Which brake pads are best for your car? Ferodo, Textar, Bosch, ATE, Lucas, TRW – which company has the best brake pads

Pads are an important component of the brake system and play a big role in driving safety, so they, like brake fluid, should be given due attention when choosing to install the best brake pads on your car.

These points will help you choose the best pads:

The automobile market is overflowing with various options that a car owner can choose based on his needs and capabilities, and such abundance causes difficulties, because many questions immediately arise in the head: how to choose which company is better, is the original better or can you buy an analogue, and the like . And to make such a difficult choice easier, we wrote this article.

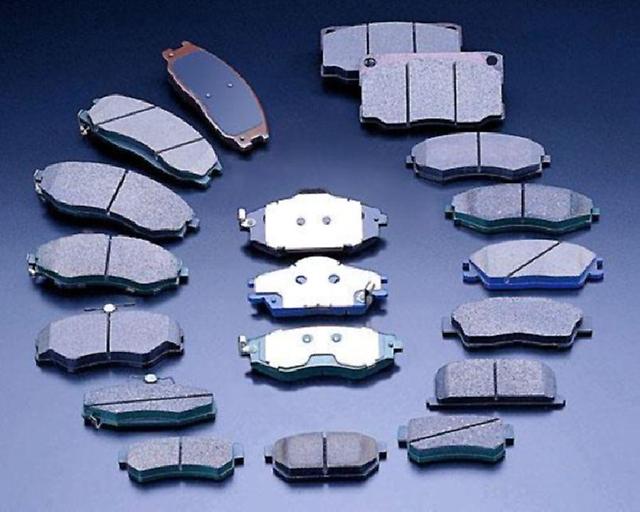

Types of brake pads

All brake pads are made from friction material and a metal plate. The friction mixture can include more than 10 different components.

An asbestos substitute is used as a reinforcing component; the composition also contains oxides of various metals and graphite dust, bound together by high-temperature resin. Metals and their quantity determine the coefficient of friction, and graphite is needed to prevent the pad from sticking to the disc.

Depending on the components and their proportional ratio, brake pads are divided into 4 main types :

Semi-metallic pads consist of up to 65% metal, both ferrous and non-ferrous, mixed together with graphite and inorganic fillers. Such brake pads dissipate heat well, but due to their hardness, they expose the brake disc to a greater extent to wear, and therefore are characterized by increased noise and suboptimal performance at low temperatures.

Low metal ones can contain no more than 30% steel or copper, and the main component is organic materials.

Organic pads are made from organic materials such as glass, carbon, Kevlar, and no more than 15% metal.

They are much softer, wear out faster, and the dust that is generated can clog the holes of the ventilated discs; It is better not to use them when driving aggressively, but they are distinguished by quiet operation and quick initial braking.

Ceramic brake pads are the most expensive, but have the best performance during hard driving. Following from their name, you can immediately understand that their component is ceramic fibers, and also, as a filler, there are non-ferrous metals or synthetic rubber.

A ceramic pad provides a stable coefficient of friction (unlike a semi-metallic pad, in which it changes depending on temperature). They wear out less intensively and expose the brake disc to less wear.

Such brake pads will be the best choice for aggressive city use.

All manufacturers have their own special technology for manufacturing brake linings and, depending on the requirements and purpose, use their own components, of which there can be about three hundred.

Brake pads by category

When asked which brake pads are best, when choosing them, keep in mind that pads are divided into 3 categories :

- 1st - delivered to the conveyor;

- 2nd - going to the auto parts market;

- 3rd - the most budget-friendly, as they are supplied to developing countries.

Conveyor brake pads meet all standards and are original. The price of such spare parts is usually twice as expensive as others.

The automaker packages such pads in branded packaging, although in fact they were manufactured by some reputable company, and the same pads, but in a different packaging and with a different catalog number, can be bought cheaper than the “original”.

Market AfterMarket, the so-called “non-original pads” are the most common on store shelves due to their more affordable price (one third cheaper), which is achieved due to a decrease in the quality of the materials used.

Those exported to developing countries are characterized by lower quality standards, so they are not only made from less reliable materials, but also do not undergo the necessary tests, since they are intended for sales in countries with lower regulatory requirements. The price of such spare parts is only a third of the cost of the original, but the pads will have to be replaced more often.

All pads, no matter what they are or what materials they are made from, must be marked indicating the operating temperature and coefficient of friction. These numbers play an important role when choosing brake pads, as they will characterize their operating conditions.

First of all, brake pads are characterized by operating temperature , and if you do not have a racing car, then for moderately fast driving and driving around the city you do not need to buy too expensive ones.

Pads that can withstand temperatures of 300 – 350 °C will be enough for you. At the same time, the brakes of sports cars have pads that can withstand up to 900 °C, and their normal operation begins only after heating up to more than 100 degrees.

That is, in urban driving conditions such expensive brakes are practically useless, since only when hot they have a coefficient of friction of at least 0.5 units, and at an operating temperature of 150 degrees, only 0.2 units, although the standard indicators of the original pads, which are quite enough for normal use, ranges from 0.3 to 0.5.

Pads designed for sales on the secondary market come with a coefficient of 0.25 - 0.35 units, which is enough to quickly immobilize the car during non-aggressive driving.

Therefore, for everyday driving around the city, you do not need to install expensive sports pads (such as Brembo), which will squeak and whistle, which is very annoying, but it is better to choose brake pads from another company from the second or even third category.

Although there is one “BUT” when choosing pads, if you rely on the operating temperature and friction coefficient - with the same indicators there may be different degrees of wear .

When you decide to choose brake pads according to the required technical characteristics, then look at the wear indicator, because if they are too soft, then such pads will need to be changed more often, and too hard pads can wear out the brake disc faster, which can even result in vibration when braking .

Basic selection rule

3 basic rules for choosing pads:

- in order to avoid the occurrence of extraneous sounds after replacement, select pads of the same brand/series and/or according to the mixture composition along with the brake discs;

- buy brake pads belonging to the first two categories;

- selection must be made taking into account driving style and operating conditions.

But in addition to these conditions, we must not forget that the market is teeming with counterfeits and brake system consumables of dubious quality.

How to spot fake brake pads

How not to buy a fake

It is better to make a purchase in a trusted store, and you need to choose brake pads based on the appearance of both the box and the pads themselves. Here are some tips:

Brake pad markings

- a certification mark (R90 or 90R) must

- there should be no foreign bodies on the lining (small microchips are allowed);

- in addition to the base and friction part there may be an additional layer , do not be afraid of this, Ferodo pads do this to remove heat from the caliper and the brake fluid;

- pay attention to the operating temperature numbers - the higher the figure, the better the brake pads will be;

- In the box of a self-respecting manufacturer, as a rule, there should be a passport , a quality certificate , a warranty card , and even installation instructions.

The most modern method of protection is a unique product code (a set of letters and numbers that is never repeated), so if you want to check the brake pads you like before buying, you can check the last 4 characters of the batch number on the packaging, or “break through” the code on the website manufacturer.

Which brake pads are better

How to choose good front brake pads

You should not buy pads whose cost is significantly lower than the average price in auto stores; such a tempting price may just indicate that they were produced using cheap friction mixtures that are not capable of ensuring effective operation.

Which brake pads are best to choose is a rather rhetorical question if it concerns the choice of a specific brand of manufacturer, because, as we have already discussed earlier, there are many subtleties in the task of selecting the most optimal option.

Which brand of brake pads is better?

Today, the manufacturer can be recommended solely for advertising purposes, but, nevertheless, there are still some that are worth paying attention to when choosing the best brake pads for your car. The most authoritative of them:

Brake pad test

Ferodo, Brembo, Textar, Bosch, ATE, Lucas, TRW, Remsa, Jurid, PAGID . Each of these brands has its own advantages and its own consumer niche.

Pads from Ferodo and Brembo are installed on cars with a sporty driving style.

ATE is also installed in the calipers of fast and tuning cars, because, according to the manufacturer, they are able to work well even at temperatures of about 800 degrees.

Lucas and TRW brake pads are manufactured specifically for normal city driving, where operating requirements are more modest.

Remsa is part of the TRW concern and produces not only pads, but also brake discs. Their affordable price does not affect the effectiveness of the characteristics.

One of the leaders in the car market, Bosch, previously supplied its pads as an analogue to Japanese cars, but has now lost its position, and only a couple of German companies use them as a basic option.

Pagid pads are installed on premium cars.

Jurid is an American company that specialized exclusively in brake pads, therefore its spare parts are intended for supply to the assembly production of automobile factories for both passenger cars and trucks, as “originals” (such pads are designated by the index “J”), although they can be found on shelves and the secondary car market with the index “D”. The product of this company can also be presented on the market under the brands FRAMR, BendixR, PrestoneR and some others.

STS , a Russian brand that can be considered as a more or less good option to install in the caliper of a budget or domestic car.

You cannot skimp on the braking system of your car; it is better to give preference to quality that is suitable for your car.

It is better to refrain from purchasing inexpensive brake pads, the cost of which is significantly lower than the average price in auto stores.

A low price often indicates that during the production of the pads, cheap components were added to the friction mixture, which will not ensure effective operation.

The topic of choosing “which brake pads are best” is quite controversial and extensive, each car owner always has his own opinion, so if you want to buy the most optimal brake pads for your car, based on its operating conditions, always take an additional interest in pad tests and read reviews.

Source: https://etlib.ru/blog/425-kakie-tormoznye-kolodki-luchshe-postavit

Which brand of brake pads is better to choose: rating for foreign cars 2017 – 2018, spare parts correspondence table

Sooner or later, the driver faces the question of replacing car parts due to a breakdown or long mileage. Brake pads are one of the first to fail. Which company is better to choose, how to correctly distinguish an original from a fake and how not to make a mistake in a purchase, read the article below.

Additionally, we have compiled a rating of popular manufacturers and product compatibility by car brand.

We wish you pleasant reading.

Video: brake pad installation

Are you thinking about what brake pads to install on your car? To begin with, we recommend studying the design of the element and the principle of operation of the part. Detailed information in the video below.

How often should brake pads be changed all around?

Car manufacturers recommend replacing front brake pads at the following intervals:

- manufactured by domestic manufacturers - 10-15 thousand km;

- foreign manufacturers with higher quality materials used for their manufacture - 15-20 thousand km;

- used to equip sports cars - up to 5 thousand km. The products are used intensively and belong to a separate category.

Rear pads differ in drum and disc ones; they wear out less intensively, so they have to be changed less often. The main part of the load during braking is placed on the front wheels of the car.

The actual mileage of a car for replacing brake pads usually differs from that recommended by the manufacturer. The reasons are:

- Pad manufacturing material . Products made from low-quality materials wear out much faster.

- Driving style . When operating a vehicle under frequent acceleration and sudden braking, the wear rate of the pads increases significantly;

- Vehicle driver experience

Note : the result of untimely replacement of pads is that the brake discs wear out intensively, increasing the risk of an accident on the road.

Determine for yourself whether the pads are actually faulty based on the following main signs:

- when braking, the car skids;

- when you press the brake pedal, vibrations are felt in it;

- the brake pedal is pressed softer and an increase in the working stroke is felt;

- braking efficiency decreases;

- The parking brake does not work even with maximum cable tension.

Average prices for all-round replacement depending on brand in Moscow

The following summary table will help you navigate the average prices in Moscow for work on replacing front and rear brake linings. Costs for parts are not included in the table.

| Car make/Service | Replacement of front pads (RUB) | Replacing rear disc pads (RUB) | Replacement of rear drum pads (rub) |

| VAZ (LADA) | 600 | 700 | 1550 |

| Hyundai | 850 | 950 | 2000 |

| KIA | 800 | 900 | 1900 |

| Toyota | 850 | 950 | 2000 |

| Mitsubishi | 850 | 950 | 2000 |

| Mercedes Benz | 1050 | 1000 | 2400 |

Addresses of the best service stations for replacement by district in Moscow and St. Petersburg

In accordance with the rating and customer reviews, the best service stations in Moscow providing services for replacing brake linings are:

| Administrative District | Name of service station | Address |

| VAO | Optimum Auto Shchelkovskaya | Shchelkovskoe highway, 100, room 106 |

| Company | Auto-System | Ozernaya, 46, building 2, building 11 |

| SAO | Maximum | Ilmensky proezd, 10, building 1A |

| NEAD | Yauza Motors Medvedkovo | Polyarnaya, 39 |

| SZAO | Stilberg-Auto South Tushino | Svobody, 35, p. 9 |

| Central Administrative District | Tradeinvest | Shluzovaya embankment, 2/1, building 1 |

| Southern Administrative District | Bavaria Motor Club | Nagatinsky 1st proezd, 2, building 2 |

| SEAD | Autokip | Volgogradsky Prospekt, 32, building 11 |

| South-Western Administrative District | Pit Line | Odoevskogo proezd, 10 |

In St. Petersburg:

| Area | Name of service station | Address |

| Admiralteysky | Union on Obvodny Canal | Nab. Obvodny Canal, 91A |

| Vasileostrovsky | Admiral-Auto | Tanning line, 30 |

| Vyborg | Weber-Auto | Neyshlotsky lane, 5, building 1 |

| Kalininsky | Autopremier | Vatutina, 12 |

| Kirovsky | Union Strike | Kronstadt square, 5 |

| Kolpinsky | Mechanics Sofia | Sofiyskaya, 127, building 5 |

| Krasnogvardeisky | Rovels Ladozhskaya | Khasanskaya, 1 |

| Krasnoselsky | In Gatchina | Gatchina highway, 17A |

| Moscow | A21service | Yuri Gagarin Ave., 1 |

| Nevsky | Avtolitsa on the Far East | Dalnevostochny Ave., 18 |

| Petrogradsky | Rowels on Professor Popov | Professor Popova, 38SH |

| Seaside | V-Studio | School, 75 lit. A |

| Pushkinsky | Stayer-Shushary | 2nd Badaevsky Ave., 3 building 1 |

| Frunzensky | Stayer on Sofiyskaya | Sofiyskaya, 8K1B |

| Central | SG Auto | Kremenchugskaya, 2 |

China VS Original

When deciding which brand of brake pads to choose, car enthusiasts are faced with a dilemma: give preference to original, but expensive products, or save money and purchase products from unknown Chinese manufacturers.

Some Chinese companies make good pads. A common complaint against them is that the quality of such products differs in delivery batches.

Before choosing such parts, first of all, get an idea of the eligibility criteria.

We advise you to pay attention to the following details:

- stable friction coefficient that does not change depending on the temperature of the product;

- noticeable progression when braking;

- absence of creaking and extraneous sounds when braking;

- careful treatment of the surface of the brake discs;

- long service life;

- high reliability of connection of the friction plate with the surface of the metal substrate.

To purchase high-quality pads that meet all requirements, when choosing them, follow the recommendations below:

- Please note the “R90” certification mark on the box of each product.

- Carefully inspect the working surface of the selected pad for uniform color and the absence of foreign substances. The presence of small chips and cracks on the surface is allowed.

- Check that the friction material of the pad is connected to the metal backing or gasket.

- Choose products with the highest possible friction coefficient - 0.3-0.5. Maintain a high operating temperature of the pads (300-3500).

Ratings of product manufacturers and user reviews of individual models will help make the task of choosing easier.

Top 3 rating of brake pad manufacturers for foreign cars 2017 – 2018

The main criterion taken into account when compiling ratings of brake pads is the results of tests conducted by specialized organizations in order to check these products for their effectiveness in various situations.

Basic conditions for conducting tests:

- hot braking from a speed of 100 km/h on a car with brake discs preheated to 2000;

- cold braking from a speed of 100 km/h – the temperature of the car’s discs and pads does not exceed 500;

- cooled down braking from 100 km/h - the discs and pads of the car, after performing cyclic braking on it, cool down to ambient temperature;

- mountain cycle - reducing the vehicle speed from 100 to 50 km/h, subject to repeated cyclic braking.

According to the test results under the above conditions, the rating of brake pads for foreign cars 2017 – 2018 is headed by the products of the following brands:

Bosch

The pads are produced by the well-known company Bosch, they demonstrate the lowest wear among products of this type and high braking efficiency in a heated state. The high level of performance is evidenced by the fact that the company supplied equipment to Japanese companies. On the modern market, products are represented by parts for cars and trucks of famous brands.

Ferodo

Ferodo pads are chosen by car enthusiasts who prefer a sporty driving style. Ferodo, the oldest manufacturer of brake pads, relies on a unique friction lining composition. It contains:

- high-strength ceramics;

- resins prepared according to a proprietary composition;

- rubber;

- special fibers that provide a reinforcing effect.

The company's products are ideal for various popular car brands.

Brembo

The pads, produced under the well-known Brembo brand, provide consistently high braking performance in various conditions and operating modes of the vehicle. Initially, the products were installed on racing cars, and today they are also available for ordinary cars.

Confirmation of the high quality of Brembo products is their use in Chrysler, Mercedes and Porsche vehicles.

During the production of overlays, advanced technologies and composite materials with unique characteristics are used.

Which pads are best for domestic cars?

If we focus on product test results, the rating of brake pad manufacturers for domestic cars looks like:

- Hankook Frixa (South Korea) and Allied Nippon (Japan);

- Lynx (Germany) and TRW (Germany);

- DAMFI (Ukraine) and TIIR (Russia).

The pads presented in the rating belong to the same price category and are suitable for various brands. All that remains is to choose a product that suits the owner in terms of price and technical characteristics.

Table of pads for the specified car make

| car brand | Suitable pads |

| Kalina | BOSCH, FERODO FDB 527, TRW GDB 1446 |

| Granta | WEEN 151-1102 |

| Camry 50 | FERODO FDB1892, HSB HP5244, AKOK G1256TF |

| VAZ 2112 | BOSCH, TRW GDB 1446, SBS 15011222310 |

| KIA Rio 3 | REMSA 1362.52, SBS 1501223442, PATRON PBP3494 |

| Renault Logan | BOSCH 0 986 467 720, DELPHI LP885, LYNX BD-6301 |

| VAZ 2114 | REMSA 022102, FERODO FSB240, BOSCH |

| Ford Focus 2 | BOSCH 0 986 494 127, FERODO FDB1594, LYNX BD-5901 |

| Lacetti | BOSCH, BREMBO P 10 001, FERODO FDB 1889 |

| Ford Focus 3 | BOSCH 0 986 494 127, FERODO FDB1931, SBS 1501222561 |

| Kalina 2 | BOSCH 0 986 461 661, TRW GDB 1446, SBS 15011222307 |

| Niva Chevrolet | BOSCH 0 986 494 462, TRW GDB 265, SBS 15011222310 |

| Pajero 4 | BOSCH, BREMBO P 83 024, FERODO FDB 1021 |

| Chord | BOSCH 0 986 505 337, FERODO FDB 285, NIPPARTS J3604006 |

| VAZ 2017 | FERODO FDB527, ATE 13/0460-2965.2 |

| UAZ Patriot | WEEN 151-2611 |

| Mazda 6 | FERODO FDB 1619, BOSCH, BREMBO P 49 036 |

| Gazelle | WEEN 151-1101, BOSCH 0 986 424 214 |

| Chevrolet Lacetti | BOSCH 0 986 494 133, FERODO FDB 1889, BREMBO P 10 001 |

| VAZ 2115 | MARKON 20293175, ASP K260201, TRW GS 8210 |

| Lancer 10 | MASUMA MS3450, TRW GDB3133, BREMBO P 54030 |

| Hyundai Solaris | TRW GDB 3494, LYNX BD-3619, FERODO FDB4387 |

| Peugeot 308 | BOSCH 0 986 TB3 059, FERODO FSL4004, LYNX BD-6101 |

| Ford Mondeo 4 | BOSCH 0 986 TB2 939, FERODO FSL1897, LYNX BD-3004 |

| Priora | BOSCH 0 986 491 700, TRW GDB 1446, SBS 15011222321 |

| Polo | BOSCH 0 986 468 890, FERODO FSL385, BREMBO P 85 003 |

Source: https://obzorus.com/tormoznye-kolodki-kakoj-firmy-luchshe-vybrat/

Which brake pads are best?

The brake system is an important component of a car that requires special attention from the owner. At the same time, the key factor for reliable operation is timely replacement of consumables (brake fluid, discs, pads, etc.). In this article we will talk about which brake pads are better and what to pay attention to when choosing them.

Classification of brake pads

Few people know, but there are three different types of brake pads:

First view

Series "O.E.", deliveries to the conveyor. This type of pads goes directly onto the conveyor and is produced in accordance with all the manufacturer’s requirements. Therefore, you can be confident in the quality of the part, its efficiency and maximum service life.

As a rule, such pads are packaged in original boxes (packages) from the manufacturer of the part itself or the car manufacturer. The main disadvantage of the “O.E.” pads - high price.

In addition, first-line products are not so easy to find in regular stores, because 9 out of 10 parts go directly to the automotive assembly line, and only 10% are sent to the retail chain.

“Aftermarket” deliveries (directly to the retail spare parts market)

Such parts have an affordable price, which is 30-60% of the cost of the original part. There are several reasons:

- firstly, the composition and quality of the material used may be worse than in the original;

- secondly, one concern often has several companies that produce brake pads. Moreover, each of them may differ in its product quality. For example, we can cite two manufacturers - Textar and Pagid. They are both owned by the same concern. But there is a difference between them. The first company produces parts for retail chains (the quality is still very high). The second company focuses on the production of premium parts, for example, for cars such as Audi TT, Porsche Cayenne, Volkswagen Golf and so on.

Export supplies (for developing countries)

The name of the series of such products speaks for itself. Of course, this does not mean that the brake pads are made in a clunky way.

They are simply manufactured to meet less stringent requirements and regulations of the countries where they will be sent for sale. The peculiarity of such products is the minimum price.

When compared with original products, the export version will cost 4-5 times less. In the manufacture of such structures, as a rule, the simplest mixtures are used.

Rules for choosing brake pads

Car enthusiasts often cannot decide which brake pads are best and rush to the first product they come across. In this case, the main criterion becomes only the price. This approach is wrong. All that is required is to know the basic rules for choosing quality products. With their help you can buy a really high-quality part (even an export version). So let's get started:

1 package

Pay special attention to how the product is sealed and what is printed on the packaging. It is logical that a high-quality part should be well sealed and have all the necessary inscriptions. Make sure that the box bears the ECE R90 mark, which confirms that the pads have passed at least the minimum certification in Europe.

2. Appearance

Inspect the brake pad. There should be no damage, cracks, nicks or other obvious defects. The last option is small scratches up to 2-3 millimeters long.

Evaluate the quality of fit of the friction material - it should “sit” tightly on its base. Another important point is the base plate. Any deformation or damage is excluded here. It is very important that the element has the correct shape and geometry.

Video: How to choose good front brake pads

The brake pad consists of two main elements - friction material and base (made of metal). Some manufacturers may install an additional layer between these two elements.

For example, manufacturers ThermoQuiet or Ferodo have products with a so-called “silent” friction element. In addition to everything, a special layer element is installed between the base and the block itself.

The latter's task is to prevent the transfer of heat from the overheated pad to the brake caliper, as well as the brake fluid.

4. Material

Another important point is the source material used to make the pads. There are a lot of options here - borate, graphite, carbons, and so on. The total number of additives contained in a brake pad can reach 150. Of these, about twenty are designed to reduce the level of squeaking during braking. In this case, all elements are combined using a special resin.

If the manufacturer has not “baked” the block sufficiently, then the retaining compound (resin) will be “baked” while driving. That is why, after installing new pads, it is advisable not to press the brake too hard, but to let the brake elements get used to it. Otherwise, during active braking, you may notice smoke from the brake disc area.

Modern pads may have steel or aramid fibers added to them. The former, as a rule, can be found in products for sports cars, and the latter - in Kevlar pads. It is important that the part does not contain asbestos. Such an element, as a rule, is included only in the cheapest products.

After inspecting and studying the composition, you can proceed to the main characteristics of the part - the coefficient of friction and the temperature of the pad.

If you are not going to race and are an average driver, then the optimal temperature for the pad is 330-350 degrees Celsius.

If the car is often used in sports mode, then the linings must be appropriate (the optimal temperature is 700-900 degrees Celsius).

Many car enthusiasts make the mistake of installing sports brake pads on cars for normal driving. You can't do this. Such products warm up only when they reach 150-200 degrees Celsius, which does not allow their use in the urban cycle (they will be ineffective).

Another important point is the friction coefficient. The nominal friction parameter of pads for ordinary cars is 0.3-0.5. A lot depends on the manufacturer here. For example, products from the “O.E.” series have a friction coefficient of about 0.4-0.5, and simple pads (export supply) - 0.3-0.35.

Which brake pads are better? We analyze brands

In the variety of manufacturers, it is sometimes difficult to navigate and give preference to one of the manufacturers. We have already mentioned that a good manufacturer makes spare parts for specific car models.

This is ideal. But let's look at the alternative - analog parts that are of proven quality and specification.

At the same time, be prepared for the fact that for good overlays you will have to pay from 30 to 60% of the cost of the original.

So, which manufacturers are worth considering? - There are several options:

- Brembo. The products of such a company are well known for their quality and sports orientation. The products of this company are more suitable for owners of sports cars who cannot imagine their life without speed.

- NIBK or LUCAS. Most car enthusiasts prefer pads from these particular manufacturers. Their main advantage is versatility, high quality and more or less affordable price. Of the shortcomings, only one can be highlighted - dislike of high speeds.

- STS is a product from a domestic manufacturer. Despite existing stereotypes, these pads are of good quality and are perfect for urban driving. It is impossible not to note the more affordable price of these devices, which is precisely what attracts car enthusiasts;

- ATE are products that adherents of quality tuning like to install. The peculiarity of such pads is their ideal composition and ability to withstand maximum overheating.

- Bosch. At one time, this company was a leader among brake pad manufacturers, but in recent years its priorities have shifted slightly. Today, the quality of such products is very controversial.

- Samko pads are products from an Italian brand. The peculiarity of such designs is their versatility and ease of use.

Conclusion

Well, now you know which brake pads are better and what to look for when choosing them. The main thing to remember is that this is not just a car part, but a guarantor of your safety.

Source: http://AvtoMotoProf.ru/avtoakssesuaryi/kakie-tormoznyie-kolodki-luchshe-2/

9 Best Brake Pads

|

Place |

Name |

Characteristics in the rating |

|

The best Asian brake pad manufacturers |

|

The best European brake pad manufacturers |

| 1 | Ferodo | Best value for money |

| 2 | ATE | The best range of brake pads |

| 3 | Lucas/TRW | Reliable manufacturer |

|

The best Russian manufacturers of brake pads |

| 1 | STS | The best quality from a domestic manufacturer |

| 2 | RosDOT | User selection |

| 3 | Marcon | Optimal price |

Brake pads are the main consumable material in the vehicle braking system.

They are designed to perform the important and responsible function of braking the wheels (and the entire car), on which, first of all, the safety of drivers and passengers depends.

Due to the widespread development of the automotive industry, brake pads have become a very popular component, which has led to an irreversible increase in the number of manufacturing companies.

It would seem that in modern realities there should be no problems with choice, but such problems constantly haunt car enthusiasts.

Due to poor awareness of manufacturing companies, users often come across downright bad brake pads that literally fall apart at the very beginning of operation.

To help you avoid such problems, we have compiled a rating of the nine best manufacturing companies in the Asian, European and Russian market segments. Applicants were selected according to a number of main criteria:

- user reviews, opinions of authoritative sources and experts in the automotive industry;

- extensive model range (number of supported vehicles);

- generalized conclusion about braking characteristics and durability parameters;

- compliance of the overall quality of products with a given price.

We recommend:

9 best brake disc manufacturers

Despite the fact that the main market segment belongs to European companies, Asian brake pad manufacturers also do not complain about the lack of demand.

This is facilitated by the prevalence of Japanese and Korean cars throughout the globe.

As for purely technical characteristics, Asian brake pads, for the most part, are distinguished by a good working life coupled with a high degree of reliability, but the price level for the original is quite high.

3 Nisshinbo

A clear representative of manufacturers of brake pads for urban and sports applications.

It cannot be said that there are unique solutions in manufacturing technology: the development is carried out according to leading world quality standards using Ferodo material, suitable for any driving style (cautious, moderate or more aggressive).

In addition, there is a convenient gradation by type of pads for certain groups of cars, which is the main feature of the company. They are mainly used by owners of Japanese cars, such as Toyota Camry or Mitsubishi Lancer, but the range of supported cars is not limited to passenger cars only.

Advantages:

- the pads have a clear gradation for certain types of cars (cars, SUVs, trucks);

- depending on the series they differ in key characteristics;

- have a high degree of performance and durability.

Flaws:

2 Hankook Fixra

One of the best car tire manufacturers is quickly expanding into the brake systems market.

Hankook Fixra - and this is the name under which the products are distributed in Russia - is designed to create brake pads mainly for Korean cars (such as the Kia Rio or the same Hyundai Solaris), of which there are a lot on Russian roads.

The main distinguishing feature of Hankook (and here this is truly a unique case) is the use of Kevlar fibers in the production of friction linings, which significantly increase wear resistance and durability parameters.

Advantages:

- the use of Kevlar fibers, which reduce wear on the discs and clutches themselves;

- high durability parameters (for almost all models);

- from “non-Korean” cars, the pads go to Renault Logan, Lada Priora, Kalina and other platform brethren.

Flaws:

1 Allied Nippon

For several years in a row, Allied Nippon has received the well-deserved title of the leading manufacturer of brake systems around the world. Needless to say, the company’s arsenal is very large. Here you can find both pads for native Japanese or Korean cars (Honda Accord, Hyundai Solaris, etc.), as well as designs for the domestic VAZ (Priora, Kalina) and a number of European cars.

The entire line of brake pads is tailored to the urban rhythm - they can easily withstand a mixed driving cycle, accompanied by constant acceleration and sharp braking, thanks to the use of mineral metallic technology - ferrocarbon.

However, the main advantage lies in the composition of the friction linings. The unique asbestos-free mixture NAM114 has a long service life and, according to this indicator, is capable of leaving analog developments from other manufacturers out of business.

Advantages:

- Availability of brake pads for domestic cars (VAZ and GAZ);

- the product is excellent for mixed driving;

- the pads can withstand short-term overloads and dissipate heat well;

- asbestos-free clutch and Ferro Carbon technology.

Flaws:

- usually high cost.

Europe is one of the pillars of the auto parts market and a reliable supplier of top-end brake pads. The products produced are distinguished by high quality parameters and working life, but the pleasure of purchasing them requires very significant costs.

The main problem of European pads is counterfeitability - very often on the domestic market you can find cheap analogues of brake elements from well-known companies, which, however, fail after a short period of use.

3 Lucas/TRW

Under the European brand Lucas, the equally well-known American corporation TRW operates in Russia, and over the past five years it has firmly occupied its place in the top five manufacturers of auto parts and components.

Conceptually, TRW does not bring anything new to the production of brake pads, but uses the existing arsenal to its full potential. That is why both the company and its products are so favored by domestic car enthusiasts.

The prices are reasonable, especially in comparison with some of the giants in the spare parts industry. One problem is the very high degree of counterfeitability.

Advantages:

- high quality of products;

- the ability to find pads for all running car models (for example, Renault Logan, Chevrolet Lacetti, Chevrolet Niva, Honda Accord, etc.);

- acceptable prices.

Flaws:

- the market is literally teeming with low-grade fakes.

2 ATE

A German giant in the production of brake systems, dating back to 1958.

As in ancient times, innovation and the pedantry inherent in the Germans are the fundamental concept for the production of pads, which are in consistently high demand among Russian car enthusiasts.

The supported models include not only European cars: here you can find pads for Solaris, and for Kia Rio, and even for the brainchild of the notorious General Motors - the Chevrolet Lacetti and the Russian American Chevrolet Niva.

In the manufacture of an important element of the brake system, wear-resistant hard alloys of titanium, chromium, nickel, etc. are used, which guarantee longevity and excellent performance of their direct duties. But the main asset of the company is ceramics - silent ceramic pads are widely used in supercars.

Advantages:

- a company with a rich production history and extensive experience;

- use of new production technologies in pads;

- a large number of supported car models.

Flaws:

- consistently high cost.

1 Ferodo

A British giant in the production of automotive components, known in Russia for its Ferodo Target series of brake systems.

It was this company that developed a unique friction material technology (oddly enough, called Ferodo), which made it possible to achieve optimal parameters for the wear resistance of friction linings and braking characteristics.

For many car enthusiasts, the key reason for purchasing brake pads from this particular brand is the optimal cost (corresponding to the quality), which other famous brands cannot boast of.

Advantages:

- very rare squeaks (usually due to isolated defects of individual models);

- friction linings do not contribute to intensive wear of discs and do not generate dust;

- You can find pads for almost all running car models.

Flaws:

The main advantage of Russian-made brake pads relative to others is the price level. This is one of the cheapest ways to equip a car with important braking components.

In general, their quality and service life cannot be compared with European or Japanese giants, however, individual models are capable of forcing the best to “fight” for primacy, albeit purely in the realities of the domestic market.

3 Marcon

A company whose products sell like hot cakes. In order not to overpay for expensive imported pads, users are increasingly looking for benefits in purchasing Russian-made goods. And often they don’t regret it at all.

The products of this company are not intended for high-speed driving and sharp braking from 100 km/h to zero, but they withstand city rhythms and moderate driving well.

Due to the soft composition of the friction linings, the pads generate dust, but they do a good job of removing heat from the friction zone (which, it is worth noting, significantly increases the service life of the discs).

Some car enthusiasts note that when installing a fresh kit, a creaking noise begins, but after a certain period of use it disappears. This situation arises from the fact that the geometry of the discs and the pads themselves do not always coincide, but during use all inaccuracies are leveled out and ground in.

Advantages:

- the possibility of repairing the pads at the manufacturer (cleaning, painting, applying a friction layer of “street” or “track” to choose from);

- good heat removal from the friction zone (affected by the softness of the lining material);

- attractive price.

Flaws:

- Some pad models are prone to squeaking.

2 RosDOT

RosDOT brand brake pads are among the best among domestic brake system elements. Users speak highly of the braking performance, ergonomics and cost of the kit, comparing them with leading European products.

It is known for certain that in the manufacture of the friction layer a special composition of anti-noise mastic is used (according to the Italian “recipe”), soft enough to suppress vibrations and prevent resonant oscillations at certain movement thresholds.

Such pads are installed mainly on domestic cars, such as Lada Kalina, Priora or Grant, as well as co-platforms Renault Logan, Nissan Tiida and similar ones.

Advantages:

- The optimum ratio of price and quality;

- in addition to the above-mentioned cars, the range includes pads for Korean and Japanese cars (the same chassis for Solaris and Kia Rio, Honda Civic and Accord);

- The grinding process proceeds quickly.

Flaws:

- Some models of pads cannot withstand operating loads.

1 STS

A worthy representative of the Russian production of brake pads. The STS company closely cooperates with German companies, which ensures the high quality of its products that meet all European standards.

Obviously, the production priority is pads aimed at models of the Renault-Nissan concern (Renault Logan, Renault Duster, Renault Capture) and co-platforms from VAZ (Lada Priora, Lada Kalina, etc.). d.).

However, among the wide range you can find components for both Korean and American-Russian cars: Hyundai Solaris (Elantra), Toyota Camry, Kia Rio (or Optima), Chevrolet Niva, " Chevrolet Lacetti”, etc. This is the very case when the quality of Russian production breaks existing stereotypes.

Advantages:

- brake pads meet all quality standards;

- support for a wide range of vehicles;

- good braking performance and durability.

Flaws:

How to choose the right brake pads?

In order to choose the optimal brake pad model, you need to pay attention to a number of characteristic parameters:

Pad type.

Currently, there are four types of brake pads: semi-metallic (noisier, temperature dependent, less wear-resistant, but more durable), organic (less noisy, less wear-resistant, creates a lot of dust), low-metallic (improved heat transfer, increased dust separation and noise), ceramic (low noise level, high wear resistance).

Price. Parameter depending on the type of pads supplied. The most expensive (and highest quality) are supplied directly from the manufacturer. Those with average characteristics go to the spare parts market. The cheapest ones are exported in batches to developing countries. For the average consumer, the first two options are acceptable.

Working temperature. For everyday driving on city roads or fast driving on the highway, pads with an operating temperature of 300 - 350 °C are sufficient. However, if you are the owner of a sports car, you cannot avoid purchasing pads that operate at temperatures of 800–900 °C.

Appearance of the product (and packaging box). To avoid purchasing a fake, you should carefully examine the packaging and the product itself.

The first must be neat, corresponding to the cost of the product, and contain the marking of compliance with ECE R90 (R-90 or 90R) to European production standards.

In turn, the product should not have cracks, chips or bends in the metal base, and the friction linings should fit tightly to it.

Pay attention to the accompanying documentation (its availability) and the quality certificate indicated on the box, and then you are guaranteed to have an original brake pad in your hands, which will become a worthy component of your car.

Attention! The information presented above is not a purchasing guide. For any advice you should contact specialists!

Source: http://markakachestva.ru/rating-of/1164-luchshie-tormoznye-kolodki.html