How to assess the wear of brake pads and discs? ZR Instructions – Behind the Wheel magazine

In most cars, during normal use, the inner pad wears out a little faster than the outer one, and this does not depend on the design of the brake mechanisms.

However, under specific operating conditions or due to the design features of some machines, the internal pads sometimes wear out noticeably more intensively than the external ones.

For example, on a second-generation Mazda 6, the inner pad on the front right wheel wears out one and a half times faster than the outer one.

The design of the brakes on the Lada Kalina is such that without removing the wheel it is generally useless to peer into the front brake mechanisms - it will not be possible to assess the condition of the pads.

The design of the brakes on the Lada Kalina is such that without removing the wheel it is generally useless to peer into the front brake mechanisms - it will not be possible to assess the condition of the pads.

In addition to design nuances, malfunctions may also occur. For example, increased pad wear due to a soured piston.

Therefore, when inspecting the brakes for the first time on a car you have never driven before, it is important to remove the wheel to assess the condition of both the outer and inner pads.

Unscrupulous servicemen often limit themselves to an approximate assessment of the wear of only the outer pads, examining them through the spokes of the wheel rim, without removing the wheel itself. It is possible that soon a dissatisfied customer will return to this service station with worn out internal pads and complaints!

As an example, let's check the condition of the brakes on the editorial Kalina, which has driven almost 63,000 km.

In addition, we provide approximate indicators for critical wear of various elements of the brake system.

For each specific car model, they may differ either up or down. This data can be found in repair and maintenance books or on the Internet.

Related materials

On Kalina, it is not really possible to determine the wear of even the external brake pads if the wheel is not removed. The distance between the spokes of the alloy wheel is decent, but the bracket severely limits visibility. But, for example, on Mazda 3 of the first two generations, the wear of the external pads is clearly visible even with the wheel on.

True, you still have to remove it to inspect the internal pads.

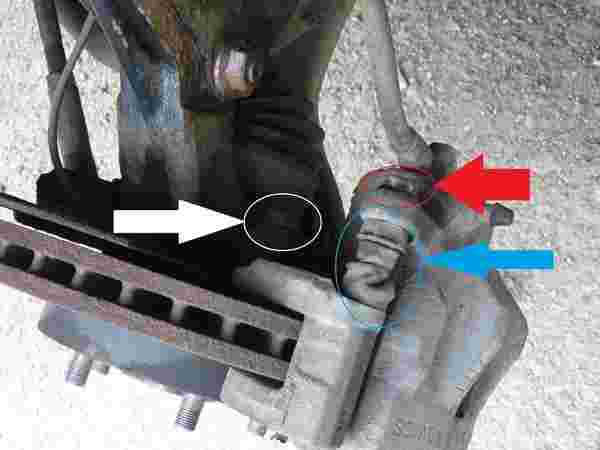

But let's return to our Kalina. Only after removing the wheel is the real picture visible. The thickness of the friction lining is approximately equal to the thickness of the pad base: wear is about 60%.

If the thickness of the friction lining decreases to 2 mm, this will mean 100% wear. Many cars have a metal tongue at the base of the block. When the lining wears critically, it begins to come into contact with the brake disc, producing a characteristic squeak.

Most often, the tongue is installed only on the inner pads.

With the wheel removed without disassembling the brake mechanism, it is clearly visible that the wear of the front pads on our Kalina is approximately 60%.

With the wheel removed without disassembling the brake mechanism, it is clearly visible that the wear of the front pads on our Kalina is approximately 60%.

Related materials

It is important to remember about difficult operating conditions, for example, driving along mountain serpentines or participating in amateur racing. In such modes, in a working brake system, the inner pad may begin to wear down many times faster than the outer one. Something similar once happened to my car.

During everyday driving, the pads on the latest generation Volkswagen Jetta sedan wore evenly. This lulled my vigilance, and I stopped monitoring the condition of the internal linings. After participating in two stages of sprints (far from the most difficult for equipment), it turned out that the internal pads were almost completely worn out.

This was especially noticeable on the left wheel. I was lucky that it didn’t come to the point of scuffing the brake discs!

Also, do not forget that if, for example, you drove 30,000 km and the wear of the front pads was about 50%, this does not mean that they will last up to 60,000 km. The smaller the thickness of the lining, the faster its further wear occurs. After all, the same portions of thermal energy from friction are absorbed by a less “fat” brake pad.

Brake disc wear

Brake disc wear is more stable and predictable. Most often, there are enough discs for two sets of pads. A reduction in disc thickness of approximately 2 mm means 100% wear. Over time, wear causes a chamfer to form on the edge of the brake disc.

The wear-out step of the front brake disc of our Kalina is already clearly noticeable when touched, but such a disc is still suitable.

The wear-out step of the front brake disc of our Kalina is already clearly noticeable when touched, but such a disc is still suitable.

The design of many wheel rims allows you to stick your hand between the spokes and feel the wear of the brake disc by touch. The main thing is not to do this while the brake disc is still hot, immediately after a trip with intense braking. This technique will be useful for those who plan to purchase a used car.

Based on disc wear, one can draw conclusions about the actual mileage of the car or the conditions in which it had to drive. But it is best to remove the wheel and carefully inspect the brake mechanism, including the inside of the disc. It happens that it is there that grooves and a wavy surface are formed due to corrosion.

Our Kalina's brake disc is 0.7 mm away from the maximum permissible wear limit. In most cases, this will be enough to drive away on another set of pads.

Our Kalina's brake disc is 0.7 mm away from the maximum permissible wear limit. In most cases, this will be enough to drive away on another set of pads.

When to change brake discs and pads?

Related materials

If the wear of the discs is already critical, and the pads are almost new, then do not rush to immediately change the entire set of consumables, especially if you operate the car in conditions that are not difficult for equipment. The work of replacing disks can be postponed for a while. But you shouldn’t completely turn a blind eye to the problem.

Remember that as the thickness of the discs decreases, braking efficiency decreases. After all, a too thin disk will dissipate thermal energy, which will also overheat faster.

In particularly advanced cases, due to excessive wear of the brake disc, the pad may even fall out of the mechanism!

With the wear of rear disc mechanisms, the situation is similar, with only one amendment: they are less loaded, and therefore wear occurs more slowly. This has both its pros and cons.

Rear brake discs and pads have a longer service life compared to the front ones (about one and a half to two times), but they also suffer more from corrosion.

Therefore, it is on the rear brakes that it is important to check the inner surfaces of the discs! Our Kalina has drum-type rear brakes.

How to assess the wear of drum brakes?

Most machines have an inspection window on the side of the drum casing to assess the thickness of the linings. However, most often it can only be used if the car is hung on a lift or standing on a viewing hole. Otherwise, it is extremely difficult to see anything through this window.

The left photo shows the location of the inspection window relative to the drum shoe. Using it with only a jack at your disposal is not very convenient.

The left photo shows the location of the inspection window relative to the drum shoe. Using it with only a jack at your disposal is not very convenient.

Removing the drums is sometimes also very problematic. For example, for cars of French brands you will have to unscrew the hub nut. In the case of Kalina, everything is simple; the drums can be removed without any problems.

You can assess the wear of the elements of the drum brake mechanisms on Kalina by removing the drum casing.

You can assess the wear of the elements of the drum brake mechanisms on Kalina by removing the drum casing.

Typically, drum wear is assessed by the internal diameter: its increase by 1 mm means a death sentence.

How are drum brakes different from disc brakes?

One of the disadvantages of drum mechanisms compared to disk ones is the lack of a self-cleaning effect. Wear products from the brake pads remain inside the drum and leave characteristic marks on the working surfaces of the friction elements.

Due to the abundance of wear products, characteristic grooves formed on the working surface of the pad. The actual wear of the linings was about 30%.

Due to the abundance of wear products, characteristic grooves formed on the working surface of the pad. The actual wear of the linings was about 30%.

Editorial Kalina is often used to participate in various competitions. That is, the conditions of its operation can be called difficult. However, to our surprise, the wear on the original pads turned out to be small - about 30%. Probably the reason is that the car has a relatively small mass, and its dynamic performance is not outstanding.

Deep grooves on the working surface of the drums are the result of exposure to wear products.

Deep grooves on the working surface of the drums are the result of exposure to wear products.

Alas, wear products have significantly damaged the working surfaces of the linings and drums. This can't be fixed. The next time you replace the pads, you will also have to update the drums, otherwise they will immediately damage the new pads.

However, there is nothing criminal in the further operation of the car in this form. The reduction in rear brake performance is not noticeable even when driving on a race track.

In general, drums, like discs, can survive two sets of friction linings.

Source: https://www.zr.ru/content/articles/910281-kak-samomu-otsenit-iznos-tormo/

How to Determine Rear Brake Pad Wear

Minimum thickness of brake pads

The braking system is responsible for safe braking of the car. The efficiency and speed of stopping depends on its serviceability.

The number of mechanisms in the brakes is quite large, and they all must work like clockwork, because the failure of one will entail at least unpleasant consequences.

Let's talk about what the minimum thickness of brake pads should be, as well as ways to check for wear.

About the main types of pads

The automotive industry has come a long way in recent years. A modern car, as a rule, has an advanced braking system; this is the presence of computer-controlled systems. This should include ABS, directional stability system, etc. The constant development of cars leads to progress in the types of brake pads. The following types are distinguished:

- with a semi-metallic friction layer (65% copper, iron powder, wire);

- organic friction layer (rubber, glass, Kevlar);

- from organics and metallic inclusions in a ratio of 70/30);

- ceramic friction layer with a small inclusion of copper.

Each of the above types has its own strengths and weaknesses. For example, a semi-metallic friction layer has good heat dissipation, but it wears out quickly and makes a lot of noise during operation.

But organic brake pads make virtually no noise and operate smoothly, but in the process they emit a lot of dust that settles on the wheel disc. We can safely say that ceramic ones are the most preferable.

They do not make noise and do not wear out too quickly. Their only drawback is their high cost.

Why do pads wear out too quickly?

There are several obvious reasons for premature lining wear. Constant driving around the city, when you have to brake often. This leads not only to wear, but also to high temperature of the disc and pads.

Many motorists prefer aggressive driving with prolonged and sharp braking. This also results in high wear rates.

While a quiet ride often contributes to a long “life” of the brakes.

If you often have to drive with a loaded trunk, then this, on the contrary, helps reduce the load on the front axle and brakes, respectively.

In general, it is recommended to change brake pad linings within the time limits specified by the manufacturer. For the rear axle this is usually 40,000 km, and for the front axle approximately 20,000 km.

Although they can fail either earlier or later, it is better to carry out regular checks.

Brake Pads, Front, Rear, Replacement Timing

When to change front and rear brake pads , uneven wear , when to change pads,...

How to determine brake pad wear yourself

Why is it impossible to objectively determine the degree of wear of the brake pads if you do it yourself?...

When do you need to change brake pads?

In addition to the mileage of the car, manufacturers also indicate the minimum permissible thickness of the friction lining at which replacement is necessary. After all, it often happens that you have already driven 20-30 thousand km, and the pads are like new, or, on the contrary, they have driven a little, and the wear is already critical.

The weight of the car also matters. The less the car weighs, the slower the pads wear out and vice versa. But in most cases, the minimum thickness of brake pads on different brands is almost the same and is 2-3 mm.

Sometimes critical wear can be seen visually without even removing the wheel. In this case, you can stock up on a set for one axle in advance. If the corresponding icon on the dashboard lights up (this option is not available on all cars), it means that the electronic sensor that determines the minimum permissible thickness of the friction linings has been activated.

“Musical” pads and runout

There are several other signs that allow you to determine the development of linings. If you recently had your brake pads replaced at a surprisingly low price, don't be alarmed that they turn out to be “musical.” This indicates their low quality and insufficient quantity of some element in the alloy.

But there are also special systems that produce a characteristic sound when the minimum thickness of the brake pads is reached. This is already a sign to the driver that it is time to make a replacement.

As for the phenomenon of beating during braking, this is more serious. Minimal losses on your part are the usual replacement of pads. In the worst case scenario, you will have to replace the disc or drum.

This is due to the fact that runout occurs as a result of uneven wear of the pads or brake disc, chips or cracks in the friction layer. Uneven wear, in turn, may be due to poor quality linings or discs.

In any case, the situation requires a quick solution to the problem.

About what not to do

Not every car owner regularly checks their brake system. This leads to a variety of consequences, including accidents on the road.

This is still good if you crash into a tree in your yard, but what if the brakes fail on the highway? Of course, experienced motorists will use engine braking, but not everyone will have time to figure out what’s going on.

So, never allow the brake pad linings to wear down to metal. This will damage the brake disc and ultimately cause the system to fail. Check the condition of the brakes regularly. It’s not difficult to do this yourself. You shouldn’t crawl under the car every 5 thousand km, but when the time comes, don’t be lazy.

What conclusions can be drawn?

So we figured out how to determine wear . This can be done visually, or using a ruler or caliper. If you do not have the time and desire to deal with this issue yourself, then entrust this matter to the specialists at the service station.

The minimum thickness of brake pads should be 2-4 mm, but values such as 1.5 mm are allowed. If the overlay is smaller, we change it. If it is within the acceptable range, but is already suitable, we are preparing to replace it soon. It is also worth regularly checking the brake discs for wear and overheating.

The latter leads to the disc warping, and the system works less efficiently - the braking distance increases and runout appears. So we figured out when the brake pads are replaced. The price for them differs depending on the manufacturer and varies between 800-3500 rubles.

But you don’t need to take the cheapest “musical” friction linings.

Source: http://5net.ru/kak-opredelit-iznos-zadnih-tormoznyh-kolodok/

How to check brake pad wear

The braking system is responsible for safe braking of the car. The efficiency and speed of stopping depends on its serviceability.

The number of mechanisms in the brakes is quite large, and they all must work like clockwork, because the failure of one will entail at least unpleasant consequences.

Let's talk about what the minimum thickness of brake pads should be, as well as ways to check for wear.

About the main types of pads

The automotive industry has come a long way in recent years. A modern car, as a rule, has an advanced braking system; this is the presence of computer-controlled systems. This should include ABS, directional stability system, etc. The constant development of cars leads to progress in the types of brake pads. The following types are distinguished:

- with a semi-metallic friction layer (65% copper, iron powder, wire);

- organic friction layer (rubber, glass, Kevlar);

- from organics and metallic inclusions in a ratio of 70/30);

- ceramic friction layer with a small inclusion of copper.

Each of the above types has its own strengths and weaknesses. For example, a semi-metallic friction layer has good heat dissipation, but it wears out quickly and makes a lot of noise during operation.

But organic brake pads make virtually no noise and operate smoothly, but in the process they emit a lot of dust that settles on the wheel disc. We can safely say that ceramic ones are the most preferable.

They do not make noise and do not wear out too quickly. Their only drawback is their high cost.

Why do pads wear out too quickly?

There are several obvious reasons for premature lining wear. Constant driving around the city, when you have to brake often. This leads not only to wear, but also to high temperature of the disc and pads.

Many motorists prefer aggressive driving with prolonged and sharp braking. This also results in high wear rates.

While a quiet ride often contributes to a long “life” of the brakes.

If you often have to drive with a loaded trunk, then this, on the contrary, helps reduce the load on the front axle and brakes, respectively.

In general, it is recommended to change brake pad linings within the time limits specified by the manufacturer. For the rear axle this is usually 40,000 km, and for the front axle approximately 20,000 km.

Although they can fail either earlier or later, it is better to carry out regular checks.

When do you need to change brake pads?

In addition to the mileage of the car, manufacturers also indicate the minimum permissible thickness of the friction lining at which replacement is necessary. After all, it often happens that you have already driven 20-30 thousand km, and the pads are like new, or, on the contrary, they have driven a little, and the wear is already critical.

The weight of the car also matters. The less the car weighs, the slower the pads wear out and vice versa. But in most cases, the minimum thickness of brake pads on different brands is almost the same and is 2-3 mm.

Sometimes critical wear can be seen visually without even removing the wheel. In this case, you can stock up on a set for one axle in advance. If the corresponding icon on the dashboard lights up (this option is not available on all cars), it means that the electronic sensor that determines the minimum permissible thickness of the friction linings has been activated.

“Musical” pads and runout

There are several other signs that allow you to determine the development of linings. If you recently had your brake pads replaced at a surprisingly low price, don't be alarmed that they turn out to be “musical.” This indicates their low quality and insufficient quantity of some element in the alloy.

But there are also special systems that produce a characteristic sound when the minimum thickness of the brake pads is reached. This is already a sign to the driver that it is time to make a replacement.

As for the phenomenon of beating during braking, this is more serious. Minimal losses on your part are the usual replacement of pads. In the worst case scenario, you will have to replace the disc or drum.

This is due to the fact that runout occurs as a result of uneven wear of the pads or brake disc, chips or cracks in the friction layer. Uneven wear, in turn, may be due to poor quality linings or discs.

In any case, the situation requires a quick solution to the problem.

About what not to do

Not every car owner regularly checks their brake system. This leads to a variety of consequences, including accidents on the road.

This is still good if you crash into a tree in your yard, but what if the brakes fail on the highway? Of course, experienced motorists will use engine braking, but not everyone will have time to figure out what’s going on.

So, never allow the brake pad linings to wear down to metal. This will damage the brake disc and ultimately cause the system to fail. Check the condition of the brakes regularly. It’s not difficult to do this yourself. You shouldn’t crawl under the car every 5 thousand km, but when the time comes, don’t be lazy.

What conclusions can be drawn?

So we figured out how to determine brake pad wear. This can be done visually, or using a ruler or caliper. If you do not have the time and desire to deal with this issue yourself, then entrust this matter to the specialists at the service station.

The minimum thickness of brake pads should be 2-4 mm, but values such as 1.5 mm are allowed. If the overlay is smaller, we change it. If it is within the acceptable range, but is already suitable, we are preparing to replace it soon. It is also worth regularly checking the brake discs for wear and overheating.

The latter leads to the disc warping, and the system works less efficiently - the braking distance increases and runout appears. So we figured out when the brake pads are replaced. The price for them differs depending on the manufacturer and varies between 800-3500 rubles.

But you don’t need to take the cheapest “musical” friction linings.

fb.ru

How to determine brake pad wear. Main signs of brake pad wear

In this article, we will look at the main signs of brake pad wear and, with their help, we will learn how to determine the wear of the brake linings.

Every car enthusiast knows that the safety of the driver and passengers largely depends on the serviceability of the brakes. That is why during car maintenance you should pay close attention to the condition of the brake system.

In particular, be sure to pay attention to the condition of the brake pads, as they are most susceptible to wear. Let's look at what signs can be used to determine that brake pads need to be replaced.

Why do brake pads wear out at all?

The thing is that during the braking process, the pads, when you press the brake pedal, are pressed against the brake discs, as a result of which braking occurs, and the process of wear of the pads occurs. Automakers recommend changing pads after twelve thousand kilometers.

But, it is clear that each car enthusiast has his own driving style, so those motorists who prefer an active driving style have brakes that fail more often than those who drive their cars calmly. Therefore, when operating the vehicle, pay attention to the following.

How can you determine brake pad wear - the main signs?

1. If you press the brake pedal, you notice that the effectiveness of the braking system has decreased - this is a reason to check and determine the wear of the brake pads.

2. One of the most characteristic signs of brake pad wear is the appearance of a characteristic high-pitched sound when braking. That is, if, when you press the brake pedal, the pads begin to squeal or grind, this means that it is time to change them, since pads with a worn surface begin to make such a sound.

3. In addition, during sharp braking you may feel a beating. It occurs due to the fact that part of the surface of the pads has worn unevenly and cracks will soon appear on the parts, and this sharply reduces the safety of the vehicle.

4. During an external inspection of the vehicle, pay attention to whether there is a characteristic carbon deposit on the wheels. This coating indicates that the surface of the pads has begun to actively deteriorate and it is time to change them.

The same should be done if there is a metal coating on the wheels or disks. This type of deposit forms when the pads have been worn down to metal. It is worth noting that in the case when the element of the brake system in question is worn down to metal, the braking process will take place abruptly, with jerks.

Thus, it becomes obvious that determining the wear and time of changing brake pads is quite possible, and for this you do not need to carry out complex diagnostics or be a professional in car repair.

Video: how to properly check brake pads.

Conclusion. The main thing is to show just a little attention and you will always be sure that the car’s brakes will not let you down.

(1 time, rating: 5.00 out of 5) Loading…

avto-i-avto.ru

Instructions: How to determine the wear of a car's brake pads?

Car brakes are subject to serious stress during operation, which is natural given the heaviness of the vehicle, which must be stopped at any speed.

Load shedding leads to mechanical wear of brake system parts, in which the pads suffer the most. When you press the brake pedal, they are pressed against the brake discs.

If the car is in motion, friction occurs, which is impossible without mechanical wear.

According to recommendations, brake pads on cars must be changed every 10 thousand kilometers so that the car’s braking quality is always maximum.

It should be noted that the recommendations give average figures for the pad change cycle, while different drivers may wear out the mechanical part of the brakes at different rates.

With a calm driving style, the pads can last up to 20 thousand kilometers, while with regular sharp pressure on the brake pedal, they will wear down to critical values after 4-5 thousand kilometers.

We recommend reading: Which brake pads to choose: the main differences and inspection in the store

Worn brake pads are a danger to the car driver, his passengers and people around him.

Under no circumstances should you hit the road if your brakes are faulty and worn out pads need to be replaced urgently.

But how can you determine whether brake pads are worn out and whether they need to be replaced? This can be done directly from inside the car while driving or by external signs.

How to determine pad wear while driving a car

There are several characteristic signs that will tell the driver that it is necessary to think about replacing the pads:

- A characteristic high-pitched sound when a car brakes. It may appear if the pads are severely worn and require urgent replacement;

- The car began to slow down. If this is not the first day you have been driving a car, you will notice that as the pads wear out, its braking distance will increase, and the brake pedal will have to be pressed harder and harder for the car to start stopping;

- When you press the brake pedal sharply, you can feel the brakes beating, as if the car is going over bumps. This is due to the fact that as you work, the pads wear unevenly. Cracks, chips and “burrs” form on them, which lead to a similar effect when the pads touch the brake discs.

If the stated signs are not enough to determine the wear of the pads, you can conduct a visual inspection.

How to determine the wear of brake pads by external signs

Drivers are recommended to check the condition of the brake pads every 2-3 thousand kilometers.

To visually inspect them, it is necessary to remove the wheel cap and pay attention to the presence of plaque on the wheels or the brake pads themselves.

If there is a gray coating, then from this we can conclude that the pad lining is currently being worn out. Until it wears out, the brake system will work without obvious failures.

If you find metal particles in the gray coating, it means that the lining has failed and the process of abrasion of the metal of the pad has begun. In such a situation, it is urgent to replace this component of the brake system.

Is it possible to change the pad on one wheel?

Smooth braking of the vehicle is achieved by simultaneous activation of the braking system on all wheels. Replacing the pads is provided in pairs for the front and rear axles of the car. The pads located on the rear axle of the car are less susceptible to wear than the front ones, and they need to be changed, on average, 3 times less often.

Source: http://autoprivat.ru/remont_avto/kak_proverit_iznos_tormoznyh_kolodok.html

How to check the wear of brake pads?

Slowing down the speed of a car until it stops (braking) occurs when the pads rub against the discs or drums. These parts come into contact when the brake pedal is pressed.

Motorists most often do not think about how to determine brake pad wear; this question usually arises when problems with the system become noticeable. The pads wear out faster because their main part during braking is friction linings, which are softer than metal and wear out faster.

It is important to understand in time why the mechanism began to work worse and urgently carry out repairs. At what level of wear should you change brake pads and how to determine their wear, you will learn from this article.

1 — brake disc; 2 — pad guide; 3 - caliper; 4 — brake pads; 5 - cylinder; 6 - piston; 7 — pad wear indicator; 8 - sealing ring; 9 — protective cover of the guide pin; 10 — guide pin; 11 - protective casing.

What causes pads to wear out?

For different car models, there is a certain service life of the brake bars. But this does not mean that they cannot fail before the car “runs” the kilometers indicated in the manual. There are several factors due to which the pads become unusable before the established service life expires:

- Riding mode. The urban driving cycle leads to wear and tear of parts faster due to frequent stops at traffic lights.

- Load level. The more cargo you carry in the trunk of your car, the faster the rear brake pads wear out. At the same time, this takes some of the pressure off the front brake pads, which means they will last longer.

The average service life for these elements is about 10,000 km, after which they are replaced. But signs of brake pad wear may appear earlier and are important to be aware of.

What indirectly indicates pad wear?

How do you know that these parts have become unusable without the hassle of inspecting them? Many modern cars are already equipped with an electronic brake pad wear sensor, which will promptly warn the car owner that the friction linings of the elements are no longer suitable for work. In addition to the electronic sensor, there are also mechanical ones, which are a metal strip and are attached below the lining. In this case, the abrasion of the friction layer can be recognized by a characteristic grinding and whistling sound, which will be clearly audible when you press the pedal. In this case, the operation of the brakes will be somewhat impaired, but not to a critical level, and the driver will be able to promptly change faulty car parts. Mechanical warning lights can be installed on one wheel (usually the front), two (front or rear), or all of them.

The presence of a brake pad wear indicator greatly simplifies diagnostics. If they are not there, extraneous sounds can be heard only when the linings are worn to the limit, and the quality of braking will decrease significantly: you will have to press the pedal with more force, and in addition, the braking distance will increase.

Brake pad wear sensor

If there are particles of road dirt between the disc and the pad, this will lead to accelerated wear of the brake components. Signs of such problems will be the brake pedal beating when you press it.

If there is uneven wear of the brake pads, in which the friction layer on one of the elements wears out faster, you can find out about this by the car skidding to the side when braking.

Pressing the pedal sharply in this case can cause the car to be thrown off the road, especially on wet surfaces.

Therefore, uneven wear is very dangerous, and if it is noticed, the car must be urgently repaired.

You can also find out about the maximum wear if the pressed pedal remains in the same position after being released.

This happens when the friction layer is almost completely erased, and the metal of the bar, heating up during friction, grips the disk.

But an accurate determination of the cause of the problem is only possible during inspection, since these signs may also indicate failure of other elements of the brake system.

Immediate signs of pad failure

If you notice any of the above signals, do not delay repairs - extreme wear of the brake system elements makes driving a car, without exaggeration, deadly.

It is best if the diagnostics and, if necessary, replacement of spare parts are carried out by professionals at a car service center: this will guarantee the correctness of the check.

But, if this is not possible, or you prefer to repair the “iron horse” with your own hands, then you can conduct a visual inspection to determine the cause of wear of the brake elements yourself.

The fact that the planks are unsuitable for further work can be determined by the following signs:

- The thickness of the friction layer has become below the permissible value established by the manufacturer.

- The thickness of the brake disc has decreased below the maximum permissible value (this parameter, as in the previous case, can be measured using a micrometer).

- Traces of mechanical damage in the form of cracks or depressions were found on the friction lining, on the base of the pad or on the disc of the braking mechanism.

- A protruding lip appeared on the outer edge of the block.

- The disc is skewed.

- A carbon coating has appeared on the surface of the disk, which indicates that the surface has begun to deteriorate.

The need for urgent replacement of the braking system strips is indicated by the appearance of a dark-colored coating containing small metal particles under the wheel cap. This indicates complete erasure of the friction layer and that the base of the part has already begun to wear off.

Under no circumstances should repairs be put off if problems are discovered, since the safety of the vehicle, driver and passengers directly depends on the serviceability of the braking system.

Source: https://bodyshop-info.ru/diagnostika-i-remont/kak-proverit-stepen-iznosa-tormoznyx-kolodok

How to check brake pad wear

Home » Repair and service » How to check brake pad wear

In order for the brake system to always be normal, it is necessary to constantly monitor its components. Since brake pads work exclusively on friction, they wear out faster than other parts.

It is impossible to say exactly when wear will occur; their conventional operational life is from 8 to 15 thousand kilometers during normal driving without “recklessness”.

Checking the brake pads gives you an idea of when to replace them.

Brake system

Each vehicle is equipped with:

- brake mechanism;

- parking brake;

- spare brake. Used in emergency cases, when the main brakes fail. In passenger cars, this is usually achieved by dividing the brake system into several circuits diagonally or front/rear.

The brake system consists of a drive and a braking mechanism with a drum or disc, as well as brake pads. Drum brakes are now used less frequently, although they last longer.

Today, almost all cars have a disc brake; such a system is considered fixed and has a caliper and two pads that are stable in one position. When the brake pedal is pressed, they compress the disc. There are also systems with a floating block; they are more complex.

During braking, the caliper piston touches one of them, it moves away, leans against the disc and moves it towards the other, after which clamping occurs.

The main reasons affecting the wear rate

A brake pad has two components: a frame and a friction lining. In short, it is the pad that performs the main task of braking, stopping the brake disc with its friction.

Front brake pads wear out two to three times faster than the rear ones. This is because a large load during braking falls on the front wheel mechanism, and the weight of the car is redistributed to the front axle.

The wear rate is directly affected by:

- the material from which the parts are made. Each manufacturer sets its own thickness for the product, so you don’t need to look at the price and purchase original linings;

- vehicle weight;

Pads

- sudden changes in air temperature;

- driving conditions. Sharp accelerations and emergency braking certainly shorten the life of products;

- brake assembly design. If there is a failure in the cylinders, this will also affect the pads.

It is noteworthy that in the winter season, replacement is performed less frequently, which suggests that in winter there are few maneuvers while driving.

Signs of wear

Sometimes, just to assess the condition of the linings, it is not at all necessary to get into the brake system. Many people are interested in how to check brake pads without removing the wheel? Wear can be determined by the following signs:

- When emergency braking occurs, a specific sound occurs in the wheel. This indicates that uneven wear of parts has occurred. Their plates are worn out and touch the brake discs, creating a squeak. A similar noise is accompanied by disk wear.

- Pad wear sensor. Almost all modern cars have indicators showing the condition of the mechanism. The sensor looks like a lamp; when it lights up, it means it’s time to change the pads. Sometimes oxidation of the contacts occurs, and the indicator may simply not work, then wear will have to be determined visually.

- The system began to behave strangely when the speed decreased. The brake fluid level decreases, and the pedal is pressed softly, slightly pressing down, or, conversely, when pressed, a lock is activated.

Brake pad replacement process

- If you find metal shavings on the discs, you need to go to a service station, since not only the pads have worn out, but also the disc has worn out.

- Long braking distance.

Checking the pads without removing the wheel

Checking brake pad wear is not difficult, especially when the vehicle has alloy wheels with large holes through which the brake assembly is visible. As a rule, only the outer block is visible. If you determine its thickness visually, then 1.5–2 millimeters is considered critical.

When, even without removing the wheels, you notice that the thickness of the lining is less than 5 millimeters, this is a reason for replacement. If the holes on the wheel are too small and the brake mechanism is hard to see, you need to start dismantling the wheel.

When nothing interferes with the view, it is easy to assess the condition of the second lining and, at the same time, the brake disc.

Proper Pad and Disc Inspection Process

Before checking, review the table of permissible dimensions of brake parts. When the data matches, start making replacements. The process is divided into the following stages:

- We place the vehicle on a jack and remove the front wheel.

- We clean the disk from settled dust.

- Using a caliper we determine the thickness of the disc. The permissible wear parameter is 10.8 mm.

- In the inspection window we determine the thickness of both pads; you can take a caliper.

- Use a screwdriver to see how the pads move. When they move tightly, it means they have compressed the disc. If the wear is uneven, a new cylinder and caliper must be installed.

- To get to the rear ones, remove the wheel and drum.

- We measure their thickness and the size of the drum surface. The diameter should not exceed 201.5 mm.

Brake pads

Parts need to be replaced if:

- linings in oil;

- products thinner than 1.5 mm;

- the linings are not tightly connected to the base;

- Discs need to be replaced if there are scratches or deformation.

Replacing front brake pads

- We secure the car with the handbrake and place barriers under the wheels. All you need are keys No. 13 and 17, as well as a screwdriver.

- We dismantle the wheel and check the brake fluid level at the same time. It should be between the MIN and MAX marks on the tank body.

- We press on the piston and pull the caliper until it stops.

- Use a wrench No. 13 to remove the lower bolt, and use a wrench No. 17 to hold the guide pin at this moment. We lift the body and take out the pads. We remove dirt, if any.

- We install new products, the springs are installed parallel to the top of the pads. We move the bracket body down and fasten the bolt in place, after which we bend the tendril of the lock washer.

- Install the wheel.

Next, you need to press the brake several times to check the piston.

Worn brake pad

Replacing rear brake pads

The replacement process is almost the same:

- To immobilize the car, we put it in gear. You cannot turn on the handbrake, as it will press the pads against the disc, and replacement will not be possible. For safety, we place blocks under the wheels.

- We remove the wheel and remove the guide pins with a No. 12 wrench.

- We remove the drum.

- Disconnect the springs from the pads.

- We take out the front block, remove the drive lever from the cable and remove it. Do the same with the back.

- Now we install new parts exactly the opposite way.

ktonaavto.ru

How to determine brake pad wear

The quality of braking directly depends on the reliability and serviceability of the brake system as a whole, and the condition of the discs and pads in particular. You cannot drive a vehicle with faulty brakes - this is rule No. 1, which every driver remembers. In this regard, it is necessary to know how to determine brake pad wear.

The problem is that they are subject to very high stress. Therefore, over time, there is a natural need to replace them.

Now there are certain rules for monitoring the technical condition of a vehicle. According to them, the pads need to be changed approximately every 10 thousand kilometers. In addition, from time to time you should simply conduct a diagnostic inspection, which will allow you to identify malfunctions.

Causes of wear

Very worn rusty pads

As already mentioned, pads and discs are subject to enormous stress, since they actually absorb all the kinetic energy of a moving car.

It is not only the distance traveled that determines the degree of wear. Driving style has a huge impact.

If you prefer a quiet ride, devoid of sudden starts and braking, then the pads can remain in order even after 20 thousand kilometers. But if you often drive on dense city roads and like to brake sharply before every traffic light, then your pads may become unusable after 5 thousand kilometers.

Characteristic signs

Possible signs of wear

The following symptoms indicate a malfunction:

-

Shocks during sudden braking;

-

Long braking distance;

-

Inappropriate and strange behavior of the braking system;

-

The appearance of dust and metal shavings on the pads and other elements.

Diagnosis of the condition

The difference between a new pad and an old one

Those. The main way to determine malfunctions is the driver’s personal feelings. As a rule, he knows perfectly well how a car should behave on the road, so any deviations immediately make themselves felt.

The bottom line is that the pads wear down unevenly over time, causing each wheel to brake with varying degrees of efficiency. The pad that was subjected to a higher load will develop more cracks and chips. As a result, it will make more noise and begin to knock more when braking.

A striking example of the fact that brake pads require replacement is a decrease in the efficiency of the system as a whole. If you have to press the pedal harder than usual when braking, then there is significant wear. In some cases, it happens that the brake system operates too sharply, this also indicates poor condition of the pads.

Checking through the window in the caliper

After you have covered several thousand kilometers, you should regularly carry out external inspections. In particular, you need to look under the wheel cover.

It is necessary to pay attention to the color of the coating - if it is dark, then this indicates that the block still has the main lining. As soon as it wears off, metallic inclusions appear.

The more there are, the more damaged the block is.

Although it should be added that this diagnostic method is not suitable for ventilated brakes and alloy wheels.

Features of front and rear brake pads

While driving, the front brake pads are subject to the most stress, as a result of which they have a much shorter service life than the rear ones. In this regard, some manufacturing companies even install special sensors that monitor the condition of the pads. If there is no such device, you need to independently inspect and diagnose the condition.

Rear brake pads last about three times longer than front brake pads, so they cause far fewer problems.

However, you still shouldn’t forget about them. As soon as they become unusable, repairs must be carried out immediately.

If this procedure is regularly carried out in accordance with all requirements, the car will fully meet all established safety requirements. This means you don't have to worry about anything going wrong while driving.

Even if you don't have time to personally perform repairs, you should still know how to determine whether your brake pads and rotors are worn out. If necessary, you can simply drive the car to the nearest service center, where a replacement will be made.

You shouldn’t wait until the need for a technical inspection becomes very urgent.

Video

Signs of brake pad wear in the following video:

auto-wiki.ru

Instructions: How to determine the wear of a car's brake pads?

Car brakes are subject to serious stress during operation, which is natural given the heaviness of the vehicle, which must be stopped at any speed.

Load shedding leads to mechanical wear of brake system parts, in which the pads suffer the most. When you press the brake pedal, they are pressed against the brake discs.

If the car is in motion, friction occurs, which is impossible without mechanical wear.

According to recommendations, brake pads on cars must be changed every 10 thousand kilometers so that the car’s braking quality is always maximum.

It should be noted that the recommendations give average figures for the pad change cycle, while different drivers may wear out the mechanical part of the brakes at different rates.

With a calm driving style, the pads can last up to 20 thousand kilometers, while with regular sharp pressure on the brake pedal, they will wear down to critical values after 4-5 thousand kilometers.

We recommend reading: Which brake pads to choose: the main differences and inspection in the store

Worn brake pads are a danger to the car driver, his passengers and people around him.

Under no circumstances should you hit the road if your brakes are faulty and worn out pads need to be replaced urgently.

But how can you determine whether brake pads are worn out and whether they need to be replaced? This can be done directly from inside the car while driving or by external signs.

How to determine pad wear while driving a car

There are several characteristic signs that will tell the driver that it is necessary to think about replacing the pads:

- A characteristic high-pitched sound when a car brakes. It may appear if the pads are severely worn and require urgent replacement;

- The car began to slow down. If this is not the first day you have been driving a car, you will notice that as the pads wear out, its braking distance will increase, and the brake pedal will have to be pressed harder and harder for the car to start stopping;

- When you press the brake pedal sharply, you can feel the brakes beating, as if the car is going over bumps. This is due to the fact that as you work, the pads wear unevenly. Cracks, chips and “burrs” form on them, which lead to a similar effect when the pads touch the brake discs.

If the stated signs are not enough to determine the wear of the pads, you can conduct a visual inspection.

How to determine the wear of brake pads by external signs

Drivers are recommended to check the condition of the brake pads every 2-3 thousand kilometers.

To visually inspect them, it is necessary to remove the wheel cap and pay attention to the presence of plaque on the wheels or the brake pads themselves.

If there is a gray coating, then from this we can conclude that the pad lining is currently being worn out. Until it wears out, the brake system will work without obvious failures.

If you find metal particles in the gray coating, it means that the lining has failed and the process of abrasion of the metal of the pad has begun. In such a situation, it is urgent to replace this component of the brake system.

Is it possible to change the pad on one wheel?

Smooth braking of the vehicle is achieved by simultaneous activation of the braking system on all wheels. Replacing the pads is provided in pairs for the front and rear axles of the car. The pads located on the rear axle of the car are less susceptible to wear than the front ones, and they need to be changed, on average, 3 times less often.

Source: http://autofluids.ru/remont-i-servis/kak-proverit-iznos-tormoznyh-kolodok.html