DIY giant wheels

“If they don’t let you in at the door, then we’ll go in through the window.” Agree, every car owner wants his steel horse to drive exactly according to this principle: to easily overcome any obstacles and confidently cope with even the most difficult road conditions.

It’s easy to turn an ordinary car (and even a motorcycle!) into an all-terrain vehicle. “Re-shoe” her. “Sit” the body on huge wheels and any swamp will be on your shoulder. “Such specialized tires can cost as much as part of a new car,” you say. “Save money and do it yourself!”, we will answer.

How to make low-pressure tires with your own hands? Let's talk about this today.

UAZ on low pressure tires

You've probably seen cars with hyperwheels on the roads or at least on TV. These tires are called low pressure tires. Most often they are installed on fishing, military and agricultural equipment. Large tires are also used by hunters and travelers, and lovers of extreme recreation.

Remember what ATVs or snowmobiles look like? These are the tires we are talking about. The pressure in such tires is low - 2–4.25 kg/cm². It helps ensure that the weight of the machine is equally distributed across all wheels (depending on the number), thereby reducing the pressure of the unit on the ground.

In fact, the name of the rubber duplicates its main feature - due to the low pressure, such wheels resemble cushions for cars, which give the unit the properties of high cross-country ability.

Such rubber has minimal impact on the surface, which is why it is able to move so deftly off-road.

Interestingly, grip does not suffer, and the efficiency of low-pressure tires is almost 20% greater than that of standard rubber.

Tire range

There are several types of low pressure tires. They differ in functionality and construction (shape).

- Arched tires are 2–5 times wider than standard ones. Thickness - up to 700 mm. Outwardly, they look like barrels. These tires are the kings of off-road driving. And the pressure in them is no more than in a simple toy ball.

- There are oval tires that are called wide-profile. The pressure in such tires is almost two times lower than in standard wheels. They are good for lifting machines.

- There are tires with a medium profile , where the circumference is almost identical - 0.95–1.15. These are toroidal tires , which can be tubed or tubeless. (One of the most affordable types of low pressure tires).

- Pneumatic rollers are very durable, rigid wheels. They are specially equipped with lugs that increase cross-country ability.

If you can't buy it, do it yourself

Indeed, such tires can cost as much as half a car. Therefore, homemade low-pressure tires are a real solution for those who want such tires, but are not ready to pay the full price.

How to make low-pressure tires yourself and what is needed for this? The work is divided into two stages. We create the tire itself and the metal base on which it is attached.

First, let's look at the sources. The basis for the manufacture of low-pressure tires is most often used tires from industrial, agricultural or aviation transport. Truck tires are also suitable. These wheels will become the “foundation”.

And then we have to get rid of excess rubber from the tread and on the sides. The cores inside need to be removed. You may even have to remove some of the cord. The main thing is to make the tires lighter and get rid of everything “extra”.

Before starting work, be sure to wash and dry the wheel.

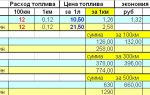

When making low-pressure tires with your own hands, you need to understand where they will be used.

After all, for example, a high, self-cleaning tread is better suited for driving on very dirty roads.

For peat bogs, on the contrary, you need to lower the tread grooves so as not to lose traction. Wheels ride better on sand and snow, where the elements of the pattern are very closely adjacent to each other.

Airplane tires can be used to make low-pressure tires

Homemade training

For those who will be making homemade low-pressure tires for the first time, it is advisable to have one or two more original wheels. First of all, just in case.

And secondly, it wouldn’t hurt to practice first. Before you start peeling off the tire layers, it is advisable to cut open an experimental wheel and examine “what’s inside.”

It is important to understand the depth of the layers and try to bite off the rubber and pull out the wire threads.

Studying the instructions

What tools will be needed? The set is ordinary: knives and a sharpener, an awl, a hammer, wire cutters and a winch. So, the tools are ready, the source code is already in the garage. It's time to get to work, as a result of which we will get homemade low-pressure tires.

Step 1. Essentially, we will cut out the new tread pattern, so we mark the pattern itself on the wheel with a marker.

What pattern should I apply? It all depends on your imagination and on what “feats” you expect from new wheels. Most often, car enthusiasts draw a “Christmas tree”.

Step 2. Next, we make a cut in a circle inside the wheel, which will allow you to remove the wire. We mark and cut out small rectangles along the inner circle. Through them you can see the same wire that we pry up and pull out with the help of a winch.

Step 3. Based on the created tread pattern, we make side cuts along the perimeter of the circle. We grab the rubber that protrudes at the place of the cut with pliers and pull it with a winch so as to “pull out” the extra layer of the wheel (according to the picture). According to the drawing, we cut the drawn piece with a knife.

Step 4. So we remove the rubber from the tread and sidewalls layer by layer.

Step 5. Clean the surfaces with sandpaper and straighten them with a hammer if necessary. The camera is ready.

Step 6. We assemble a new frame by connecting the disk and plates using welding and metal tubes. We grind the welding areas.

Interestingly, you can also make rims for low-pressure wheels yourself. For example, from an old aluminum basin. And they are attached using a conveyor belt or a fire hose.

Step 7. We put the camera on the frame and pump it up.

Step 8. Install the tires on the car.

Step 9. Let's go off-road!

Big wheels mean big road

Know that giant wheels and super cross-country ability are not a guarantee of safety. On the contrary, driving a car on such tires is not easy. Avoid driving on hard and smooth surfaces. Turn especially carefully and carefully. The sides of low-pressure tires wear out quickly, so there is a risk of skidding. Take care of yourself and remember: big wheels make a big difference!

Source: http://365cars.ru/tuning/kolyosa-gigantyi-svoimi-rukami.html

How to make low-pressure wheels with your own hands, rims

Using the right tires is one of the main conditions for good cross-country ability for any all-terrain vehicle. Since the cost of a specialized kit, often manufactured in small batches or even to order, cannot be called humane, let’s look at how to make low-pressure wheels with your own hands. In the video we will demonstrate the process of transforming standard truck tires into tires.

Feasibility of installation

Let's look at the features that make low pressure tires so effective:

- light weight compared to conventional off-road tires of comparable dimensions. Thanks to this internal combustion engine, it is much easier to turn the wheels, which equates to an increase in torque without changes to the engine or transmission;

- increased contact area with the road surface. As you know from a physics course, the larger the area over which the mass is distributed, the less pressure on the surface at each point. This is what determines the use of low-pressure wheels on swamp and snowmobiles. A similar effect is used in agricultural machinery, where excessive load on the soil is harmful to crops. At a certain ratio of the mass of the vehicle, the displacing area and the amount of air placed in the tire, the car becomes buoyant.

The only noticeable drawback of low-pressure tires is their vulnerability to punctures by sharp objects. This disadvantage is due to the high elasticity of the rubber, which is an additional advantage when overcoming off-road conditions.

Design options

Since in our case we are interested in the process of making all-terrain tires with our own hands, we will not dwell on factory design options. Types of low-pressure tires that are available for self-production:

- a tube made from a tire of the required size is used as a base. In this case, you can completely make the disk yourself or retrofit the finished wheel with the necessary stops and fasteners. Since the chamber is very elastic, it needs additional support, which will prevent it from breaking under lateral loads. Along the perimeter of the contact patch, the camera is tied with pieces of dense material or chains, which is necessary not only for attaching the camera to the disk, but also to create the effect of lugs. The ability to cling is important not only on sand, loose soil or snow, but also on water;

- Low pressure hydrators. Truck tires are used as a base, from which part of the tread and profile layer is cut off. As a result, the tire becomes lighter and acquires additional elasticity. To reduce the risk of disassembling the wheels when driving at low pressure, as in the previous case, it is necessary to make an additional side stop. We'll look at how to make the pads, as well as the design of the disc, in the photos and videos below.

Chamber version

First of all, you need to select or grind your own discs that will fit the parameters of the hubs of your vehicle. What to do if you need to adjust the width of the disk to the camera:

- cut the disk, cutting out the inner part of the required size, then welding the disks again if it is necessary to reduce the seat size;

- if the width needs to be increased, then a part of another disk is welded between the two cut halves. These wheels can be made to order for you, since making welding joints is a fairly common service.

To manufacture the type of low-pressure wheels we have chosen, metal rods will be required (the safe thickness depends on the size of the chamber, as well as the frequency of the jumpers).

The side supports are welded to the base of the disk, and then transverse jumpers are attached to them, which will be the seat on the disk for the camera.

For improved lateral support, the entire system is reinforced along the inner perimeter of the tire profile with a circular rod.

Some inventors use chains for jumpers that go around the contact patch. The solution is not bad, since it allows you to get additional snow, water and lugs. You can also use tow ropes, which, after tying, will cover the portion of the camera, preventing it from being damaged.

Let's make some refreshments

To make your own low-pressure tires you will need:

- used truck tires (for example, from Gaz-66 or VI-3 tires installed on Kraz 255). If you buy tires specifically for tires, then choose rubber that is not “chewed” inside. Otherwise, after removing the top layer, you will get a weak spot or even a hole that will have to be vulcanized;

- a construction knife and a set of replacement blades, since the construction of the tire uses fairly strong threads that quickly dull the blades;

- a template that can be made from thick cardboard or sheet steel. In order for the tires to be not only effective, but also to look good, the tread must be cut as evenly and symmetrically as possible. You will also need a chalk or marker with which you will outline the template;

- durable clamps. These are often used by straighteners to clamp body panels when restoring damaged cars. An ordinary clamp will do, but in this case you need to act more carefully;

- a manual or mechanical winch, as well as a cable that pulls the cut piece of the tread layer. You can use a manual gearbox or a winch mounted on a vehicle. You won’t be able to manually create force to make the rims, since the layers of rubber are very tightly bonded.

Self-production

To make rims, the first step is to pull out the side metal cord. To do this, make a cut, departing approximately 10 mm from the inside of the tire. Hook the cord with a screwdriver, and then, hooking it with a hook, pull out the metal rim using a winch.

Using a template, apply the future outline of the tread along the entire perimeter of the wheel. Some obradyshas can be seen with the protector left in the center. It is along the contour of the outline that it is necessary to make cuts in the rubber.

For this, it is best to use a construction knife, as you can control the depth of the cut by setting the required blade length. If you are confident in your abilities, you can use a grinder. To avoid cutting through the tire, use the sound as a guide.

As soon as you cut through the rubber layer and reach the metal cord of the tire, the sound will acquire the appropriate color.

Cut the tire profile along the inner perimeter (where the metal wire ring used to be). It is the cut section that must be grasped with the clamp.

Use a winch to create tension, and then use a utility knife to gradually trim off the peeling piece. After stripping the entire tire, you will get strips.

Please note that when tension is created, the tire will tend to lean in, so it is necessary to implement a stop.

Particular attention should be paid to this point if you do the lifting using a winch installed on the car. It is not necessary to create a lot of force for peeling. For extra safety, place an old jacket on the cable, which will serve as a kind of damper if the clamp does break.

Discs

The video clearly shows the process of making discs with your own hands. Since the tire becomes elastic after stripping, it is necessary to ensure good side support.

To ensure that when the pressure decreases, the rims do not deflate and do not tend to be dismantled, a special sealant is used during installation.

If all recommendations are followed, self-made low-pressure tires are practically not inferior to factory-made analogues.

Source: http://AutoLirika.ru/tuning/kolesa-nizkogo-davleniya-svoimi-rukami.html

Low pressure tires

Car enthusiasts have probably come across serial or home-made vehicles with huge wheels installed. Such wheels are produced mainly on special orders.

Such designs are called low-pressure tires, or LHP for short.

Such tires are quite widely used on military vehicles, fishermen, travelers, hunters, agricultural and geological exploration equipment.

The name itself immediately defines the main distinctive feature of these tires - wheels of this type have low pressure, so in appearance they resemble the cushions on which the car moves.

SNDs exert little pressure on the coating, resulting in an optimal effect for off-road driving.

Despite the reduced pressure on the ground surface, the degree of traction still remains high, which allows you to confidently move through rough terrain, swamps and mud.

Numerous studies have shown that low-pressure tires are 20% more efficient than standard tires.

SND have several distinctive features:

- Due to their special design, these tires have an increased area of contact with the surface, thanks to which cars on such tires can overcome almost any obstacle.

- The low specific pressure makes it possible to use such tires on agricultural machinery, since when cultivating the soil it is necessary to ensure minimal loads on the ground. For the same reason, SNDs are used on a variety of all-terrain vehicles.

- Driving a car equipped with such wheels requires special skills. It is recommended to drive on hard surfaces as little as possible and to take turns smoothly, since the side surfaces of the SND are their weakest point and are very unstable to wear.

Depending on the design architecture and functional characteristics, several types are distinguished:

- Arched.

As a rule, this type is used for off-road driving and is installed on the drive wheels. The arched design uses high-profile rubber (thickness up to 700 mm), and the width of the product is 2-5 times greater than in standard tires. In appearance, arched tires look more like barrels than regular summer or winter tires. The working pressure inside them (on average 0.05 MPa) is no more than the pressure in an ordinary children's ball. - Wide-profile. These SNDs have an oval profile, and their design features allow them to be used at different operating pressures. On average, the pressure in them is 1.5-2 times lower than in standard ones. One of the main features is resistance to frontal rolling, which allows the tires to be used on vehicles with increased load capacity.

- Toroidal. This type is performed in both chamber and tubeless versions. The design provides for an averaged profile with an almost equal circle diameter in a ratio of 0.95-1.15. Due to their features and price range, they are very popular among car enthusiasts.

- Pneumatic rollers. These are equipped with lugs, which not only serve as a means to improve off-road performance, but also act as a general stiffener. Thanks to this, the operational characteristics of the wheel increase several times and high structural strength is achieved.

The cost of low-pressure tires is several times higher than the cost of regular tires. If we take into account the fact that they need to be manufactured for specialized purposes, then prices can reach half the cost of the vehicle. That is why most often extreme car enthusiasts make such tires on their own.

Homemade wheels and tires

First of all, you need to select the source material on which such tires will be made. It is best if the design is based on aircraft tires - they are made of high-strength rubber and the best quality. Tires from agricultural machinery or industrial all-terrain vehicles are also suitable.

Each bus consists of several interconnected elements. To manufacture the SND, it is necessary to remove excess rubber from the tread and side surfaces, and remove the seat cores from the inner part.

If necessary, you can even remove the rubberized part of the cord base, but this is quite difficult to do without affecting the nearby layer.

So, the main task is to lighten the tires and make them such that they will allow the car to move over difficult terrain and weak-bearing soils.

The manufacturing procedure includes several stages:

- We clean, wash and dry the workpiece. We mark the patterns of the new tread (the places of the cuts) with a marker.

- We cut through the rubber along the inner perimeter of the circle to rip out all the excess wire.

- After this, we cut out small “windows”.

- Through the holes we see a wire, which we pry up using available tools.

- We fix the tire and hook the wire to the winch.

- Using a winch we pull out all the wire.

- We trim the perimeter of the circle just below the cord and fix it with pliers.

- We tear off the excess rubber using a winch.

- We cut the pulled piece of rubber using a knife.

- We remove the bulk of the material from the surface of the tire (treads and sidewalls), layer by layer, until the tire is represented exclusively by the original carcass.

- We clean the surfaces with sandpaper.

- We assemble the frame. We weld metal tubes (plates) to the disk and weld them together using similar tubes of the appropriate size.

- We carefully polish the resulting workpiece so that the wheel chamber is not damaged by sharp fragments left after welding.

- Pull the tube onto the rim and inflate the tire. As a result, we obtain a ready-made wheel design that can be used for predetermined purposes.

- The time has come to “put” the resulting wheels on the vehicle and test it on the move.

Video: DIY low-pressure tires

This video describes the tire stripping technology and the machine for this procedure.

Homemade products and Syrians on unusual wheels

Examples of factory vehicles and products produced by folk craftsmen, in the design of which SND are used.

- Industrial:

- Mini swamp rover KIT TM06.

- Amphibious all-terrain vehicle Tiger XBH 8X8.

- SUV TRACK.

- Homemade:

- Snow and swamp vehicle XPEN.

- Lightweight 4WD car.

- MVH all-terrain vehicle.

As you can see, snowmobiles, swamp vehicles, caracats and ATVs cannot do without SND, the special design of which allows you to easily move along swampy or snowy surfaces. ATVs and cross-country motorcycles also often have similar tires installed. Thanks to them, all-terrain vehicles can traverse rough terrain faster and more efficiently.

Source: http://allkoreancars.ru/oborudovanie/shiny/shiny-nizkogo-davleniya.html

Making low-pressure tires with your own hands - photo instructions

The popularity of personal off-road vehicles is growing every year. This is evidenced by numerous exhibitions and forums of homemade craftsmen.

What to make low-pressure tires from

Where to start

Let's start making

Homemade wheels

And the more people who want to see a carakat or a small all-terrain vehicle on ND tires in their garage, the more the number of people who dare to build it with their own hands grows.

If everything is more or less clear with the base, you can take an old motorcycle or something from a VAZ classic, then what to do with the tires? Buy? The financial component of this component is quite large; according to some estimates, it can be up to 50% of the cost of the homemade product.

That is why it is worth thinking about how to make low-pressure tires with your own hands, especially since the cost of such tires will be several times lower than factory ones.

Raw material

Before you start making low-pressure wheels, you will need to find the source material. The most suitable cameras would be for helicopters or airplanes. The characteristics of the rubber used there correspond to the increased operating requirements established in aviation, which ensures a long service life.

Old truck tires are fine

In such tubes, the structure and thickness are the same at all points, which greatly facilitates the manufacturing process and the durability of the tire. However, the relative high cost and scarcity forces us to look for other solutions. Perhaps one of the optimal solutions in this case is truck tires. In this case, the physical and time costs more than compensate for the financial ones.

Stripping tires for all-terrain vehicles

So, when we start making the tube, we decide on the size and choice of tire (the most popular are GAZ-66, ZIL 131). Next, prepare the required tools and workplace.

Tools

Our tool will not be complicated: knives, preferably with a double-sided cutting edge, a sharpener for straightening knives, a hammer, an awl, wire cutters and a “pucker”. Using a “shredder” we will remove layers of rubber from truck tires.

Dralka - winch on the base

The mechanism itself is a fixed winch with an electric drive, the activation button of which is located directly at the workplace. For ease of operation, sometimes a foot drive is used. The main thing is that the winch speed is not too high.

Let's start production

First, we get rid of the outer bundle of wire cord. To do this, we cut a window, cut one of the turns with wire cutters, and wind the wire around the pliers and pull it out along the entire diameter. Then we cut the entire sidewall in the direction from the cord to the tread at a distance of 7-10 cm from each other. The depth should reach the first layers of cord.

Using a piece, the fang is undermined. We use a knife and trim only along the edges of the fang. The fang is undermined strictly clockwise, otherwise the top layer of cord will appear on the right.

The formation of the tread of a future tire should begin with graphic markings. The tread pattern in low-pressure tires with your own hands is determined by functionality, complexity and imagination. The most common and easiest to manufacture is the “herringbone” option with or without a central flange.

For the base it is better to select truck tires

Having drawn the entire drawing, we proceed to cutting the contours. In this case, the knife blade is placed at such an angle to the surface that the cross-section of the tread has the shape of a regular trapezoid.

Thus, having cut through all the ends of the outlined pattern, you can begin peeling. Usually the preparatory process takes most of the time and requires perseverance and patience.

However, the peeling process itself, its speed and accuracy will depend on the preparation.

Peeling process

When stripping a wheel, care should be taken not to cut the tread tooth. The layer of cord that appears on the right will disappear after the last canine is processed.

Using pliers we catch the fang, and gradually increasing the tension of the winch cable, we cut the side edges with a knife. The work is not difficult, but it requires concentration and attention at all stages, since a minimal cut in the wrong direction can lead to irreparable results.

Half the work is done

Homemade low-pressure tires in which such a mistake was made may subsequently begin to delaminate.

Tread selection and disc selection

To choose low-pressure tires, for example, for a field, you need to focus on the following indicators. To operate a modernized car in mud, you should have a high tread with a self-cleaning effect.

For peat bogs, a very rough and high tread is not required, as it will displace (tear) the top layer and reduce traction.

In sandy areas (or operation in snowy areas), tires should have thin tread elements.

At the end of our story about how to make low-pressure wheels, we should mention disks.

Homemade disc made from aluminum cans with rivets

Most often, such disks are made from standard ones, with some adjustment of parameters. Sometimes they are expanded by inserting a liner strip. Lighter all-terrain vehicles such as caracats and scooters can be equipped with disks made of aluminum basins (in heavier versions, the disks cannot withstand loads).

The disks and cameras are secured using belts, the role of which can easily be played by a conveyor belt or a fire hose.

Source: http://gredx.ru/articles/delaem-shiny-nizkogo-davleniya

How to make low-pressure tires with your own hands?

Sometimes even the most experienced driver in a well-prepared SUV cannot cope with and overcome any obstacle in his path. Whether it's snow, mud or sand, the car just gets stuck and can't move forward. City residents can avoid these problems by simply avoiding going to places from which they will no longer be able to get out on their own.

But for many residents of our vast Motherland, moving between remote settlements, where there are no asphalt roads and never have been, is vital. In this situation, the wheels of the car, namely its tires, play an important role.

Therefore, some car owners resort to tricks and make low-pressure tires with their own hands, not having the funds for more expensive modifications to the car.

Since the cost of special wheels is about 4 times more expensive than regular ones, homemade low-pressure tires are very popular. The design itself consists of a tire mounted on a disk. First the tire is made, and only then the metal base. Then comes the process of assembling the entire structure.

The easiest way is to take tires from GAZ-66 or ZIL-131 as a basis, since they are easy to find. Aviation tires are more durable, so they are recommended to be used for the first manufacturing experience. Used tires are also suitable.

In order to understand how to make low-pressure tires, you need to know the structure of an ordinary car tire. As you know, it is a kind of “layer cake”, consisting of many shells made of a metallized base, fabric and rubber covers.

Discounts on new cars! Advantageous loan from 9.9%

Installment plan 0%

Manufacturing stages

The work of making a low-pressure tire with your own hands consists of gradually removing several layers from a standard tire according to a pre-planned plan.

Most of the material is removed from the sidewall and tread. The stiffening ribs in tires of this type are protruding elements of the pattern that remain untouched.

A “herringbone” with a narrow path - a flange - in the middle (or without it) is usually used as a report.

Prepare the necessary tools in advance

Before partial removal of layers, it is necessary to cut the first tire and carefully examine its structure. This will help determine the depth of a particular layer. The second spare tire will serve as a kind of teaching aid.

It is recommended to practice all the intricacies of making homemade low-pressure tires. For example, pulling cord threads or cutting off identical pieces of rubber according to the intended pattern. Professionals in this field recommend cutting at depth in those places where the boundaries of the strongest layers lie.

This method saves time and effort.

Necessary actions

Having started directly making low-pressure tires with your own hands, you need to perform certain actions in strict sequence.

- Preparatory stage. To begin stripping a tire, it must be thoroughly cleaned, washed and dried. After this, markings are applied to the surface with a marker.

- Contour section. It is easiest to make a cut in the side of the tire, so after cutting to the depth of the first layer of tire cord threads, you need to begin to remove the metal fibers, first cutting the wire with wire cutters. Based on the previously drawn sketch, a wide cut is made that passes through the treadmill and the sidewall. Using pliers, the surface of the tire is cut and part of the casing is torn off. If there is a winch, increase the cable tension until the layered rubber element, called the fang, is completely separated.

After completing the job, it is extremely important to make sure that the base of the homemade low-pressure tire is not damaged anywhere. Otherwise, all the work will have to be done again with a new tire.

- After the previous steps, the tire is sanded with sandpaper and slightly straightened with a hammer.

Homemade disk and assembly of the final structure

A ready-made structure is usually used as a base. It is cut lengthwise and metal inserts are inserted there for expansion. The second option is to weld on a series of studs or rods.

The wheel is mounted using belts wrapped in rubber rings and a disk. A fire hose, an industrial conveyor belt, or strips of tarpaulin can help in this process.

At times, they resort to cutting aluminum into strips, with each of these strips secured with bolts or rivets.

Installation begins on one side of the disc, and after bending around the rubber, ends on the other base. The smallest number of tapes is 12.

The final step in the process of making homemade low-pressure tires is their inflation.

Thus, when faced with even the most severe off-road conditions, you can find a way out of the situation by using low-pressure tires on your car. To do this, you need to allocate a little of your time, make fairly modest financial investments and put in a little effort.

Source: http://CarExtra.ru/sovety/shinyi-nizkogo-davleniya-svoimi-rukami.html

Characteristics and installation of low pressure tires

This type of wheels is an attempt to combine wheels from an all-terrain vehicle and a conventional all-terrain vehicle. Pneumatic all-terrain vehicles have increased buoyancy, this is their main weapon in the fight against off-road conditions. An ordinary SUV, naturally, does not have any positive buoyancy, but quite the opposite, it has negative buoyancy.

How to combine this? Wheels with low pressure have no other tools besides increasing the contact patch. There are no powerful lugs, no hard cord sidewalls, and off-road, all this is needed. The designers made a tire to which they added some aggressiveness and increased cross-country ability.

The tire rims are not simple, but collapsible. The discs have an anti-collision device, that is, something that prevents the cover from coming off the rim. With weak load-bearing soils, the pressure drops, and with increasing density, it increases accordingly. According to the developers, this wheel resists wear well and can be used on asphalt at speeds of up to 90 km/h.

Disc with anti-collision device

- They will protect the chassis and save you money, increasing ground clearance by 3 cm.

At the same time, the wheels are balanced and, according to the developers, 250 grams of cargo are needed on one side. Tires for swamp vehicles have a displacement of about 600 liters and float easily, but at the same time they themselves weigh up to 1.5 tons, and mostly up to 1 ton.

The wheels are ideal for driving on weak load-bearing and frictional soils. That is, snow, dry sand, swamp carpet - this is their element, and it doesn’t make much sense to use them in areas where there is a lot of clay and the soil is viscous, because the tread gets washed out quite quickly and becomes clogged with clay. They stop working.

Ultra-low pressure tires are suitable for installation on all-terrain vehicles. This type is not suitable for installation on a regular car, since it simply cannot fit into the wheel arch. This low pressure is achieved due to the large width. Their cross-country ability is very high. They cope with almost all types of soil, and sometimes can even swim.

All-terrain vehicles with ultra-low pressure tires are indispensable where a regular SUV cannot go. Movement on asphalt surfaces should be limited, as they begin to wear out quickly.

They have poor side surface protection. Their movement is quiet and calm, they do not leave deep furrows behind them.

This is due to the fact that when in contact with the ground, the large width and weak pressure do not press down the ground well.

Everything related to this method does not apply to centralized swapping. You should use a control monometer (up to one meta-atmosphere) and a compressor. The compressor power is selected based on the power of the on-board network. The stamp should be left in place to continuously monitor pressure during deflation and inflation. There will be a tap with a rubber plug on the iron or aluminum disk.

The tire pressure of the vehicle should be measured. Everything will depend on what surface the vehicle was moving on: asphalt or primer. For example, if you take the option with asphalt, then the pressure should be reduced to a level of 0.6-0.7. Dirt tracks – 0.2-0.3. We screw on the pressure gauge, remove the valve fixing rubber and lower the wheel. In case of descent, all that remains is to remove the rubber band.

Low pressure tire pressure measurement

Inflating a low pressure tire is not as interesting as it might seem. A standard compressor produces about 70 liters per minute. We connect the terminals to the car battery. Everything is done in reverse order.

The nipple cap is unscrewed and a monometer is connected, which shows the current pressure. The dirt cap is removed, the compressor quick release coupling is connected, and the tap is opened.

The average time for pumping one wheel is 2-2.5 minutes.

Low pressure tires must be constantly checked and devices that can restore the required pressure must be carried with you. Descent – 1-2 minutes, pumping – 6-8 minutes

To do this, you must perform a number of actions.

The first step is to prepare the inner surface of one half of the disk for installation. Using a regular brush, we treat the disc with a special side sealant. If necessary, sealant can be purchased complete with wheels.

Next, the tire and spacer ring, or beadlock, are inserted. The spacer ring is made of composite materials, namely frost-resistant plastic. This material improves the physical and mathematical characteristics of the car. In simple terms, it provides high resistance to mechanical damage upon impact.

Spacer rings for installing tires

After installing the spacer ring, you should once again treat the inside of the disk with sealant, namely the inner groove into which the rubber O-ring is placed. Depending on the purpose, different sealants are used, namely multi-component and single-component. The sealing ring ensures better adhesion of one half of the disk to the other.

After installing the O-ring, it must be carefully placed in the groove, guiding it around the entire circumference of the disc. Next, we once again apply a layer of sealant at the junction of the two halves of the disk.

The next step is to treat the outer side of the tire with bot sealant to ensure better interaction with the second half of the disc.

After installing the disk, screw on the aluminum hub part. The hub part is selected separately, based on the dimensions and weight of the car. The disc and the hub part are connected with bolts and self-locking nuts. Flat washers should be installed under the bolts and nuts. The tightening force is also selected individually.

The final stage is pumping up the wheel. 0.6 atmospheres is an indicator that is average and working.

When choosing tires, you should be guided by the purposes and the vehicle on which they will be mounted. Each of the presented types is excellent for off-road driving.

Source: http://tuningkod.ru/tyuning-avtomobilej/avtomobilnye-shiny/sdelat-shiny-nizkogo-davlenija-svoimi-rukami.html

How to make low pressure wheels yourself

FordUseful

All-terrain vehicles, which are becoming more and more popular, are characterized by special components that have specific qualities. These parts include wheels with low pressure tires. Products of this quality are available, you can buy them without any problems, but you can make low-pressure wheels with your own hands.

The essence of the design is that at low pressure and under the weight of the vehicle, the tires “spread” over the surface of the ground, thereby maximizing the area over which the pressure of the load is distributed. This feature allows you to significantly increase the cross-country ability of vehicles, turning it practically into an all-terrain vehicle.

Design Features

Low pressure wheels have a number of advantages that determine the specifics of their use:

- The main feature of the design is the large surface area in contact with the ground, due to which the pressure on it decreases and the likelihood of passing into places inaccessible to a regular car increases.

- Specific range of applications. They are used in special conditions, for example, in agriculture, where minimal pressure on loose soil is needed, for military and geological exploration purposes for passing through sands, swamps, as well as for hunting and fishing.

- The operation of such tires must be carried out in special conditions, since driving on the road or at high speed quickly damages the wheels.

- Requires special management skills. It is necessary not only to observe the speed limit (low-pressure tires cannot withstand high speeds), but also to skillfully turn the vehicle. Turning is a particularly dangerous maneuver for such all-terrain vehicles.

Do-it-yourself selection of materials for making low-pressure tires

The most suitable starting material for making your own low-pressure tires are wheels from a helicopter or airplane.

They are ideal for work, have the same layer of rubber over the entire surface, and are also characterized by high wear resistance. But, obviously, not everyone has an unnecessary set of helicopter tires in their garage or barn at the dacha.

Therefore, the most common source for the manufacture of low-pressure wheels are truck tires.

It is from these that most craftsmen make wheels for their homemade all-terrain vehicles.

To work with rubber you need the following tools:

- winch with low speed and a button located on the wire;

- knives of different sizes and thicknesses;

- whetstone or device for sharpening knives;

- hammer;

- wire cutters;

- pliers;

- sandpaper;

- awl.

Main stages of manufacturing

To make your own low-pressure tires, you need:

- Remove the bundle of outer wire cord. This can be done through a hole cut with a knife using a winch or pliers. The entire inside of the wheel is cut off.

- The future tread pattern is applied to the top of the tire.

- Excess layers of rubber are removed with a winch at low speeds, cutting and adjusting the layers using a knife. The operation must be carried out with a high degree of care and extreme caution so as not to damage the canine protector.

- The places where the rubber was cut must be leveled and thoroughly cleaned. Sandpaper is suitable for this. Tire rubber can be easily corrected with its help.

Source: https://FordProf.ru/poleznoe/shiny-nizkogo-davleniya-kak-sdelat-svoimi-rukami.html