How to restore a car battery yourself: 4 methods and 3 causes of failure

The battery is one of the fundamental devices of a car, which, like all other components, has the ability to gradually wear out during the operation of the car.

After the battery ceases to perform its direct function, many car enthusiasts hastily decide to replace it.

However, there are several effective ways to restore a car battery.

The battery performs one of the most important functions - ensuring continuous transmission of current to power automotive electrical equipment.

Without a battery that does not hold a charge, the normal and full functioning of devices of this type will become incorrect or simply impossible.

But not all batteries that for some reason do not hold an electric charge should be immediately replaced with new ones, because it is possible to “bring them back to life.”

Car battery device

The battery is a sealed container made of plastic. Plates with positive and negative charges are mounted inside. Until a few years ago, only lead was used to make such plates.

In modern models, lead is partially used; nickel, cadmium and many other alloys can be used. Also, sulfuric acid is poured inside the container, due to which a galvanic couple is formed.

When electric current is applied to the terminals, the energy storage process starts. When the maximum is reached, the battery automatically becomes a source of electric current, the power of which reaches 12 volts.

Causes of malfunctions

Every time you start the engine, the battery loses part of its energy, but only until the engine begins full operation. At this moment, the generator is switched on to replenish the supply of electricity. But this is provided that the car is working correctly.

Important! If the battery uses up its entire reserve in a short period of time or simply does not generate electricity, then this will necessarily affect the functioning of the car itself.

There are several main reasons why a car battery does not work correctly.

- The most common cause is plate sulfation. This is very easy to notice; the battery loses its charge very quickly. The fix is quite simple - you will need to restore the capacity.

- Non-working bank. Occurs if there is a short circuit between the plates. The result is an overheated can that begins to boil immediately after starting the engine.

- The carbon plates begin to crumble, and the electrolyte turns black and becomes quite cloudy. This is the only reason why battery restoration is not advisable.

If we analyze the above, we can note that there are two fundamental reasons for battery failure.

The first is a manufacturing defect, as a result of which the plates short out. The second is incorrect operation, leading to sulfation.

Battery recovery methods

An important task lies on the “shoulders” of a car battery - starting the car, as well as recharging the on-board system when the engine is turned off. If he cannot cope with this for some reason, then two options arise.

In the first case, you can simply replace the battery with a new one, which is what the manufacturer recommends in the warranty card. In the second, you can independently make attempts to correct the situation.

Low current

Recovery can occur on the principle of repeated charging using a low-power current. This procedure is carried out with intermediate breaks. The essence of the method is that in the interval between the first and last recharging, the battery will accumulate the necessary energy.

Breaks in recharging are necessary so that the potentials of the electrodes located on the plates can be evenly distributed. This method for electrodes is absolutely safe.

If you use a charging-recovery device with pauses, then the most dense electrolyte will move from the plates to the spaces between the electrodes.

If you restore the battery using the low current method, the density of the electrolyte will become evenly denser. The car owner should only wait until the current reaches 2.5 V and the density level reaches the minimum level. Full restoration of battery capacity requires about eight cyclic approaches.

Electrolyte

Many experienced drivers note that replacing the electrolyte is also a fairly effective way to restore the battery yourself. To do this, you will first need to rinse the battery, that is, drain all the liquid, then rinse the container with warm, or preferably hot, soda solution.

It's easy to prepare. Three tablespoons of soda should be added to a jar with 100 ml of water. But it is more advisable to use distillate. The resulting solution is poured into the battery and left there for half an hour.

Next, the liquid is completely drained, and the whole procedure is repeated two more times. After the last drain of the soda solution, the battery must be rinsed with plain hot water several times.

Accordingly, after such washing, a new electrolyte is poured in, and the battery is charged for at least a day. But the restoration is not over yet. For another ten days, the battery must be recharged daily for six hours.

Reverse charging

You can also make it yourself. To do this, you will need a current source whose voltage will be at least 20 volts and the current will be about 80 amperes. Such a source could be, for example, a welding machine. Before starting the procedure, you should unscrew all the plugs located on the top panel of the battery.

After this, the positive output of the charging equipment is connected to the terminal with a negative charge. And, accordingly, the negative output of the device must be connected to the positive terminal.

Important! In some cases, the battery begins to boil; this should not bother the car owner. The reverse charging process should last exactly half an hour. Upon completion, the electrolyte is completely drained, and the battery should be thoroughly rinsed with boiling water.

Finally, a new electrolyte is poured in, and the battery itself is charged to a regular charger for a day.

Distilled water

In this way, you can restore the battery in just an hour. If it is completely discharged, it should be recharged. Then the electrolyte is completely drained from the charged battery; to do this, the caps are unscrewed. Then a thorough washing is carried out using distillate.

The next step is to fill in a special solution of Trilon B of the ammonia type (2% Trilon, 5% ammonia). From this moment, the desulfation process begins, which should last about an hour.

During this period, characteristic smoke and even occasional splashes may be released from the battery. Do not be alarmed, such side effects are absolutely safe for the human respiratory system.

The cessation of smoke emission will indicate the completion of the procedure.

The next step is to repeatedly rinse the battery with distilled water, fill in new electrolyte and simply recharge the battery.

Of course, none of the methods guarantees that the battery will work uninterruptedly for several more years. Such restoration methods can extend the life of equipment by a day, a week or a month. No one knows the exact period; everything depends on a combination of external factors, for example, on how the battery was used, correctly or carelessly.

Source: http://ilovekiario.ru/autosovet/vosstanovlenie-akkumulyatora-avtomobilya.html

4 ways to restore a car battery

Low current restoration

The battery is responsible for the process of continuous supply of the required voltage. Accordingly, they are an indispensable component of the operation of certain mechanisms of the machine and its devices. Everyone knows that nothing lasts forever.

As a result, every car needs regular technical inspections in order to identify unusable parts. As a rule, any battery (the most common are acid-alkaline and lithium) can be repaired.

This option is better than immediately running to the store for a new one.

As for acid-base (they are also called lead-helium), their structure is presented as follows - a pair of “plus-minus” plates made of lead in sulfuric acid. They are the most common in the automotive industry and in the production of flashlights. However, such a battery does not last long.

The first way to restore batteries is to use repeated charging using a low current. In this case, the charging process must provide time intervals between recharges. Thus, starting from the first recharge and ending with the last, the voltage in the battery gradually increases and, as a result, it will stop accepting the charge itself.

Pauses are necessary so that the potentials of the electrodes located deep in the mass of the plates themselves and on their surface are leveled, which makes restoration safer. In parallel, the densest electrolyte begins to flow directly from the pores of the plates themselves into the space located between the electrodes.

Along with the cyclic charge and along with the increase in battery capacity, the density of the electrolyte itself also increases.

It is necessary to wait until the section voltage is equal to two and a half volts, and the density indicator reaches a normal level. Only then should the car battery “rest”.

This cycle should be repeated up to eight times. Also, the charge current itself must be exactly ten times less than the capacity of the battery being charged.

Electrolyte replacement

Direct battery restoration can also be done using the replacement method. To do this, you need to completely drain the electrolyte, and then thoroughly rinse the battery several times with hot water.

After this, you will need three teaspoons of ordinary soda, which must be diluted in one hundred milliliters of water. The resulting liquid must be boiled, poured in instead of the electrolyte, and after twenty minutes, drained.

This action must be repeated several times, followed by rinsing three times with the same hot water.

This method is great for car batteries. The last stage of this process ends with the infusion of new electrolyte and daily charging. After this, the battery is charged for six hours for ten days in a row. The charger must have the following characteristics - voltage no more than sixteen volts, but not less than fourteen, and current no more than ten amperes.

Reverse charging

Recovery using reverse charging is also possible. However, this method requires the presence of a fairly powerful source of voltage itself (the same welding machine). It must have a voltage of at least twenty volts with a current of at least eighty amperes.

Having obtained the necessary device, the next step is to open the caps of the cans and charge them back. To carry out such charging, you need to attach the “plus” of the charger to the “minus” of the battery, and to its “plus” - the “minus” of the charger.

And this can extend its life for several years and protect the car owner from unexpected financial expenses.

During the charging process, the battery will boil, but that’s okay. The charging itself should last no less and no more than half an hour, after which the old electrolyte is drained, the container is washed with hot water, and only then can a new electrolyte be poured in. The next step is to use another charger with a current of up to fifteen amperes. They charge the battery all day long.

Charge recovery in distilled water

Using the last, fourth method, the battery can be restored in less than one hour. If it is completely discharged, it should be pre-charged. After this, the electrolyte is also completely drained and washed several times with water.

Next, you need to pour a solution of ammonia-type Trilon B into the washed battery container, which contains two percent of the same Trilon and five percent of ammonia itself. With its help, the so-called desulfation process is carried out, which lasts up to one hour.

During this process, a characteristic gas release occurs and small splashes appear on the surface of the poured solution.

After all of the above, it is necessary to rinse the battery several times with plain distilled water, followed by pouring in an electrolyte of acceptable density. Then the battery is charged and it can be considered completely repaired. To summarize, we can say that, in general, restoring a car battery can be considered not a very difficult matter.

Video “How to restore the capacity of an old battery”

The recording shows a method for charging a lead-acid battery at home.

Source: http://MineAvto.ru/remont/elektrooborudovanie/vosstanovlenie-akkumulyatora-1057.html

How to restore a car battery

You should not immediately throw away the battery if the charge begins to disappear or the starter starts to turn over and over again. In many cases, the battery must be repaired. Knowing how to restore a car battery, you can extend its operation for several more seasons.

Battery defects

Battery malfunctions can be caused by both external and internal reasons. The first include:

- Damage (cracks) in the plastic case of the battery caused by external influences or processes in the battery itself (overheating, swelling, etc.). If the damage is significant, repairs are not practical and it is better to purchase a new battery. Minor damage can be repaired yourself using available tools and materials, after draining all the electrolyte. Upon completion of the repair work, fresh electrolyte should be added and the battery charged.

- Oxidation of contact terminals. Repair comes down to cleaning off the oxides with sandpaper and rags or a rag. It would be a good idea to clean the contacts on the connected cables as well. After cleaning is complete, the contacts and terminals can be treated with a small portion of machine oil.

The list of internal faults looks a little more impressive, and some of them do not allow the battery to be restored at all:

- If the battery is used incorrectly, for example, deeply discharged or systematically undercharging, the cells may be damaged. And if a discharged battery is left in the cold, the electrolyte freezes, which causes damage to the plates or case. Restoring the battery in such cases is impractical.

- Shedding of carbon plates is diagnosed when the electrolyte darkens. Restoring the battery in this case is also unrealistic and you should purchase a new one.

- Plate sulfation is the most common internal battery failure. At its initial stage, the battery can be restored and below it will be indicated how this is done.

- Closing the plates. A sign of this defect is overheating of one of the cans and boiling of the electrolyte in it. In some cases, replacing the lead plates is a salvation, but you need to be prepared to completely replace the battery.

Recovery methods

Sulfation

A manifestation of this defect is a white coating of coarse-crystalline lead sulfate on the plates. A layer of crystals covers the pores of the active substance, preventing the passage of electrolyte when charging the battery.

Due to this malfunction, the resistance inside the battery increases sharply with a simultaneous decrease in its capacity. As a result, the battery begins to charge rapidly. The electrolyte temperature and voltage also increase noticeably, which entails a sharp release of gases.

Once installed in a car, such a battery discharges extremely quickly.

Sulfation of battery plates

Sulfation can occur due to a battery discharge of less than 10.2 V, its prolonged storage in a discharge state, too low electrolyte level in the banks, its low density, or contamination with foreign impurities.

How to choose a battery

The battery can be restored only with slight sulfation. If the process has gone far, the battery will have to be changed. The recovery process consists of several charging and discharging cycles of the battery.

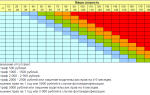

First, you need to fully charge the battery and bring the electrolyte density to 1.285 g/cm3. This can be done by pouring in a denser (1.4 g/cm3) electrolyte.

Attention! Do not add acid under any circumstances! This will only make the situation worse.

If there is a need to reduce the density, you will need to add distilled water.

After this, you need to note the time and discharge the battery with a current of about 0.5 A using an incandescent lamp. It is necessary to reduce the voltage in each bank to 1.7 V or to 10.2 V in the entire battery. Next, using the magnitude of the discharge current and the elapsed time, you should determine the actual capacity of the battery.

If its value is below the nominal value, then the charge-discharge procedure will have to be repeated. Practice shows that in most cases it is enough to carry out 3-4 charge-discharge cycles.

Having achieved the nominal capacity value, you can consider the battery restored, put it on charge and, upon completion, use it in normal mode.

Short circuit

This defect can occur when the separators are faulty or the plates are warped during the process of discharging with high-ampere current (prolonged use of the starter, or a spark test).

The active substance begins to penetrate through the cracks that appear on the plate. Sliding down, it fills the internal space and connects the different-pole plates.

The discharge current increases sharply, which leads to battery failure.

Damage to battery plate separators

Troubleshooting involves adding a special desulfating additive to the electrolyte. First, its density must be brought to 1.28 g/cm3. To ensure complete dissolution, the resulting mixture should be left for 48 hours, then poured into the battery and the density value measured again.

If its value has not changed noticeably, then you can begin the charging-discharging process, which should be repeated several times. If the battery does not heat up during charging and the electrolyte does not boil, then the current can be reduced by half. If after two hours the density value has not changed, then charging can be stopped.

If there is a noticeable change in the density value of more than 1.28 g/cm3, it is necessary to add water to the electrolyte, and if there is a deviation downward, sulfuric acid must be added. Having brought the density value to the nominal level, you can repeat the charging process.

There are also cases when dirt, grease and moisture create a conductive layer that will slowly kill your battery and discharge it to “zero” in winter. This phenomenon is quite rare and the mechanic may not know about it or simply miss it, which will ultimately lead to an erroneous recommendation to replace the battery. It’s easy to check the leak yourself using a multimeter, eliminating premature waste.

Leakage in the battery case

Reverse charging

The process involves changing the polarity of the battery. Before restoring a car battery using this method, you need to find a powerful voltage source of at least 20 V and a current of at least 80 A. A welding machine is quite suitable.

First, you should open the caps of the cans and connect the “plus” of the voltage source to the “minus” of the battery, and the “minus” of the source to its “plus”. Then you can begin the charging process within half an hour. The electrolyte will boil violently. When charging is complete, turn off the equipment, drain the electrolyte, rinse the battery with hot water and refill with fresh electrolyte.

After this, using a conventional 10–15 amp charger, you should charge the battery within 24 hours. Please remember that the polarity of the battery has already been reversed.

Once this process is completed, the battery can last for several years if properly maintained.

Maintenance-free batteries

Almost all new car models are equipped with so-called maintenance-free batteries, which, according to manufacturers' plans, should not distract attention. However, their operation and charging differs in some nuances.

First of all, you should remember that during the warm season such batteries are constantly recharged in the car. But charging them using a special device is more gentle and correct than constant recharge from a generator.

The situation changes significantly with the arrival of winter. In cold weather, the lubricant in the engine thickens and a higher starting current is required to start it. This may cause the battery to drain quickly. Therefore, charging a maintenance-free battery in winter is an urgent need.

This process must be carried out very carefully, since it is impossible to determine the density of the electrolyte in it. You can only rely on the value of the residual stress and draw conclusions from the current situation.

A partially charged battery should be charged continuously for about three hours by applying a voltage of 14–14.5 V, controlling only the current value - from 25 A at the very beginning of the process to 0.20 A when fully charged.

For a completely discharged battery, the charging cycle should last at least a day and be carried out with maximum attention.

The voltage regulator must be set to a value numerically equal to ten percent of the capacity of the battery being charged in ampere-hours. At the first signs of active gas formation, the process should be stopped.

Upon completion of charging, be sure to check the voltage value for compliance with the nominal value.

Terminal oxidation

To prevent most problems with a car battery, it is enough to periodically clean the contact terminals and terminals, and also fully charge it every six months using a stationary device. And regular care of the rotating and rubbing parts of the engine and starter will extend the battery life to at least 5 years.

Source: http://autoleek.ru/jelektrooborudovanie/akkumuljatornaja-batareja/kak-vosstanovit-avtomobilnyj-akkumulyator.html

How to restore a car battery

Restoring a car battery is the most popular type of battery repair, which involves several procedures that restore it to factory condition.

These procedures should only be carried out by experienced drivers or qualified personnel.

Failure of this device may occur in the following cases:

— when the plates are sulfated, the battery almost does not release its own capacity during operation; — breakage of the outer plates in the battery; — closure of the plates;

- maybe the battery is just dead.

So, how to restore the battery.

If you find out that the battery plates have shorted, then you should not rush to charge it immediately.

Equipment for the restoration procedure will require distilled water, an electrolyte of sufficiently high density, a hydrometer, a charger, but not an ordinary one, but one that allows charging with small currents, as well as a desulfating additive. And, of course, a syringe and an enema.

The most basic thing to do is to wash the battery with distilled water.

It is worth noting that if the water is constantly black and the coal chips are not even washed out, then there is no hope of restoring the battery.

If the crumbs are still washed out, and the water has become almost clear, then you can proceed to restoration work, in particular, desulfation of the battery plates.

To do this, you should find and carefully study the instructions for the desulfating additive to electrolytes.

Next, you need to pour electrolyte into the battery according to the instructions and do not touch it for two days. This is necessary in order to completely remove all the air from the battery, or rather from the plates.

After this time, you need to check the condition of the electrolyte and, if necessary, top it up to the required level. Now you can start charging the battery, while removing all the plugs.

Next, charge until the voltage at the terminals is about 13-14 V. And then reduce the voltage to 10.2 V using a 0.5 A light bulb. Then charge again to the required voltage.

This is done until the battery capacity is restored.

During such a discharge/charge cycle, you should adhere to several rules:

— the charging current should not be high. The electrolyte must not heat up, and if this suddenly happens, you must immediately reduce the charging current.

— after the voltage at the terminals reaches 13 - 14 V, the charging current must be reduced by approximately two times and wait two hours. If after this the voltage does not change, then charging can be completed. Then you need to determine the capacity of the battery, and if the results do not correspond to those written on the battery label, then the cycle should be repeated.

If the capacity satisfies the requirements, then the process of restoring the car battery is completed successfully.

In addition to this method, you can restore the battery using reverse currents or using pulsating currents, which perfectly remove lead sulfate from the plates.

To do this, you need to drain the old electrolyte and rinse it with distilled water. Then pour a 10% ammonia solution into it, then you need to drain the solution and rinse the battery again.

Then charge the battery using a pulsating current with a pulse of one percent charge; the charging current should be 10% of the full battery capacity (battery for passenger cars).

Restoring a vehicle battery can also be done in other ways.

The methods described above are perfect for standard situations that occur quite often, but in absolutely all cases a competent individual approach is required.

Consequently, the methods for solving this problem, depending on the specific case, will be completely different, and sometimes even completely new. Here everything depends only on your skill or the skill of the technician who will restore the vehicle’s battery.

But in any case, I would like to add that it is necessary to monitor your own battery, this is especially important in the winter season. It is necessary to carry out maintenance on time, add distilled water if necessary, and also increase the density of the electrolyte in winter. You shouldn’t leave it in the cold for a long time, much less with the terminals on.

If you follow these simple recommendations, then during the entire life of the battery you will not have to remember about its restoration.

Source: http://autovogdenie.ru/kak-vosstanovit-akkumulyator-avtomobilya.html

How to restore a car battery

Home » Repair and service » How to restore a car battery

Hi all! Many car enthusiasts are familiar with the situation when their battery hopelessly loses capacity. But there is no need to rush to the store for a new one. After all, the old battery can still be returned to service. You just need to know how to restore your car battery. This is what we will talk about.

Content

Why does the battery break?

Before we figure out how to restore a car battery, let's determine the reasons why it fails.

Causes of capacity loss:

- plate sulfation is the most common malfunction. It is easy to diagnose - the battery quickly loses charge. It is usually possible to do capacity restoration;

- one of the cans does not work - most often it occurs as a result of a short circuit between the contact plates. In this case, the closed jar begins to overheat and boil when used on the machine. And the battery’s capacity drains a lot – it’s often not enough to start the car;

- shedding of carbon plates - the electrolyte becomes cloudy or black. In this case, the battery is usually not recoverable;

- electrolyte freezing – if you use a battery with a low density in severe frosts, the electrolyte will freeze. As a result, the body may crack and the plates may become deformed. In this case, you will definitely have to buy a new battery - the battery cannot be restored.

To put it simply, there are two reasons for premature battery failure. Or a manufacturer’s defect, for example, poor-quality coating of the plates, can lead to short circuits in the banks. And the second reason is improper operation. Most often, the result is sulfation of the plates.

Since this is the most common malfunction, let's take a closer look at it. It is worth noting that the recommendations for battery restoration given in the article apply to acid batteries. The alkaline type is repaired differently.

What is plate sulfation

As you know, the operating principle of a lead-acid car battery is based on the use of liquid electrolyte. And its main characteristic is density, which should be in the range of 1.25 g/cm3 - 1.27 g/cm3 for a charged battery.

During the charging process, active substances accumulate on the lead plates, and the density of the electrolyte increases, because distilled water is absorbed. And when the battery is discharged, its density drops, distillate is released, and sulfuric acid is absorbed.

Also, in the process of energy absorption, crystals - lead sulfates - begin to appear on the plates. Under normal operating conditions, i.e. when the battery operates cyclically, this phenomenon does not harm it. The next time you charge, the sulfates are simply washed away.

But there is an unpleasant dependence in the operation of the battery:

- small discharge – small crystals are formed that easily dissolve;

- deep discharge - large sulfates appear that do not dissolve in the electrolyte.

Thus, if the battery is used incorrectly, the surface of the plates decreases due to sulfation, and its capacity decreases.

Battery desulfation

Restoring car batteries with decreased capacity as a result of plate sulfation is done using the following methods:

- physical cleaning of plates;

- chemical cleaning;

- desulfation using a charger.

Let's look at these methods in more detail.

Physical cleaning

This is a rather extreme method. Restoring a battery involves removing the packages of contact plates and manually cleaning them.

How to revive the battery:

- Windows are cut out in the top lid - it is best to do this with a thin soldering iron or a hot knife - plastic debris will not fly into the jars. Although, you can also use a jigsaw;

- the plates are removed through the holes and cleaned;

- after this, they must be thoroughly rinsed with distilled water;

- the insides of the cans are also washed with distillate;

- the contacts are placed back, the windows are sealed;

- Electrolyte is filled into the battery to the level;

- The battery is being charged.

On the one hand, everything is simple. On the other hand, there is one big but - lead plates are very fragile, especially after prolonged use. Therefore, there is a high probability that they will be destroyed during the cleaning process. You can repair your battery using this method only if it is completely hopeless.

Chemical method

To do this, you will need a special chemical solution of Trilon B. Resuscitating the battery using this method does not take much time - desulfation takes place in 1-2 hours. The only difficulty is in preparing the solution itself.

What you need to do to restore capacity:

- The battery is fully charged;

- the electrolyte is completely drained from it;

- the jars are washed well with distilled water;

- The Trilon B solution is poured into the battery and left for about an hour. The process of dissolution of sulfates will be accompanied by gas evolution and boiling. When the reaction is over, the operation can be repeated;

- the battery must be rinsed again with distilled water, after which fresh electrolyte of the required density is poured into the jars;

- The battery is being charged.

This method of recovery is quite effective after deep discharge. But there are also disadvantages to it - during manipulations with the battery, pieces of lead can get between the plates - as a result, the banks can short out.

Battery desulfation using a charger

The most common method of repairing batteries at home is to use chargers. The process is simple but long-term.

Repairs can be done in several ways, but their essence boils down to alternating a full charge with a discharge. Those. sulfates dissolve naturally. Let's look at how to restore an old battery using a charger.

By the way, first of all, you need to check the electrolyte level. If it is below normal, be sure to add distilled water. You cannot pour electrolyte - during the desulfation process, its density will rise and it will corrode the plates.

Pulse charge

To do this, you will need a battery charger that can operate in pulse mode and is equipped with a desulfation function. It connects to the battery and that's it. The device does the desulfation itself. The operating principle is quite simple:

- the battery is charged at low current for 10 minutes;

- it is then loaded and discharged for one minute.

The time interval may be different, but the essence does not change. This option can be used in slightly advanced cases. Another disadvantage is the price of the device. It can be higher than the cost of the battery and varies between 5-10 thousand rubles.

Restoration with a regular charger

The simplest and most accessible method. Moreover, most motorists have a regular charger. Let's figure out how to restore the battery using this method.

Sequencing:

- The battery needs to be charged at a low current. We set the charger to 14 V and 0.8-1 A. The battery needs to be charged for 8-10 hours. If it starts to boil, you need to reduce the current;

- the result of such recharging will be a slight increase in voltage in the battery;

- The battery is removed from the charge and left for 24 hours;

- after this you need to slightly increase the current - up to 2-2.5 A and leave the battery to charge for 7-8 hours;

- as a result, the density should rise slightly and the voltage should increase;

- the battery discharges to 9 V. To do this, you need to connect the car high beam lamp to the terminals and wait until it sits down;

- the cycle is repeated until a voltage of 12V and normal density are obtained.

The method, of course, is not fast, but quite effective and allows you to revive rather neglected batteries.

If the battery is shorted

This breakdown is very detrimental to the entire battery, because... a non-performing bank affects the working ones. The fact is, while charging the battery, the voltage is evenly distributed between all plate packs. And when one bank does not work, too high a current is supplied to the others. As a result, the acid battery begins to boil, which causes sulfation of the plates.

Let's figure out how to restore a car battery with a non-working bank. In fact, it's not all that scary:

- you need to find out which jar is not working. When charged, it can boil, or vice versa - others will boil, but the closed one will be dead;

- all the electrolyte is poured out of the jar;

- a hole is cut in the top cover;

- lead plates are removed from the jar and washed well in distilled water;

- Now you need to find the cause of the short circuit - for this, the plates are carefully inspected. By the way, if the battery is old, the cause of the short circuit may be in the sediment at the bottom of the can. Therefore, if it is there, it needs to be washed;

- After washing and inspection, the bag is put back into the jar and the lid is sealed.

If you do everything carefully, there is a high probability that the battery can be repaired. It is important to remember that you cannot flop it too much and turn it upside down - other plates can also short-circuit.

If the battery is maintenance free

Restoring a maintenance-free battery is much more difficult - it does not have access to banks. Those. There is no way to check the density of the electrolyte. On some forums, when asked whether it is possible to get to the insides of the battery, they advise drilling the top cover.

It’s better not to do this - in such batteries, a gas exhaust system is installed in the top cover. If it is violated, the battery will definitely not be repaired. Therefore, let's look at how to properly restore such batteries:

- First, you need to determine the electrolyte level in the jars. This can be done by shining a bright flashlight through them;

- if it is below normal, a small hole is made in the upper part of the battery (above the electrolyte level) - 2-3mm in diameter;

- distilled water is poured through it with a syringe;

- the holes are sealed.

Also, cyclic charging and discharging helps to restore capacity.

Gel battery

Restoring gel batteries is somewhat simpler - you don't need to drill anything. This type of battery cannot be restored in two cases:

- destruction of plates. Usually occurs when the battery is used for a long time at high temperatures;

- swelling of the battery.

Unlike acid batteries, gel batteries most often fail completely.

What to do for resuscitation:

- the top cover is removed;

- there are rubber caps under the lid - they also need to be removed;

- It is advisable to take a flashlight and shine it inside each can. If the surface of the plates is light and of normal shape, go to the next step. And if there is black dust inside, you can throw away the battery - you won’t be able to bring it back to life;

- Two cubes of distilled water are added inside each jar and the battery is sealed. It is important to ensure that the top cover fits tightly.

Then the battery is charged, and if necessary, the procedure is repeated.

If it has lost a lot of capacity, it can be revived by driving it through cyclic charges and discharges. This procedure is described above, the main thing is not to discharge the battery below 10.5 V.

Thus, it is quite possible to restore the battery with your own hands. Of course, this will take time, and in some cases the result may not be very good. But, nevertheless, it’s worth a try. And you will always have time to buy a new battery. In addition, dry-charged batteries are also restored using the same methods.

That's all, I hope the material was useful and you can restore your battery. Don't forget to leave your comments.

Best regards, Maxim Markov!

carsmotion.ru

How to restore a car battery and does it generally make sense to restore the battery?

The car battery has the important task of starting the entire device. It is also necessary to recharge the vehicle’s on-board network if the engine is inactive.

The rechargeable battery may lose its performance due to problems with the vehicle's electrical system or when starting the engine.

There are two ways to solve the problem: purchase a new device or restore what you already have.

Source: http://autofluids.ru/remont-i-servis/kak-vosstanovit-akkumulyator-avtomobilya.html

Working methods for restoring a car battery after a deep discharge

The situation when the battery, in the language of car owners, “died”, arises quite often. One, leaving the car overnight, forgets to turn off the heated seats; the other, when putting it into winter storage, does not remove the terminals and does not service the battery. The result is intense self-discharge. What to do?

If you read all the recommendations posted on thematic forums, it becomes clear that no one “shines” with special originality.

Here are the most common “tips”:

- Scrap it and don't worry about it. You can get 400 - 450 rubles.

- Don’t waste a hundred and a half to a couple of hundred and give it to the service. Maybe they will resuscitate it.

But the question arises: is it possible to restore the battery yourself? Is there really nothing that can be done? Can. Even if you don’t get the expected result, it’s still worth a try. Otherwise, the expression “zealous owner” is not about you (sorry), dear reader.

How to proceed

Try to charge the battery. But not from a generator, as many are trying to do. By the way, there is an opinion that it is enough to “drive” around the city, and everything will return to normal.

No! Given the intersections, traffic lights and potholes on our roads, the battery can never be charged as required. Even driving on a country road will not give the expected result. After all, the engine must operate at fairly high speeds.

Ideally, you will have to drive for several hours on a completely empty and straight highway. Is this real, even at night?

The battery should be restored to its functionality only from the charger, but not in the usual way. After all, as a rule, the current is set depending on the battery capacity. This is exactly what car owners focus on when calculating its strength (about 10% of the nominal value). In this case, this should not be done. Charging is carried out with a low current, no more than 3 A.

The battery is left connected overnight. In the morning you should check the density of the electrolyte. Even if it has increased slightly, this is a good sign. Perhaps all is not lost. If you continue to charge, the desired density level may be restored.

On a note!

You shouldn't expect quick results. It sometimes takes several days to fully restore a maximally discharged battery.

Another option is to add some fresh electrolyte. As soon as the battery stops “taking” a charge, you need to check the density. If it is normal, then you can still drive on this battery.

What to do if there is no result? Most often, after a complete discharge, irreversible processes occur associated with mechanical destruction of the elements. For example, “shedding” of plates. There's nothing you can do about it. Unlike older batteries, in modern products the bank cannot be changed. This means it’s a waste, there is no other solution.

There is another way - charging in water (distilled). But there is no point in dwelling on it, since in practice only a professional can perform all operations. By the way, it is often practiced in specialized workshops. But there is everything necessary for the implementation of this engineering solution + practical experience of workers.

Source: http://ElectroAdvice.ru/battery/kak-vosstanovit-akkumulyator-avtomobilya/