Engine cooling system

Reliable and trouble-free operation of the internal combustion engine (ICE) cannot be achieved without a cooling system. It is convenient to present its basic principles of operation in the form of a diagram of the engine cooling system.

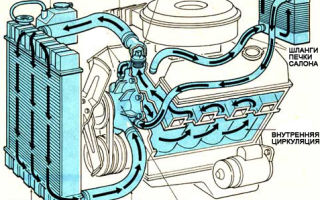

The main purpose of the system is to remove excess heat from the engine and protect it from overheating. An additional function is heating the car using the interior heater stove.

The design and principle of operation shown in the diagram of the engine cooling system are approximately the same for different types of cars.

Diagram, design and principle of operation of the engine cooling system

The main elements that make up the engine cooling system circuit are found and are similar in different types of engines: injection, diesel and carburetor.

General diagram of the engine cooling system

The liquid cooling system makes it possible to equally absorb heat from all components and parts of the engine, regardless of the degree of thermal load. An engine using a water-cooled system produces less noise than an air-cooled engine, has a faster warm-up rate at start-up, and is not as prone to detonation.

The engine cooling system contains the following parts and elements:

- A cooling jacket (“water jacket”) is considered to be cavities communicating between double walls in those places where excess heat is most needed to be removed.

- The radiator of the cooling system is designed to dissipate heat into the surrounding atmosphere. It structurally consists of many curved tubes with additional ribs to increase heat transfer.

- The fan, activated by an electromagnetic or, less commonly, hydraulic clutch, when the coolant temperature sensor is triggered, increases the air flow flowing into the car. Fans with a “classic” (always on) belt drive are rarely found these days, mainly on older cars.

- The centrifugal liquid pump (pump) in the cooling system ensures constant circulation of coolant. The pump drive is most often implemented using a belt or gears. Turbocharged and direct injection engines are usually equipped with an additional pump.

- The thermostat is the main unit that regulates the flow of coolant, usually installed between the radiator inlet pipe and the “water jacket” of the engine, and is designed in the form of a bimetallic or electronic valve. The purpose of the thermostat is to maintain the specified operating temperature range of the coolant in all engine operating modes.

- The heater radiator is very similar to the smaller radiator of the cooling system and is located in the car interior. The fundamental difference is that the heater radiator transfers heat to the passenger compartment, and the cooling system radiator transfers heat to the environment.

The principle of operation of the engine cooling system is as follows: the cylinders are surrounded by a “water jacket” of coolant, which removes excess heat and transfers it to the radiator, from where it is transferred to the atmosphere. The liquid continuously circulates to ensure optimal engine temperature.

Operating principle of the engine cooling system

Coolants - antifreeze, antifreeze and water - during operation form sediment and scale that disrupt the normal operation of the cooling system.

Water is not chemically pure in principle (with the exception of distilled water) - it contains impurities, salts and all kinds of aggressive compounds. At elevated temperatures they precipitate and form scale.

Unlike water, antifreezes do not create scale, but during operation they decompose, and the decomposition products have a negative effect on the cooling system: corrosion deposits and layers of organic substances appear on the internal surfaces of metal elements.

In addition, various foreign contaminants may enter the cooling system: oil, detergents or dust. The system can also be contaminated by special sealants used for emergency repair of damage in radiators.

All these contaminants settle on the internal surfaces of the cooling system. They are characterized by poor thermal conductivity and clog thin tubes and honeycombs of the radiator, interfering with the efficient operation of the cooling system, which leads to engine overheating.

Video about how the cooling system works, what it consists of, and malfunctions

Flushing the engine cooling system

Flushing the engine cooling system is a process that many drivers often neglect, which sooner or later can cause fatal consequences.

It is recommended to carry out such work simultaneously with replacing the coolant. Taking into account the car model and its brand, this must be done from 1 time per calendar year to once every three years.

Signs that it's time to flush the cooling system

- If the temperature gauge needle is not in the middle, but tends to the red zone while driving;

- It’s cold in the cabin, the heating stove does not provide sufficient temperature;

- Radiator fan turns on too often

It is impossible to flush the cooling system with plain water, since contaminants are concentrated in the system and cannot be removed even by water heated to high temperatures.

Scale is removed with the help of acid, and fats and organic compounds are removed exclusively with alkali, but both compounds cannot be poured into the radiator at the same time, since they are mutually neutralized according to the laws of chemistry. Manufacturers of cleaning products, trying to solve this problem, have created a number of products that can be divided into:

The first two are too aggressive and are almost never used in their pure form, as they are dangerous for the cooling system and require neutralization after use. Less common are two-component types of cleaners containing both solutions - alkaline and acidic, which are poured into the cooling system alternately.

The greatest demand is for neutral cleaners that do not contain strong alkalis and acids. These products have varying degrees of effectiveness and can be used both for prevention and for thorough flushing of the cooling system from heavy contaminants.

Flushing the cooling system

Flushing the cooling system:

- Antifreeze, antifreeze or water is drained. Before doing this, you need to start the engine for a couple of minutes.

- Fill the system with water and cleaner.

- Turn on the engine for 5-30 minutes (depending on the brand of cleaner) and turn on the interior heating.

- After the time specified in the instructions has passed, the engine must be turned off.

- Drain the used cleaner from the cooling system.

- Rinse with water or a special compound.

- Fill with fresh coolant.

Flushing the cooling system is simple and accessible: even inexperienced car owners can perform it. This operation significantly extends the service life of the engine and maintains its performance characteristics at a high level.

Malfunctions in the engine cooling system

There are a number of the most common malfunctions in the engine cooling system:

- Airing the engine cooling system: remove the air lock.

- Insufficient pump performance: replace the pump. Select a pump with the maximum impeller height.

- The thermostat is faulty: it can be fixed by replacing it with a new device.

- Low performance of the coolant radiator: flush the old one or replace the standard one with a model with higher heat-dissipating properties.

- Insufficient performance of the main fan: Install a new fan with higher performance.

Video - identifying cooling system faults in a car service center

Regular maintenance of the engine cooling system guarantees long-term operation of the vehicle as a whole.

Source: http://AvtoMotoProf.ru/obsluzhivanie-i-uhod-za-avtomobilem/sistema-ohlazhdeniya-dvigatelya/

Car engine cooling system: design and principle of operation

Internal combustion engines (ICE) and their components are subject to intense heat during operation of various vehicles. At the same time, both overheating and hypothermia of the motor can provoke its failure.

In this regard, one of the most important tasks of power unit developers is to ensure optimal thermal conditions for their operation. A well-organized engine cooling system helps to obtain the best operational parameters of the internal combustion engine, which include:

- Maximum power.

- Minimum fuel consumption.

- Extended service life.

The influence of temperature parameters on motor operation

During one operating cycle, the temperature in the internal combustion engine cylinders changes from 80...120 degrees Celsius during the intake of the combustible mixture to 2000...2200 degrees Celsius during its combustion. In this case, the power unit gets quite hot.

If the motor is not cooled intensively enough during operation, its parts become very hot and change in size. The volume of engine oil poured into the crankcase also decreases significantly (due to burnout). As a result, friction between interacting parts increases, which leads to their rapid wear or even jamming.

However, overcooling of the internal combustion engine also negatively affects its operation. Condensation of fuel vapor occurs on the cylinder walls of a cold engine, which, washing away the lubricant layer, dilutes the engine oil in the crankcase.

To eliminate the negative consequences associated with violation of the thermal regime, cooling systems are designed to prevent overheating and overcooling of the motor during operation.

As a result, the chemical properties of the latter deteriorate, which contributes to:

- increased engine oil consumption;

- intensive wear of rubbing surfaces;

- drop in power of the power unit;

- increased fuel consumption.

Classification

When the motor is running, it is necessary to ensure that 25 to 35% of the generated heat is removed. To effectively absorb (remove) it, water, air or a special liquid (antifreeze, antifreeze) is most often used. The coolant material determines the cooling method of the power unit.

There are systems:

- Forced air cooling.

- Closed cycle liquid cooling.

Liquid cooling system

Currently, a closed, closed-cycle liquid cooling system is used to effectively cool automobile engines.

Design

The system necessarily contains an expansion tank, which serves to compensate for changes in the volume of liquid when its temperature changes. In addition, coolant is poured through it.

The system also includes:

- water jacket of the power unit (the space between the double walls of the cylinder block and its head in places where excessive heat is removed);

- temperature sensor;

- bimetallic or electronic thermostat that ensures the optimal temperature in the system;

- a centrifugal pump that provides forced circulation of coolant in the system;

- a fan, which increases the flow of oncoming air to the main radiator of the system;

- a radiator that transfers heat to the environment;

- heater radiator, designed to transfer heat directly to the vehicle interior;

- a control device built into the dashboard of a car.

Operating principle

Coolant is poured into the system through the expansion tank. Constantly circulating inside the system, it removes heat from the engine components that heat up during operation, heats up, enters the radiator, is cooled in the radiator by the counter flow of air and returns back.

If necessary, the fan turns on, enhancing cooling efficiency. For closed cooling systems, the coolant temperature should not exceed 126 degrees Celsius. This ensures optimal thermal operation of the power unit.

Additional functions

In addition to its main task - removing heat from heating elements, the liquid engine cooling system also provides:

- Warming up the power unit in the cold season

Modern liquid cooling systems have two circuits through which coolant can circulate. This is done so that at the moment of starting a cold engine, when its parts and the liquid itself are at a low temperature, the coolant circulates in a small circle (past the radiator).

This is ensured by a thermostat, which, when the temperature rises to a certain level (70-80 degrees Celsius), opens, allowing the coolant to circulate in a large circle (through the radiator). Thus, the process of warming up the engine is accelerated.

- Heating the air inside the car

During the cold season, hot coolant is used to heat the air in the car interior. For this purpose, there is an additional radiator installed in the cabin and equipped with its own fan. With their help, the heat taken from the hot liquid is distributed throughout the entire volume of the cabin.

- Reducing the temperature of the air forced into the cylinders

Especially for engines equipped with turbochargers, dual-circuit systems are provided, in which one circuit provides liquid cooling, and the second provides air cooling.

In addition, the coolant cooling circuit is also a dual-circuit system, one circuit of which cools the cylinder head, and the other cools the block itself.

This is due to the fact that in a turbocharged engine the temperature of the cylinder head should be 15...20 degrees Celsius lower than the temperature of the block itself. A special feature of this cooling system is that each circuit is controlled by its own thermostat.

Advantages and disadvantages

A liquid engine cooling system is present in almost all modern cars. Fundamentally different from air cooling systems, it guarantees:

- uniform and rapid heating of the power unit;

- effective heat removal under any engine operating conditions;

- reduction of power costs;

- stable thermal operating conditions of the motor;

- the possibility of using the generated heat to heat the air in the cabin, etc.

Among the few disadvantages of a liquid cooling system are:

- the need for regular maintenance and the complexity of repairs;

- increased sensitivity to temperature changes.

Malfunctions and ways to eliminate them

All liquid cooling systems have characteristic malfunctions. The most common:

- the thermostat is stuck in the closed position (liquid circulation is carried out in a small circle);

- pump breakdown;

- damage to the exhaust valve built into the expansion tank plug;

- leakage of coolant due to depressurization of the system (damage to seals, corrosion, etc.).

- In addition, quite often the thermostat gets stuck in the “Open” position (the coolant circulates in a large circle), which increases the warm-up time of a cold engine and contributes to instability of the thermal regime during its further operation.

All these malfunctions are characterized by a significant increase in the operating temperature of the power unit, which can lead to boiling of the coolant and overheating of the engine.

All defects are eliminated by replacing faulty and/or damaged parts or components.

Air cooling system

Vehicles were equipped with air-cooled motors in the 50-70s of the last century. Typical representatives of such cars are the Zaporozhets or FIAT 500. Nowadays, air-cooled engines are practically never found in the automotive industry.

Design and principle of operation

Structurally, the forced air cooling system is mounted in the engine compartment of the vehicle and consists of:

- suction or forcing fan;

- guide fins of the engine cooling jacket;

- controls (throttle valves that control the air supply or a clutch that regulates the fan speed in automatic mode);

- temperature sensor installed in the power unit;

- control device displayed on the dashboard inside the car.

The motor is cooled by counter cold air. To enhance its flow, a forced-type fan is most often used. It enhances the flow of cold dense air and provides it in large quantities at low energy costs.

The suction fan requires more power, but provides more uniform heat removal from the parts of the power unit.

Advantages and disadvantages

Motors with forced air cooling differ:

- simplicity of design;

- low requirements for changes in ambient temperature;

- light weight;

- easy maintenance.

The disadvantages of an air cooling system include:

- a large loss of motor power, which is spent to ensure the operation of the fan;

- high noise level during fan operation;

- insufficient cooling of individual engine elements due to uneven airflow;

- inability to use excess heat to heat the interior.

Source: https://dvigatels.ru/uhod/sistema-ohlazhdeniya-dvigatelya.html

How does the engine cooling system work?

When running, a car engine generates a lot of heat, so it needs to be constantly cooled to avoid damage.

Typically, this is done using coolant (water) mixed with an antifreeze solution and circulated in special channels. Some engines are cooled by air currents that move over cylindrical cooling fins.

How coolant circulates

A typical liquid cooling system equipped with a motor driven fan. Please note that the overflow hose contains hot water for the heater. The sealed cover of the expansion chamber is equipped with a valve with a spring, which opens at a certain pressure.

Water cooling system

The cylinder block and cylinder head, cooled by water, are interconnected by fluid channels. At the top of the head, all channels are combined into a single drain.

The pump, driven by a pulley and belt from the crankshaft, directs hot fluid from the engine to the radiator, which is a heat exchange device.

Unnecessary heat leaves the radiator with the air flow, and the coolant returns through the inlet to the bottom of the block and again passes through the channels.

Typically, the pump sends coolant up through the engine and down through the radiator, which is very beneficial given that when the fluid heats up, it expands, becomes lighter, and rises above the cold fluid. In other words, hot liquid always flows upward, and the pump only helps it circulate.

The radiator is connected to the engine by rubber hoses, and the honeycomb is connected to the upper and lower tanks by numerous thin tubes.

The tubes pass through holes in a bank of thin sheet metal cooling fins, so the honeycomb has a large surface area and loses heat quickly when air passes through it.

Older models have vertical pipes, but modern low-front cars use cross-flow radiators with horizontal pipes.

In an engine operating under standard conditions, the coolant does not heat above its boiling point.

The liquid never boils, because... the pressure in the system is increased, which means the boiling point exceeds normal.

To protect against overpressure, the radiator cap is equipped with a shut-off valve. When the pressure rises excessively, the valve opens and coolant flows out through the bypass pipe.

In a cooling system of this type, with constant overheating of the engine, the liquid is gradually consumed, and the supply must be replenished.

In later models, the cooling system is sealed and any excess fluid is collected in the expansion chamber, where it cools and is then sucked back into the engine.

Why do you need a fan?

The radiator needs a constant flow of air, which passes through the honeycombs and cools them properly. When the car moves, this happens naturally. When stopped, the air flow is controlled by the fan.

The fan can be powered by the engine, but if the car is stationary or the engine is not overloaded, a running fan will consume excess fuel.

To avoid unnecessary costs, some vehicles use viscous couplings (fluid couplings), which are equipped with a temperature-sensitive valve that runs the fan until the fluid temperature drops to the desired value.

Some cars are equipped with electric fans that turn on and off according to the temperature sensor.

To ensure that the engine heats up quickly, the radiator is separated from it by a thermostat, which is usually located above the pump. The thermostat is equipped with a valve, under which there is a cylinder with wax.

As the engine warms up, the wax melts, expands and opens the valve, allowing coolant to flow through the radiator.

When the engine stops and cools down, the valve closes again.

Water expands when it freezes, so if it freezes in the engine, the block or radiator could burst. Therefore, antifreeze (usually ethylene glycol) is added to the water to lower the freezing point to a safe level.

Antifreeze does not need to be drained every summer. As a rule, it lasts two to three years.

Air cooling system

An air-cooled engine has deep cooling fins on the outer surface of the cylinder block and cylinder head.

As a rule, the ribs widen towards the top, because the heat is concentrated there.

Horizontal air-cooled motors have ventilation ducts on the fins.

In a heater with water valves, air flows through a bundle of pipes. The temperature in the bundle is determined by the amount of hot water passing through it.

A channel also passes through all the ribs, through which air flows, taking away excess heat with it.

The volume of air passing through the fan is determined using a temperature-sensitive sensor, so the temperature remains constant even on cold days.

Oil cooling

Air-cooled and high-performance water-cooled engines sometimes use an additional small radiator to cool the engine oil.

17koles.ru

Engine cooling system: how does it work?

When the car is running, the fuel mixture burns, releasing a huge amount of heat. To prevent the engine from overheating and being destroyed, a cooling system (CO) is installed in vehicles, consisting of several elements; we will describe the functions of each of them in detail.

Cooling system operation

As soon as the engine starts, the pump blades begin to rotate. They force the coolant to circulate through a small circle of CO circulation. The engine warms up and reaches operating temperature. After this, the thermostat opens, the coolant goes into circulation mode through a large circle of CO, already including the radiator.

Already cooled, technical fluids enter the engine jacket. If the coolant temperature rises to 100 degrees or higher, the fan turns on, increasing the air flow that passes through the radiator, thereby making the cooling process much more efficient.

In cars produced a couple of decades ago, the fan is connected to the pump shaft by a belt, and therefore rotates constantly.

What to put in the cooling system?

Antifreeze or antifreeze is used as coolant. They contain chemical elements and compounds that prevent water from turning into ice even at the lowest temperatures. Coolants also contain substances that prevent:

- Foaming;

- The appearance of corrosion and rust;

- The water pump is lubricated.

But water cannot be used as a coolant, since it will very soon destroy the metal CO. As it heats up, the coolant increases in volume, and its excess begins to be released into the expansion tank, connected to the radiator neck with a flexible hose. Coolant is poured through the expansion tank and, if necessary, topped up.

There is another radiator inside the car, the so-called stove. In winter, car owners, as a rule, open the heater damper and the heated coolant circulates through the heat exchanger, warming the interior air in the car.

CO is quite simple and requires virtually no maintenance. If there are no coolant leaks, the system operates without problems for 2 years.

After two years, the coolant in the system should be replaced, and at the same time constantly monitor the condition of the pipes: rubber can dry out and crack due to age, and this can happen on the road.

Then it will be impossible to continue moving. Therefore, every 5–6 years it is necessary to replace all rubber pipes.

In vehicles produced recently, CO still works for:

- Oil cooling;

- Air ventilation system;

- Turbocharging;

- Air conditioning;

- Interior heaters;

- Gas in the recirculation system;

- Automatic transmission fluid.

Types of cooling systems

It should be noted that the modern automotive industry uses three types of cooling systems:

- Liquid;

- Air;

- Combined.

Liquid CO, which removes heat with a flow of liquid, is used most often than all others. It operates with much less noise than its air sister, and it cools the engine parts evenly and very efficiently.

Typical failures in the cooling system

CO breakdowns are not classified as malfunctions for which driving is prohibited, however, every reasonable car owner is very interested in extending the life of his iron horse, and his heart - the engine. And first of all, this concerns the need for intensive heat removal.

The most common causes of breakdowns in CO include:

This can happen due to a sudden change in ambient temperature. Another popular failure is coking of the hoses and pipes of the system. They lose elasticity when exposed to the same high temperatures.

Coolant can also leak due to damage to the radiator from an impact, or as a result of chemical exposure to antifreeze components. The thermostat may also fail. It is in contact with liquid, and therefore corrodes, and then can jam.

A serious problem for the system is the breakdown of the pump or circulation pump due to low-quality spare parts or wear. You can understand and catch this by the characteristic whistle of the bearing. This means it's time to replace the circulation pump.

Sometimes the CO simply becomes clogged due to the deposition of salts in the channels. Coolant circulation is disrupted, and heat removal is impaired, which leads to engine overheating.

Cooling System Maintenance

Basic rules for operating CO and their observance allow car owners to avoid or minimize the negative impact of malfunctions on the operation of the car. The coolant level in the system should be constantly monitored.

Its volume may vary, and it depends on the operating conditions of the vehicle. If the coolant level drops constantly, then you need to look for the location of the antifreeze leak. Coolant stains are often found on components and assemblies in the engine compartment.

Engine overheating can occur when:

- Thermostat is stuck

- Channels become clogged

- The coolant level in the system is insufficient.

The reason for insufficient engine heating should be sought in a jammed thermostat.

Share this article with your friends:

blog-mycar.ru

How it works: engine cooling system

Order spare parts at a discount!

Camera – 08/13/2017 – ag. Koptevka (near the camping)

Source: http://autoprivat.ru/remont_avto/kak_rabotaet_sistema_ohlazhdeniya_dvigatelya.html

Engine cooling system - how does it protect the “heart” of the car?

The engine cooling system is of great importance. It supplies a special cooler to the heated engine elements and removes excess heat from the parts. Without these processes, the normal functioning of the car’s power unit is impossible.

- Sheinin: “I speak for myself, anyone can cure prostatitis, take the proven Prost...”

In the cylinders of an internal combustion engine (car engine), during combustion of the working mixture, temperatures up to +2000 ° C are observed. It is clear that such heating of motor elements is unsafe.

It can cause detonation or self-ignition of the combustible mixture, a decrease in the power of the internal combustion engine, breakdown and jamming of parts, and increased wear. The normal temperature for operation of the power unit is considered to be in the range of 80–110°.

The main purpose of the cooling system is precisely to reduce the heating of the internal combustion engine to the specified value.

Engine cooling

- They will protect the chassis and save you money, increasing ground clearance by 3 cm.

It also performs several other important functions in diesel and gasoline engines. These include cooling:

- composition in the automatic gearbox;

- spent mixtures in the recirculation circuit;

- composition used in the lubrication system;

- air flow in turbocharging.

Cooling systems used today are divided into several types. They can be open, closed, mixed.

In the first case, reducing the heating of the motor is achieved by supplying an air flow to it (the operation is carried out naturally or by force). Open cooling has some disadvantages.

In particular, when using air, it is very difficult to achieve uniform cooling of all internal combustion engine components and at the same time make the engine powerful and small in size.

The liquid system has no such disadvantage. Therefore, it is used on most modern vehicles. Next, we will consider in detail its structure and operating principle. Mixed systems combine air and closed cooling. They are considered difficult. Therefore, now automakers rarely equip their cars with them.

Uniform cooling of engine parts is ensured by a liquid system. In this case, water, antifreeze or antifreeze is used as a coolant.

Such a system qualitatively removes heat from all elements of the internal combustion engine, regardless of the thermal loads placed on them. Moreover, such selection is carried out evenly.

Due to this, liquid-cooled units almost completely eliminate the risk of detonation. And the noise level during their operation is reduced to a minimum.

Liquid cooling

A carefully thought-out design of the engine cooling system guarantees high efficiency of its operation. It consists of the following parts:

- shirt;

- control elements;

- thermostat;

- fan;

- centrifugal pump;

- radiator;

- expansion tank.

The cooling jacket is understood as a special cavity. It wraps around engine components that are subject to extreme heat. The cooling medium, when moving along the jacket, picks up excess heat from the engine elements and sends it to the radiator. The latter is made in the form of a set of curved tubes and special. ribs This design allows the radiator to dissipate excess heat into the environment.

The circulation of liquid through the system is ensured by a centrifugal pump (also called a pump). It is driven by a gear or a drive belt. A fan is necessary to generate additional air flow. The latter blows air through the system when driving at low speeds and during stops.

In modern vehicles the fan is connected to a separate electric drive. On older cars, its operation is ensured by a belt drive. A certain supply of antifreeze is stored in the expansion tank.

This element is equipped with an overpressure valve, which eliminates the risk of coolant boiling.

The thermostat provides the set temperature of antifreeze (antifreeze). This part is placed between the inlet pipe of the radiator, which reduces the heating of the car engine, and the water jacket. The thermostat is an electronic or bimetallic valve.

It is closed when the engine is cold. In this case, the cooler circulates outside the radiator (inside the internal combustion engine) in a so-called small circle.

And when the liquid heats up to operating temperature, the valve opens, after which the system we are considering begins to function in full mode.

The operating principle of the engine cooling system is relatively simple. It is the same for both diesel and gasoline units. The coolant used circulates through a water jacket under the action of a centrifugal pump. This leads to a decrease in the temperature of various elements of the internal combustion engine and simultaneous heating of the coolant. Antifreeze can move along the jacket in two directions:

- from exhaust to intake manifold (lateral movement);

- from the first to the last cylinder (longitudinal diagram).

The coolant circulates, as noted earlier, in a large or small circle (the thermostat opens and closes). In the radiator, the heated cooler is blown by a flow of oncoming air (naturally). If this is not enough, the fan turns on. After cooling, the used composition is returned back to the water jacket. The described cycle is repeated many times.

The operation of the cooling system is controlled by a special electronic unit, a temperature sensor and additional actuators. The latter usually include an internal combustion engine cooling relay, a fan control module, a pump relay, and a fan heater.

The system sensor constantly monitors the temperature value and modifies it into an electrical type signal, which is supplied to the control unit. The latter has special software.

It allows you to decipher incoming signals and send commands about the need to automatically perform a particular action by actuators.

Often an additional temperature sensor is mounted at the radiator outlet. Its installation is especially relevant for modern cars with a large number of actuators and high engine power. An additional sensor significantly expands the functionality of the cooling system.

The cooling system needs to be regularly checked for functionality. Often there is an antifreeze leak in it.

This problem is usually caused by freezing of the coolant at sub-zero temperatures or failure of pipes and hoses (the latter may lose their elasticity and become coked).

A leak also occurs in cases where the radiator is subjected to any mechanical stress (strong pressure, shock). This problem can be solved simply by replacing the hoses and filling in a new coolant.

Sometimes the thermostat fails. Most often this occurs due to corrosion of its valve, which is constantly in contact with the liquid. In this case, you need to install a new thermostat. If you wish, you can do this operation yourself.

During active use of the machine, the circulation pump may break. The driver is warned that it is not functioning by a characteristic whistle emanating from the engine. The pump itself rarely breaks down.

But the bearings in it have to be changed quite often.

During long-term operation of the system we are describing, blockages may form in it due to salt deposits in the engine block head or in the radiator. Such contaminants cause damage (at best, poor performance) of the internal combustion engine. Therefore, blockages must be removed. The following symptoms indicate that the system is dirty:

- too frequent autostart of the radiator fan;

- the temperature indicator is in the red zone (or constantly tends to it).

It’s even better to regularly flush the system, performing this procedure simultaneously with replacing the antifreeze (that is, about once every 2-3 years). Cleaning is usually carried out with special compounds. It is advisable to purchase products that are neutral in their chemical activity. The process of flushing the system is simple.

You need to drain the used coolant (water, antifreeze, antifreeze), fill in a cleaning compound instead, and start the engine for 15-30. After this, turn off the engine, drain the used cleaner, rinse the system again (now with regular clean water) and fill it with a new cooler. All.

Flushing is complete.

Source: http://tuningkod.ru/tyuning-avtomobilej/sistema-oxlazhdeniya-dvigatelya.html

How it works: engine cooling system

Today, from our regular column “How it works,” you will learn the structure and operating principle of the engine cooling system , why a thermostat and radiator the air cooling system is not widespread .

The cooling system of an internal combustion engine removes heat from engine parts and transfers it to the environment. In addition to the main function, the system performs a number of secondary ones: cooling the oil in the lubrication system; heating the air in the heating and air conditioning system; exhaust gas cooling, etc.

When the working mixture is burned, the temperature in the cylinder can reach 2500°C, while the operating temperature of the internal combustion engine is 80-90°C. It is to maintain optimal temperature conditions that there is a cooling system, which can be of the following types, depending on the coolant: liquid, air and combined.

It should be noted that the liquid system in its pure form is no longer practically used , since it is not capable of maintaining the operation of modern engines in optimal thermal conditions for a long time.

Combined engine cooling system:

water is often used as a coolant , as it has a high specific heat capacity, availability and harmlessness to the body.

However, water has a number of significant disadvantages: scale formation and freezing at subzero temperatures . In the winter season, it is necessary to fill the cooling system with low-freezing liquids - antifreeze (aqueous solutions of ethylene glycol, mixtures of water with alcohol or glycerin, with hydrocarbon additives, etc.).

The cooling system under consideration consists of: a liquid pump, radiator, thermostat, expansion tank, cylinder and head cooling jacket, fan, temperature sensor and supply hoses.

It is worth mentioning that the engine is forced to cool, which means it maintains excess pressure (up to 100 kPa), as a result of which the boiling point of the coolant rises to 120°C .

When starting a cold engine, it gradually heats up. At first, the coolant, under the action of a liquid pump, circulates in a small circle , that is, in the cavities between the cylinder walls and the engine walls (cooling jacket), without entering the radiator. This limitation is necessary to quickly bring the engine into an effective thermal regime. When the engine temperature exceeds optimal values, the coolant begins to circulate through the radiator, where it is actively cooled (called a large circulation circle ).

|

small circle of circulation |

large circle of circulation |

Next, we will consider separately each element of the engine cooling system.

| THERMOSTAT . At its core, this little device works like an automatic valve. When the thermostat is closed, it does not allow coolant to enter the radiator. But at an ambient of 85-95°C , it opens and then the liquid circulates in a large circle (through the radiator). Moreover, the higher the temperature of the environment, the wider the thermostat opens, which increases its throughput. |

Design and principle of operation:

| The thermostat is made of brass and copper. Consists of a cylinder filled with a mixture of wax and graphite dust (various manufacturers use their own designs and components). A pin is pressed into the cylinder with the mixture and connected to the valve. When heated, the artificial wax expands significantly, pushing out the pin, which opens the passage of coolant to the radiator. The steel spring, as the working fluid cools, returns the valve to the closed state. |

| LIQUID PUMP . The pump ensures forced circulation of liquid in the engine cooling system. The most commonly used pumps are centrifugal-type vane pumps. The pump shaft 6 is installed in the cover 4 using a bearing 5. A cast iron impeller 1 is pressed onto the end of the shaft. When the pump shaft rotates, the coolant through the pipe 7 flows to the center of the impeller, is captured by its blades, and is thrown to the pump housing 2 under the action of centrifugal force and through window 3 in the housing is directed into the cooling jacket of the engine cylinder block. |

|

The RADIATOR ensures the removal of heat from the coolant to the environment. The radiator consists of upper and lower tanks and a core. It is mounted on a car on rubber cushions with springs. The most common are tubular and plate radiators. In the first, the core is formed by several rows of brass tubes passed through horizontal plates, increasing the cooling surface and giving rigidity to the radiator. In the second, the core consists of one row of flat brass tubes, each of which is made of corrugated plates soldered together at the edges. The upper tank has a filler neck and a steam outlet pipe. The neck of the radiator is hermetically sealed with a plug that has two valves: a steam valve to reduce pressure when the liquid boils, which opens at an excess pressure of over 40 kPa (0.4 kgf/cm2), and an air valve, which allows air into the system when the pressure decreases due to cooling of the liquid and thus protecting radiator tubes from flattening by atmospheric pressure. Aluminum radiators are also used : they are cheaper and lighter, but their heat transfer properties and reliability are lower . |

The coolant “runs” through the radiator tubes and is cooled by the oncoming flow of air. The FAN increases air flow through the radiator core.

The fan hub is mounted on the shaft of the liquid pump. They are driven together by belts from the crankshaft pulley. The fan is enclosed in a casing mounted on the radiator frame, which increases the speed of air flow passing through the radiator. The most commonly used are four- and six-blade fans.

| THE EXPANSION TANK serves to compensate for changes in the volume of coolant when its temperature fluctuates and to control the amount of liquid in the cooling system. It also contains some reserve of coolant for its natural decline and possible losses. |

| The coolant temperature SENSOR The electronic control unit receives this impulse and sends certain signals to the actuators. Using a coolant sensor, the computer determines the amount of fuel required for normal operation of the internal combustion engine. Also, based on the readings of the coolant temperature sensor, the control unit generates a command to turn on the fan. |

Air cooling system:

In an air cooling system, heat is removed from the walls of the combustion chambers and engine cylinders by forced air flow created by a powerful fan. This cooling system is the simplest , as it does not require complex parts and control systems.

The intensity of air cooling of engines significantly depends on the organization of the direction of air flow and the location of the fan. In in-line engines, fans are located in front, on the side, or combined with the flywheel, and in V-shaped engines, they are usually located in the camber between the cylinders.

Depending on the location of the fan, the cylinders are cooled by air that is forced or drawn through the cooling system. The optimal temperature regime of an air-cooled engine is considered to be one at which the oil temperature in the engine lubrication system is 70... 110°C in all engine operating modes.

This is possible provided that up to 35% of the heat that is released during the combustion of fuel in the engine cylinders is dissipated into the environment with the cooling air. The air cooling system reduces the engine warm-up time, ensures stable heat removal from the walls of the combustion chambers and engine cylinders, is more reliable and convenient to operate, easy to maintain, more technologically advanced with a rear-mounted engine, and engine overcooling is unlikely . However, an air cooling system increases the overall dimensions of the engine , creates increased noise during engine operation, is more difficult to manufacture and requires the use of higher quality fuels and lubricants. The heat capacity of air is small , which does not allow a large amount of heat to be evenly removed from the engine and, accordingly, to create compact, powerful power plants.

Source: https://autogrodno.by/home/kak-eto-rabotaet/1376-1376.html