Building your own paint booth

Car painting is carried out in specially equipped rooms with good ventilation and special equipment. This ensures proper air exchange and maintains the required temperature. There are ready-made powder coating booths on sale, but their cost is too high.

Many entrepreneurs are deterred by the high price of such premises from starting their own car painting business. An alternative option would be to use a DIY spray booth.

If you comply with all the necessary standards and install the necessary equipment, then such a camera will not be inferior to a purchased one, but at the same time it will cost much less.

Even the most ordinary garage is suitable for organizing such a camera with your own hands.

Basic requirements for the device

If you consider the stages of painting a car, you can understand what requirements should be observed when setting up a paint booth. It consists of the following steps:

- Before painting, the car body is sanded. In this case, the task of ventilation is both to remove dust from the paint booth and to clean the air entering the chamber from the outside.

- When painting a car, the ventilation system must ensure that the air is cleared of varnish and paint particles.

- When drying a car, the air must be heated and circulated indoors.

Thus, a powder coating booth consists of an enclosed area intended for painting and drying; heat generator for heating air; ventilation systems equipped with the necessary filters; lighting.

Paint booth diagram

When installing a painting and drying chamber, the room in which it is located should not depend on the ambient temperature. Thus, good thermal insulation must be performed. The room temperature should be maintained at about 20-25 degrees, excluding sudden temperature changes.

Special requirements apply to room lighting. It should be fully illuminated evenly and the workplace should be especially well lit. The light should be a combination of shadowless lighting and fluorescent lamps, and should not have any flicker.

Paint booths can be equipped with single-motor or double-motor ventilation. The single-engine unit works only for supply air purification. It is easy to assemble with your own hands. The twin-engine one ensures air purification at the inlet and outlet, therefore it is more efficient.

In any case, ventilation should be at floor level and ensure air circulation throughout the room without dead spots. Filters must clean the air from both dust and oil particles.

Watch a video selection on implementation in a regular garage:

Selection of premises, equipment and interior decoration

A garage or any non-residential premises is suitable for a do-it-yourself paint booth. As with any construction, before starting to set up a paint booth, you need to make drawings of the location of ventilation, lamps, as well as all the necessary elements that the powder paint booth should contain.

Painting booth diagram

It is better to perform the interior decoration of the room with a metal profile. It is economically beneficial to use PVC panels, but they have a high degree of flammability. It is better to complete the finishing using non-combustible materials. Similarly, do-it-yourself thermal insulation is also done with non-flammable insulation, ensuring a reduction in heat losses.

The base structure for the camera can be made of concrete or metal. Concrete is preferable, since it is at floor level and is convenient to drive into by car.

The metal base should be at a height of 30-50 cm from the floor. This creates the inconvenience that you will have to make an additional entrance for cars yourself. Both bases provide good air exchange, which helps remove exhaust air to the outside.

The room must be equipped with a sealed door. White powder paint is used to paint the walls. It has a fairly long service life and is resistant to external influences.

It is advisable to paint the walls of the room white; colors are better perceived against its background, which is important when painting cars.

The room for painting a car should be well lit. In this case, the lamps should be located not only on the ceiling, but also on the walls, providing side lighting.

The best solution for lighting is fluorescent lamps; they are quite economical and do not flicker. LED lamps have become popular recently. Although they have a high price, they pay for themselves due to the advantages they have:

- consume less electricity compared to fluorescent lamps;

- do not require replacement;

- have a high level of safety, which is important for a powder coating booth;

- Provide bright and even lighting.

To illuminate the lower part of the machines, you can use portable lamps or place lamps at the bottom of the room along the walls, protecting them from accidental damage.

To make a decision about equipping a painting and drying chamber with special drying equipment, you need to decide how many cars will be constantly painted. If a small flow is expected, then you can get by with air drying and installing a heat generator.

If a large flow of vehicles is expected, then the best option is to use infrared lamps. They consume little energy and are therefore beneficial from an economic point of view. Provide high drying speed and quality of the paintwork after drying.

The powder painting booth can be equipped with a room for car painters, which should be adjacent to the painting and drying chamber. This room is intended for the craftsmen to relax, where they can change clothes and eat.

It is advisable that it have a window opening into the painting booth. To do this, make a corresponding hole and insert a double-glazed window into it. Through the window, technicians can monitor the drying of the car and quickly respond to any emergency situations.

Organization of the ventilation system

The ventilation system must ensure a uniform flow of clean air throughout the room. When designing, you need to build a ventilation system with your own hands so that there are no dead zones.

Therefore, ceiling and floor filters are located across the entire width of the room. The powder painting booth must be equipped with an exhaust ventilation system with shut-off and control valves, which is located in the underground space.

Organization of the ventilation system

Supply ventilation should ensure the removal of air from all points in the room, especially in the car painting area. If there are no dead zones, then during an hour of work when painting a car, the air in the room should be renewed at least 8-10 times.

The ventilation system must be equipped with filters. The supply air should be cleared of dust, which affects the quality of the coating, and the exhaust air should ideally be cleared of paint fumes. Depending on the method of organizing the ventilation system, paint booths can be of two types:

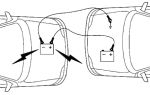

Ventilation of a single-engine spray booth

- single-engine, in which air under pressure comes from the upper ventilation duct. Thanks to the pressure of the incoming air, the paint mist falls down and is discharged out through the floor openings;

- twin-engine, which are equipped with both a blower motor located at the top and an air exhaust motor located at the bottom.

Naturally, having two motors is more efficient. But this option is more expensive and more difficult to install. It is justified when there are a large number of cars being serviced, so it is more profitable to install one engine.

In dual-motor chambers, a second motor is placed in them to force exhaust air out. If the floor is metal, then it is already raised, so there is no need to make trenches.

Ventilation of a dual-motor spray booth

Watch the video of what types of ventilation systems there are:

Varnishes, dust and paints quickly clog the filters, which slows down the air circulation in the painting and drying chamber, so the ventilation must be able to regulate the air flow. In addition, cleaning the filters should not take much time; they should be conveniently located.

The quality of painting is greatly influenced by the presence of dust, so its amount should be kept to a minimum. From the garage where painting is done, all rubbish that can accumulate dust should be removed: various rags and carpets.

Fires when working with paints and varnishes occur quite often, so special attention should be paid to fire safety. Non-combustible materials must be used for finishing and thermal insulation. All devices located in the room must be explosion-proof. Electrical appliances must be grounded.

Heat exchangers must have protective thermostats against overheating. The room where paint and varnish work is carried out must be equipped with a fire extinguishing system.

Watch the implementation video:

Our photo selection of interesting solutions:

Source: http://StrojKarkas.com/postrojki/ustrojstvo-pokrasochnoj-kamery.html

DIY paint booth in the garage

When the need arises to paint a car on your own, a paint booth in the garage will be a great solution to the problem.

Basic requirements for building a room with your own hands

Spray booth - operating principle

- The space must be insulated and free of flammable materials;

- the wall (with a height of at least three meters) is covered with a matte film, which, thanks to the magnetization effect, attracts and holds dust particles. The surface is easy to clean, its lifespan is enough to paint ten cars. Powder matte coating on a vertical plane is additionally treated with a fire-retardant layer.

- the paint booth in the garage is designed to be extremely sealed;

- a room built with your own hands must comply with all technical safety standards.

The role of filters in the painting business

Filters for a spray booth Thanks to the high ceiling in a narrow-purpose room, a filter structure with an exhaust pipe can be constructed on the upper perimeter.

- If the paint booth in the garage is single-engine, then a filter roll surface is laid over the entire ceiling area. To retain large debris, removable pocket filters are attached in front of the ventilation system.

- The double-engine room is equipped with an additional filter in the floor. The structure is mounted with your own hands in the air duct system or under a metal deck. The mist of paint spraying falls down and is taken away by suction through special holes.

The load on the device is significant, so filter components with the possibility of coarse cleaning are used, or a fine cleaning cassette mesh is mounted in front of the device.

Manipulations with lathing and flooring

The floor in the painting booth must have trenches. Trenches are made in the finished floor and covered with a metal grid. This technique raises the floor level by no less than 15 cm. A ventilation motor is mounted into the resulting ground cavity.

What to do when the paint booth in the garage is not equipped with the necessary floor:

- with a continuous floor covering, two trenches or one rectangular hole with a meter deep can be dug. If this type of work cannot be carried out, a second floor is laid with your own hands with a deviation of 20 cm. In the intermediate space, ventilation units are installed with output outside the garage;

- when the room has a ready-made inspection hole, the recess is covered with a metal grid made of reinforcement. Boards are laid out under the sheathing in the shape of wedges. An acute angle should be formed towards the entrance of the room. An air duct pipe is brought out from the underground cavity, which will become the bottom ventilation of the room.

Correct lighting

Lighting the paint booth If the paint booth in the garage is technically correctly lit, the worker will easily notice dust particles in the air and quickly eliminate flaws in the fresh paint. Do-it-yourself installed fluorescent lamps are optimal for the human eye, so painting work will always be productive.

Imitation of daylight is created by installing fluorescent lamps in two rows. Light sources are installed along the ceiling-wall perimeter. If this electrification option is not possible, the lighting is left on the ceiling. Portable lighting is used to paint the lower parts of the vehicle.

Frequent and uniform spot lighting on the surfaces of the room is the main guarantee of quality work.

Heating system

Heating in a paint booth Any paint booth in a garage must meet all temperature requirements.

Deviations in one direction can undermine a worker’s health and reduce the quality of paint applied to a metal surface.

In the cold season, electric heating elements and local heating will be sufficient.

You can install a heat gun, warm air from which will flow to key ceiling points and warm up the interior space.

If the DIY painting room is not intended for large-scale operation, purchasing a heat generator will become unprofitable, since rare use of the equipment is unlikely to pay off.

Profitable car drying

To decide on the method of performing work, start from the degree of workload of the camera:

- air drying (relevant for single painting). The main disadvantage is the duration of the procedure;

- For commercial purposes, household infrared equipment is beneficial. Complete drying is observed much earlier than when working with air.

Benefits of infrared drying

- The red light lamp is ready to dry any painted surface in a short time.

- The device consumes electricity sparingly.

- The equipment is capable of drying any putty or primer, which is important for large-scale car reconstruction.

"Inside"

Often a paint booth in a garage is lined with plastic sheets or metal corrugated sheets. Processing this surface will not be difficult. Accumulated dust on light-colored walls and ceilings will immediately catch your eye if the coating is made of a matte white color. Finishing works have decorative elements. The owner's imagination allows him to perform boxing in the most unconventional way.

Cycle of painting works

- The first stage is necessary for the intake of air with dust in the chamber, its filtration and final entry into the box in a purified form;

- painting activities heat up air masses, so a complex ventilation system systematically removes too heated air outside the garage;

- drying the car. After being filtered, the air in the room is heated to 60 degrees and circulates through the box (dries the paint of the car).

Automation. Remote Control

When funds allow, the paint booth in the garage will become more advanced with an automated control system.

The control panel is made of heavy-duty materials and has manual and automatic operation modes. Thanks to the built-in timer, local painting forms are of the same quality as factory-made ones.

What determines the cost of boxing?

- sheathing material;

- number of motors;

- branching of ventilation ducts;

- normal or industrial purpose of the premises;

- quantity and complexity of work performed.

Safety precautions

Observe safety precautions! The concrete floor provides unhindered entry into the chamber. The base is built on the same level as the adjacent rooms. The flooring material promotes normal air exchange.

The finished metal floor is fixed at least 40 cm higher than similar surfaces of adjacent rooms. To soften the difference in floor surfaces, a bridge is being built.

Particular attention is paid to the fastening parts of the ventilation system.

Clogging and deformation of the air intake passages can imperceptibly provoke the accumulation of fumes from paint solutions. An unpleasant phenomenon can cause a local fire or even an explosion.

A sound recommendation from a specialist before carrying out construction activities is mandatory, because it is difficult to take into account all the factors of safe painting work. Competent advice will prevent rework in the future.

Source: http://stroybudni.ru/garazh-svoimi-rukami/oborudovanie/pokrasochnaya-kamera-v-garazhe-svoimi-rukami.html

DIY spray booth

Many people today decide to start painting cars in their own garage. A DIY spray booth is an opportunity to do what you love on a professional level.

It is clear that you can go the simple and standard route by purchasing expensive equipment for a service station and installing it in your garage. In this case, you will have to buy a lot, including a paint drying booth. This option is not bad, but it will require investing a considerable amount of money.

Car painting booth

There is another way, which will be discussed in this article. This is the construction of a paint booth with your own hands.

A spray booth is a special room designed to carry out a difficult process. In this case, painting a car is the most difficult process.

It goes without saying that in order for painting to be carried out competently in such a room, everything must be thought out to the smallest detail.

It is important first of all to pay attention to the ventilation system of the chamber, which must be built correctly.

A filter for a spray booth is a must-have component for any room of this type. A system of this type will allow for cleaning the air mixture that is pumped from the outside, and even in the chamber itself.

It also removes mist from paint and varnish outside. It is clear that without good ventilation there is no point in talking about any painting process, since the quality of the work decreases several times.

Therefore, a good hood and filters are the most important elements.

It goes without saying that the air that enters the chamber must be as clean as possible, that is, completely filtered.

If you do not pay attention to this, defects will occur more often throughout the entire plane of the surfaces being painted. To avoid this, it is recommended to install a fine air filter.

And it is recommended to place it at the outlet of the air box. In principle, it should be a tin box installed above the ceiling.

Painting a car in a spray booth

A paint drying chamber, in principle, should consist of several basic components:

- the premises itself;

- equipment providing ventilation in the chamber;

- equipment that provides heating for the drying chamber;

- bright light.

Let's start with the first one. The room for work is selected depending on individual preferences. In particular, what size the room should be, how to decorate the ceiling, etc., is decided by the owner himself.

Although there are certain rules that must be followed. These include the following canons:

- there must be a trench or a second floor in the painting booth for air removal;

- walls must be made of a material that does not generate dust and is not a source of dust;

- the ceiling must have a certain shape (usually a sloping shape that does not allow air to collect in one place).

Well, ventilation, which should work in the room both in painting mode and in drying mode. As for the painting mode, it involves performing the following processes:

- supply of clean air at a temperature of 25–30 degrees;

- possibility of taking clean air from outside;

- the ability to remove unnecessary air and dust from the chamber.

But in the drying mode, the processes are slightly different, although in reality everything is the same. So this is:

- air supply, but with a temperature of 45–90 degrees;

- the intake of clean air from outside is not complete, but by 10%;

- the ejection of exhaust air from the chamber is only 10%.

Do-it-yourself car painting booth

Ventilation systems are usually divided into two main types:

- ventilation with a single-engine unit, where the air is heated inside the room and always from above;

- ventilation with dual-motor units, where in addition to the forcing air from above there is also a lower unit that sucks out the air.

Both types of cameras have a similar operating principle and good isolation from the external environment. In both of them, air is forced into the painting room through a ceiling filter. And excess pressure is created, which squeezes out the air with the paint. The air outlet passes through the second floor or through a trench in the floor.

As for the units, in a dual-motor paint booth, one engine will supply air to the painter, and the other will suck it out. And this will happen on this principle of operation, when a little more air is supplied than is taken out. It turns out that, although the air exchange in the drying chamber becomes more active, vacuum does not occur.

The essence of the air exchange occurring in the room can be explained in other words. To do this, imagine the following picture: in front of us is a plastic canister with a closed lid, in which two holes are made. One hole is opposite the other.

We release cigarette smoke into the canister. After this, we blow clean air into one of the holes. What's happening? Smoke will come out of the other hole. We take a vacuum cleaner and thread the hose into the hole where the smoke was coming from. And we will have more active air exchange.

The video shows how to make a spray booth with your own hands:

Now about twin-engine paint booths. They are generally not economically viable for self-production. You will have to make a complex design.

This is a rather complex device that involves a suction motor that creates a vacuum.

But everything needs to be done in such a way that clouds of vapor from paint or varnish do not pass through the structure itself, and also do not deposit on the blades. Otherwise, it will cause the device to become unbalanced.

Let's move on to the ceiling, where we will consider the design for supplying clean air. It is from here that it will enter the painting booth. And in order to successfully assemble the structure with your own hands, you need to buy the following materials: air vents, snail, filters. You will also need to make your own container into which the air will initially flow.

Let's start with the &snail&. This is a kind of device that pumps air. The main purpose of the snail is to provide supply and exhaust ventilation. Such devices are equipped with galvanized steel impellers and curved lamellas, which increase their productivity and pressure.

In addition, each ventilation method has both advantages and disadvantages. And if at home the use of dual-motor ventilation is not considered cost-effective, some still use it.

The fact is that two-chamber options provide better ventilation and air circulation. And if your paint center expects a large flow of traffic, then building a dual-motor ventilation option will be a profitable proposition.

On the contrary, if you think that you will limit yourself to painting a few cars, building a single-motor camera will be more correct.

The video shows the correct operation of the ventilation unit:

The most ideal option would be to build a camera inside another room, and not separately.

If it is possible to install the painting machine inside the workshop where the main type of work will be carried out, all that remains is to dig trenches for air removal.

As for the walls, they can be built from plasterboard, which is sheathed on a metal frame. In this case, you can use mineral wool, which provides thermal insulation.

Now about the floor. Two trenches should be dug and always parallel. At the point where they are brought out onto the street, combine them into one common one.

Subsequently, the trenches can be covered with a metal grid or welded ceilings made from angles or pipes.

And further. In order for air to be discharged evenly along the entire length of the room, the trench should be made in such a way that the gap narrows towards the air outlet. Otherwise, if this is not done, air exchange will occur only at the point where it goes outside.

Cameras with a water curtain have their own characteristics. Their equipment includes:

- a metal tray with water, which is covered with a grill;

- special panel for regulation;

- pump;

- door latches;

- station exhaust ports;

- water curtain panels;

- nozzles;

- corner pipe;

- exhaust fans and much more.

Hood for spray booth

These types of chambers for cars can be additionally equipped with an overhead road, a heating and air convection device and a control system.

Now let's see how to make a spray booth that combines several modes. It turns out that there is another option for creating an air outlet from the chamber. This is supply and exhaust ventilation used in three modes.

The first mode of using supply and exhaust ventilation involves active circulation of air, which undergoes continuous ventilation and then enters back into the chamber. The main purpose of this mode is to ensure thorough cleaning of the air from dust and other elements .

The next mode takes air from the street. And the air coming from outside must undergo filtration, heat up to the required temperature and enter the chamber.

As for air removal, it leaves through special holes made in the floor. The main purpose of this mode is to maintain a constant temperature while the dyeing process occurs.

This removes drops of paint and mist formed from the varnish.

The third mode involves pumping air from the chamber. And in this case, the air undergoes mandatory filtration, heating up to sixty degrees, it flows back into the chamber. This mode helps dry the car after painting much more efficiently.

During the design process, special attention should be paid to the location of ventilation openings - both inlet and outlet.

So, if they are positioned incorrectly, this will lead to the appearance of so-called dead zones in the camera.

As a result, during the process of spraying paints and varnishes, fine dust hangs in the chamber, which subsequently affects the quality of the surfaces being painted.

Now let's look at the cameras used today in the most advanced car painting centers. A powder painting booth, and this is what we are talking about, implies the presence of equipment on which the speed and quality of painting products will depend.

The first and most important condition for the normal operation of such a chamber is to ensure a mode that would prevent the spread of powder in the room. In addition, you should stock up on equipment that would ensure the capture and collection of powder that has not settled on the product. Well, it’s not worth talking about ensuring safe working conditions.

The operating principle of such a spray booth is based on the automatic application of powder paint to metal products, in this case cars. In addition, such a chamber additionally provides for the installation of special fine air filters. This ensures direct release of purified air into the room.

Video about what kind of ventilation system is needed for a spray booth:

The automatic floor cleaning system in such a chamber does not surprise anyone. By moving a special brush along the floor, the powder is swept into a special hopper, which, in turn, is equipped with a vibrating sieve and ejectors that suck in the powder.

Well, that seems to be it. We hope that this article will help those who are planning to build a spray booth with their own hands.

Source: http://calypsocompany.ru/avto/pokrasochnaya-kamera-svoimi-rukami

DIY paint booth in the garage

It's rare that a car survives its short life without being repainted. Foreign cars of non-Chinese origin can withstand 300-400 thousand kilometers; a car from the domestic auto industry ends up in the paint booth after about 100-150 thousand kilometers.

There are few ways to restore the paintwork - take it to a company service center, use the services of garage technicians, or make a paint booth in the garage.

Even taking into account the additional costs of renting equipment, a do-it-yourself paint booth in the garage will cost much less than the services of painters.

What does a paint booth consist of?

The cost of painting can range from 20 to 80 thousand rubles; for that kind of money you can temporarily equip your garage with a painting box. Even with painting equipment installed, the room will not cease to remain a garage, and after the painting work is completed, the garage can be easily restored to its original appearance.

To convert a garage space into a paint booth with your own hands, you will need to buy or rent the following equipment:

- Air compressor with a working pressure of 8-12 atm with a receiver and a water and oil separator;

- Two fans – supply and inflating;

- A set of four halogen spotlights, one and a half kilowatts each, or a heat gun;

- Fabric filter system;

- Three LED lights and six long fluorescent lamps;

- Set of measuring plastic utensils;

- Reinforced polypropylene film - canvas and fasteners.

Advice! Do not attempt to use oxygen tanks in your paint booth instead of an air compressor. In the event of the slightest spark, the paint booth in the garage will turn into an open-hearth furnace in seconds.

Oxygen painting gives an incredibly even and thin layer of paint, even without the use of gloss enhancers, due to the high purity of oxygen. But the risk is very high, so it’s easier to install an additional filter and moisture separator, and high-quality varnish and additives will provide shine and gloss.

How to make a spray booth

It’s worth mentioning right away that a do-it-yourself paint booth in the garage and the listed set of equipment will allow you to paint “almost well and with high quality” at most a few cars. For a semi-professional or professional approach, the level of equipment must be significantly higher, both in terms of painting tools and in terms of re-equipping the paint booth itself.

Converting a garage into a paint booth is carried out in three stages:

- A hood is installed in the garage;

- The walls, ceiling, and garage doors are finished with protective coatings and cladding;

- Heating and drying devices are installed.

Important! The quality of the paint layer directly depends on the amount of water vapor and dust in the atmosphere of the spray booth, so 30% of the equipment is designed to remove dust and fog from droplets of paint and varnish from the garage, the rest is for uniform drying of the painted surface.

The principle of operation of the camera consists of two successive stages - painting parts using a spray gun and drying a layer of paint or varnish using heating devices, for example, halogen lamps or heating elements.

Anything that does not fall on the surface to be painted and hangs in the atmosphere must be carefully removed from the chamber so that the fog does not settle on the paint surface.

The air flow should come from above, and the air flow contaminated with solvent and paint should be removed through openings in the floor or in the lower part of the walls of the garage.

Arranging a garage space for a simple paint booth

To paint small car body parts and furniture elements, a small chamber about half the size of a garage is sufficient. The cost of building such a paint box will be an order of magnitude less than for a large room.

To paint a car body, the chamber volume can be temporarily expanded to the size of the entire garage with the installation of additional lamps and heaters.

Due to the low power of drying and ventilation equipment, the productivity in painting full-size body parts will be less.

In the garage space reserved for the camera, first of all, you need to remove absolutely all things and objects, leaving only the bare floor, roof and walls. The easiest way to separate the space of the paint box is with an awning - a curtain made of synthetic fabric made of polyester fibers. Such a fabric barrier should be attached around the perimeter using Velcro or zipper, as in the video:

For a small spray booth, it is enough to install two supply fans under the ceiling. Most often, air is taken from the second half of the garage; it is cleaner and warmer than outside. Removal of polluted air is carried out using the same pair of fans, but installed below, on the rear wall, almost on the floor of the garage.

To dry a painted surface in a small chamber volume, it is best to use powerful halogen lamps. A powerful stream of light makes it very easy to dry and heat the surface of a part prepared for painting. After painting, the ventilation can be set to minimum capacity and the drying process can be visually monitored.

When decorating walls, you can use experience that tells you how to cover a paint booth in a garage in the video:

For hot drying using heating elements, thin sheet metal is best suited. The walls of a small painting booth can be finished with cement-sand plaster, but before painting the surface will have to be moistened with a small amount of water from a sprayer.

Plaster, like a sponge, will bind dust and water, making the walls conditionally “clean”. Metal or OSB boards collect dust very well, and it can only be removed with a vacuum cleaner. Plastic panels, due to strong electrification, can collect ten times more dust than metal or wood.

The ceiling must be covered with OSB boards and sealed with reflective polypropylene film or aluminum foil.

During the painting process, it is very important to clearly see how a layer of varnish or paint is laid down, so even for a small chamber you need at least three rows of lamps: a row at a height of 60-70 cm from the floor, the top row of lamps at a level of 180-200 cm, and a ceiling lighting. On average, a paint booth from a standard garage requires 6-10 fluorescent lamps.

Setting up a semi-professional paint booth in the garage

It will cost more to build a semi-professional quality paint booth in a garage, but it is much easier to carry out such a conversion. To do this, you don’t have to reinvent the wheel, but use traditional and most effective technical solutions, for example, as in the video:

For a box for a painting booth, you can choose any garage, from a frame made of sandwich panels to a brick or cinder block one.

The first step is to install ventilation equipment in the garage. The exhaust part will require an inspection hole in which a pump-out fan will be installed. The exhaust from the fan in the pit is directed through a sheet metal duct into the filter box, after which the purified air is directed to the intake window of the supply fan.

A metal frame, welded from transverse and longitudinal channels with a window size of 50-60 cm, a structure height of no more than 15-18 cm, is laid on the surface of the concrete floor of the garage. Perforated steel sheets or a thick metal mesh will need to be laid on top of the frame. The gaps at the points where the frame meets the walls of the garage will need to be sealed with sealant and covered with tin.

Thus, contaminated air from the painting booth, dust and everything that falls on the floor is pumped out through a mesh in the floor by a ventilation device located in the inspection hole.

A supply ventilation window is assembled on the garage ceiling from plasterboard and a steel corner. Through it, clean air is pumped into the spray booth.

To prevent the entry of dust and dirt, the plane of the window is covered with a flour mesh.

The walls and ceiling of the garage for the painting booth are sheathed with thin sheet metal or composite insulation made of polyethylene foam with aluminum foil.

Such cladding can be easily removed from dirt using a regular washing vacuum cleaner. It is necessary to install two rows of fluorescent lamps along the walls of the garage.

For additional lighting, you can use portable flashlights with halogen lamps.

If the garage is finally “donated” for the installation of a painting booth, experts recommend replacing sectional or swing gates with roller shutters. This gate design best “holds” the tightness of the spray booth and requires virtually no modifications to operate.

The main equipment - a compressor, a receiver and a set of filters - must be installed in a separate room. A system for collecting water and oil vapors must be installed in the circuit with the air blower and the receiver cylinder. The filter for the compressor can be made from ordinary non-woven fabric in the form of 3-4 meshes mounted in a metal box.

Conclusion

The cost of converting a garage into a full-fledged paint booth will cost approximately 1.5-2 thousand dollars, excluding the cost of purchasing compressor equipment.

The average payback period at the initial stage will be 7-8 months with a profitability level of 10%. A mini garage floor camera will cost up to $800.

and can pay for itself in 4-5 months, since the number of orders for detailed painting is approximately three times higher than orders for a complete repaint of the car.

Source: http://bouw.ru/article/pokrasochnaya-kamera-v-garazhe-svoimi-rukami

How to make a spray booth with your own hands

Content

What should the room be like for a paint booth?

Paint booth lighting

Spray booth ventilation

Homemade spray booth

Stages of work execution

Tips for equipping a room with your own hands

If you decide to paint your car yourself or open a car service workshop, then a do-it-yourself paint booth will be the ideal solution.

You can take your car to a service station for painting or buy ready-made equipment.

But the latter option will not be cheap, so many car owners decide to make a painting booth themselves.

Before you start manufacturing, you should carefully study the question of how to make a paint booth. This is a very labor-intensive process that requires serious preparation and considerable effort. The painting chamber will not only serve as a room for painting the car, but also as a drying chamber.

In order for a car painting booth to meet all requirements and standards, before starting production you need to make a drawing, clearly calculate how much and what equipment you will need and strictly adhere to all construction rules, always taking into account safety requirements. This is a very important point, because you will have to work with flammable and toxic materials in the paint shop.

If you decide to paint your car yourself or open a car service workshop, then a do-it-yourself paint booth will be the ideal solution.

What should the room be like for a paint booth?

There are a number of essential requirements for the space where the paint booth will be located that must be taken into account and met. The quality of the work performed and your safety will depend on this in the future.

A spray booth can be installed either in an existing building or built from scratch.

The latter option has more advantages, because initially you can think about where and how the ventilation and air purification systems, lighting and others will be located:

- A mandatory rule for such an object is the presence of two doors. This is necessary so that in the event of a fire you can easily leave the paint booth. The ventilation system comes first. It must be clearly designed and properly constructed. Without good ventilation, excellent work results will not work. Ventilation hoods and filters must be of high quality, because these are the most important elements of the system.

- The room is sealed. Any car enthusiast knows about the dangers of dust, which, when falling on the surface to be painted during painting or drying a car, causes significant damage to the coating. Absolutely all surfaces in the painting workshop should be easy to clean. Painting a car is a fairly messy process, so being able to clean the camera regularly is very important.

- Lighting. Before you start building the camera, you need to make a design and provide all the lighting elements necessary for work. It is necessary to have a sufficient amount of both daylight and artificial lighting. Some elements of lighting fixtures must be mobile. This will be needed for painting hard-to-reach parts.

It is necessary to have sufficient amounts of both daylight and artificial lighting

- Thermal insulation of a room reserved for painting and drying cars.

- Size. The room must be sufficient so that when placing a car in it, during painting, the master can move freely around the car and carry out his work without hindrance.

Basic requirements that must be met during the manufacturing process of the spray booth:

- fire resistance of materials used in construction;

- thermal insulation;

- room tightness;

- possibility of easy cleaning of the box;

- availability of good lighting;

- powerful ventilation system.

Paint booth lighting

A do-it-yourself car painting booth should be equipped with good lighting. The best results and ease of use will be ensured by several ways of attaching light sources:

- Attach to the ceiling along the entire length of the paint box. Please note that some problems may arise during the vertical painting process.

- Ceiling and wall mounting. This is the most successful arrangement of lamps.

A do-it-yourself car painting booth must be equipped with good lighting.

- Ceiling with additional use of mobile light sources. This option is good for small spaces and a variety of types of painting.

A do-it-yourself car painting booth must be equipped with a secure network with a well-thought-out security system. Ideally, professionals should install the electrical network. It is better not to save on this and entrust this type of work to specialists.

The optimal illumination in the painting booth should be around 1000-2000 lux. Experienced craftsmen say that for good illumination of the room, lighting devices should be installed at the rate of 40 W per square meter. Portable lamps should be brighter than stationary ones. The ideal placement of light is on the ceiling, walls and back wall of the chamber. Plus portable light sources.

When choosing the type of lamps to be installed, you need to pay attention that the illumination in the paint booth should be approximately the same as outside on a sunny day. You can install fluorescent, LED or incandescent lamps. When choosing between these types, you should pay attention to the following nuances:

- energy saving;

- lifetime;

- lighting brightness;

- slight temperature.

Recently, craftsmen have given preference to LED lamps.

Spray booth ventilation

A do-it-yourself painting room must be built taking into account all the requirements, and ventilation is the most important component of the chamber. A well-designed indoor air ventilation system is responsible for cleaning it and removing paint mist.

There are two types of cameras:

- Single-engine. Air is forced into these chambers from above, creating pressure and depositing the fog downwards, bringing it out.

- Twin-engine, with upper and lower injection motors. One supplies dust-free air, and the other, using a suction method, removes it from the box.

The second option is preferable, but will cost more. If you decide to make a spray booth for business, then it is better to make a dual-motor booth. Ceiling filters must be installed. It is desirable that they be two-phase, that is, they filter out large and then small particles from the air.

Homemade spray booth

A homemade camera is profitable and convenient because everything in it can be done exactly as needed. You can set up a paint booth in your garage or build one from scratch. The most expensive investment will be the equipment of the ventilation system, followed by the price of the construction of the box itself, lighting and other small nuances.

A homemade camera is profitable and convenient because everything in it can be done exactly as needed

There are both pros and cons of making such a room.

Advantages:

- Make your own drawings and build a camera “for yourself.”

- Significant cost savings.

- The ability to independently select both expensive equipment and cheap analogues. Sometimes it is quite possible to save on something and choose something that is the most expensive and of the highest quality.

- Use different systems based on your needs. Some can be simplified, while others, on the contrary, can be made more powerful.

Flaws:

- There is a high probability of manufacturing errors.

- Costs for setting up and debugging equipment after completion of construction.

- An automatic control system cannot be manufactured independently.

Stages of work execution

The first step is to determine whether the camera will be built from scratch or made in an existing garage or other room. A DIY paint booth starts with drawings. It is in them that the wiring diagrams and installation of ventilation, lighting and other systems are indicated. At this stage you need to be extremely careful.

Drawing of a paint booth for cars

You need to start with the ventilation system, as this is the most important function in the spray booth. You shouldn’t skimp on this; the quality of the paint largely depends on the cleanliness of the air. We carefully carry out the lighting layout, taking into account all the necessary nuances.

The interior of the chamber must be made of non-flammable materials, preferably white. It is preferable to make the ceiling sloping, this will improve air circulation in the room. Grates should be placed in the floor, with filters under them. During operation, it is important not to forget about their timely replacement.

It is advisable to provide automatic control in the painting box.

Tips for equipping a room with your own hands

The high cost of ready-made paint booths encourages auto repairmen to get creative and come up with different ways to reduce the cost of their work. Therefore, now many are wondering how to build a spray booth with their own hands. If you approach the issue with all seriousness and responsibility, then it is quite possible to make a paint box yourself.

The main thing to consider when making your own:

- good ventilation;

- optimal lighting;

- finishing the premises with non-combustible materials;

- provision of a separate room for materials and equipment.

Tips for equipping a room with your own hands

If you took into account all the details and followed all the rules in the manufacture and arrangement of the paint booth, then painting cars will bring you pleasure and profit, and will not upset you with the troubles associated with negligence during construction.

Source: https://1000sovetov.ru/article_kak-sdelat-pokrasochnuyu-kameru-svoimi-rukami