Power steering repair

Failure of the power steering is quite a serious breakdown. In some cases, the steering may not work completely and it will be impossible to control the car.

In this case, there are two ways to solve the problem: replacing the power steering or repairing it. The second option is more profitable, since purchasing a new device may not be economically feasible.

As a rule, power steering repair is justified in most cases.

Power steering malfunctions

Turning the steering wheel requires significant effort to overcome the weight of the car and turn the wheels in the desired direction.

A special power steering device (hydraulic booster) allows you to compensate for the efforts and facilitate the process of driving the machine. The power steering pump creates a certain fluid pressure inside the system, under the influence of which the steering rack moves.

Upon completion of the maneuver, the rotating mechanism returns to the neutral position.

The main reasons for power steering failure may be:

- Reduced fluid level in the system.

- Insufficient drive belt tension.

- Oil leakage due to damaged hoses and connections.

- Formation of air bubbles inside the system.

- Pump failure.

- Wear of power steering components associated with excessive loads and violation of operating rules.

Testing the power steering must begin by monitoring the quality and level of oil in the expansion tank. A liquid is considered suitable for further use if it does not have a waste odor or dark tints.

High-quality oil should be transparent, and the appearance of a grayish or earthy color indicates the need to replace it. Many drivers believe that fluid is poured into the power steering system once, and there is no point in changing it.

However, this is a big misconception, which can ultimately cause the power steering to fail.

To check the performance of the hydraulic booster, start the engine and check for noise in the area of the power steering pump. A working unit should not make any noise unless force is applied to the steering wheel.

- Turn the steering wheel alternately in both directions until it stops. If in this case a characteristic howling or buzzing sound occurs in the pump area. At the same time, it intensifies as the angle of rotation of the wheels increases, therefore, either the pump itself or the shaft bearing has failed. If the bearing fails, the seal of the system may be compromised, as evidenced by the appearance of foam in the tank. The oil may foam and spill over the top edge. As a rule, in this case the liquid will have an earthy tint.

- Alternately turn the steering wheel all the way left and right. If in this case, in the XX mode, the forces are large, but with increasing speed they decrease, therefore, the cause of the malfunction is the wear of the pump working unit. When additional forces appear on the steering wheel, it may also be wear on the ball joints or defects in the rotary (support) bearings of the front struts. Wide tires in the first few days after installation can create a certain load on the steering wheel. However, the main sign of wear on the pump working unit is a change in the steering forces as the speed increases.

- If a slight vibration (beating) occurs during the rotation of the steering wheel, and its intensity increases as the steering wheel is turned at a large angle, most likely the pump drive belt is slipping. This may be a consequence of poor belt tension (wear) or bearing defects. Sometimes a squealing (squeaking) sound may also appear.

- If the oil in the tank is of high quality, its level is within acceptable limits and there is no extraneous noise in the pump area, however, the steering wheel has become stiff, most likely the reason is the jamming (sticking) of the bypass valve.

- When a difference in effort is felt while rotating the steering wheel in different directions, it means you need to check the pressure switching unit. Most likely the mechanism has worn out. Defects in the shift mechanism can also create jerky forces on the steering wheel (heavy-jumpy-easy).

Video - what to do if the hydraulic booster breaks down?

Self-repair of hydraulic booster

Troubleshooting problems with damaged hoses or drive belt tension is quite simple. Check the system for defects and, if necessary, replace worn parts or tighten the belt. The problem with a low fluid level in the expansion tank can also be easily solved. However, in other cases, problems are not resolved so quickly.

Air in the system . Air bubbles can be removed using special equipment, which is rarely used by ordinary drivers. As a rule, in this case it is advisable to use the services of service centers or auto repair shops. Bleeding the system under high pressure will remove air from it.

Minor fluid leak . If there is a slight oil leak in the power steering system, and there is no way to troubleshoot the problem, you can solve the problem with the help of special additives. The unique composition will eliminate small leaks by restoring the elastic properties of worn gaskets.

Pump failure . You can repair the pump yourself if you have sufficient experience, basic knowledge of the design and the appropriate tools. If you are not confident in your abilities, then most likely you will just have to buy and install a new pump.

As a rule, the main malfunctions of the pump are easily eliminated, even without knowledge of its design features.

The complexity of this event lies not so much in the repair itself, but in the competent dismantling of the worn-out unit, subsequent disassembly of the pump and its correct installation after repair. As you know, the main working element of a power steering pump is the blades.

Basically, they fail or work with insufficient performance when a large amount of dirt accumulates or any defects appear.

Source: http://VipWash.ru/rul/remont-gidrousilitelya-rulya

Do-it-yourself power steering pump repair

To make it easier for the driver to control the vehicle, in modern cars a power steering is installed on the steering column. One of the main elements of this mechanism is a pump that pumps hydraulic fluid through the power steering system. During operation, it is subjected to heavy loads, so periodically there is a need to repair the power steering pump.

You can change this unit yourself. It is even possible to replace a failed bearing. In this case, a power steering pump repair kit will come in handy, which can be purchased at any car store.

Before making a decision to carry out repair work, you need to check the presence of fluid in the tank, as well as its compliance with the brand approved for use on this machine. Often, the cause of signs of malfunction is the appearance of air locks in the system.

Therefore, if you suspect this, you need to bleed the hydraulics, removing all air pockets. In this case, the performance of the power steering can be completely restored. If, when checking the quality of the working fluid, it is discovered that it does not meet the standard, it must be replaced with a fluid of the required brand.

If you decide to repair the power steering pump, you need to prepare a workplace and the necessary tools, as well as materials for the work:

- you need a key for “12”, as well as heads for “14” and “24”;

- you will need a snap ring remover;

- prepare in advance two copper washers, a gasket for the rear casing, two O-rings and an oil seal; they can be replaced by a power steering pump repair kit;

- It is necessary to have a bearing marked “6202” and an outer diameter of 35 mm;

- To pump oil out of the tank you need a large syringe and container;

- clean the workbench and cover it with clean cardboard for disassembling the pump;

- Prepare fine sandpaper and rags for wiping.

In order to remove the power steering pump and repair it yourself, you need to perform the following steps.

- Lightly loosen the axle bolt that secures the pump unit to the bracket using the hole provided in the pulley. Completely unscrew the tensioner lock nut and remove the belt.

- Using a syringe, pump out the hydraulic fluid from the reservoir. Turn the steering wheel left and right until it stops so that the oil completely leaves the system, do this several times to completely clean the pipelines.

- Loosen the clamp on the hose that comes from the expansion tank and remove this pipeline.

- Unscrew the bolt that secures the high pressure hose coming from the pump to the system.

- Remove the axial bolt securing the pump to the bracket and insert a screwdriver or a metal rod of suitable diameter in its place to lock the pulley. After this, unscrew the nut that secures the pump pulley.

- Pull the released power steering pump unit up and place it in a specially prepared place. Remove dirt and oil from the unit body.

- Using a puller, remove the bearing retaining ring.

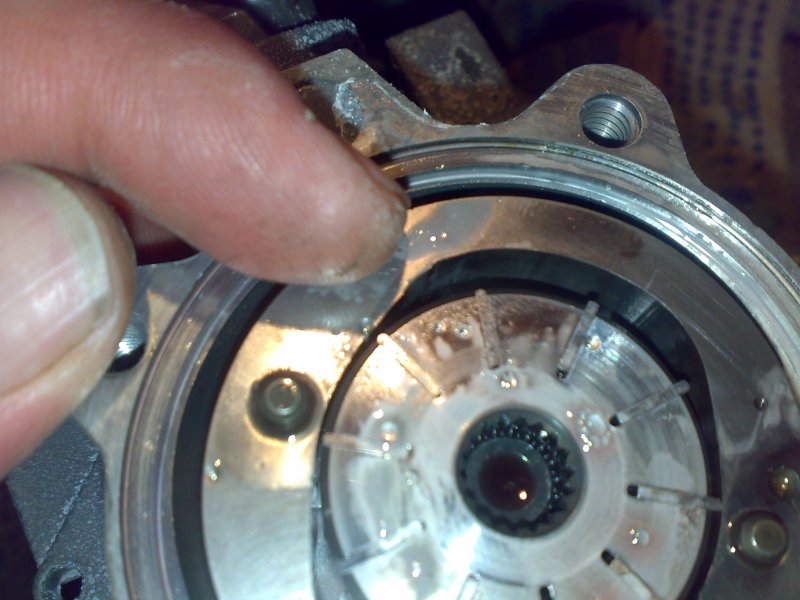

- Unscrew the bolts securing the rear cover. Carefully pry it up with a small screwdriver and remove it, making sure that the rotor blades do not fall out of the housing.

- Pull out the blades and place them on pre-prepared numbered pieces of paper so as not to mix anything up during assembly. Attention! Remember the position of the blades when assembled. When installed in the housing, the rounded part of these blades should be turned outward.

- Remove the plate and all parts underneath it.

- Knock out the shaft while gently tapping it with a screwdriver.

- Press the bearing off the pump shaft.

- Replace the unusable bearing with a previously prepared one.

- Check the parts of the pump unit for defects and wear. Clean surfaces from dirt and roughness. Experts say that simple cleaning of internal parts reduces gaps and allows you to extend the operation of this unit without replacing any parts.

- Reassemble in reverse order. Be sure to replace the oil seal, O-rings and washers with new ones prepared in advance.

If it is difficult for you to repair the power steering pump yourself or you don’t have time for it, then it is possible to replace the power steering pump with a new one. This will significantly reduce repair time. Also watch the video on the topic:

Very useful article! And even though I have a Hyundai H1 4×4 Starex 4WD, I think that these tips are very, very useful for me. My steering wheel is jammed (most likely a bearing). Disassembled.

As soon as I find a bearing and a repair kit for it, I will assemble it. It's a shame I didn't see this article earlier. I had to struggle with unscrewing the return hose from the fitting.

All you had to do was place a wrench on the bottom of the fitting and unscrew the top.

Thank you for the article!

Very useful article. I'm currently struggling with the Ford Exp3 4.6. And it howls and is tight... but you have to sort through it... My head is already a mess from studying and generally searching for information....

Source: http://ymp3.ru/avtoremont-i-tyuning/remont-nasosa-gidrousilitelya-rulya-gur-svoimi-rukami

Power steering pump repair

Sooner or later, during the operation of your car, you will have to repair the “heart” of the power steering – its pump. In itself, this compact device is quite reliable, but nothing lasts forever.

The vast majority of power steering uses vane (vane) pumps. If you have experience in car repair work, then you can try to repair the power steering pump yourself .

Removing the pump from the car will not be difficult. Before removing the power steering and especially before disassembling the pump, thoroughly clean it of dirt to avoid getting into the mechanism.

Drain the working fluid from the tank as much as possible. If it has already served enough, then it is better to replace it immediately. Necessary:

- Unscrew the steering shaft coupling.

At the same time, pay attention to the position relative to the shaft in which it is located, so that during installation you can assemble everything in exactly the same way. It is better to make a mark, for example, with a core.

- Disconnect the tie rods.

After this, lift the car on the left with a jack and remove the front left wheel.

- After removing the wheel, you will have access to the power steering from the arch side of the removed wheel.

- Unscrew the bolts securing the power steering to the side member.

When disconnecting the hoses, hydraulic oil will flow from them, so take care in advance of some kind of container where it can be drained. Close the fittings with caps or pieces of rubber hose during repairs.

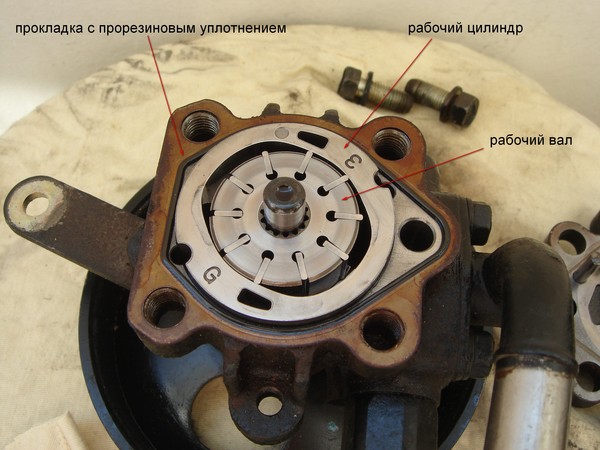

After this, we proceed to disassemble the pump. Its cover is attached to four bolts, which need to be unscrewed and the cover removed. The internal structure of the pump is not striking in its complexity, but it is clearly visible that the parts are fitted with great precision. The entire internal structure is:

Further more interesting design of the power steering pump

- working cylinder;

- rotor;

- power steering axis;

- retaining ring;

- records.

Carefully inspect the surfaces of all parts.

At the same time, remember, or even better, take a few pictures that will tell you the order of reassembly. There should be no scratches or burrs on the pump parts. Carefully try how the plates move.

They are not fixed and should move freely in the grooves.

Pay special attention to the presence of burrs in the grooves of the rotor where the plates are located. If there are any, carefully remove them using very fine grit sandpaper, approximately P1000-P2000.

Do the same with the plates if there are burrs there. Do not overdo it. Your task is only to remove hangnails. If the inner surface of the working cylinder has a groove, then the task becomes a little more complicated. The inner surface will have to be sanded.

This can be done using a router or drill with an appropriate attachment. The degree of abrasiveness should be the same as the above sandpaper. You can use a regular drill wrapped in such paper. But make sure to secure it well.

It would be ideal to polish the inner surface of the cylinder. After abrasive, thoroughly rinse and wipe all parts. There should not be a crumb of abrasive in the pump mechanism. When reassembling, you will notice that all gaskets and seals are new.

To do this, you need to purchase a power steering pump repair kit for your power steering model in advance. It happens that it is not easy to find, then you will have to buy all the replacement elements separately. Moisten all rubber parts in power steering fluid before installation.

When assembling the pump and replacing the cover, tighten the bolts one at a time to avoid distortion of the sealing gasket.

Source: http://spote.ru/remont-nasosa-gidrousilitelya-rulya/

DIY power steering repair

Since power steering was invented, driving has become much more comfortable. However, power steering (as we will further abbreviate the expression “power steering”), like any part in a car, needs care and periodic maintenance.

Here are some recommendations to help prevent premature power steering failure:

- Before each departure, monitor the fluid level in the power steering reservoir. It is advisable to always carry liquid with you in the trunk.

- Do not hold the steering wheel in its extreme position.

But what to do if play appears when turning the steering wheel?

What should I do if the steering wheel becomes very difficult to turn and a buzzing noise is heard in the system?

What measures should you take if you find other problems with the steering column?

The first step is to check the fluid level in the tank. Then it is worth diagnosing the power steering pump and its hoses.

Warning!

I must say that power steering repair is a very responsible matter. After all, your life and the lives of your passengers may depend on the quality of the steering. Therefore, at the beginning of this article we would like to advise you to carry out repairs from a competent specialist.

Self-repair is allowed only if you have extensive experience. The recommendations in this article are of a general nature and should not be taken as a strict guide to action. Power steering models for cars and trucks are different.

And each driver is personally responsible for their own repairs.

The first stage of repair is diagnostics.

First, it would be a good idea to inspect the hoses (the tubes that connect the parts of the power steering system). If the hoses leak, you need to have them repaired by specialists. It is extremely difficult to restore them with your own hands.

To inspect the power steering pump, we need to remove it.

Power steering pump

We can say that the power steering pump is its heart. After all, it is he who pumps the fluid, with the help of which the steering is facilitated. The pump contains rubber gaskets, seals, bearings and balls and much more. All this can become unusable over time.

More serious damage may be associated with pistons that may not work correctly. There may be various reasons for this. From the usual play of some parts to the entry of air into the power steering system. As with hydraulic brakes, air causes the system to malfunction. In this case, bleeding the system will help.

If you suspect that it is necessary to change gaskets and other consumables, then it is advisable to find out the number of the repair kit you need.

Some car enthusiasts prefer to purchase a hydraulic booster from a disassembly site and use parts from it. This option sometimes pays off in case of serious breakdowns.

Power Steering Removal Procedure

- Clear the pump and hoses of debris. This must be done to prevent dirt from getting into the cavities of the system when disconnecting the hoses.

- Drain the fluid from the power steering reservoir. This can be done using a special syringe.

- Take a strong 6mm hexagon and unscrew the screws of the steering shaft coupling.

Don't forget to mark its position in relation to the power steering shaft. We use a pry bar to move the coupling from the splines of the power steering shaft to the steering shaft.

- We remove the steering rods using pullers from the bipod.

- Remove the left wheel (after jacking it up).

- Find the pump mounting bolt.

For example, on Audi cars it is located under the radiator fan. There is an adjusting bolt under the mounting bolt. It performs the same role as the alternator belt tension adjustment bolt. Only in this case the tension of the power steering belt is adjusted. So if you need to tighten this belt, use this bolt.

Also on some cars there is another bolt that secures the power steering pump to the side member. Be careful not to drop the gearbox on your foot when removing the bolts.

- Now you can disconnect the hoses (pipes). Place some kind of container under the fittings that secure them. Because liquid will pour out of the hoses.

- Let's seal the hose fittings.

- Wash and clean the power steering again before disassembling it.

So, you have removed the power steering pump

On some vehicles, the pump can be removed without removing the pipes.

Pump disassembly

Before disassembling the power steering pump, try to find its diagram and disassembly and repair instructions. Since different pumps have different designs. Some are almost completely understandable. It’s better not to disassemble others.

Let's look at an example of disassembling a pump from an old Audi 80 (1988). In this case, the list of actions below is carried out in order to change the rubber seals and seals.

It is advisable to put each of the parts on a separate A4 sheet, putting down a serial number. This will help us later put everything in the right order.

- After we have washed the pump, we remove its pulley, which is secured with 3 bolts.

- The pump is made of two halves, which are attached to each other with 4 bolts. Unscrew the bolts. Thus, we disassemble the pump into two halves.

- We inspect the “halves” for wear on the rubber seals. All worn rubber parts must be replaced. 026 198 049 A is the repair kit number for the pump in question.

- We remove the plate, which in appearance resembles a fungus.

- We remove the retaining ring and then the rotor. At the same time, be careful that the vanes (they look like plates) do not fall out of the rotor.

- Now you can remove the pump shaft.

- We have an oil seal in front of us. Let's take it off.

- Washing pump parts.

- New spare parts (including oil seals and rubber bands) that will be installed must first be lubricated with new power steering fluid.

We assemble everything in reverse order. We connect the pipes.

Bleeding the system . We pour new fluid into the reservoir and turn the pump by the pulley by hand without putting on the belt. The goal is to fill the system with new fluid and expel air.

Experts say that replacing oil seals does not always solve the problem. If the rotor parts are worn out, then more serious professional repairs are required. In some cases, you simply need to replace the pump.

This article provided general information with some examples. Power steering breakdowns can be very different and it is almost impossible to cover them in one article. We hope these recommendations help some of you!

After the repair, we advise you to undergo diagnostics from a specialist, since the steering is not a car system that you can joke with...

Source: https://v-mireauto.ru/remont-gidrousilitelya-rulya-svoimi-rukami/

DIY power steering repair instructions

Repairing any part or entire vehicle assembly requires preliminary preparation. A detail such as a hydraulic booster is no exception, because steering with a faulty mechanism is more difficult. First, you need to prepare the necessary tools, the presence of which guarantees correct and quick repair and replacement of the device.

For this we need:

- Jack. To work, you need to lift the car to remove the front wheel. This will allow you to gain access to the device being repaired.

- Special puller for removing steering rods. It can be purchased at any auto parts store.

- "15" inch socket wrench. They unscrew the bolts that secure the hydraulic booster.

- A container for draining the working fluid from the system.

- Clean rags.

Repair stages

The hydraulic booster is a rather complex steering mechanism (unit), which makes it more difficult to repair on your own. But, this is quite possible if you follow some steps, which I will discuss below.

Let's consider the stages of performing a comprehensive repair of a hydraulic booster, which will allow you not only to identify the cause of the malfunction of this device, but also to repair it if necessary.

Dismantling

The dismantling process consists of some step-by-step actions that are performed in a precise sequence. Compliance with this will facilitate correct and more efficient disconnection of the device, and subsequently steering will become much more comfortable.

So, let's look at these stages.

Therefore, first of all, you need to clean the connecting hoses. Next, you need to pump out the liquid from the tank. If possible, you need to pump out as much of it as possible. Next you need to disconnect the elastic coupling of the steering shaft. For this, a hexagon “6” is used. The mount is located underneath the car. In this case, you need to make marks regarding the location of the coupling to the power steering shaft.

This is done to ensure that it is installed correctly during installation. After it is disconnected, it must be moved so that it does not interfere with further installation. To do this, you can use a long screwdriver or a pry bar.

Use this tool to slide the clutch onto the steering shaft. Next, we disconnect the steering rods; for this we use a special puller. Now we need to remove the left front wheel to gain maximum access to the unit.

To do this, you need to lift the car in the area of this wheel using a jack.

When the wheel is removed, we have all the conditions to continue dismantling the power steering. So, you can dismantle the hydraulic booster.

To do this, we find a fastening (as a rule, it is fastened with three bolts) under the arch on the side of the left front wheel, and loosen it. There is no need to remove all the bolts at once, you only need to remove two.

You still need to drain all the working fluid from the system, so the power steering must still be in its place. To unscrew the fastener, use a 15" socket wrench.

We place a prepared container under the system to drain the liquid. The hoses are disconnected one by one and the remaining liquid in the system is drained from them.

It will not be possible to drain all the liquid, so for further work the hoses need to be blocked with something to prevent spontaneous leakage.

To do this, you can use special plugs or use the traditional method - plug it with a rag. After this, the last bolt is unscrewed.

Defect detection

Sometimes, a malfunction can be identified during the first inspection of the unit without removing it from the car. Such malfunctions may be mechanical damage to elements or their wear.

In this case, repairing the power steering is not particularly difficult. Since if there are such obvious problems, they can be eliminated by quickly replacing parts.

And for this there is no need to dismantle and completely disassemble the device.

But if a malfunction occurs inside the mechanism, repair is not possible without partial or complete disassembly of the device. Disassembly should only be done over a lined cloth or film. The fact is that during disassembly the remaining oil may leak, and in order not to stain anything, it is necessary to use the above protective agents.

Trouble-shooting

Power steering repair is directly related to troubleshooting.

Malfunctions can be different:

- Faulty hoses. If the hose is damaged, fluid will leak from the power steering system. This problem can be repaired in two ways. The first is partial elimination by placing an additional hose over the leak. To do this, you need to have a piece of hose with a slightly larger diameter and two clamps. The patch is applied to the leak site and tightened with two clamps. The second option is to completely replace the fluid path. The hose can be replaced with a new one. Using the second method is more rational; it will allow you to forget about the breakdown for a long time.

- Pump failure. In this case, it is necessary to disassemble the pump to inspect its components for faults. This, of course, will not be so easy to do, since some of the models are not collapsible. But still it is necessary to disassemble it. It is necessary to inspect the following parts: ellipse (inspect it for wear), bearing and seals. If these parts have any defects, they must be replaced.

- Removing play. Very often, the cause of play can be faulty racks, worn parts and seals. Repair of the power steering, associated with the removal of play, involves a complete replacement of worn parts, special attention is paid to all seals.

Repairing the power steering will allow each driver not only to eliminate faults, but it is an opportunity to study some of the devices of their car in more detail. Therefore, repairs are not only beneficial for the vehicle, but also for you. After all the work has been done, driving will be as pleasant and comfortable as before.

Video “Power steering repair”

The recording shows the process of repairing the power steering. After watching the recording, you will learn how to remove and repair power steering racks on a foreign car "Volkswagen Passat".

Source: http://MineAvto.ru/remont/rulevoe-upravlenie/remont-gidrousilitelya-rulya-2163.html

Why does the power steering break down: rack repair, power steering replacement and adjustment

Home » Power steering » Why does the power steering break down: rack repair, power steering replacement and adjustment

What to do if the steering wheel with power steering does not work well and turns hard, what should you do if the amplifier is leaking, how to remove it and how to check the system yourself? If the amplifier has stopped working, is leaking, or the steering wheel with power steering is difficult to turn, this may indicate a malfunction in the unit. Problems are solved depending on what exactly the breakdown is.

To begin with, we suggest that you familiarize yourself with the main signs and reasons why the amplifier does not work:

- The main symptom is that when turning the steering wheel, shocks appear. In practice, such a malfunction usually indicates a weak belt tension. You need to check the quality of its tension and condition; if necessary, tighten the drive belt. If the steering wheel turns with difficulty at idle, then perhaps the reason lies in the oil pump; you need to check that too.

- It happens that leakage of working fluid in the system is due to poor connection of the hoses. It is necessary to check the condition of the pipes and, if necessary, eliminate the leak.

- Air lock in the system. In this case, you will need to bleed the system and remove the air lock from it; if this does not work, then drain the liquid and refill it.

- Problems with the steering mechanism. Malfunctions of this kind are resolved by dismantling and repairing the mechanism or replacing it with a new one, depending on how complex the breakdown is.

- Difficulties in turning the steering wheel occur unevenly - sometimes when turning left, sometimes when turning right. Sometimes the steering wheel functionality is restored. Such symptoms indicate that the hydraulic system is clogged. You can try to wash it, as well as the integral steering mechanism. If clogged, the working fluid needs to be changed.

- Also, only the filter located in the expansion tank under the hood could become clogged. You can try to replace either the filter element itself or the entire tank assembly.

- The next symptom of a malfunction in the amplifier is the appearance of uncharacteristic noise when the steering wheel is rotated. This symptom may be associated with incorrect installation of the tie rod ends. It is also possible that the reason lies in their poor fastening.

- Another sign is that after performing a maneuver to turn the steering wheel, the steering wheel returns to its original position with difficulty. If the system as a whole is otherwise functioning correctly, then the most likely cause is poor alignment of the flow control valve. Alternatively, the problem may also be loose ball joints.

- Pump failure. This problem is considered one of the most difficult. The pumping device is one of the main ones in the hydraulic booster system.

Photo gallery “Main amplifier problems”

1. Damaged booster pump2. Oil leak

Diagnostics and troubleshooting

So, if the amplifier does not work well when cold or hot, then the power steering will need to be repaired or replaced. This procedure can be done with your own hands or with the help of specialists, depending on the complexity of the process.

How to disassemble and diagnose, as well as troubleshoot the pump:

- One of the most difficult stages in this case is disconnecting the pump from the nozzles with consumables. Depending on the design features of the car, the disconnection procedure may vary; let’s consider a universal option. First you need to loosen the drive belt or disconnect the drive with the gear, then unscrew it from the mount to the engine. After removing the case, it will need to be washed from dirt and dust.

- Then the pump housing must be disassembled. At this stage, you may need replacement parts; for this, buy a repair kit in advance. When disassembling, mark or take a photo of the process to remember how everything is attached. After disassembling the pump, you will need to clean the inside of the part from dirt.

- Having done this, visually identify the cause of the problem. It may consist of burrs, a worn bearing, worn seals, gaskets or oil seal, or an uneven surface of the internal component of the stator (cylinder).

- Visually inspect the rotor mechanism, in particular, check the condition of the grooves. There should be no nicks or chips on the edges of the grooves; it is desirable that they be sharp and smooth. Also perform a visual inspection of the inner surface of the stator mechanism. As practice shows, it is its wear that often leads to malfunctions in the pump.

- To troubleshoot problems, sand the rotor to remove any rough edges or burrs. You will also need to sand the surface. First of all, rough cleaning is carried out; for this you can use a needle file, after which it will be necessary to smooth the surface with sandpaper.

- At the final stage, you should replace the cover, and do not forget to install a new seal. When assembling, the cover should be tightened with four screws; the best option would be to tighten them diagonally, that is, crosswise. When all the elements of the pump are installed, you will need to make sure that the shaft rotates inside the device without problems (the author of the video about repairing the pump using the example of a Chevrolet car is the Chevrolet Aveo channel).

But the pump is not the only element of the system.

About faults that are less difficult to repair:

- As mentioned above, one of the main malfunctions is wear of the drive belt. The belt replacement procedure is generally not particularly complicated. Before replacing, you need to check its condition - there should be no signs of damage, defects, peeling, etc. on the surface of the belt.

- The problem of leakage of working fluid from the system is relevant for many cars. First you need to identify the leak - oil can come out of bad connections, damaged hoses, as well as the pump, or from damage to the expansion tank. All these elements must be checked immediately; damaged parts must be replaced.

- If the quality of the oil used is too low, then most likely the reason lies in a clogged filter, which is usually located inside the tank.

You will have to drain the liquid and change the filter itself, and then pour new oil into the system. When replacing the fluid, you must also act carefully to prevent the formation of an air lock in the system. For this you will need an assistant. When pouring oil into the expansion tank, you must turn the steering wheel to its extreme positions - first to the left, then to the right. This procedure is repeated several times when it is cold, after which the car engine is started and everything is repeated again, only with the power unit warmed up. When you turn the steering wheel, bubbles will appear on the surface of the oil in the tank. When they stop coming out, this may indicate that there is no blockage in the system. - If bearings or seals are worn out, inoperative parts must be replaced (the author of the video about self-repairing the amplifier is the HYDRAULICS REPAIR channel).

Recommendations for use

What must be taken into account in order to prevent problems with the operation of the power steering:

- First of all, it is regularly necessary to monitor the condition and level of the working fluid in the expansion tank. Try not to allow the power steering to operate at a minimum fluid level. Over time, this can lead to pump inoperability.

- To timely detect problems in the system, you should diagnose its performance from time to time. And not only with the engine running, but also with it turned off.

- In addition, you should periodically check the condition of the hoses and all pipes through which the working fluid moves. You should also pay attention to the diagnosis of connecting points - they are more susceptible to damage than others. Such actions will allow you to promptly detect oil leaks.

- Never leave your vehicle with the wheels turned to the side, as this may also affect the future performance of the pump.

- Always check the condition and tension of the drive belt. If the tension is too weak, this will lead to incorrect operation of the power steering and accelerated wear of the strap. If the belt is too tight, this will also not lead to anything good.

- If the power steering fails, for example, due to a broken pump or a broken belt, then the car should be operated only to the nearest service station or garage.

Loading …

Video “Example of assembling and adjusting an amplifier on a bench”

The video below shows the assembly process, as well as adjusting the power steering using special equipment (the author of the video is the Zavod Avtoagregatov channel).

Do you have any questions? Specialists and readers of the AVTOKLEMA website will help you ask a question

Source: https://avtoklema.com/rul/remont-rejki-gidrousilitelya-rulya-2784/

Power steering malfunctions, DIY repairs

Malfunctions of the power steering can lead to irreparable consequences, because driving a car, especially over long distances, is quite tiring, and the driver’s fatigue directly affects the increase in the likelihood of the car flying into a ditch or another accident.

Therefore, in order to alleviate the driver’s plight and reduce the likelihood of an accident, modern passenger cars are very often equipped with power steering. Initially, amplifiers were used only on trucks, but over time they also appeared on passenger cars.

The vehicle can be equipped with hydraulic, electro-hydraulic and electric power steering.

The most common are hydraulic boosters. Their design is not very complicated, but still, during the operation of the car, breakdowns of this steering unit may occur.

Malfunctions of the power steering can manifest themselves in the form of:

- Increased noise under the hood;

- Increased effort on the steering wheel;

- Leakage of working fluid.

Increased noise

Increased noise occurs in several cases. The appearance of extraneous sounds under the hood while turning the steering wheel most often indicates a loosening of the tension in the power steering pump drive belt.

To repair the power steering yourself and fix this problem, you need to check the belt tension. In working condition, with increased pressure on the belt with your thumb, it should bend by 0.1-0.15 cm. If the belt bends much more, it should be tightened with a tensioning mechanism.

Increased noise may be due to the fact that there is not enough fluid in the system, resulting in air getting into it. In this case, you need to add the recommended fluid to the power steering reservoir. But after this, you should definitely bleed the system to remove air from it.

This operation can be performed differently on different cars.

If there is a special fitting

In one case, bleeding is carried out using a special fitting, which can be found on the power steering housing. To make pumping easier, the front part of the car is hung up, the steering wheel is turned in any direction until it stops. In this case, the engine must be turned off.

Then the bleeder fitting is loosened a little so that air can escape through it. After this, the steering wheel does not quickly turn in the other direction until it stops.

When turning the steering wheel, all air from the system should escape through the fitting. A signal that air has escaped will be the appearance of liquid from the fitting. If the fluid has leaked, then, without changing the position of the steering wheel, the fitting must be tightened so that air does not get back into the system through it. When carrying out this operation, you need to constantly monitor the liquid level in the tank.

Then you should lower the front of the car. To complete bleeding the system, you need to start the engine and start turning the steering wheel from side to side until it stops. But you cannot hold the steering wheel in the extreme position for a long time.

During this operation, air bubbles will appear in the tank. You need to turn the steering wheel with the engine running until these bubbles disappear.

Hydraulic booster without fitting

If the hydraulic booster is not equipped with a fitting for bleeding air, the pumping process is performed slightly differently. Initially, operations are carried out with the engine turned off. To do this, the front of the car is hung out. Liquid is poured into the tank to the level. Then you need to turn the steering wheel from lock to lock several times.

Then the car lowers to the ground. Then you will need to start the engine and let it run for a few minutes. Next, the steering wheel must be turned again from the stop, first to the left, then to the right, without stopping in the extreme positions. In this case, you need to monitor the liquid level and top up if necessary.

During this operation, foam forms on the surface of the liquid in the tank. Then you need to stop the engine and wait until the foam disappears. The pumping has been completed.

If you constantly hear noise under the hood, this indicates wear on the bearings of the power steering pump. In this case, the pump is replaced.

Increase steering wheel power

Malfunctions of the power steering, which are manifested by an increase in force on the steering wheel, indicate a clogged system. In this case, you will need to check the filter element of the power steering reservoir. If it is noticeably clogged, the tank needs to be replaced.

Then flush the system by replacing the working fluid twice and then pumping the system. This operation should also be carried out when turbidity of the liquid is detected.

Leakage of working fluid

Very often, power steering malfunctions come down to leakage of working fluid. It can leak in places where pipelines are attached or in case of damage to these pipelines.

In the first case, it is recommended to replace the clamps on the pipelines. If the pipeline is damaged, it must be replaced, which will require draining the working fluid from the system. Moreover, it is advisable to change all pipelines at once. After replacing the pipelines, new fluid is poured into the system and pumping is carried out.

It is important to remember that reusing power steering fluid is not recommended, as this can lead to failure of power steering components.

Source: http://x7.by/remont/93-neispravnosti-gidrousilitelja-rulja-remont-svoimi-rukami.html