How to properly check compression in the cylinders of an internal combustion engine

Sooner or later, a car owner is faced with the need to diagnose and repair his iron horse. The list of such works includes many items. This could be work related to power plants, transmissions, chassis or car body elements. Before you start repairing your car, you need to find out what broke and for what reasons.

The work associated with manipulation of the engine is very delicate. The mating parts are small and precise, so any deviation from the norm will inevitably lead to serious consequences.

Engine compression: what is it?

One of these procedures is measuring compression (pressure) in the engine cylinders. Compression directly affects the entire operation of the engine. Parameters such as engine power and thrust, fuel and oil consumption, and engine durability depend on it.

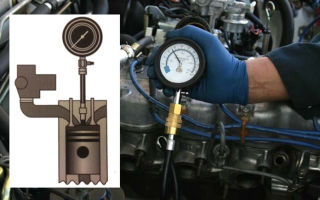

Timely diagnostics of the connecting rod and piston group of an internal combustion engine allows you to adequately assess the damage, which will subsequently save your time and money. For such engine diagnostics, you need a key for unscrewing the spark plugs, and a special diagnostic device - a compression gauge.

How to choose a compression meter

Any car owner can measure the pressure in internal combustion cylinders. To do this, just buy a simple compression gauge and a spark plug wrench. If the tool is inexpensive, then it is usually enough for two or three engine diagnostics. It’s better not to skimp and purchase a high-quality and reliable device, because a breakdown can happen to any car, at any time of the day.

The main thing when choosing a tool for measuring compression in an engine is to choose a compression meter with a threaded tip. There are models with a clamping tip, but such compression meters are less accurate and show not entirely correct pressure readings in the cylinder.

The threaded connection is additionally sealed with a gasket, which ensures the tightness of the entire indicator measurement system. The air release valve should be located on the head of the plunger rod, and not on the pressure gauge body itself. This valve arrangement allows for more accurate compression measurements.

Otherwise, the indicators will be underestimated.

For owners of vehicles with a diesel power plant, it is recommended to contact a specialized service center for vehicle maintenance and repair. This is due to the fact that such a power plant has a non-standard socket for glow plugs.

To unscrew such a spark plug or fuel injector, you will need a special tool and skill. A compression gauge for such engines also requires a special one - equipped with a special adapter.

What compression should the engine have?

Firstly, compression can be measured at temperatures from 75 to 90 degrees Celsius, since these values ensure maximum working contact between the rubbing surfaces.

Secondly, it is necessary to completely turn off the fuel supply to the combustion chambers. Such conditions are created so that gasoline does not wash away the oil from the cylinder walls, which provides an oil wedge.

Thirdly, turn out absolutely all the spark plugs, since it is necessary to remove resistance to the movement of the piston and the rotation speed of the starter. At some car service stations, this condition is not met, and only one spark plug is removed, where compression is measured. Thus, it is impossible to obtain correct readings from the device.

And the last prerequisite is a fully charged and working battery. Otherwise, the starter will not be able to ensure normal rotation of the crankshaft of the power unit, and the readings of the measuring device will be greatly underestimated.

Several methods for measuring compression on an internal combustion engine.

When the throttle valve is closed, very little air enters the internal combustion engine, and the compression will be about one kilogram per centimeter. This indicator will be identical to the pressure leak in a particular cylinder. With this method of measuring compression, the compression meter readings are very sensitive and accurate.

The magnitude of the readings allows us to draw conclusions about the proper fit of the valves to the seats, the integrity of the oil scraper or compression piston rings, their adherence to the piston walls, the absence of piston defects, the correct assembly of the crank mechanism and gas distribution, the correct assembly of components and mechanisms of the internal combustion engine.

With the throttle valve open, compression readings in the cylinders are usually measured to identify more severe engine damage.

Such damage includes punctures and cracks in the cylinder walls, burnout of the cylinder head gasket, destruction of the piston rings and similar destruction of parts and mechanisms of the internal combustion engine.

There is also a way to measure compression in cylinders on a cold engine. This is done because at low coolant temperatures the rubbing pairs do not adhere tightly to each other.

This measurement method is used to check compression in diesel power plants, since the compression in them is very high.

If such an engine has less than twenty-four atmospheres, then such a unit needs serious repairs.

An example of the procedure for measuring compression in an internal combustion engine:

- Remove the spark plugs from the vehicle's cylinder head.

- Pour some oil inside the cylinder.

- An assistant at the wheel must turn the starter for three seconds to distribute the oil along the cylinder walls.

- Screw a compression gauge into the spark plug hole.

- An assistant must turn the starter until the compression gauge needle is fixed in a quiet position.

- Repeat the procedure for each cylinder.

- After completing the work, install all dismantled components of the internal combustion engine in the reverse order of removal.

When measuring compression, do not forget to write down the results obtained for further comparison and drawing up an overall picture of the diagnostics performed.

It should be remembered that all these operations must be performed only in a well-ventilated area with a ventilation system.

This procedure for measuring compression is applicable only to engines running on gasoline.

How to check engine compression (video)

Bottom line

Measuring the compression of the internal combustion engine will help you draw a conclusion about the health of your car. Some may find this procedure too costly (either in time or financially), but it will help you prevent serious problems, one of the first signs of which is impaired engine compression.

Source: http://ProCrossover.ru/avtolyubitelyu/dvigatel/kompressiya.html

Correct compression measurement in the engine

The compression indicator is one of the most important parameters in the operation of an internal combustion engine.

With its help, you can determine the serviceability of parts of the cylinder-piston group, the degree of wear of the CPG or piston rings.

This indicator depends on the compression ratio of a particular engine (the ratio of the working volume to the piston stroke length). The more boosted the engine is with a higher compression ratio, the higher its compression parameters.

Over time, the CPG parts wear out, gaps appear, and the machine loses its power. The total loss from such work can reach 15-25 percent. The engine runs intermittently, does not display its rated data, and exceeds average fuel consumption. Therefore, there is a need to check the compression in the cylinders, and this can be done with your own hands, without having unique knowledge.

Methods for checking compression in cylinders

You can measure pressure in the field with only a set of wrenches and a rag on hand. But such a measurement will only answer the question of whether it is present in the cylinders or not.

It is impossible to measure compression correctly and set its exact value. Checking engine compression is a simple procedure that you can do yourself.

However, this will require a special device - a compression meter.

Devices for measuring compression

To check the compression value in the cylinders we need a compression gauge. This is a device consisting of several parts. These include:

- special pressure gauge. It is better to take a part with a scale marked from 0 to 35 Bar. This parameter can be measured in atmospheres, kgf/cm2. or MPa, but the generally accepted unit of measurement is Bar, equal to 0.99 atmospheres;

- a flexible hose that screws directly into the pressure gauge. Equipped with a pressure relief valve. This will help measure compression on both gasoline and diesel internal combustion engines;

- one or more attachments that are screwed into the engine in place of the spark plugs;

When choosing a product on the market, it is advisable not to buy the cheapest meters. As a rule, their durability is short. But if you are not a car mechanic and do not plan to use the device often, purchasing a professional kit is also pointless. You should pay attention to models in the mid-price segment. The price of such devices is 750-1100 rubles.

| ZMZ-406 | 510 |

| Will measure | 625 |

| Avtodelo | 670 |

| Friend PRO | 750 |

| Friend | 1100 |

| FuelMerPro VAZ, GAZ TopAuto | 1290 |

| JTC | 3135 |

Preparing the engine for measurements

The operating instructions for the VAZ 2106, 2107, 2108 models do not contain specific recommendations after what mileage it is necessary to measure compression.

However, it is worth making it a rule to carry out this procedure along with replacing the candles. Standard spark plugs last 15-20 thousand km.

When replacing parts, it would be useful to measure the pressure in the cylinders - this will help to identify malfunctions in time. There are signs when this procedure should be carried out earlier:

- the engine does not start well when cold;

- the motor does not produce the required power and traction characteristics;

- one or more cylinders do not work (troit);

- increased fuel consumption;

- The oil guzzling has begun, and bluish smoke is pouring out of the exhaust pipe.

Before measuring compression, you need to prepare the engine. It should be heated to an operating temperature of 70-90 degrees. If it is a two-stroke boat unit - up to 60-80 degrees. We stock up on a standard set of keys, as well as a special spark plug attachment. Now everything is ready for measurements.

Instructions for checking engine compression

The following provides step-by-step instructions for determining compression on a gasoline carburetor or injection engine.

- Warm up the engine.

- Remove the spark plugs from the spark plugs.

- For models with a carburetor, you need to reset the switch terminal.

- Disconnect the fuel pump hose to prevent the supply of fuel to the combustion chambers. You can take measurements without disconnecting the fuel line, but then gasoline will get on the cylinder bore and can remove the oil film, which will subsequently lead to scuffing.

- We unscrew all the spark plugs from their seats to provide the crankshaft with minimal rotational resistance.

- Screw the hose of the measuring device into the threaded connection.

- The assistant sits behind the wheel, presses the gas pedal all the way and turns the starter. The pressure gauge needle will begin to oscillate and stop at a certain position. To correctly determine compression, you need to limit yourself to the first four strokes. That is, the engine must complete one working cycle. With the engine running, the exhaust valve will then open and the pressure will drop. Therefore, even a faulty unit can “inflate” good values.

- We check all four cylinders and analyze the results.

The procedure for determining compression on diesel units is fundamentally similar to the instructions, but there are several points:

- Diesel engines have glow plugs. Compression must be checked through these technological holes.

- Power is supplied not by a carburetor or injector, but by a high-pressure fuel pump (HPF). If the engine is equipped with an archaic mechanical injection pump, then you can use a shut-off valve and then remove the fuel line. To turn off an electrical device, simply remove the corresponding fuse from the unit.

It is also possible that it is simply impossible to measure compression on a hot engine. This happens when:

- the car simply won’t start;

- The motor has been removed from the vehicle.

In this case, you have to measure the compression when cold. If there is no battery, a starter is connected. The procedure is absolutely no different from the one described above. However, the readings of the compression device will a priori be lower due to the presence of thermal gaps in the motor. It is worth subtracting 25-30% from the optimal value.

If you don’t have specialized instruments at hand, you can check for compression at home. A thick rag is inserted into the spark plug well and the starter is turned. A working engine with proper compression will simply push it out due to the created pressure. Some craftsmen even create their own homemade compression meters, but their serviceability is questionable.

The video below will help you understand all the nuances of the procedure in more detail.

Data analysis

If you do everything correctly, you will be able to take correct values. Different types of engines have their own standards, with which it is worth comparing the results obtained.

Motor typeMinimum value, BarOptimal value, Bar| Old gasoline engines with a compression ratio of up to 8.5 | 11 | 13 |

| New engines, with a compression ratio of 8.5 | 12 | 14-15 |

| Diesel units | 22 | 30 |

Troubleshooting

Now we know how much Bar should be in the cylinders. If the compression measurement shows lower values, then it is necessary to troubleshoot the parts of the cylinder-piston group.

- The most harmless is the occurrence of piston rings after inactivity. It is treated by simply pouring decoking agent into the spark plug channels with a syringe;

- piston burnout. Diagnosed by probing the piston head with a thin wire through the hole;

- deformation, burnout or stuck valve. The cylinder simply does not work at low speeds, and the pressure value is critically low;

- worn rings and valve stem seals. Diagnosed using a nutrometer. Signals include increased oil consumption or blue exhaust smoke;

- a crack in the bridge or a chip in the piston. The oil enters the combustion chamber, where it burns, producing bluish exhaust smoke. The part must be replaced.

Of course, when serious breakdowns are diagnosed, the car body should be sent for service and defective parts should be replaced, but timely diagnosis will help to avoid unnecessary expenses. And measuring compression in the cylinders is just such a procedure.

Source: http://DaciaClubmd.ru/repair/engine/kak-proverit-kompressiyu

Checking compression in cylinders yourself

Compression translated from Latin. means compression. For motorists, cylinder compression is the pressure at the end of the compression stroke. The first and most important reason for checking compression in the cylinders is to diagnose the condition of the car engine without disassembling it.

How to check compression in cylinders with your own hands

The pressure in an engine cylinder is a meaningless number for an amateur or amateur. An experienced auto mechanic, having measured the pressure in the engine cylinders, will determine with fairly accurate parameters the degree of malfunction and wear of parts of the valve mechanism and connecting rod-piston group of the engine.

Let's start with the fact that compression testing should be carried out in several cases. Your engine power has dropped, you have carried out a major overhaul of the cylinder block or repair of the cylinder head, which means checking the compression in the cylinders is a sacred matter. In the first case, the compression in the cylinders is checked necessarily, and in the second for control.

How to check the pressure in an engine cylinder

Taking into account the fact that you do not run a service station, you need a compression gauge. Modern samples of compression meters are equipped with the latest technology. The kit includes adapters (adapters) that allow you to check compression in engine cylinders on cars of any make (model).

Motor testers and compressors, in fact, should not interest you. These are devices for commercial use in car repair shops.

In addition to the device, you will need a manual specifically for your engine type, which shows the parameters of standard compression values.

The procedure and rules for checking compression in the cylinders of any car manually are, in principle, no different.

- checking compression in the cylinders is carried out on a “warm” engine;

- first turn off the fuel supply to the engine (turn off the fuel pump, injectors);

- Let's turn everything out! Candles, and not selectively, as some would-be masters practice;

- a prerequisite is a fully charged battery and a working starter;

- The compression test can be carried out both with the throttle valve open and with the throttle valve closed. Each of these methods will show different results of the engine condition. When the damper is open, defects such as: piston burnout, coking of rings, burnouts or deformation of valves and scuffing on the surface of the cylinders are quickly determined; When the damper is closed, a change in the compression level most often indicates engine malfunctions such as: valve sticking, leakage due to a crack in the wall of the combustion chamber or burnout of the cylinder head gasket;

- We begin to check the pressure in the engine cylinder, one by one. Using the starter, crank the crankshaft until the pressure stops increasing. We record the testimony. We reset and do the same with all cylinders.

The compression in the cylinders has been measured, and what should we do with these numbers?

The first thing you must understand is that measurement results are a relative category. You are interested in the difference in readings for different cylinders, but not in the absolute value of compression. This way, you can quickly determine which cylinder is faulty.

Reduced pressure in any engine cylinder indicates that, most likely, the piston rings are burnt or the valves are not seated tightly in the seats.

In any case, it's time to roll up your sleeves and start repairing the engine.

Good luck, and may the compression in your car’s engine always be normal.

Source: https://carnovato.ru/kompressija-cilindrah-davlenie-proverka/

How to check engine compression yourself

Checking engine compression is one of the methods for diagnosing malfunctions in a car engine, or more precisely in its cylinder-piston group (CPG).

Such a check will not immediately identify the malfunction, but still incorrect pressure readings that differ from the nominal ones will allow us to conclude that something is wrong and a more in-depth check of the operation of the car’s piston group with more specialized equipment is necessary.

The main symptoms of negative processes occurring in the CPG are:

- Sudden loss of engine power;

- One of the cylinders has stopped working - the engine “troubles”, increased engine vibration is felt;

- Increased oil and fuel consumption.

In most cases, replacing the ignition system plugs solves the problem, but if this does not help, then it is worth measuring the compression of all engine cylinders. And so, let’s get started, now we’ll find out how to check engine compression with our own hands, in detail

A little theory

Compression is the highest indicator of pressure in the cylinders, which is measured at idle without starting the engine. The engine is cranked using an electric starter or a crooked starter (last century). A compression meter is used to measure compression.

The principle of operation of the compression meter

To carry out measurements, the spark plug is unscrewed and a threaded tip is screwed in instead or a non-threaded tip is pressed, it all depends on what model of the device you have.

When the cylinder moves in the engine, air enters the hose under pressure. When the pressure in the cylinder has reached its maximum, this value is recorded by a pressure gauge.

Despite the fact that this device is easy to use and affordable, this does not give reason to think that measuring engine compression is a simple matter.

Any indicators of a compression meter require analysis and a final verdict only from a specialist who knows exactly in what situations it is worth believing the readings of the device and taking action, and in what cases these indicators are purely informative.

In order to find out what compression should be in the engine cylinders of your particular car model, you should refer to the technical documentation for the car and find out the compression ratio.

Having found out the compression ratio, we multiply it by 1.3 and get an approximate indicator of the compression value.

But it should be understood that modern compression meters cannot carry out perfectly accurate measurements and, like other devices, they also have errors (up to approximately 3 atmospheres).

Also, compression level readings depend on factors such as:

- Quality of fuel and its octane number;

- Oil viscosity;

- On the degree of engine warm-up;

- Battery charge levels.

Therefore, the analysis of the obtained measurements is not based on standard indicators (although they are also partially taken into account), but a comparative analysis of compression readings in all engine cylinders is carried out, but more on that a little later.

Choosing a compression meter

A very important point is which engine is installed in your car, gasoline or diesel.

Gas engine

In this case, it is enough to purchase an inexpensive compression gauge with a threaded tip that can be screwed into the spark plug hole. If there is a tip without a thread, then you will have to press it in, but this is not convenient and the readings of the compression meter will not be accurate.

Pay attention to the position of the pressure release valve. In high-quality compression gauges, it is located directly in the tip, which is inserted into the spark plug hole, and not under the pressure gauge itself. This will allow you to get more accurate measurements, without underestimating the readings.

Diesel engine

In this case, the situation is much more complicated and it is not recommended to carry out such measurements yourself for several reasons:

- It is necessary to remove the glow plugs or injectors. Not every driver can do this and not everyone has a special tool to perform such work;

- You will need a special adapter, which is purchased separately or may already be included in the kit of expensive compression meters.

In this case, it is better for you to contact a car service.

You can purchase an imported compression tester, which is initially equipped with a large number of adapters for various brands of cars, but such a kit is not cheap and is used mainly in car repair shops.

Alternative

Compressographs

A more complex, convenient, but not much more effective device. The main difference is the ability to record the received data on plastic cards or paper at different periods of time and subsequently analyze them.

But if you want to track the increase in pressure over time, it will be difficult with this device. This is the main disadvantage of the compressograph.

Motor testers

They are the most modern instruments for measuring engine compression.

Their operating principle is not based on fixing the pressure in the cylinders, but on measuring the pulsation of the current consumed by the starter.

The strength of the current consumed is directly proportional to the increase in compression in the cylinders and the increasing load on the engine crankshaft.

The main advantage of this device is that in just a few minutes you can take readings from all cylinders without unscrewing the spark plugs.

However, readings in this device are taken not in pascals, but in percentage terms. The cylinder that works more efficiently has a higher percentage.

Reasons for decreased engine compression

There are many factors that influence the reduction of engine compression. Let's look at the main ones.

Air quantity in cylinders

A high compression ratio is directly proportional to the amount of air entering the engine cylinder; a decrease in air volume, accordingly, leads to a decrease in pressure in the cylinders when they reach TDC (top dead center).

Reasons for reducing the volume of air in the cylinders:

- Changing the throttle position;

- The air filter is clogged.

Setting the valve timing

Errors in setting the valve timing can lead to changes in the closing and opening times of the exhaust valves, which leads to a shift in one direction or another when the maximum pressure in the cylinder is reached, and accordingly the compression will be different.

Such errors, as a rule, are the result of incorrect installation of the camshaft drive belt, so entrust this work to specialists.

Valve drive clearances

Incorrect adjustment of the valve drive clearances in any case leads to a decrease in engine compression, so do not forget to carry out such adjustments, on average, after 10 - 20 thousand kilometers.

Engine temperature

The better the engine warms up, the higher the air pressure in the cylinders, since hot air expands and has a larger volume. When the engine cools, the cooled air is compressed accordingly and the compression decreases.

Air leaks

Compressed air tends to leave the cylinder, and this is natural. Accordingly, air leakage is possible through anything that is not hermetically sealed.

Consider the situation of loss of compression due to air leakage.

In order to identify the cause, you must do the following:

- Align the cylinder slightly short of TDC;

- Put the car on the handbrake and engage either 4th or 5th gear;

- Open the oil filler neck;

- Direct a stream of compressed air into the cylinder with a pressure of at least 2, but not more than 3 atmospheres. To do this, you can use either a compressor or an inflated car bladder.

What to pay attention to:

- Hissing and air escaping through the spark plug hole located nearby, which indicates a “breakthrough” of the cylinder block gasket;

- The intake valve is not tightly closed if air hissing from the carburetor is released;

- Air leaking out of the oil filler neck means things are bad. This means that either the piston has burned out or a crack has formed in it;

- If air comes out through the exhaust pipe, check the exhaust valve, it is most likely burnt out.

Also, minimizing air leakage is achieved when:

- The cylinder is completely round, without scratches on its surface;

- The valves are perfectly ground and fit securely to the seats;

- The piston ring locks have minimal clearances;

- The piston rings seal tightly against the cylinder liners and lie tightly in their grooves.

From words to deeds

Before checking engine compression, you need to prepare the car.

To do this you should:

- Warm up the engine to 80 - 90 degrees, this can also be done on a cold engine, but more on that later;

- Turn off the fuel supply to the cylinders. For your decision, for example, turn off the fuel pump;

- Be sure to turn out ALL the spark plugs, not just a few, but ALL of them, this is important;

- Check the battery charge, it should be fully charged.

Engine compression can be measured in two ways:

- With closed throttle;

- With the throttle valve open.

In the first case, the pressure in the cylinders will not be high, in the range of 0.6 - 0.8 MPa, since air will not flow in large quantities. Therefore, compression in our case will decrease if the slightest misdensity exists in the system. This will allow us to identify hidden defects in the CPG.

In the second case, the air flow will be large, and accordingly the pressure in the cylinders will increase and can reach 0.8 - 0.9 MPa.

The second method is more suitable for identifying serious malfunctions in the engine, which we have already written about above, see Air leakage.

But, no matter what method you use, you need to remember one important nuance - watch the rate of increase in pressure, as this is a kind of “litmus” when diagnosing breakdowns.

For example, if the pressure gauge reading on the first stroke, during measurement with a compression meter, was equal to 0.3 MPa, and then sharply jumped up on the next strokes, 99.9% this is a problem with the piston rings.

A radically opposite situation also occurs, when the pressure gauge readings at the first step during measurements are 0.8 MPa, and then do not increase. In this case, you should pay attention to the integrity of the head gasket or the serviceability of the compression gauge valve.

Naturally, after this testing stage, other diagnostic tools should be used to ensure more reliable detection of faults.

Measurement on a “cold” engine

If there is a problem with starting the engine, or the car does not start at all, then the engine compression can be checked “when it is cold”.

We take a gasoline engine. In this case, if, when checking for a “cold” engine, the compression level indicators are at least two times lower than optimal, compared to checking on a warm engine, and this is in the range from 4.5 to 5.5 atmospheres, then this is primarily due to the presence of the rings in the pistons, which is already a malfunction.

We take a diesel engine. It is not a fact that you will perform the check, but you need to know that it is not possible to start a diesel engine if the compression readings in it are no more than 17 atmospheres. And if not more than 24 atmospheres, then you cannot do without a major overhaul of the diesel engine.

Also, when checking compression in a diesel engine, do not allow the presence of oil in the cylinders, let the engine settle so that the oil flows into the crankcase, then the pressure gauge readings will be realistic.

Analyzing the results obtained

Analysis of the results obtained comes down to comparing the pressure gauge readings in all cylinders. It is worth paying attention to the cylinder whose pressure level differs from the pressure readings in other cylinders; it can be either less or more.

If the difference in readings does not exceed one atmosphere, then there is no point in sinning on the CPG. Return to diagnosing the car's ignition system, check the spark plug. Also check the fuel supply to the cylinders.

Indications in more than one atmosphere are also typical for cars with a mileage of more than 50 thousand km.

The reason for the distinctively higher pressure in the cylinder may be the presence of a large amount of oil in it, the cause of which must be clarified separately. Turn out the spark plug and see if it is in oil, then this is our case.

Main regulatory indicators

All necessary data can be taken from the maintenance documentation for a particular car brand.

Basic data, taking into account testing only on a warm engine, is presented below.

Standard compression level:

- Modern gasoline cars that are filled with A-95, 98 gasoline - from 11 to 14 atmospheres (range of readings from 0.5 to 1.0 atmospheres);

- Old cars filled with gasoline A - 80, A-92 - from 9 to 10 atmospheres (range of readings from 0.5 to 1.0 atmospheres);

- Modern diesel cars - about 45 atmospheres (range of readings from 2 to 3.0 atmospheres);

- Old diesel cars - about 28 atmospheres (range of readings from 2 to 3.0 atmospheres).

Depending on the installed diesel engine, standard readings can vary from 28 to 45 atmospheres.

By checking engine compression, the following faults can be diagnosed.

Let's sum it up

When checking engine compression, try to adhere to the rule that all data obtained during measurements will be only relative. Yes, they should be taken into account during the analysis, but the main thing for you will be a comparative analysis of the data taken from each cylinder.

The difference in values will be a fundamental factor for you in identifying a faulty cylinder and quickly carrying out other necessary diagnostics to identify the causes of the malfunction.

And in order to rely on the absolute standard compression value, it is necessary to have data from early measurements taken at different times during the vehicle’s operation, which is not always done.

Moreover, the data archive, in addition to the results of basic measurements, should contain: under what temperature conditions the test was carried out, temperature and oil viscosity, vehicle mileage and its general technical condition, etc.

Source: http://x7.by/remont/98-kak-proverit-kompressiyu-dvigatelja-svoimi-rukami.html

How and how to check the compression of a car engine with your own hands, the differences between gasoline and diesel, what is the norm, etc.

Compression testing is a common method for diagnosing the technical condition of an engine.

By determining the pressure level, the degree of wear of the cylinders, pistons and rings, as well as the valve group, is determined.

Many motorists are aware of this method, but not everyone knows that you can check the compression yourself. Based on the results, preliminary conclusions are drawn about the “health” of the engine.

General concept of compression

Among car enthusiasts, compression is often confused with the compression ratio specified in the car's operating instructions. These are different concepts, although there is some connection between them.

Compression is a variable value that reflects the actual pressure in each cylinder, measured when the crankshaft is rotated by the starter. It is never indicated in the vehicle’s technical passport, since it depends on a number of factors:

- tightness of cylinder-piston (CPG) and valve group seals;

- engine temperature;

- starter rotation speed and battery charge;

- the presence of motor oil in the work area where fuel combustion occurs.

Based on the actual pressure in the cylinders, it is customary to judge the degree of wear of the CPG and the condition of the valves. The lower the compression values, the worse the conditions for burning gasoline in the chambers. The air-fuel mixture does not burn completely and releases less energy, and engine power decreases.

The compression ratio is a constant characteristic equal to the ratio of the working volume (the internal size of the cylinder along with the combustion chamber) to the piston stroke length. It shows how many times the combustible mixture is compressed before the outbreak.

If the compression ratio is a dimensionless quantity, then compression is measured in units of pressure. The most common in the post-Soviet space is 1 physical atmosphere (Atm), but others are also found in modern pressure gauges:

- 1 Bar (equal to 0.99 Atm);

- 1 MPa (9.9 Atm);

- 1 kgf/cm2 (0.97 Atm) - used in Soviet times;

- 1 psi (0.068 atm).

Since compression measurement is always carried out with a certain error, differences in hundredths between the first three units are usually ignored.

Compression standards in engine cylinders

To assess the technical condition of the power unit, you need to know what compression values are considered normal, because engines are different.

As a result of repeated practical measurements made over many years, the following relationship between the compression ratio and the measured pressure was revealed: when taking measurements on a car with a hot engine, a working starter and a fully charged battery, the minimum permissible compression value is equal to the nameplate compression ratio multiplied by a factor of 1 ,3.

In numbers for different engines this is expressed as follows:

When the piston group of a car is severely worn out or the valves are burnt out, the compression in the “sick” cylinders drops below the permissible values indicated in the table.

If, for various reasons, a large amount of motor lubricant gets into the CPG, then all the gaps become sealed, and the pressure rises above normal.

This phenomenon can mislead an inexperienced motorist who undertakes diagnostics.

A difference in cylinder performance exceeding 1 bar is also unacceptable. It indicates that one or more components of the CPG are not operating at full capacity, or are even inactive, increasing fuel consumption by 10-25%.

Compressometer - a device for measuring pressure with your own hands

Measurements are carried out with a special device - a compression meter, consisting of the following elements:

- pressure gauge with threaded fitting;

- steel tube or flexible hose with built-in check valve and air release button;

- a nozzle for screwing into a cylinder, equipped with adapters for other threads or a rubber cone.

Compression gauge complete with various attachments and adapters

The pressure gauge is screwed into a tube (flexible hose), and a threaded tip is installed at the other end. The check valve serves to record the pressure gauge readings, because when checking, the piston “pumps up” pressure over several revolutions of the crankshaft (about 10).

To analyze power units running on gasoline and diesel fuel, pressure gauges with different measuring scales can be used. If for gasoline engines a device designed for 20-25 Bar is sufficient, then for diagnosing a diesel engine a scale of at least 50 Bar is required.

How often should compression ratio be measured?

The exact frequency of checking compression of power units has not been established. There are symptoms that indicate the need for measurements:

- one or two cylinders are not working well, causing the engine to shake and “trouble” even at idle;

- there was a significant consumption of engine oil (over 100 g per 1 thousand kilometers);

- engine power has dropped;

- bluish or white smoke comes out of the exhaust pipe;

- Cold starting is difficult.

Conditions for successful measurement

To successfully diagnose a gasoline engine, the following conditions should be organized:

- the engine is warmed up to an operating temperature of 70-90 ° C;

- the battery is charged and the starter easily rotates the crankshaft;

- fuel supply is turned off;

- spark plugs are unscrewed.

For the procedure, you need to attract an assistant who will turn on the starter and press the gas pedal to ensure air supply to the cylinders.

On a gasoline engine, you need to unscrew the spark plugs.

Before unscrewing the spark plugs, it doesn’t hurt to blow out their wells to avoid dirt getting into the combustion chambers. Instead of spark plugs, the tip of a compression gauge is screwed into the holes one by one. Another way is to press the device against the hole manually, after putting on a rubber cone.

Unlike a gasoline unit, a diesel engine should be checked in a cold state, since its successful starting largely depends on the presence of compression. You will have to screw in the tip instead of the dismantled injectors or glow plugs - for this you need to use the appropriate adapters from the kit.

How to correctly measure compression on a gasoline unit

Before measuring pressure, you should perform the following steps:

- Warm up the engine.

- Remove the high-voltage wires from the spark plugs and put them aside. In some imported car models, you will have to remove the ignition coils to gain access to the spark plugs.

- In older cars with a carburetor, you need to disconnect the switch connector.

- Stop fuel supply. On carburetor versions this is done by removing the hose going to the mechanical fuel pump. The electric pump that powers the injection motor should be de-energized by removing the corresponding fuse.

- Unscrew the spark plugs and wipe the seat sockets.

Pressure measurement starts from the first cylinder

Measurements are taken in each cylinder in turn. The inspector screws in the tip of the device and gives a command to the assistant, who turns on the starter by pressing the accelerator pedal all the way. When the pressure gauge needle begins to fluctuate in one place, you need to turn off the ignition and record the readings. After which you can move on to the next cylinder.

1.4 MPa is an excellent compression indicator for a gasoline engine

How to measure compression: video

How to determine compression on a diesel engine

The process of measuring compression on a diesel engine is no different from diagnosing a gasoline power unit, only the readings from the device will be higher. The difference lies in the preparation, at the stage when it is necessary to cut off the flow of fuel. Depending on whether the car has an old mechanical pump or a new electric injection pump, the fuel supply must be turned off in one of the following ways:

- On mechanical injection pumps (high pressure pumps), a shut-off lever should be used to shut off the fuel. Then you need to disconnect the fuel line.

- Electric pumps are de-energized by removing the fuse or disconnecting the connector.

It is better to check a diesel engine “cold”. If the device shows pressure below 22 Bar, it will be difficult to start the engine, especially in winter. To start diesel engines with an unsuitable piston group, a radical method is used - pouring 4-6 ml of oil into the cylinders, which helps seal the gaps and increase pressure.

Instructions for checking compression “at home”: is it possible to do without a pressure gauge and other equipment

When there are no measuring instruments available, experienced motorists use the “old-fashioned” method. It is impossible to obtain accurate readings with its help, but determining whether there is compression in the cylinders is as easy as shelling pears. The verification procedure is as follows:

- Turn off the fuel supply and disconnect the high-voltage wires.

- Remove the spark plugs.

- Take a piece of thick fabric without protruding threads, roll it into a ball and insert it shallowly into the candle hole.

- Crank the crankshaft with the starter.

If pressure is present, then when the shaft rotates, the cylinder will “spit out” the rag. Otherwise, it will remain in place, only a slight hiss will appear.

Compression assessment without a compression meter: video

Exceptions to the rules: when you have to measure pressure on a cold engine

Sometimes it is necessary to evaluate the condition of the CPG and valves under exceptional conditions. For example, on a “cold” engine, compression measurement is carried out if:

- the car does not start initially;

- the power unit has been removed from the vehicle;

- There are doubts that there is enough pressure to start.

A separate case is checking a dismantled engine. At dismantling sites, you often find units in excellent condition that can serve the next owner for a long time.

Before purchasing a motor, the condition of the CPG is diagnosed. If the assembly is removed along with the starter, compression is measured in the usual way, only “cold”.

To rotate the crankshaft, you need to connect a working battery to the unit, and check the pressure with a compression gauge.

A CPG without a starter is tested with a pneumatic tester. This device is a manifold with an air regulator and two pressure gauges connected to the compressor by hoses.

The principle is simple: air is supplied to the cylinder at a certain pressure, which is displayed on the first pressure gauge. The second device shows the total amount of leakage through leaks in valves and pistons.

If the loss value is within the normal range, the engine can be purchased.

Checking the engine without a car: video

What to do if diagnostic results are disappointing

When the pressure in one or more cylinders deviates from normal, you are dealing with a malfunction of the power unit. As a rule, such problems require partial or major repairs of the “heart” of the machine. If the indicators are too low, the following breakdowns are possible:

- Wear of rings, pistons and liners (with the same values on all cylinders). The “diagnosis” can be clarified if a second measurement is taken with the addition of 4-5 ml of motor oil to the cylinders. Increasing the compression will confirm the result. If the readings do not change, then the following problem occurs.

- The presence of leaky valves in the chambers (at different values).

- One of the valves or pistons is burnt out (no pressure at all).

Piston burnout in the center (left) and side (right)

A pneumatic tester can provide more accurate results. The breakdown is detected as follows: if air goes into the crankcase, then the pistons pass, and if it goes into the manifold, the valves.

Malfunctions associated with a drop in compression below normal are eliminated by disassembling the power unit and replacing worn parts.

There is no point in changing one valve, since over time the next one will fail. It is better to install a new valve group.

The same applies to pistons - a set is installed at once, and the parts are selected by weight so that the difference is no more than 5 g. Fitting is done by removing a thin layer of metal from the inside of the heaviest pistons with a scraper. If, after removing the block head, the measurement showed a large ellipse-shaped hole in the cylinders, then they should be bored on a machine to the next repair size.

If you do not respond to a drop in compression below normal in a timely manner, the consequences may be as follows:

- cold starting the engine will become more difficult, and then completely impossible, without injecting oil into the cylinders;

- consumption of motor lubricant due to waste will increase to 1-1.5 liters per 1000 km, which may cause spark plugs to fail and rings to become coked;

- due to the large difference in compression in the cylinders, the engine will operate unstably and vibrate;

- fuel consumption will increase significantly;

- the power of the power unit will drop to such an extent that driving will become impossible.

This is what a burnt valve on the side looks like

The reason for excessive compression is the presence of motor oil in the combustion chambers in large quantities, which leads to compaction of all gaps. The problem arises due to unsuitable oil reflecting caps, when lubricant enters the chambers not from below, but from above, through the valves. This problem is considered relatively harmless: oil deflectors are replaced in 2-3 hours, depending on the make of the car.

Compression measurement continues to be one of the simplest and fastest methods for diagnosing power units. When engine problems occur, the first thing you need to do is check the pressure. And based on the test results, you should decide on the further sequence of actions: carry out more in-depth diagnostics or disassemble and repair the motor.

Source: http://autoclub.su/izmerenie-kompressii-v-cilindrax-dvigatelya-proverennaya-metodika-obnaruzheniya-neispravnostej-svoimi-rukami/