to straighten as a result of pressure and moves the arrow on the control panel.

This type of controller is almost never used for several reasons:

- the measuring element itself runs through the entire engine compartment, connecting to the tube on one side and to the control panel on the other;

- The capillary tube is quite thin and is quickly damaged during operation.

Photo gallery “Varieties of DTOZH”

Diagrams of different types of sensors are shown in the photo.

Magnetic type DTOZhBimetallic sensor Capillary sensor circuit

Where is the sensor located?

Before checking and changing the device, you need to know about its location. Where the sensors are installed depends on the car manufacturer.

The device location can be like this:

- in the cylinder head;

- on the upper line of the radiator device;

- in the thermostat housing.

Regardless of where the controller is installed, the device is fixed next to the outlet hose through which the coolant enters the radiator. This is important because it is this mounting location that allows you to accurately determine the temperature of the consumable.

Symptoms of a problem

The AndRamons channel provided a video about the controller verification process.

The main symptom of a controller malfunction is the inoperability of the ventilation device when the power unit warms up. But the machine can also be equipped with a fan activation sensor that performs the switching function. Then the reason should be sought in damage to the electrical circuit or failure of the controller.

What other symptoms can be used to determine the inoperability of the DTOZH:

- increased fuel consumption;

- difficult engine start when the unit is warmed up;

- increased idle speed;

- engine detonation;

- unit overheating.

Many modern cars have an electronic fault detection system. Errors may appear on a special screen on the dashboard when the DTOZ breaks down. But usually fault codes indicate both a possible breakdown of the sensor and damage to the wiring or controller connector.

Checking the DTO on a car

Correspondence table for temperature, resistance and voltage parameters for checking DTOZH

The essence of diagnosing the controller on the car and outside the car is to check the resistance and voltage values.

Checking the second parameter is done using a voltmeter:

- Connect the probes of the device to grounding, as well as to the signal contact of the controller.

- The engine must be cold. Turn on the ignition.

- Measure the voltage parameter and compare the data obtained in accordance with the table.

To diagnose the temperature parameter you will need a thermometer:

- measure the temperature of the consumable;

- start the engine and let it warm up, while heating the internal combustion engine, measure the voltage value taking into account the temperature change;

- If the obtained parameters do not correspond to the table ones, then the device has failed.

User Yakovlev Dmitry showed in the video how to check the controller.

Using an ohmmeter, perform a resistance test:

- Diagnostics are carried out at different temperatures of the machine motor. The parameters are compared with the table ones.

- If the resistance value on a cold engine is in the correct range, then the temperature of the consumable may deviate to the side by several degrees.

Check outside the car

For diagnostics outside the car:

- Place the device in a tank of water and check the temperature.

- Measure the DTOZ resistance parameter. Check the results obtained with those indicated in the table.

- The container with water gradually heats up. During warm-up, periodically check the resistance level and temperature.

Replacing the coolant temperature sensor

You can only replace a failed DTOZ with a similar device.

Required Tools

To complete the task you will need:

- container for collecting waste liquid;

- wrench 19;

- sealant.

Step-by-step instruction

Dismantling and installing the controller is performed as follows:

- Some of the coolant must be drained from the radiator; this will be required to dismantle the sensor.

- Disconnect the connected wires from the device.

- The controller itself is disabled using a 19mm wrench.

- Run device diagnostics if necessary. If you are changing the device, then before installation it is necessary to treat its threads with sealant.

- Screw the new controller into place and connect the wiring to it.

- Fill the cooling system with previously drained antifreeze. Make sure that there is no refrigerant leaking through the unit.

Loading …

Video “How to change the controller correctly”

A visual guide to replacing an antifreeze temperature sensor is described in a video filmed by user Vasily Kalugin.

Source: https://autodvig.com/sistema-ohlazhdenija/gde-nahoditsya-datchik-temperatury-11075/

Coolant temperature sensor: 7 signs of malfunction

There are many sensors in a car. All of them control the operation of various systems of the car and its engine. If the sensors give incorrect readings, the performance of the vehicle is jeopardized. The same can be said about DTOZH.

DTOZH is designed to maintain stable operation of the internal combustion engine (hereinafter referred to as ICE). Due to DTOZH, the car warms up faster and reaches too high temperatures less often. Some people confuse the DTOZH with the coolant temperature gauge sensor.

These are two completely different devices. The DTOZH provides its readings to the electronic engine control unit, and the second sensor notifies the driver about the temperature of the working fluid in the cooling system.

The failure of the second sensor does not lead to serious consequences, unlike the first.

Speaking about DTOZH, we should also mention the purpose of the engine cooling system, since the operation of these two units is inextricably linked. Most often, a liquid cooling system is used, the main task of which is to remove heat from the engine.

In addition, the system also has the functions of cooling the oil in the lubrication system, the air that circulates in the turbocharging system, exhaust gases, and the working fluid of the gearbox.

It also has the function of heating air in ventilation and heating systems.

The operation of such an important car system directly depends on such a small detail as the DTOZH. Therefore, do not underestimate the sensor and neglect its diagnostics.

The design of the DTOZH resembles a resistor. The design of the sensor provides for a change in its resistance to electric current when the ambient temperature fluctuates. These changes are recorded and used to issue commands to the internal combustion engine.

The predecessors of modern DTOZH were thermal relays. Thermal relays were installed in injection systems. When the contacts were in the open position, the engine became hot. If the contact closes, it means the engine has already warmed up enough (reached operating temperature).

The design of modern DTOZH is based on a thermistor, which establishes the dependence of resistance on temperature. The thermistor is based on cobalt and nickel oxides.

As the temperature rises, the number of free electrons in these substances increases, due to which the resistance drops.

Some thermistors in DTOZH are characterized by a negative temperature coefficient. In this case, the thermistor produces maximum readings when the engine is cold. A voltage of about 5 volts is supplied to the sensor. After this, as the power unit warms up, the resistance decreases.

The engine electronic control unit (hereinafter referred to as ECU) monitors voltage changes and calculates the fluid temperature. After the engine warms up, the ECU begins to lean the fuel mixture. A malfunction of the DTOZH can also lead to an erroneous enrichment of the fuel mixture.

The result of this will be increased atmospheric pollution and premature failure of candles.

If the engine speed at startup is insufficient, the engine may stall. A floating command from the ECU to increase the speed can prevent this. To maintain drivability while the engine is starting, the recirculation valve must be closed until the engine reaches its set operating temperature.

Here, the result of a DTO malfunction will be floating engine speed. The engine may also stop. The ignition angle also depends on the functioning of the sensor, since this parameter is regulated by the system. The emission of harmful gases with this adjustment is significantly reduced.

Ultimately, engine power and thrust, as well as the level of fuel consumption, directly depend on the operation of the DTOZH.

Thus, DTOZH is very important for the correct functioning of the car.

Where is the coolant temperature sensor located in a car? The location of the DTOZh installation differs for different models.

Most often it is installed in the cylinder head near or on the thermostat housing.

It is mandatory to locate the sensor near the outlet pipe through which the coolant flows back into the radiator. This arrangement is necessary for the accuracy of data transmission to the ECU.

Types of sensors

DTOZH are classified according to the principle of dependence on changes in resistance:

- DTOZH with negative temperature coefficient. The principle of operation of such sensors is that the internal resistance decreases as the temperature increases and vice versa.

- DTOZH with a positive temperature coefficient. The operating principle is the opposite of the previous type of sensors. In these sensors, the resistance increases as the temperature increases.

Currently, the first type of sensor is the most popular. Sometimes there are two sensors in a car: the main one and the additional one.

The main sensor performs the function of transmitting the temperature value to the computer, and the additional sensor turns on the fan.

It is generally accepted that DTOZH is quite reliable due to its simple design. However, sooner or later, almost every component of the car is subject to wear and tear. In the case of DTOZH, there is a violation of the calibration. Such a violation leads to an unplanned change in resistance and incorrect operation of the ECU.

The most obvious sign of failure of the DTOZh is the failure of the fan to turn on when the temperature rises above the set values.

This indicator is not considered reliable if the car has both primary and secondary sensors. In this case, the malfunction will be more accurately indicated by oxidation of the wiring or failure of the additional sensor. The main signs of a DTOZ malfunction are as follows:

- a drop in engine speed or spontaneous stopping at idle;

- longer vehicle warm-up time;

- increased frequency of the engine going beyond the optimal temperature range during operation;

- increased fuel consumption;

- decreased driver control over the car;

- smoke from the exhaust pipe takes on a black tint;

- violation of engine stability.

In addition, detonation knocking in the engine is sometimes possible. Some older car models have a special controller. When the needle of this controller goes beyond the critical zone, the vehicle must be stopped immediately.

In this case, sometimes there is also a malfunction of the DTOZH. And in more modern models, the on-board computer notifies drivers of engine overheating. But such a message does not always indicate a malfunction of the sensor.

This often occurs due to wiring breakage and oxidation.

Causes of malfunctions

DTOZh breakdown rarely bothers motorists due to its simple design. But there are still enough reasons for failure. The use of low-quality antifreeze and motor oil leads to the destruction of the surface of the DTOZH. The sensing element of the sensor may become covered with sediment in the form of crystals. The reason may also lie in a manufacturing defect.

You should not buy DTOZH at flea markets and various cheap auto parts markets. DTOZH purchased on such a market will often not meet the declared parameters and the slightest damage will lead to sensor failure. An antifreeze leak can cause the gasket to wear out.

A voltage surge in the on-board power supply and corrosion of contacts can also cause sensor failure.

Checking the functionality of the coolant temperature sensor

Required tools and equipment

For the procedure for checking, removing and replacing the sensor, you will need the following tools:

- key to 19;

- multimeter;

- a container into which you will drain the coolant (a regular bucket will do);

- electric kettle for heating water;

- thermometer;

- container for hot liquid (a glass or small bucket will do).

Check procedure

How to check the coolant temperature sensor? This process is short and does not require any special diagnostics at a car dealership.

Do not forget - in order for the sensor to correctly indicate the temperature of the coolant, it is necessary that the DTOZH be immersed in this liquid. To do this, it is necessary to regularly check the presence of refrigerant in the system. This check is the first step that should be taken if there is a suspicion of a malfunction of the DTOZH.

The next step is to check the contacts for oxidation and corrosion. It is also necessary to identify violations of the connection of the DTOZH to the system.

After studying the vehicle's operating instructions, check the number and location of sensors. After this, find the DTOZH and establish that everything is in order with its connection.

To do this, the DTOZH will have to be dismantled, since the test involves immersing it in a container for hot liquid.

Take the sensor and place it in a container of boiling water. Next, you need to measure the resistance at the output. In this case, sensors on different car models will show different values. Tables with optimal resistance for each model are available on the Internet.

If the indicators of the reference and measured values are different, then the DTOZH must be replaced. The design of the sensor is so simple that it does not require repairs.

How to check the coolant temperature sensor? It is necessary to lower it into heated water (as mentioned above). Then take a thermometer and place it in a container of cold water. It is recommended to use an electronic thermometer.

Connect a multimeter to the sensor that is configured to measure resistance. Then lower the DTOZH into water and take measurements. Then the container with cold water is heated to 15, 20, 25 degrees, and the obtained measurement results are recorded.

If the results do not coincide with the reference ones, replacement will be required.

There is a way to check DTOZH without a thermometer. The temperature of water at boiling reaches 100 degrees. This temperature is taken as a basis and the resistance is measured. When water boils, the resistance should be approximately 176.7 ohms. With errors, it can reach about 190 ohms. If the indicators do not match, the sensor will also need to be replaced.

As an example, below is a table showing the dependence of temperature on resistance.

| Temperature in degrees Celsius | Resistance (Ohm) |

| 5 000 — 6 500 | |

| 10 | 3 350 — 4 400 |

| 20 | 2 250 — 3 000 |

| 30 | 1 500 — 2 100 |

| 40 | 950 — 1400 |

| 50 | 700 — 950 |

| 60 | 540 — 675 |

| 70 | 400 — 500 |

| 80 | 275 — 375 |

| 90 | 200 — 290 |

| 100 | 150 — 225 |

Replacing the coolant temperature sensor

Replacing the coolant temperature sensor is easy to do yourself. Before replacing, you must first drain the coolant into a prepared container. Next, the old sensor is dismantled.

The DTOZH is screwed into a special threaded hole. Unscrew and remove it, and then install the new sensor in reverse order.

Before installation work, check the vehicle's operating instructions for the exact location of the sensor.

After purchasing a new sensor, it is recommended to check it for defects using the methods described above. Before screwing the new sensor into the seat, it is recommended to treat the threads with sealant.

After installing the new sensor, wiring is connected to it. Then the coolant in the system must be brought to normal. That is, liquid leakage is unacceptable.

After making sure that they are absent, you can start the engine.

Conclusion

We found out that DTOZH is a necessary component of the power unit. Its failure can lead to serious problems with the vehicle's performance. Signs of breakdown of the DTOZh are very diverse and can be easily confused with the causes of breakdown of other vehicle components.

Since DTOZH is a thermistor, it transmits information about changes in ambient temperature by changing electrical resistance.

Devices made by different manufacturers produce different resistance drops at the same temperature readings. Therefore, when purchasing a new sensor, you should make sure that it is suitable for your car model.

Timely diagnosis of the coolant temperature sensor will help to avoid very unpleasant problems associated with the use of the car. Good luck and easy travels!

Article rating:

(1

Source: https://motorsguide.ru/system/zamena-datchika-temperatury-ohlazhdayushhej-zhidkosti

Coolant temperature sensor (DTOZH)

Any system that controls a car’s engine is equipped with engine temperature sensors (ETS), since the functioning of the vast majority of engine systems controlled automatically by an electronic control unit (ECU) depends on this parameter.

The temperature parameters of the engine have a direct impact on many characteristics of the fuel mixture, exhaust gases and even the transmission; fuel consumption and engine operating mode depend on them.

A faulty coolant temperature sensor (DTOZ) reports incorrect data to the control unit (ECU), which affects the behavior of all systems that control the engine, and in particular the control of the ignition and fuel supply systems.

Engine temperature measurements taken by the sensor, but not matching the actual coolant temperature, lead to serious complications. As a result, the engine will be impossible to start, or it will stall during operation.

Thus, despite the relatively simple design of this sensor, it is one of the most important engine control elements, since it monitors the internal temperature of the engine and informs the ECU about its operating condition (overheating, operating temperature, cold engine, at the warm-up stage).

The principle of design and operation of DTOZH

What is the purpose of the engine temperature sensor (also known as coolant temperature sensor)? First of all, you need to understand that the engine cooling system cannot do without its proper and correct operation.

Traditionally this is a semiconductor resistor or thermistor. Its electrical resistance is determined by the coolant temperature: when the engine temperature is low, the resistance of the sensor’s measuring elements increases, and when heated, it decreases.

The electronic control unit measures the voltage drop across the sensor and, based on this indicator, determines the coolant temperature. If there is not enough coolant, the sensor produces incorrect values. After all, it is installed so that its working part is always in the coolant flow.

Therefore, for a car of any brand, the place where the engine temperature sensor is located is most often traditional: on the thermostat housing of the engine cylinder block (less often, on the cylinder head).

Sometimes there are 2 sensors - 1 for each cylinder block or 1 intended for the electronic control unit (located in the cylinder head, transmits readings to the dashboard), the second one starts the cooling system fan.

The sensor that measures the air temperature is located on the manifold receiver. Heat from the cylinders of a heating engine is absorbed by the coolant contained inside the cylinder block or inside their heads. It records changes in coolant temperature and transmits data on the state of engine parameters to the electronic control unit.

Based on the temperature of the engine, the parameters of the fuel mixture are adjusted (if it is not warmed up, an enriched mixture is required, if it is warmed up, vice versa).

If the connection in the coolant temperature sensor circuit is broken or broken, the electronic control unit perceives the engine temperature characteristics as low, and an excessively rich mixture is supplied, which leads to excessive fuel consumption and environmental pollution.

Sensor malfunctions or short circuits are perceived by the ECU as signs of engine overheating. As a result, the injection system supplies a lean fuel mixture, and engine operation becomes unstable.

However, often DTD problems are caused not so much by a breakdown, but by the condition of the connectors and wires.

In addition, the thermostat itself may be a factor influencing the functioning of the DTD: if the thermostat is open, unsuitable for a given car, or absent altogether.

The engine warms up slowly or does not reach operating temperature parameters at all; accordingly, the DTOZH will record a low temperature.

Checking DTOZH faults

In some situations, a visual inspection for corrosion deposits around the clamps can help identify the cause of the malfunction. Their loose fit, cracks in the housing and leakage through the coolant sensor.

In other cases, the DTOZh must be checked:

• when a corresponding trouble code appears in the memory of the electronic control unit;

• when starting is difficult, unstable operation and the engine stops at idle;

• with an increase in fuel consumption and an increase in the CO content in the exhaust;

• when the warning lamp constantly indicates engine overheating.

Most often, it is possible to check the functionality of the sensor only by measuring its parameters such as voltage and resistance. It is more convenient to carry out these manipulations with the sensor removed, placing it in water and consistently changing its temperature. When the engine warms up, the voltage should change smoothly in the range from three to one or 0.5 volts over five minutes.

Before checking the DTOZH, it is necessary to check the serviceability and condition of the engine cooling system:

• checking that the system is filled correctly: the radiator and cooling system must be filled with coolant according to the norm (to avoid burns from the coolant, the radiator cap can only be removed when the engine has cooled down);

• checking the tightness of the radiator cap: if the tightness is insufficient, air enters the cooling system, which leads to overheating of the engine and incorrect readings of the temperature sensor;

• checking the composition of the coolant: usually the coolant contains water and antifreeze in equal proportions, but the composition must comply with the manufacturer’s recommendations.

• checking the condition of the coolant: if a regular coolant has been used for more than 3 years, and a long-life coolant has been used for more than 5 years, and also if signs of contamination appear, it is better to replace the coolant;

• checking the serviceability of the fan: a working fan (as well as a thermal switch or thermostat, if they are provided by the cooling system) allows you to avoid overheating of the motor.

Replacing DTOZH

Basically, coolant temperature sensors are replaced only when they are completely out of service - they are shorted, open, or give unreliable readings. However, in addition to this, there are several cases where experts recommend replacing the engine temperature sensor even with an optimally functioning engine control system.

Firstly, this is a rebuild and replacement of the engine, since such manipulations affect the functioning of the DTOZH. In addition, the sensor, like any part, itself wears out over time. Its readings will be less accurate, so when replacing the engine it is advisable to update the sensor as well.

Secondly, this is a significant overheating of the motor, which can lead to engine seizure. In this situation, it is recommended to replace the DTOZH and thermostat, since severe overheating impairs their operation and causes premature failure.

When replacing the sensor, the coolant must be drained. In this case, you don’t have to empty the radiator entirely, but simply lower the liquid level below the sensor. But it is better to refill the cooling system with refrigerant.

During the replacement process, it is recommended to treat the sensor thread with a sealant in order to prevent coolant leaks. And finally, it should be securely fastened to prevent dynamic damage.

A properly functioning coolant temperature sensor ensures optimal functioning of all engine control systems. Therefore, installing a new sensor helps to get rid of a lot of troubles later.

Good luck to all!

Source: http://mazda-x.ru/datchik-temperatury-dvigatelja/

Coolant temperature sensor - signs of malfunction and replacement

The cooling system is responsible for the optimal temperature regime of the power plant, at which the power output is maximum. This system includes a radiator cooling jacket and pipes through which fluid circulates. Circulation is provided by a pump driven by the crankshaft.

Various types of coolant temperature sensors

The system also includes a thermostat, which ensures quick warm-up of the engine by shutting off the pipeline going to the radiator, while the liquid circulates only inside the cooling jacket. When a certain temperature is reached, the thermostat opens the pipe, after which the liquid circulates in a large circle, including the radiator.

The radiator cools the heated liquid. To cool the liquid faster, a fan is installed on the radiator, which creates additional air flow. But this fan does not always work; it turns on only when the liquid temperature exceeds a certain value.

Coolant temperature sensor

To monitor the coolant temperature, a coolant temperature sensor is included in this system. The readings of this sensor are displayed on the dashboard, which provides the driver with information about the temperature conditions of the engine.

But this is not the main task of this sensor. The coolant temperature sensor transmits temperature data to the electronic control unit, after which this unit adjusts the fuel supply depending on the temperature.

When the engine is cold, based on the readings of this sensor, the control unit sets an enriched mixture; after warming up, the fuel mixture becomes normal.

Based on the readings of this element, the electronic unit regulates the ignition timing.

Design, principle of operation

Coolant temperature sensor device

The design of this sensor includes a thermistor - a resistor that changes resistance depending on the temperature surrounding it. This thermistor is placed in a metal case with a thread applied to it.

A tail section made of plastic is connected to this body. This part contains contacts for connecting wiring.

One contact is positive and it comes from the electronic unit, the second is negative and it is connected to ground.

In order for the thermistor to work, a voltage of 5 V is constantly applied to it. This voltage is supplied to it by the electronic unit through a resistor having a constant resistance.

Since the coolant temperature sensor thermistor has a negative temperature coefficient, as the temperature increases, its resistance will decrease, and the voltage supplied to it will also decrease.

Based on the drop in this voltage, the electronic unit calculates the engine temperature and also displays its value on the dashboard.

The exact installation location of this temperature sensor differs from car to car, but only slightly.

It can be installed in the cylinder head near the thermostat housing, or on the thermostat housing itself.

It must be located near the outlet pipe through which the liquid flows into the radiator. It is located near this pipe in order to transmit accurate temperature data.

Signs of sensor malfunction

On VAZ 2108, VAZ 2109, VAZ 21099 the sensor is located in the exhaust pipe of the cylinder head

This sensor is considered to be very reliable due to its comparative simplicity of design. However, there may be problems with it too. Usually they come down to a violation of the calibration, which leads to a violation of the resistance and, as a result, incorrect operation of the electronic unit, since it performs part of its functions based on the engine temperature.

One of the most obvious signs of failure of this sensor is the failure of the fan to turn on when the temperature exceeds the set value.

But this indicator will not be reliable if there are two sensors - the main one, for transmitting the temperature value to the electronic unit, and the additional one, responsible for turning on the fan.

In this case, failure to turn on the fan will indicate damage, oxidation of the wiring, or failure of the sensor responsible for its operation.

On modern cars, a malfunction indicating incorrect operation of the coolant temperature sensor is displayed on the display of the on-board computer. However, a fault message does not always indicate sensor failure. Often problems in its operation are associated with broken wiring or oxidation of contacts.

Sensor check

To check the integrity of the wiring on a VAZ-2110, 21102, you need to disconnect the block with wires from the coolant temperature sensor and release the plastic clip

Checking the functionality of this sensor is not difficult. But before you do it, it is advisable to check the integrity of the wiring going to it. You can also check the voltage coming from the control unit.

To do this, you need to disconnect the chip with wires from the sensor and connect it to a voltmeter. After this, start the engine and measure the voltage supplied to the sensor; it should correspond to 5 V.

If the voltage is normal, check the sensor for resistance.

To remove, check and replace the sensor you will not need much:

- Key to 19;

- Multimeter;

- Container for draining coolant;

- Electric kettle;

- Thermometer;

Before removing the element, you need to partially drain the liquid from the system. It is not necessary to drain it all, since it is located at the top of the engine; it is enough to drain it to a level below the position of the sensor.

Then the chip with wiring is disconnected from the sensor. Using the 19 key, it turns out of its seat.

Video: Checking the coolant temperature sensor

Check the sensor using an electric kettle with a thermometer and a multimeter set to resistance measurement mode. You can check in two ways.

- In the first method, the working part of the sensor is immersed in an electric kettle with cold water, and a thermometer is also placed there. You can only use an electronic thermometer that can measure high temperatures. A multimeter is connected to the sensor itself and the electric kettle is connected to the network. As the water temperature rises, the sensor resistance will drop. So, at a water temperature of +15 C, the resistance should be 4450 Ohms. At +40 C, the multimeter reading should be 1459 Ohms. The water needs to be heated to a temperature of 100 C. At this value, the resistance is minimal - 177 Ohms. If the values differ, it means that the sensor is providing incorrect information.

- The second method is suitable if you do not have a thermometer. To measure resistance, the sensor is immersed in water after it has boiled. In this case, the water temperature will approach 100 C, approximately 95-97 degrees. This is quite enough for taking measurements. After lowering the working part of the sensor, there is a resistance on it, which should be slightly more than 177 Ohms. If the difference is large, the sensor is faulty.

Replacing the coolant temperature sensor

The coolant temperature sensor cannot be repaired, so if it is found to be operating incorrectly, it is simply replaced.

Video: Replacing the coolant temperature sensor (DTOZH) VAZ 2115 (2113, 2114)

After purchasing a new sensor, it is advisable to immediately check it using the specified methods. If all readings are normal, it is installed in place of the one removed. Before screwing it into the seat, the threads are treated with sealant.

After installing the new element, a leash is connected to it; it is impossible to confuse the position of the chip, since it has special guide grooves. Next, the coolant in the system is brought to normal. Then you should check whether liquid is leaking through the sensor, and then start the engine.

If replacing the sensor does not give any result, the engine continues, for example, to overheat or does not reach the proper temperature, look for the cause in other elements of the system. It is possible that the thermostat does not work and the liquid is constantly circulating either in a small or large circle.

Source: http://AvtoMotoProf.ru/obsluzhivanie-i-uhod-za-avtomobilem/datchik-temperaturyi-ohlazhdayushhey-zhidkosti-priznaki-neispravnosti-i-zamena/