Alternator belt whistling: 5 main causes of belt whistling. How to eliminate whistling - tips

During the operation of the car, the owner is faced with many problems, including an unpleasant situation with the alternator belt.

He begins, seemingly for no reason, to “whistle”, and it is not so easy to immediately guess why this is happening. In our case, we are not talking about a worn or old belt. Everything is clear here - I replaced everything.

No, everything is much more interesting, and, as in an exciting English detective story, we will look for a cause-and-effect relationship.

Inspect the belt and look for reasons why the belt whistles.

So, why does the new alternator belt “whistle”? As it turns out, there are several reasons for this and they are all presented below.

Briefly about the hanging belt

Belt drive is the most common method of transmitting rotation to the generator rotor. The method has been used for a long time and differs from others in its simplicity: only two pulleys on shafts that are connected by a belt.

The belt itself is responsible for a lot. It is he who is responsible for transmitting rotation from pulley to pulley. You should be aware that one part of the belt is tighter than the other . It is the difference between these tensions that determines the traction force and its coefficient.

The belt provides precise transmission and is quiet in operation. High-quality products are able to withstand long-term loads, smooth out shocks and jerks. They are compact, take up little space, but simultaneously operate several important components of the car: generator, pump, air conditioning compressor and power steering pump.

The generator rotor must rotate constantly. This is facilitated by the belt connection to the crankshaft. The pulleys, which are screwed onto the generator and crankshaft shafts, are connected by a belt, which must be flexible.

The “whistle” of the belt is similar to a disgusting clang. It is caused by the belt slipping. The sound of such a whistle is unpleasant and can be heard at a great distance. Of course, you should not drive in such a situation.

Belt whistling and its causes

Some motorists refer to the fact that the belt was allegedly of poor quality and replace it, but everything starts all over again. For this reason, in order not to waste valuable time and extra money, it is recommended to inspect the entire belt drive. Analyzing the conditions under which the whistle occurs is the most useful judgment a car owner can make.

The check comes down to the following steps:

- the integrity of the belt is checked (we agree with the version that today even new products can be of poor quality);

- the degree of tension is checked (as is known, belt squeaks often occur due to weak tension);

- the cleanliness of the shaft is checked (another reason for the “whistle”, which is described in detail below);

- the line of two pulleys is checked for displacement.

Five main reasons why a generator whistles

Below is a list of the most common causes of alternator belt whistling:

- Cleanliness of car parts is an important rule that the owner of the vehicle must observe. Oilwhich is random got on the belt or shaft, causes an unpleasant squeak. This happens due to the fact that the belt loses its former adhesion to the surface of the shaft and slips.

If you remove the belt and then thoroughly remove all traces of oil, the problem will be solved.

- The belt may simply sag and weak tension will cause a “whistle”. The solution is quite obvious - you will need to look under the hood, check how the belt is tightened and if it is weak, then tighten it.

- The whistle may begin due to incorrect pulley line. As you know, two pulleys must be strictly in one line and a slight slope leads to an unpleasant sound.

You need to check the offset and set the pulleys as needed.

- A belt that is too tight can also cause a “whistle.” Car owners probably know that a very stiff belt prevents the pulleys from rotating normally. This situation is especially often observed in the cold season and the whistle stops as soon as the engine warms up and the belt regains its shape;

- A failed bearing can cause a “whistle” from the hanging belt. We replace the bearing with a new one and that’s it.

The provisions listed above are the main ones. But this does not mean that there cannot be other reasons. The most important thing is to respond to the problem in a timely manner and take immediate measures to eliminate it, then you will forget how the generator belt whistles.

Source: https://etlib.ru/blog/244-kak-ustranit-svist-remnya-generatora

Why does the alternator belt whistle when cold and what to do in such cases

The whistling of the alternator belt when the engine is cold is a common occurrence when operating cars even with low mileage.

Why it occurs, how dangerous it is, how to eliminate it without replacing the belt and tensioner itself, how to lubricate it so that it doesn’t whistle, we’ll look into this article.

Purpose and types

The main purpose of the alternator belt, as the name suggests, is to transmit rotational motion from the engine crankshaft to the alternator to ensure charging of the car battery and the operation of the car’s electrical system as a whole.

In most cars, the purpose is even broader. Sometimes it rotates the pump (water pump), the air conditioning compressor clutch, the power steering pump, and other rotating mechanisms of the car.

Fig.1

Why is it that in all cars a belt drive is chosen to transmit rotational motion from the crankshaft to the generator, if there are more reliable and durable ones, for example, a gear drive?

Belt drive has several significant advantages:

- simplicity;

- the ability to perform kinematic connections over long distances;

- Perhaps the main advantage is the protective functions.

The protective function of the belt drive is that if the generator (compressor, hydraulic booster, pump) jams, the powerful torque of the engine crankshaft will not destroy the generator and other components. The belt provides slippage. At worst, it will simply break, but the other nodes will remain intact.

The following requirements apply to generator belts:

- reliability (service life is usually at least 30,000 km);

- elasticity, the ability to maintain tensile strength during changes in temperature and humidity throughout the entire service life;

- good anti-slip properties;

- resistance to aggressive agents.

In order to meet these high requirements, manufacturers use different types and technologies for the production of alternator belts:

- wedge - to provide a larger area of contact with the pulley, lateral resistance to slipping;

- poly V-belts - to increase the properties of V-belts;

- toothed poly-V-belts - to increase the flexibility of V-belts;

- woven covering of the non-working area - to increase service life.

A modern alternator belt from an official manufacturer is a high-tech product using high-quality materials. However, no matter how high quality it is, during operation it wears out and its linear dimensions increase .

While the engine is running in the engine compartment, its operating temperature can vary in the range from – 30 to + 100 degrees. This also causes a change in the geometric dimensions of the alternator belt. To maintain the tension force at a constant level, tension regulators are used.

In cars of the 80s, tension control was often done by changing the geometric position of the generator. In this case, one side of the generator was fixed permanently. The second mount had a groove.

Video - why the alternator belt whistles when cold and how to solve the problem:

If the tension weakened, the second fastening was loosened, the generator was moved using the device, tightening the generator belt, then the fastening bolt was clamped again. A little inconvenient, but no additional rollers, rods or other components.

Currently, three types of tensioners are used:

- roller with eccentric (the central bolt is loosened, the eccentric bolt is rotated to achieve the required tension, the central bolt is clamped);

- a roller with a screw rod (does not require two keys, tension adjustment is simpler, although the design itself is less reliable);

- dynamic tensioners (self-adaptive, do not require adjustment during operation).

There are car models in which there are no elements for regulating the tension of the alternator belt at all. In this case, it is especially important to select a product from a recommended manufacturer according to the instruction manual.

Why does the alternator belt whistle when cold?

There is only one mechanical reason for whistling - friction. There are many examples of sounds in a car caused by friction. This is the squeaking of brakes, the sound of worn bearings, the noise of rubbing body elements.

But such a bright and familiar sound to all car enthusiasts, like the whistling of an alternator belt, no longer exists in cars. Why the whistle?

Firstly, based on the materials of the rubbing surfaces: rubber on metal. If you rub rubber on glass, the sound will be even more unpleasant.

Secondly, the frequency of sound depends on the speed of the rubbing parts. The sound is high-frequency (whistling), since the speed of the belt relative to the slipping pulleys is high.

Everyone knows the fact that as engine speed increases, the frequency of the whistle increases. With a further increase in engine speed, the whistle may stop altogether. And motorists calm down: the whistle has passed.

But no! In many cases, the whistling continues, but in the ultrasonic range, which the human ear cannot hear. But it is doubly harmful for car components. Therefore, it is very important to establish the source of the sound and its technical cause.

Technical reasons for a whistling alternator belt may be:

- insufficient tension due to its wear and, as a result, slipping;

- violation of the structure of the material (poor quality product);

- ingress of foreign materials into the friction area (oil, antifreeze, water, other liquids);

- violation of geometric alignment, misalignment of pulleys;

- loosening of the pulleys (this is especially dangerous);

- generator bearing wear;

- jamming of the generator, pump, hydraulic booster (such problems usually appear if it does not whistle at idle, the sound appears when they increase or move at speed).

When such a whistle appears, it is necessary to accurately determine the technical cause and eliminate it immediately.

The alternator belt whistles - what to do in this case?

The method for eliminating alternator belt whistling directly depends on the technical reasons for its occurrence.

Tension check

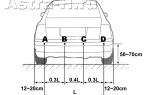

To check the tension of the generator belt, pressure P is usually applied to the section in the middle of the longest run (see Fig. 1). The amount of drawdown h should be from 5 to 10 millimeters.

Strong tension (less than 5 millimeters) leads to rapid wear of the belt, bearings or bushings of the generator. Weak tension leads to slipping and whistling, and can cause incomplete charging of the battery and other problems in the operation of electrical equipment.

This problem can be resolved by adjusting the tensioner. If the adjustment limits are not enough, the alternator belt should be changed.

Video - whistling due to tensioner misalignment:

To check the structure of the working area of the product, it is necessary to provide good lighting and access to the rubber surface. Sometimes experienced specialists rub the surface of the belt with chalk, then microcracks will be more noticeable.

The fabric base of the non-working surface is also checked. If there is damage, breaks, chips on the working surface, deep microcracks, such a product must be replaced.

How to lubricate a generator belt to prevent it from squealing

There are a number of special auto chemical products on the market that can help solve this problem.

Video - air conditioner and drive belt tensioner Hi-Gear:

The ingress of foreign liquids, especially oil, is the most common cause of a whistling alternator belt.

There is a proven repair method - wetting the belt with alcohol or, as a last resort, an inactive solvent mixed with water in a ratio of 1 to 2 (to ensure fire safety). In no case with pure gasoline (!).

Then you can let the engine run a little (a minute or two) so that the solvent lubricates the pulleys and rollers, since they can be sources of oil. Then you should find the source of the oil and fix the problem.

Pulley check

Distortion of pulleys is possible after an accident or repair of vehicle components. In a generator, the pulley may become dislodged as a result of wear on the rotor bushing. In this case, repair of the generator is necessary.

You can determine the skew visually by looking along the direction of movement of the belt drive.

The quality of pulley fastening should be checked immediately after routine or repair work on any components involved in the rotational movement of the generator belt.

Checking bearing wear

Wear of the bearings of the generator or pump, hydraulic booster, or rollers can cause these units to jam and cause a whistle. Sometimes the sound of a worn pump bearing caused by a leaking oil seal is mistaken for belt whistling.

This can be determined by antifreeze leakage in the pump area. You can only check whether the bearings are jammed by removing the belt. Next, check the “ease” of rotation of all pulleys and rollers (with the exception of the crankshaft).

Jamming of the generator is also possible, but this problem can also be identified by the lit battery light on the dashboard. By the way, this warning can also occur when the belt slips.

Some tips to increase its service life

- before and after long-term parking, especially in the warm season, you can slightly “soften” the working area of the belt by lubricating it with a special auto chemical agent (for example, using a conditioner and a Hi-Gear drive belt tensioner) or, in extreme cases, with a gasoline-water solution in a ratio of 1: 2, it will help prevent cracking;

- protect the belt during routine maintenance, make sure that there are no electrical wiring, clamps, or rags near it;

- after driving for a long time on a dusty road, use a compressor to blow through the rotation area of the alternator belt;

- check the degree of tension at the beginning of each season: summer, autumn and beyond;

- in severe frosts, be sure to check the tension, because... excessive tension can lead to its irreversible stretching and premature failure;

- If you are putting your car into hibernation for the winter, loosen the tension for the winter period.

Video - how to eliminate the whistling of the alternator belt when the engine is cold:

May be of interest:

Source: http://voditeliauto.ru/poleznaya-informaciya/avtoustrojstva/generatora/svistit-remen.html

Alternator belt whistling

Car service "Ankar"

Many car malfunctions can be determined by sound. Because each has its own special sound. One of the malfunctions that even an inexperienced driver can detect is the whistling of the alternator belt.

Some are sure that the whistling of the alternator belt indicates replacement, but this is not necessary. There are many reasons why the alternator belt whistles .

In this article you will find out why the alternator belt whistles? Let's look at common questions: why does the alternator belt whistle when cold, and what to do about it?

Why does the alternator belt whistle: 8 main reasons

1. Water got in

In many cars, the alternator belt is not closed. It is located in the open space of the engine. And if there is no crankcase protection , it turns out that water gets on the belt, or wet weather.

And it turns out that even a new, working one can whistle for a while, then the whistle stops. The new alternator belt whistles even in new cars; if it is open, it is enough to drive through a puddle.

After 20-30 seconds the water dries and the problem is resolved.

2. Ingress of liquids

Oil may come from the oil filter or from some other components.

3. Distortions, tensioner wedge

Bearings, unfortunately, do not last forever and after 100-120 thousand km they begin to jam . And because of this, it can begin to “walk” to the right and left, that is, warp. Also, due to the tensioner wedge, it begins to “walk” not parallel on the pulleys. To prevent the generator belt from whistling, it is necessary to constantly check the pulley to see whether it is spinning or not spinning, and whether there are any distortions.

4. Overrunning wedge

Many people do not know what an overrunning clutch is and what it is needed for. And modern generators are equipped with this particular coupling. The anchor of the generator itself is attached to it. In order for the belt to run smoothly, without jerking , the overrunning clutch is responsible for this.

This also causes the alternator belt to whistle.

5. Pulleys

The largest pulley is at the crankshaft, the smallest is at the generator. Over time, the pulley can become dirty . Dirt and pebbles get clogged into the grooves, causing wear and whistling of the alternator belt. Clean the grooves from dirt.

6. Pollution

During operation it may become covered with various deposits. The store currently sells enough cleaning products . Just spray on your belt and it will stop whistling.

7. Tension

Over time, it stretches out and needs to be constantly tightened . This is done simply with the help of adjusting bolts.

If, after adjusting the tension, the whistling does not stop, this means that the condition is bad and needs to be changed.

8. Worn out, defective and fake

Sometimes a whistle occurs after replacing the alternator belt. And even worse than with the old one. This happens due to poor quality material.

Belt wear is determined visually. If there are cracks, the teeth are broken, or the condition is poor, then it should be replaced.

In conclusion…

Why does the alternator belt whistle when cold? There may be several reasons for this: either wear, contamination, pulleys, liquid ingress, or tension. That is, you need to clean it, remove contamination from the belt and pulleys, and look for any ingress of liquids or water. If all this is eliminated, then most likely whistling of the alternator belt when it is cold .

Source: https://carrepair7.ru/svistit-remen-generatora

How to get rid of the whistling and squealing of the alternator belt. Why does the alternator belt whistle?

The whistling and squealing of the alternator belt is difficult to confuse with other sounds made by a car engine. What to do if the alternator belt starts to whistle?

The belt whistle appears in one and only case - when the belt slips on the pulley.

There are several reasons why such slippage occurs. Let's take a closer look at them.

Belt wear

During engine operation, the alternator belt, which transmits torque from the crankshaft to the generator, is subjected to significant loads.

As a result, over time the belt wears out, stretches and does not provide tight contact with the pulleys.

Often the surface of the belt is strewn with grains of sand that have ingrained themselves into it. Because of these grains of sand, the belt will not always be able to rotate the generator pulley and will slip from time to time.

Carefully inspect the belt. If there are cracks on it, ingrained grains of sand or threads hanging from the belt, such a generator belt must be immediately replaced with a new one.

Another fairly common reason for a squealing alternator belt is that it is not tensioned enough.

It happens that after engine maintenance or after replacing the belt, it is not tensioned sufficiently. In this case, a loose belt behaves in the same way as a worn belt.

How to check belt tension? Experienced drivers and car mechanics cope with this task by touch. For everyone else, we recommend using a dynamometer. Pull the longest part of the alternator belt with a force of 10 kgf. The belt should stretch no more than 10-15 mm.

After loosening the nut securing the generator housing to the adjusting bar, use a pry bar to move it in the direction opposite to the engine. Once the desired tension is set, tighten the nut.

There is another extreme - too much belt tension. A belt that is too tight will make it difficult for the pulleys to rotate properly. A similar situation occurs in winter, when a belt, hardened by low temperatures, whistles until it warms up from a warmed-up engine.

Loosening the belt is done in the same way as tightening it, but exactly the opposite.

Liquid on the belt

When even a small amount of fuel, engine oil, brake fluid, antifreeze, etc. gets on the working surface of the alternator belt, the belt begins to slip, creating a familiar unpleasant squeal. The same thing happens if process fluids get on the pulleys.

If you find oil, gasoline or antifreeze on the belt or pulleys, be sure to find the source of the leak. Check the seals, gaskets, pipes and their interfaces with the engine mechanisms.

A very similar effect is observed when water gets on the alternator belt after driving through a deep puddle. In this case, there is no need to worry - after a few minutes the belt will dry out and the whistling will stop.

Pulleys

A violation of the linear movement of the pulleys occurs when one of them begins to write “figure eights”. This problem is typical for pulleys with a rubber damper, which, due to loss of elasticity, ceases to perform its functions.

In this case, there is no point in delaying troubleshooting, since at first the defective pulley will only cause the generator belt to squeal, and after some time it will begin to periodically throw off the belt until it breaks it altogether.

The cause of a loose fit of the belt to the grooves of the pulley, causing a whistle, can be either the operation of worn-out pulleys with significant wear, or the installation of non-original spare parts.

Excessive load on generator

Another cause of belt squealing and whistling may be improper operation of the vehicle's electrical equipment.

If you turn on too many electrical consumers on a machine with a cold engine, the magnetic field resistance to rotor rotation will increase significantly due to the increased load on the generator.

As a result, the generator pulley will resist rotation and the belt will begin to slip with accompanying sound.

When you hear the generator belt whistling, do not put off solving the problem; fix the problem as early as possible. Your passengers, those around you, and your car will thank you for this.

Source: https://goodmaster.com.ua/avtomobil/kak-izbavitsya-ot-svista-remnya-generatora.html

The generator belt whistles - what is the reason and how to eliminate the squeaking belt with your own hands

Hello, dear car enthusiasts! Any experienced driver who has spent many years driving vehicles without leaving the car can diagnose hundreds of different breakdowns.

Any of the parts that become unusable disrupts the coordinated operation of the entire mechanism, which in turn gives rise to external signs and sounds indicating a particular malfunction.

This could be: sound, vibration or failure of controls to perform their function. However, the language of mechanical breakdowns can be understood not only by the driver, but also by his passengers, as well as bystanders.

There is no mistaking the piercing whistle that the generator belt makes. If the alternator belt whistles, then be sure that your car will attract the attention of everyone around you.

Many people mistakenly believe that the whistling of the alternator belt is a sign of wear, which indicates the need for its urgent replacement. This statement is only partly true.

The nature of the unpleasant sound can be completely different. In order to understand why the alternator belt whistles, you need to understand the structure of this “musical” unit.

Alternator belt whistling - let's understand the device

Replacing the timing belt and tension pulley

In order for the car's systems to receive electrical energy stably, its device must have a generator. The generator rotor must rotate continuously, which is ensured by a belt connection to the crankshaft.

Pulleys are screwed onto the generator shaft and the crankshaft, which are connected to each other by a flexible ring - a belt, which transmits rotation to the generator. The whistling of the generator belt comes from this simple device.

The design of pulleys and belts may be different, but the principle of their relationship remains unchanged. Based on the fact that a squeak or squeak can only appear when the parts rub strongly against each other, it is logical to assume that when the belt tension is weakened, the pulley slips.

But there may be several reasons why friction occurs and the alternator belt creaks:

- belt wear when its tension is no longer possible;

- using a belt made of low-quality material;

- contact with the pulley or belt of technical fluids, fuels and lubricants, coolant.

What to do if the alternator belt squeals?

Whistling from the alternator belt and rollers

Replacing the alternator belt is not a panacea for the appearance of an unpleasant creaking - whistling - squeaking sound. Many car enthusiasts have noticed more than once that the alternator belt creaks, the service life of which is still very long.

Before deciding to urgently replace the belt, it is necessary to inspect the belt drive and analyze under what conditions the squeak appears.

When opening the hood of a car, you need to pay attention to the following signs:

- whether the integrity of the belt is damaged (a belt that has become unusable must be urgently replaced);

- what is the degree of belt tension (poor tension is one of the most common causes of squeaking);

- whether the belt and pulleys are dirty with lubricants and other liquids (pulleys and belt must be dry and clean);

- whether the line on which the two pulleys are located has shifted.

If, when checking the belt drive, the reason why the alternator belt squeaks is not established, it is necessary to: eliminate the cause, or replace the alternator belt with a product from another manufacturer.

Sometimes a belt that is too stiff does not transmit rotation effectively even with good tension. This also happens in cold weather, when the belt cools down greatly and becomes hard. When the engine starts, it makes a squeaking sound, but as the engine warms up, the sound disappears.

Owners of cars with a tension roller in the design of the belt drive should also keep in mind that an unpleasant squeak can also occur in case of severe wear of the bearing, replacing which will completely solve the problem.

And you will stop being nervous and attracting the attention of others with an unpleasant squeak - the whistling of the generator belt.

Source: http://CarTore.ru/306-svistit-remen-generatora.html

Why does the alternator belt whistle, what to do and how to eliminate the drive belt whistle

In most cases, there is one reason for the appearance of a whistle, squeak, squeak or squeal from under the hood of a car - the alternator belt or timing belt is whistling. On modern cars, in addition to the generator, the drive belt can also rotate the pulleys of the power steering, air conditioning compressor, engine cooling pump and other attachments.

The reasons for whistling may vary. For example, a whistling alternator belt in wet weather can be caused by moisture getting on the belt and pulleys. And if the generator belt whistles when cold, this may be due to thickened lubricant in the generator bearings or tension rollers.

In this article we will talk about why the alternator belt whistles, what to do in such cases, and how to eliminate the drive belt whistle yourself.

The whistling may appear for a while and then disappear (for example, the whistling of the alternator belt when the engine is cold, during rain or when the air conditioner is turned on), or it may be constant. What to do and where to start looking for the cause of the whistle?

Many car enthusiasts believe that the whistling of the alternator belt appears only because it is worn out or sagging, but this is not entirely true. It is not always possible to eliminate whistling by replacing the old belt with a new one or “tightening” it. Often the causes of whistling may not be obvious.

In order to understand how to eliminate the whistling of the generator belt, you must first understand why it whistles (squeaks, creaks), and what are the reasons for the appearance of these sounds.

During operation, the alternator belt, like other vehicle drive belts, is subjected to prolonged high loads. With its help, torque from the engine crankshaft is transmitted to the generator and other attachments.

Most alternator drive belts are V-shaped, which provides greater frictional force where they contact the pulleys. They are called V-belts. The same belts that have several wedge-shaped tracks (so-called “rivulets”) are called poly-V-belts.

V-belts are available with and without teeth. It is believed that belts with teeth work better at breaking, do not break and slip less often.

Now we have come to the answer to the main question - why does the alternator belt whistle ? It's very simple - in 99% of cases, the whistle appears due to the friction of the belt on the pulleys and tension rollers as a result of slipping! That is, if the belt cannot turn the pulley of a generator or other equipment, then it simply slips, making an unpleasant sound similar to a whistle, squeak, squeak or squeal.

Therefore, you need to look not for the cause of the whistle, but for the reasons that cause the belt to slip. And there can be five main reasons:

- Weak or very strong alternator belt tension;

- Poor quality or worn belt;

- Getting dirt, moisture, oil and other technical fluids onto the belt and pulleys;

- Faulty generator bearing or tension roller;

- Pulley misalignment.

In addition, the appearance of a whistle can be influenced by such factors as humidity and ambient air temperature, the technical condition of the generator, air conditioner, power steering and other equipment driven by the generator belt.

You can get rid of the generator belt whistling by eliminating the reasons that cause it to slip on the pulleys. Therefore, if signs of slipping appear, accompanied by an unpleasant whistle, we suggest eliminating it in the following order:

- Stop the engine, open and secure the hood to prevent it from closing spontaneously;

- Carefully inspect the alternator belt without removing it from the car. There should be no tears, protruding threads or other visible damage on its surface. If they are detected, the belt must be replaced with a new one.

- Both the inner and outer sides of the belt must be dry and clean, without traces of dirt, oil and other vehicle technical fluids. The same applies to pulleys.

- Check the degree of belt tension - in most cases, the cause of a whistle from under the hood is precisely the weak tension of the generator belt. We wrote about how to properly check the tension level of the alternator belt here.

For information on the optimal degree of tension of your car's alternator belt, refer to its operating instructions.

- If necessary, adjust the belt tension. A good video instruction for adjusting the alternator belt is at the bottom of this page.

- If all of the above did not help and the alternator belt continues to squeak obnoxiously, then with the engine running and good lighting, carefully inspect the line of pulleys for alignment.

An indirect sign of pulley misalignment is the poly V-belt jumping from track to track and sliding off the pulley.

- Pay attention to the linearity of rotation of the pulleys - if any pulley rotates in a figure eight, it will tear and throw off the belt. Most often, pulleys with a rubber damper behave this way, which over time loses elasticity and ceases to perform its functions.

And so, if the generator belt has not stopped whistling, but it is intact, clean, well tensioned, and the pulleys rotate smoothly and smoothly, then you can try to correct the situation using another method:

- Remove the alternator belt and carefully inspect it again for damage and dirt. If the belt is intact, then you need to clean its surface from the inside and outside (you can use gasoline or kerosene); if damage is found, buy a new belt.

- With the generator belt removed, thoroughly clean the pulleys from dirt and dust. This is best done with a wire brush. You can also use gasoline or kerosene.

- Place a clean belt on the clean pulleys and adjust its tension. After this, the whistling of the alternator belt should disappear.

If all of the above did not help and the belt whistle has not gone away, then the problem lies either in the quality of the belt itself or in the equipment that is driven by it: tension rollers, generator, power steering pump, air conditioning compressor, etc. Perhaps the grease in the bearings has simply thickened or they have failed, or perhaps the reason is much more serious, so in this case it would be better to seek help from a car service specialist.

You can try to temporarily eliminate the whistling noise using special auto chemicals, so-called conditioner-tensioners for drive belts. This, of course, will not solve the problem, but the whistling will disappear for a while.

Video instructions for adjusting the alternator belt on Renault Logan and Lada Largus

Source: http://ymp3.ru/avtoremont-i-tyuning/pochemu-svistit-remen-generatora-chto-delat-i-kak-ustranit-svist-privodnogo-remnya

How to eliminate a whistling alternator belt

“Why did the alternator belt whistle?” - this question arose from more than one car enthusiast. To understand why the alternator belt whistles, it is extremely important to find out the reasons for this. The reasons why it may whistle are most often stretching and wear.

When the alternator belt stretches, it loses tension and a tight fit to the alternator and engine flywheel. In such a situation, the chance of water getting into the generator increases significantly.

And in this case, when the liquid does get in, it prevents a tight fit to the generator. As a result, some slippage occurs in the work.

So, the whistle appears because the rubber belt slips over the metal cavities of the flywheel.

The reasons why stretching occurs can be different. But most often, this is low-quality material and an old part.

The low price of products is the main reason why drivers purchase certain parts for a car, and it is basically the answer to the question “why does the alternator belt whistle.” But it is important to remember that a cheap part lasts much less than the originals.

And be prepared for the fact that a car breakdown can happen at any time. As for the belt, it can not only stretch, but also break at the most inopportune moment. As a result, the cooling system will fail and the engine will become very hot and may soon seize.

As a rule, as a result, you can observe the appearance of steam from under the hood of the car. Old age and long-term operation are also fraught with danger for the generator, as there is a large load on it.

Diagnostics and repair

A thorough diagnosis allows you to understand one hundred percent why the alternator belt is whistling. When a whistle first appears, it is necessary to carry out diagnostics and subsequent repairs. This can be done either at a service station or independently. The first step is to carefully inspect for any mechanical damage.

You need to try its tension, check whether the pulley lines have shifted. It is also extremely important to check for liquid on its surface that should not be on it. If you observe some damage, then it is necessary to draw conclusions regarding repair or complete replacement.

If there is any damage on the surface: cracks, frayed edges, it must be replaced. Since it can no longer be repaired. Don't try to glue it. This will make your situation worse.

It is important to remember that the old belt needs to be replaced with a new one and, preferably, it should be original and suitable for your car. Otherwise, this old element will work for several thousand more kilometers (if you’re lucky) and you will still have to face the problem again.

Important: often cheap, low-quality products cause the alternator belt to whistle immediately after their use.

If there is some contamination from oil or antifreeze on the surface, which causes the generator belt to whistle, then in this case you should try to wipe off fresh marks and stains, if possible. But, if the liquid has penetrated deep enough and you cannot remove it, then you need to replace it. Yes, you can still ride with such a belt, but the question is - for how long?;

If after visual contact you do not find any damage, then now you need to check the mechanical part itself - check the tension. To check the tension you need to press it with your finger.

You need to press in the middle, between the generator pulleys and the crankshaft. It should bend to about six millimeters, but no more, since this figure is abnormal.

And in this case it is necessary to apply adjustment.

Repair to replace the belt for each car has its own differences, but they are not significant. Let's consider the general, optimal replacement option.

To work you need to prepare a special tool:

- Ratchet handle;

- The wrench is set to “19” (socket) and the deep socket is set to “17”.

It would also be a good idea to prepare a set of tools for the motorist. So, take the key to “17” and unscrew the nut that secures the generator to the bracket.

It is not necessary to unscrew the nut completely, just a few turns to loosen it. If to remove the belt you need to loosen it a little, then you need to move the generator towards you or away from you.

The tension can be adjusted using a tension bolt (another name for a weighting agent) or a special strip.

After it is tightened, you need to secure all the loosened nuts and start checking.

In order for the test to be of the highest quality, you need to start the engine and at the same time turn on a couple of main energy consumers: high beams and the stove.

If you do not hear a whistle, and the charge level remains in the normal position, then we can assume that the repair was completed successfully. As a rule, after such an operation he should not whistle.

In order to replace an old element with a new one, you need to follow the same steps. You need to loosen it until it goes away on its own. It is important to remember that the new belt must be of high quality and suitable for your type of car.

There are times when just replacing the belt does not bring a positive result. In this case, the possible cause is the tension mechanism (the tightening roller may be faulty).

Such repairs can only be performed at a service station, since it is quite difficult to solve this issue on your own. In order for the car generator to work properly, it is necessary to diagnose its elements from time to time.

Follow this requirement, and it will not whistle or tear. I wish you success.

Video “How to eliminate alternator belt whistling”

This video clearly shows how to eliminate the whistling of the alternator belt if at the moment you do not have the opportunity to replace it in a timely manner.

Source: http://MineAvto.ru/remont/elektrooborudovanie/svist-remnya-generatora-1408.html