An interesting article about shock absorbers: which ones are better, gas or oil? — DRIVE2

A shock absorber is an essential suspension component of any car. Without this unit, controlled driving is essentially impossible. The main function of shock absorbers is to reduce the vibrations of springs that occur during movement, which makes the movement of the car smooth and comfortable.

Gas or oil shock absorbers - which is better?

Shock absorbers that are in working order ensure vehicle controllability and safety.

All shock absorbers can be divided into two large groups: hydraulic (oil) shock absorbers and gas-filled (gas) shock absorbers. The debate over their effectiveness and reliability, their features, advantages and disadvantages has continued for decades. Let's try to figure out which shock absorbers are better: gas or oil?

Oil shock absorbers

They dampen vehicle vibrations due, on the one hand, to the low compressibility of the oil, and on the other, to the flow of oil from one chamber to another. In this case, the vibrations are damped. But, as we know, energy cannot disappear without a trace. And the vibration energy is transformed into heat energy (the oil heats up).

Oil shock absorbers have certain disadvantages. Namely:

• There is a certain amount of air in the compensation chamber of the hydraulic shock absorber. If there is less air, the oil will flow into the compensation chamber without effort. As a result, the ability of the shock absorber to dampen vibrations decreases sharply and may even be reduced to zero.

• There may be air bubbles in the oil. Air, as you know, has a lower density than oil, so it is easier to compress. In this regard, when the shock absorber is compressed, it is not the flow of oil that occurs, but the compression of air. As a result, the whole point of hydraulic shock absorption is lost.

• During the operation of the shock absorber, the oil heats up, and it begins to lose its original characteristics and becomes more fluid. Oil begins to flow faster from one chamber to another, thereby losing the vibration damping effect.

• In cold weather, the oil in the shock absorber becomes viscous, and the process of its flow from one chamber to another slows down until the oil warms up and acquires its normal viscosity. Until the oil warms up, the suspension can work quite harshly, which not everyone likes.

• When driving on roads where the shock absorber piston moves frequently, the oil may become airborne. This can ultimately lead to reduced shock absorption by compressing air bubbles within the oil.

Gas shock absorbers

In these shock absorbers, the compensation chamber is filled with gas, which is pumped there under high pressure. To understand which shock absorbers are better - oil or gas, you should find out the features of gas devices.

Features of gas-filled shock absorbers:

These shock absorbers are stiffer, which allows for better vehicle control at high speed. The rigidity of gas shock absorbers reduces the risk of aquaplaning.

Gas-filled shock absorbers are completely indifferent to temperature drops. This does not change their shock-absorbing properties. During driving, there is no change in performance depending on the temperature increase.

Compared to oil shock absorbers, gas shock absorbers have a longer service life.

Gas shock absorbers also have certain disadvantages:

• On average, gas-filled shock absorber models are 20-30% more expensive than their oil counterparts.

• On roads with a lot of unevenness, due to the rigidity of gas shock absorbers, other elements of the car's suspension wear out more quickly.

• Rigidity makes the ride less comfortable.

Certain conclusions

Considering the above, we can conclude which option is better - gas or oil shock absorbers.

Hard gas shock absorbers are not suitable for all drivers, but only for those who practice a high-speed driving style, more like a sports one.

But it must be taken into account that they can only be rationally used on roads with good surfaces.

Replacing oil shock absorbers with gas counterparts often involves replacing certain suspension elements that are specifically suited to a sporty driving style.

If the roads you are going to drive on are in bad condition, then it is better to use oil shock absorbers.

If the car is old enough, then its frame has already lost its original rigidity. Therefore, oil shock absorbers are also appropriate here.

Source: https://www.drive2.com/b/3105579/

Which shock absorbers are better: features of choice and rating of manufacturers

A very popular question among car enthusiasts is which shock absorbers are better: gas or oil, or gas-oil? Moreover, it is of interest not only to lovers of comfortable driving, but also to those who consider themselves to be “racers.” In fact, shock absorbers provide many important parameters of a car, and above all, handling and directional stability.

Why are shock absorbers needed in a car, how are they structured and work, what types of shock absorbers are there and what are their advantages and disadvantages - the answers to these questions will help you make the right choice among the large number of manufacturers of these products represented on the Russian market.

We also recommend studying the algorithm for checking shock absorbers for performance.

Why does a car need shock absorbers?

A shock absorber is an integral part of what provides comfort in the body of a car (sprung mass in technical terminology). The opposite of this term can be clearly illustrated by an old village cart on wooden wheels with a metal rim. It’s easy to imagine how passengers in such a carriage shake when driving on an uneven dirt road.

Smoothing out this shaking from bumps and ruts (or in technical language, damping vibrations in the vertical plane arising from road obstacles) is the main function of shock absorbers. Schematically, a shock absorber can be represented as a spring located between the wheels of a car (a tire, by the way, is also a kind of spring in this diagram) and the body.

In general, to assess the response to the vertical influences of the road, a car can be imagined as a mechanical system consisting of many weights, springs and friction units, interconnected in a complex way and ensuring the required smoothness. And shock absorbers play an important role in this scheme.

Operating principle and main types of shock absorbers (oil, gas, gas-oil)

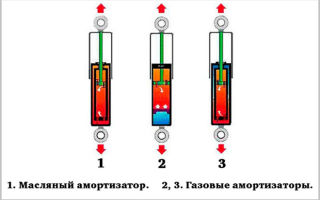

The principle of operation of a shock absorber can be illustrated with a simple example (see pictures above):

- The lower part of the spring-loaded shock absorber strut is connected to the wheel through the shock absorber rod, and the upper part is connected to the car body.

- The impact of the unevenness is transmitted through the wheel to the rod, which moves the piston inside the cylinder.

- The piston has two bypass valves (simply - holes of different diameters) that allow practically incompressible oil to pass through at a higher speed when the rod (and therefore the wheel) moves up, and at a lower speed down.

Thus, the hydraulic part of the shock absorber works as a conditionally soft spring for compression, and a hard one for tension (“rebound” in technical terminology).

The mechanical spring in the figure is shown more for clarity, but in practice it expands the possibilities of settings and serves as a kind of limiter when the shock absorber hydraulic cylinder fails.

The definition of “oil shock absorber” implies that only hydraulic oil is used as the working material in the cylinder. The dynamics of the oil shock absorber are entirely determined by the operation (performance) of the bypass valves.

To expand the dynamic range and adjustability of oil shock absorbers, a kind of gas “cushion” was invented. The fact is that gases, unlike liquids, are compressed, and nonlinearly (not proportional to the movement of the rod). This means that, being “attached” to the “oil” part of the cylinder, they will make the dynamics of such a system richer.

The figure below shows a simplified design of a monotube gas shock absorber.

It is clear that without the lower (gas) part it becomes oily (only the excess that is squeezed out needs to be put somewhere, but more on that below).

And since shock absorbers filled exclusively with gas are not yet found on production cars, it is more correct to call such a design a “gas-oil shock absorber.”

For oil and gas-oil shock absorbers, the working cylinder of the device is usually two-pipe:

- In oil shock absorbers, excess oil is released into the second (larger diameter) pipe through additional valves during compression, which is “pressed” by air in the second pipe.

- In gas-oil shock absorbers, instead of air, a gas cushion (usually nitrogen under pressure) is pumped into the second pipe.

Sometimes the gas cushion in gas-oil shock absorbers is structurally located on the side of the cylinder.

In addition to the narrower range of elasticity characteristics, the air cushion in the oil shock absorber does not effectively dissipate the thermal energy generated during intensive operation, which sometimes leads to boiling of the working fluid. In a gas-oil shock absorber this effect is eliminated.

Like any hydraulic equipment, shock absorber cylinders require high-precision machining, a complex system of valves and seals, and for gas-oil shock absorbers this system only becomes more complicated.

Since the gas-filled part of the shock absorber significantly expands the dynamic range of the system, in general the device provides a softer response to road irregularities than in the “oil” version - it’s like a series connection of two springs: soft and hard, which in total gives a softer response than just a hard one spring.

Interestingly, manufacturers do exactly the opposite and tune gas shock absorbers more for aggressive driving styles and sports cars. More precisely, on roads with good coverage, gas shock absorbers are tuned to a softer reaction from vertical influences, and on bad roads with the same settings they become harsher.

It must be emphasized that in sports driving, smoothness is not in the first place: much more important are such parameters as controllability and directional stability, which gas shock absorbers provide better than oil shock absorbers.

Which brand of shock absorbers is better?

The Russian market of shock absorbers for foreign cars, with a share of the main players of 10 percent or more, according to the magazine “Autoinstruction”, is represented by several well-known companies (diagram in the figure above):

- KYB (Kayaba) – 35%;

- Boge (God) – 16%;

- Fenox (Fenox) – 15%;

- Monroe (Monroe) – 14%;

- Bilstein (Bilstein) – 11%;

- Other companies – 9%.

It is interesting that when a survey of service centers was conducted by the publication “Kuzov” regarding the recommendations of professionals on choosing a manufacturer of high-quality shock absorbers, the picture turned out to be somewhat different.

With the undisputed leadership of such firms as KYB, Bilstein and Boge, professionals only recommend Monroe in 5% of cases, although the market share of this company is almost three times higher. And they practically do not recommend the Belarusian brand Fenox, the share of whose products is very significant - 15%.

To figure out which shock absorbers are best to install, it is necessary to briefly look at the characteristics of the leading players in the Russian market.

- KYB (Kayaba) - the products of the Japanese concern are popular not only in Russia, but also in Europe due to their high quality and reliability at a relatively low price level. Shock absorbers from this company can be found on the assembly lines of famous European automakers. The gas-oil shock absorber of the Ultra SR series is especially popular among Russian fans of sports driving;

- Bilstein is a world-famous German company that has been producing shock absorbers for over 50 years. It was here that the design of a monotube gas-filled shock absorber was developed. Bilstein products are installed on European premium brands: BMW, Porsche, Mercedes, Ferrari, Maseratti, Jaguar;

- Boge (Boge) - the brand belongs to the concern ZF Friedrichshafen AG (Germany) - one of the oldest manufacturers of shock absorbers in the world. Recently he moved to another well-known brand - SACHS and now the same type of products is produced under two brands. The concern's products cover more than 90% of the range of global automakers. On the Russian market, a 1-year warranty is provided regardless of mileage;

- Monroe is an American company whose products are probably best known in Europe and are intended for 99% of the brands and models of cars produced in the world. Monroe's latest developments - gas shock absorbers of the Sensatrac series provide high controllability and instant response to changing driving conditions;

- Koni (Koni) - shock absorbers - are the only type of product of the Dutch company for almost 70 years. The main distinctive feature of Koni shock absorbers is the ability to adjust the stiffness parameters, adapting the car both to external conditions and to the individual characteristics of the driver and the manner of driving the car.

But are all major shock absorber manufacturers widely represented on the Russian market? The figure below shows the top six players in this market in the United States according to a Ranker survey.

The first three consist of participants in the Russian rating. But the products of the American Fox Racing and the Swedish Ohlins are specific - they are intended for motorcycles, ATVs and SUVs.

The American Rancho Suspension is quite well known in Russia and specializes in supplying products for pickup trucks and large SUVs that are popular in the USA.

A few years ago, Rancho was acquired by the Tenneco concern, which in turn owns the Monroe trademark.

Thus, the top three manufacturers of shock absorbers with a high reputation for Russia are KYB , Monroe and Bilstein .

As for the objective characteristics provided by shock absorbers and affecting the safety, controllability and comfort of the car, according to the manufacturers themselves, they look like this.

Braking distance at a speed of 40 km/h:

- Bilstein - 8.0 meters;

- Monroe - 8.5 meters;

- KYB – 9.0 meters.

The differences are quite significant if you remember that in a critical situation, centimeters of braking distance are important.

Rear axle shift 90° (sharp turn mode):

- Bilstein – 59 km/h;

- Monroe – 52 km/h;

- KYB – 48 km/h.

Tests for smoothness (characteristics closely related to the subjective feeling of comfort) and directional stability are carried out in relation to each specific car model, therefore it is possible to compare shock absorbers from different manufacturers only for specific cars.

It is interesting that such tests sometimes give paradoxical results: venerable firms can lose to outsiders, both in individual indicators and in aggregate test results.

Which shock absorbers to choose for a car?

And yet, which shock absorbers to choose? Considering the variety of designs, a wide range of loads and significant differences in the characteristics of different car models, as well as individual characteristics of driving style, one cannot expect monosyllabic answers to this question.

It is necessary to rely, first of all, on the recommendations of the car manufacturer, both in terms of characteristics and in terms of shock absorber manufacturers.

If the owner wants to change the dynamics of the car using shock absorbers (or it is not possible to accurately follow the manufacturer’s recommendations), general considerations on how to choose shock absorbers for a car can be formulated as follows:

Selection by type (oil, gas, gas-oil):

- For those who prefer comfort, a quiet ride, reliability and affordable prices, double-tube oil shock absorbers are suitable;

- If it is desired that comfort requirements be combined with improved cornering dynamics, and the cost and reliability of the part are within a reasonable range, then the right choice is twin-tube gas-oil shock absorbers;

- Monotube gas shock absorbers are designed for lovers of aggressive driving styles who prefer the handling of the car over a smooth ride.

By the way, the age of the car is also an important factor when making a decision. It is hardly advisable to install expensive gas shock absorbers on older cars with high mileage: the elastic characteristics of the suspension and body strength indicators deteriorate over time, and instead of the expected effect, you can get the opposite effect.

Selection by manufacturer (which brand of shock absorbers is better):

- If the car belongs to the budget segment, and there is no need to test it in sports modes, and funds for maintenance are limited, shock absorbers from the Russian company SAAZ or the Belarusian Fenox may well be suitable;

- Those who value quality and are willing to pay for it (even if the car is not an expensive foreign car) should pay attention to the products of KYB, Monroe and Boge (Sachs);

- Experts recommend the products of Bilstein and KONI (aristocrats in the world of shock absorbers) to both fans of sports driving and owners of premium-segment cars.

And, of course, you need to beware of fakes: if in a store the price for Bilstein products is the same as for the Belarusian Fenox, then something is wrong with such a seller (and not in relation to Fenox). And the recipe for verification is the presence of a certificate of conformity, a warranty card and compliance of the unique serial number with the data on the manufacturer’s official website.

Differences between gas, gas-oil and oil shock absorbers, their pros and cons

Source: https://unit-car.com/poleznie-soveti/216-kakie-amortizatory-luchshe.html

Choosing the best shock absorbers: gas or oil

This mechanism is designed to dampen vibrations of various kinds that occur while the car is moving.

These are very important suspension parts, thanks to them the driver and his passengers can move comfortably in a vehicle without feeling the unevenness that the wheels and struts take on.

Depending on what is used as the working medium, the racks can be gas, hydraulic (oil) or gas-oil.

Differences

A significant difference between these two types is the type of material (substance, liquid) that is used to operate them. If oil is used to operate it, then the shock absorber is called oil-based. If gas is used - gas.

But it is naive to believe that a gas shock absorber uses only gas; no, both gas and oil are used for its operation. This type has a name - gas-oil, although everyone is used to calling it differently.

Oil mechanisms are more rigid due to the fact that oil is used for them. But oil is a liquid that practically does not burn. Very often, the force and stroke depend only on how the medium flows through the valves in the rack cylinder.

As mentioned above, the work of this stance is much tougher, and its inertia of movement is much less than that of its opponent.

Another thing is gas struts. Due to the fact that two types of materials are used for their operation - gas and oil, they are softer.

Gas, even if it is under pressure, is very well compressed, so this mechanism will be quite soft and its inertia relative to the movement of the rod will be higher. Another advantage will be its ability to change its properties depending on the road surface.

This is possible due to the presence of a special camera. Therefore, due to its wide range of operation, gas-oil can be considered universal and more practical than oil.

But it is not always the case. In real life, oil ones can be much softer than gas ones. It all depends on their manufacturer, and on how the valves for supplying the substance to the working environment will be configured, what volumes of the chambers, as well as on other design features.

Advantages and disadvantages

When choosing a shock absorber for your car, it is very difficult to decide which one to buy without knowing their positive and negative sides.

Oil shock absorbers:

- They allow you to dampen vehicle vibrations due to the low compressibility of the oil, as well as by moving the oil from one chamber to another. In this way, high vibrations are damped. But at the same time, the oil heats up.

- There is air in the hydraulic chamber. In the event that the air level is lower, oil will begin to flow into this chamber without any effort. As a result, it may reduce its ability to dampen vibrations, and this ability may be reduced to zero.

- A situation may arise when air bubbles appear in the oil. As a result, it may lose the meaning of its work, since instead of oil flowing, air is compressed.

- During operation, the oil heats up. When heated to high temperatures, the liquid may lose its abilities. As a result, the oil begins to flow faster through the working area of the shock absorber, thereby losing its ability to dampen vibrations.

- During the cold period, the oil may slightly change its consistency - it becomes more viscous. To return it to its previous state, you need to warm up the car a little. And this is a loss of fuel.

Gas shock absorbers:

- Due to rigidity, vehicle control becomes easier, especially at high speeds. In addition, this characteristic (rigidity) allows them to exclude the possibility of the emergence of such a thing as “aquaplaning”.

- Such shock absorbers are not afraid of temperature changes (both negative and positive). Gas is resistant to such changes, so the mechanism works normally. Their service life is much longer than for opponents.

As for the disadvantages, they are also present:

- Their cost exceeds oil ones by about thirty percent.

- Due to their rigidity, when the car moves on uneven road surfaces, rapid wear of other elements of the car’s suspension occurs. The ride also becomes less comfortable.

How to make a choice?

It would not be correct to single out one type or the other, since they are both used in the modern automotive industry, and the demand for them is the same.

Therefore, it is better to choose gas or oil shock absorbers based on the recommendations specified in the manual for your car.

But I advise you to adhere to one rule: softer racks should be used exclusively for roads with uneven surfaces (for our roads), and harder ones - for normal smooth roads.

Video “Choosing shock absorbers for your car”

In the video, an auto expert talks about the features of different types of car shock absorbers, how to check shock absorbers before purchasing and how to install them on your car.

Source: http://MineAvto.ru/remont/hodovaya/vybiraem-amortizatory-gazovye-ili-maslyanye-2399.html

Which shock absorbers are better (more reliable): gas, oil or gas-oil

So we got to one of the most important elements of the suspension, namely the shock absorbers.

Each owner of (especially not new) cars faces the following dilemma - what shock-absorbing options to buy and install on his iron horse - gas, oil, or gas-oil? Why are some better than others and vice versa? Which “takes” can you take to walk for a long time, hold the car “clearly”, not rock it too much, but also create the necessary comfort? As you can see, there are a lot of questions, in this article I will try to put everything “into order,” as they say, to fully understand the problem, and then you decide what is best and most reliable for you. There will definitely be a video at the end, so read and watch...

Let's remember, what are these car elements needed for?

A shock absorber (in relation to a car) is a suspension element that is designed to combat vertical oscillatory movements created by springs.

They do not allow the car body to sway too much, which improves speed characteristics, as well as traffic safety, because strong vibrations can contribute to the car tipping over on its side or even turning over (for example, on sharp turns) - if you want, they restrain the body.

Also, shock absorbers give comfort or sportiness to your suspension, it all depends on what you expect.

https://www.youtube.com/watch?v=nk-F6WAqdys

Now there are erroneous opinions that it is shock-absorbing elements that hold the body, BUT THIS IS NOT TRUE. It is the springs that hold it up, but the shock absorbers simply dampen vertical vibrations and ONLY support it a little (gas version).

How does it work (principle)?

Let's go over the operating principle very briefly. First, you need to take into account that each shock absorber is installed on each support point (in our case, on the wheel), that is, there are only 4 of them in modern cars. There are rarely two per wheel, but this is mainly for heavy or racing cars.

The principle of operation is elementary - the shock absorber body is a cylinder, sealed on one side with oil poured into it (the classic version, about the others below), this is the lower part. In this oil and cylinder there is a rod with a piston at the end.

The piston has check valves with different flow capacities. This rod is the top part. The top of the cylinder is sealed, usually closed with special gaskets and metal “plugs” in which the rod moves.

Thus, the oil cannot escape from the inside; it is simply “locked” there.

Piston check valves have different capacities; in one direction the “capacity” is greater (this is compression for us) in the other it is less (extension). Therefore, the shock absorber rod sags relatively quickly, but rises slowly, thereby dampening the vibrations.

To be fair, it is worth noting that now the “cylinder” is not necessarily filled only with oil; there are models with partial gas filling, but more on that below.

Types of shock absorbers

For this period of time, there are only two types, the so-called “gas” and “oil”, but many people also insist on another type, “gas-oil”. But this is just a subtype of gas shock absorbers and nothing more. This is important to remember.

Now you can rightly ask the question - “why aren’t there fully gas shock absorbers that only have gas inside and nothing else”? It’s simple - any element must be lubricated, and quite well, if you get rid of oil completely, then the service life will decrease significantly, both oil seals and working rods, they will simply be quickly erased. Because gas cannot store “lubricating” elements (or compounds).

Well, now we have come to each of the subtypes, I propose to start with the oil, as it is also called the “classic” shock absorber.

Oil shock absorber

What can I tell you about him, everything that I described above fits him 100%. That is, there is a cylinder, there is oil in it, a piston with a rod, and there are several check valves on the piston. It is only worth noting that it contains only oil and nothing else, that is, there is no gas or anything else.

The device is very durable, but not as productive. The thing is that if you frequently drive on poor roads, the oil inside can boil, that is, a cavitation effect will appear, bubbles will begin to form (if you want, it will almost boil). Cavities form inside; they very quickly pass through the piston valves, thereby impairing its operation. That is, the car will hold worse.

Due to frequent overheating, the viscosity of the oil also suffers, the liquid loses its properties and again passes through the piston valves faster.

Another feature of the oil version only works in one direction, that is, only for compression. For example, the car compressed it, but the rod does not come back out, that is, the car (through the spring) needs to be pulled back out.

It is worth noting that these options are quite comfortable and soft, if you want, energy-intensive, they often swallow holes and bumps perfectly.

BUT they don’t like heavy overloads and frequent rolls, the rod doesn’t come out on its own, it needs to be pulled, but what if the car is turning? That’s why for the city, for low speeds, they are really ideal (they provide simply excellent comfort), but for racing, or sudden acceleration and braking, they are not designed, if only because of roll.

Thus, it is possible to identify such positive and negative aspects

pros:

- Widespread on the market, 50% of cars are equipped with these options

- Simple design

- Quite cheap

- Durable enough, can go from 60,000 km and above

- The ride is most comfortable with it. Swallows bumps perfectly

Minuses:

- It is more prone to rolls, the rod does not go back on its own, it needs to be pulled out with the help of a spring, if at low speeds this is practically not noticeable, then during sharp braking or starting, either the front or the rear sags.

- Overheats quite quickly, especially in summer and if you often drive on uneven roads

- When heated, the characteristics deteriorate and a cavitation effect appears inside.

- Overheating may cause the oil to lose its properties and deteriorate.

- If air gets inside, the performance drops significantly; it needs to be replaced urgently.

Oil options are durable and on uneven roads this is an ideal solution, be it a city or a dirt road; at high speeds and racing they quickly overheat and often cannot hold rolls.

Gas shock absorbers

This is the largest subspecies; it is divided into two types of structures. Both are called gas shock absorbers, although they are essentially gas-oil shock absorbers - that is, they contain both oil and gas.

Nowadays, it is also quite common - it also has a rod, there is a piston with check valves on it, there is also a cylinder and oil pumped into it.

Only under this oil there is another chamber (in the same cylinder); it is separated from the chamber with oil by its impenetrable body.

It is in this chamber that gas (often nitrogen) is located under high pressure, usually from 12 to 30 atmospheres.

Unlike its oil counterpart, it is much stiffer; the gas chamber can also be compressed and expanded. When there is a load from above (the rod goes down), the gas chamber begins to compress, using the oil pressure of the upper chamber, after the load decreases, the gas chamber expands, pushing the rod upward itself.

What this gives us is that the wheels of the car are always pressed to the road surface, if you like, these are the hardest shock-absorbing elements, handling especially when cornering will be much better, there is practically no roll at all, it handles braking perfectly, there is also no longitudinal roll. That is why they are often used on sports and loaded cars that drive at high speeds and loads.

Another positive point is that the gas prevents the oil from boiling, transferring excess temperature to itself.

However, on a car with such elements, you will feel all its irregularities, even small ones, which is called the “cart effect”

pros:

- Excellent road holding

- No rolls

- The suspension is always preloaded, that is, it works not only to compress, but also to decompress.

- For sports and racing cars, where high speeds and overloads are ideal

- Preferably used on smooth roads

- There is no cavitation effect inside, the gas removes heat

Minuses:

- Expensive because of its structure

- Complex design

- Not a comfortable ride in all modes

- There are two chambers, and each of them can fail, which will lead to the failure of the completely shock-absorbing element

Gas oil shock absorber

As I already wrote above, this is just a subtype of gas ones, but for some reason they are persistently classified as a separate type, although this is not correct.

Here the design is already significantly different from the first two predecessors - the whole point is that this is a so-called “ twin-pipe shock absorber ”.

One chamber also contains oil and a piston with a rod; it also has check valves. Below in the chamber there is another piston-like element, it also has check valves, only it connects the first circuit and the second, into which air is pumped under medium pressure, about 3 atmospheres.

At the compression stage, the piston presses on the oil, it passes through the valves, and also enters the reserve chamber with air.

AT the compression stage, the rod begins to go up, which creates a small vacuum force in the first chamber, and then from the second chamber with air, the oil that entered there during the compression stroke enters. Thus, the oil chamber always remains in the oil space, and all the air is always diverted into the second chamber.

Gas-oil versions are more comfortable on the roads (than just gas ones), but less comfortable than oil ones, they also perfectly smooth out rolls, much better than oil versions. They can be called the “golden mean”.

pros:

- Moderate comfort on any surface

- Removal of heat and air from the working chamber

- Virtually no overheating

Minuses:

- They cost more (when compared with oil options)

- More complex design

- The resource is less than that of its counterparts, due to two cameras

Despite the fact that this option is expensive, it can be called the “golden mean”; it holds the road perfectly and gives moderate comfortable movement, that is, there will be no “cart effect” here. In my opinion, two-pipe gas engines are suitable for most modern cars in the city.

Now let's watch a short video

Istchonik

Source: https://zabarankoi.mirtesen.ru/blog/43742199830

Which shock absorbers are better

One of the most important components of the chassis of a modern car is shock absorbers. These important technical elements appeared at the beginning of the last century.

It was then that the engineers wondered about the additional softness of the suspension.

The inventors did not have the problem of choosing which shock absorbers were better - gas or oil; they solved more complex problems related to driving safety.

A little history

At the dawn of mechanical engineering, longitudinal sway of the overall structure of a car body was a significant problem. Now we choose which shock absorbers are better: gas or oil, but then the car body was supported by springs.

And their design did not fully meet technological safety criteria. The described shortcomings were especially felt in passenger cars. A wheel falling into even a small hole created additional load on the spring or spring system. And this led to very rapid wear and tear.

There was no talk about the comfort of passengers inside the cabin.

Therefore, all work to increase vehicle speed limits came to a standstill. Specialists from many design bureaus have thought about creating a damper that could remove part of the load from the main suspension.

It was this idea that was brilliantly implemented in the creation of the first shock absorbers. Over time, several shock-absorbing structures were created, the most successful of which was the MacPherson.

Engineers still don’t think about which shock absorbers are better, but use this system in modern cars.

Shock absorber designs

So, the main element in smoothing the movement is the shock absorber itself, or the “strut”, as it is popularly called. The modern market offers a huge number of such units.

How not to get lost in this vast business segment? Which shock absorbers are better - gas or oil? How to buy what your car needs? And finally, how to avoid additional financial costs? This will become clear if you delve deeply into the characteristics of these products.

Today there are two types of the mentioned mechanisms: hydraulic and gas. There is also a third option, combined (so-called gas-oil shock absorbers).

But it is quite rare, so let’s talk about the two main ones. It is worth noting that all these varieties have both their fans and critics from car enthusiasts.

Let's try to figure out which shock absorbers are better.

Oil shock absorber

Modern car manufacturers most often use hydraulic shock absorbers. They are also called oil-based, since the working fluid inside the rack housing is a special oil. Such a mechanism consists of a working cylinder, a rod with a piston, a special guide bushing and working fluid.

The operating principle of this device is the movement of oil filling the working space. Moving inside the shock absorber, the liquid dampens negative vibrations that create destructive loads on the springs.

Disadvantages of the oil system

The main disadvantage of such shock absorbers, according to experts, is the presence of an air mixture in the compensation chamber.

Insufficient air level or its complete absence negates the full operation of the entire unit. Conversely, excessive air mixture content in the working chamber leads to the unsuitability of the system.

In both cases, the structure compresses and expands without the necessary effort.

In addition, oil shock absorbers are characterized by low heat transfer. This significantly affects the smoothing of movement during long-term use of the car. The working fluid, which is located inside the shock absorber, heats up and loses its binding functions, which also quite seriously affects the performance of the chassis. This is especially noticeable in hot weather.

Bad roads are the enemies of shock absorbers

With frequent driving on uneven roads, such mechanisms quickly fail. This is primarily due to the frequent stroke of the piston in the working cylinder of the shock absorber.

The working fluid seems to be “shaken” and significantly loses its viscosity. As a result, the springs carry an additional negative load. Passengers inside the car experience so-called “breakdowns”.

In other words, hard and loud impacts when the wheel hits a hole.

When the working mixture in the unit cools, its properties are not restored. Which should also be considered a significant design disadvantage. At high speeds, a failed shock absorber can even cause an emergency (due to dangerous longitudinal rocking of the body on uneven roads).

And then a kind of chain reaction follows: due to poor shock absorbers, the brake system may fail; and this affects the increase in the overall braking distance and traffic safety. And finally, I would like to note that if the entire suspension fails, your wheels will suffer, and tire wear will exceed all pessimistic expectations.

Are there any advantages to oil shock absorbers?

It would seem that when buying hydraulic mechanisms, you are faced with continuous disadvantages. What is the point of such a purchase, and which shock absorbers are better?

Firstly, the situations described above occur when the car has been used for quite a long time. It never hurts to stop by a service station and check the condition of the car if you suddenly hear a strange noise while driving.

Secondly, a fairly common cause of shock absorber failure is aggressive and careless driving. Here you just need to remember the speed limits. You shouldn’t fly into deep holes and then count on the safety of the suspension.

Thirdly, like all equipment, the shock-absorbing system requires, albeit small, maintenance. We are talking about rubber seals that need to be treated with silicone grease at least occasionally.

Cost matters

The financial costs that you will incur when purchasing oil units are not comparable to the purchase of gas shock absorbers. Actually, we talk about this last because when it comes to security, money should take a back seat. When answering the question about which shock absorbers are better, gas or oil, do not forget that the latter are relatively inexpensive.

It is easier to observe safety precautions during operation and initially purchase products only from well-known manufacturers.

It would be worth noting that the technological process of replacing shock absorbers itself is quite complicated. It should only be carried out at specialized service stations.

Otherwise, the costs that you will incur when frequently changing these units will be quite significant.

Gas shock absorber is more reliable

Taking into account all the above factors, experts recommend turning your attention to gas mechanisms. Yes, they are much more expensive, but they are more adapted to our difficult road realities. The main difference between gas shock absorbers and oil shock absorbers is the working mixture located in the compensation chamber.

In gas devices, it is not filled with oil, but with a gas mixture, which is pumped into it under high pressure, which forces the piston to be pressed all the time. Therefore, when the car hits an uneven road, the stiffness of the shock absorber changes nonlinearly, which ensures better vehicle controllability.

The high level of rigidity of gas-filled mechanisms ensures safe driving at high speeds, minimizing the effect of longitudinal rocking. This has a positive effect on other components of the car. Fuel consumption when using such a suspension is slightly reduced.

Favorable factors include less tire wear.

Thus, gas shock absorbers (reviews from engineers and experienced drivers allow us to draw a similar conclusion) are significantly superior to oil shock absorbers. However, this does not mean that they are ideal.

Flaws

As you know, everything has its drawbacks, and the devices we are reviewing are no exception. Therefore, there is a clear answer to the question “Which shock absorbers should I choose?” does not exist. It all depends on the driver’s commitment to a particular design.

Due to the notorious rigidity, gas-filled mechanisms have a greater impact on the body, often rendering its metal segments unusable. This applies primarily to bearings and ball joints, the failure of which can lead to lengthy and rather costly repairs.

If we also take into account the rather high cost of the gas-filled shock absorber itself, it turns out that, from a financial point of view, such a purchase is unjustified. It’s not for nothing that expensive sports cars are equipped with these designs.

So when the problem of choosing arises, remember what you can face in the event of a breakdown. Although most experts claim that the quality still justifies the high price (in the case of gas shock absorbers). With careful driving and proper maintenance, such mechanisms will pay for themselves. As already noted, the manufacturer plays a huge role in the selection of such shock absorbers.

What you need to know about replacing shock absorbers

If you happen to experience repairs to gas shock absorbers, you need to remember that, as a rule, such units are replaced in pairs. Make sure that the product is fully certified.

In addition, pay attention to the warranty periods. Then you will be able to appeal if there is a manufacturing defect.

This happens quite often, and if you bought your shock absorbers on the market, then most likely you will have to do this again.

Based on all of the above, we conclude: you should opt for gas-filled shock absorbers. However, they are less susceptible to wear. This means that all unpleasant procedures for their possible replacement can be postponed, at least until the end of the warranty. And if you comply with all the conditions that we talked about, such a purchase will save your money and nerves.

Source: https://www.syl.ru/article/154191/new_kakie-amortizatoryi-luchshe-gazovyie-ili-maslyanyie-gazomaslyannyie-amortizatoryi—otzyivyi