Engine cooling system and its malfunctions

When the working mixture is burned in the engine cylinders, the temperature of the gases pressing on the piston can reach 2500°C, but on average, when the engine is running, it is 800 - 900°C.

Naturally, this causes severe heating of the parts and can lead to serious malfunctions, for example: burnout of lubricant and jamming (seizing) of pistons in the cylinders, burning of valve seats and discs, melting and rotation of crankshaft bearing liners, and much more.

In order to prevent many malfunctions from engine overheating, it is necessary to maintain the necessary optimal thermal conditions. This is ensured by a properly functioning cooling system, the main function of which is to remove heat from heated parts.

In a working cooling system, the coolant temperature in all operating modes should be maintained between 87 and 98°C. In an air cooling system (for example, motorcycles and cars with air-oil cooling), normal thermal conditions are determined by the temperature of the oil in the lubrication system and oil cooler, it should be from 70 to 110 ° C.

cooling system.

The main parts of the cooling system are: a water jacket in the engine block, a centrifugal pump (pump), pipelines, a radiator, a fan, an expansion tank, a thermostat, a fan switch sensor (if the fan is electric), a temperature sensor with a coolant indicator.

The operating principle of a working cooling system is as follows. When starting a cold engine, the thermal valve (thermopower element) is in the extreme left position when its bypass valve 5 is open and the main valve 7 is closed (see figure).

When the engine is running, the pump impeller 3, which is driven by a belt from the crankshaft pulley, sucks coolant from pipe 4 and pumps it into jacket 2 of motor block 1.

At the same time, the coolant takes away excess heat from the heated parts and heats itself up, and then, through the open bypass valve 5 of the thermostat 8, it again flows to the pump (pump) and generally circulates in a small circle, bypassing the radiator. Circulation without a radiator speeds up engine warm-up, especially in winter.

Gradually, as the engine warms up, the thermal power element 6 of the thermostat heats up, expanding and moving the valves to the right, gradually closing the bypass 5 and opening the main 7 valves. Now, the circulation of the coolant will occur as before - in a small circle, but at the same time it will also begin to partially pass in a large circle, already through the radiator 10, through pipes 13 and 9.

When the engine is completely warmed up and the coolant temperature reaches 85 - 95 ° C, the bypass valve 5 of the thermostat will close completely, and the main valve 7 will open completely, and now the coolant will circulate only in a large circle in the sequence described below. From the pump (pump) 3 it will flow into the jacket 2 of the block and cylinder heads, then through pipe 13 into the upper radiator tank 10, then through the radiator core into the lower tank 16, and then, partially cooled liquid with the help of fan 14 will flow through pipe 4 again to the pump, for a new circle, to maintain the required optimal engine temperature. Expansion tank 12 serves to compensate for the volume of liquid when heated, because, as is known, when heated or pressure increases, the liquid expands.

Having understood the basic principle of operation of the engine cooling system, it is much easier and faster to determine its malfunction.

Cooling system malfunctions.

The main signs of a malfunctioning cooling system are: leaking coolant, overheating or undercooling of the engine.

Leakage of coolant can occur through a loose connection of hoses with pipes or flanges, as well as cracks in the hoses, cracks in the expansion tank or radiator core, through faulty or leaky drain or filler plugs, and it can also leak through a worn water seal pump (pump). When these malfunctions occur, wet spots form in the parking area and there is a need to frequently add coolant.

To eliminate leaks through leaks in hose connections, you need to tighten or replace the clamps, and if that doesn’t help, then remove the hose, degrease the pipe and hose at the interface, coat them with sealant, assemble and tighten new clamps.

Leaks through leaks in the flanges of the pipes are eliminated by tightening the fastening nuts, and if this does not help, then replace the sealing gasket with a new one, assemble and tighten the nuts on the flange.

If liquid leaks through the water pump seal, it is necessary to remove the pump and replace the worn seal with a new one, then mount the pump in place. Leakage of liquid through cracks in the expansion tank or radiator core is eliminated by cleaning and soldering the cracks.

You can read in detail about eliminating coolant leaks invisible to the eye and devices for this in this article.

Engine overheating. Engine overheating is determined by an increase in the temperature of the coolant or its boiling.

This occurs due to insufficient fluid level, slipping of the fan belt or failure to turn on the electric fan, clogging of the passages (tubes) in the radiator core, breakdown of the water pump impeller or slipping of its drive belt, malfunction of the thermostat, since its main valve does not open and Because of this, fluid circulation through the radiator does not occur.

Also, overheating of the engine may be due to large scale deposits in the engine cooling jacket or radiator. In addition, overheating of the engine can occur due to a malfunction in the power system (carburetor leans the mixture) or ignition (incorrect timing).

Under no circumstances should the engine overheat; you must immediately turn off the engine and look for the problem. When overheating occurs, a loss of power occurs, since the filling of the cylinders with the combustible mixture sharply deteriorates, the oil also burns out and, because of this, increased wear of the cylinder-piston group.

The pistons in the cylinders may jam, or the cylinder head may move due to overheating and this will disrupt the plane of its contact with the plane of the engine block. Naturally, this will break the seal and no new gasket will help.

You will have to change the head or require serious repairs, described in detail in this article.

Troubleshooting the cooling system.

Thermostat. To check its condition directly on the car, you need to start the engine and feel the lower radiator reservoir with your hand. Until the engine temperature reaches 80 - 90 ° (observed on the instrument panel), the lower tank should be cold.

When the temperature reaches 80 - 90 ° (different models have different values, so check your engine manual for sure), the lower radiator tank should begin to warm up, which indicates normal operation of the thermostat. If this does not happen, the thermostat must be replaced (it is not removable).

The thermostat can be rechecked by removing it from the engine and placing it in a pan of water. We heat the whole thing on a gas stove, lowering a thermometer into a pan with a thermostat (scale up to 100°C). We observe the thermometer and the main thermostat valve.

When the temperature described above is reached, the main valve should begin to open.

Belt slipping . Slipping of the drive belt of a centrifugal pump (pump), as well as a fan and generator, can occur due to its oiliness or due to loosening of the tension.

Remove any oil that gets on the belt by wiping it with a rag soaked in gasoline, or better yet, anti-silicone. The weakening of the belt tension occurs due to its gradual stretching, as a result of which the pump rotation speed lags behind the crankshaft rotation speed (revolutions).

Because of this, the engine begins to overheat, and the battery does not receive a normal charge. The belt deflection is checked using a simple spring steelyard (scales), with a tension of approximately 5 kg, the deflection should be 15 - 20 mm.

The belt is tightened by loosening the tension bar nut (usually a generator), then, using a lever (mount, tube, etc.), tension is applied and the tension bar nut is tightened.

Radiator core clogged . Clogging of the passages of the radiator core is determined by external inspection and the presence of cracks, too. It can be eliminated by cleaning with a hard-bristled brush, washing with a stream of water from the engine side and blowing out the honeycombs with compressed air.

Electric fan . On many modern cars and, especially, motorcycles, a radiator cooling fan is installed on the electric motor shaft. The main, most common malfunction is the failure of the fan motor to turn on due to a malfunction of the fan sensor. It is located in the motor block and can be checked in much the same way as a thermostat.

To do this, you need to find in the manual for your engine the temperature at which the fan should start rotating. Then, having unscrewed the sensor from the block, we extend its wire by about a meter and add a ground wire to its body, connecting the ground wire to the engine block.

All that remains is to heat the water in a separate container to the temperature specified in the manual (fan turn-on temperature) and carefully lower the fan sensor into it without getting the wires wet. If the fan sensor is working, then the fan will certainly work, and if not, then we change it. The fan motor itself may not work.

To determine the malfunction, you need to check its brushes and, if necessary, replace them; if this does not help, then you need to ring the winding (for the presence of a break or an interturn short circuit).

Fan with viscous coupling . Some machines have such a fan installed and when it works, it is very effective.

You can check its operation by knowing the temperature of the coolant at which it should start working at full capacity (we find out the temperature in the manual of your engine). We start the engine and, having rolled the paper into a tight roll, try to stop the fan blades with it (watch your hands).

While the engine has not reached the switching temperature (observed on the instrument panel), the fan blades should easily stop with a paper roll.

Once the switch-on temperature is reached on a working fan, it will no longer be possible to stop the blades.

This is due to the fact that a thermoplate (bimetallic plate) is installed on the front of the impeller, which, when heated by heat from the radiator, begins to bend and put pressure on a thin pin, and it, in turn, opens the valve through which a special liquid with high viscosity located in the viscose fan coupling.

When this fluid enters, it gets between the discs (similar to the discs of a wet clutch) and from this, the disc associated with the crankshaft is glued to the disc associated with the fan impeller, and the fan begins to rotate at full speed, effectively cooling the radiator.

When the temperature of the motor drops, the bimetallic plate straightens, closing the valve and the liquid no longer flows, and its remains are removed by centrifugal force through special channels. At this moment, the disks begin to slip again and the fan does not work at full strength.

When the engine warms up to the required temperature, the process is repeated. The main malfunction of such fans is the gradual leakage of a special liquid through leaks in the valve pin.

If you manage to find this liquid for sale (it happens in large auto stores), then after opening the coupling, you need to replace the pin seal, and then collect and fill it with this liquid through the pin hole with a syringe.

Then, carefully insert the pin into the new seal, cover it with a thermoplate and install it on the engine (we read much more about the viscous coupling and its repair in this article). It happens that you still need to replace a bearing that is worn out and located inside the coupling.

Presence of scale. Scale located in the engine cooling jacket and in the radiator greatly impairs heat transfer. This causes constant overheating of the engine and boiling off of the coolant.

To remove scale, you need to drain the coolant and pour a solution consisting of 4 - 8 grams of chromium per 1 liter of water into the cooling system. You need to travel with this solution for about 1 month.

After this, drain the solution, thoroughly rinse the cooling system with water and fill in high-quality coolant.

Engine overcooling . Hypothermia may be due to a malfunction of the thermostat, namely, due to the main valve not closing. To eliminate the malfunction, you need to check the thermostat (described above) and replace it if there is a malfunction.

Running the engine at low temperatures leads to loss of power and causes rapid wear of the crank mechanism parts due to deterioration of lubrication conditions from condensation of fuel vapors, washing off oil from the cylinder walls and dilution of the oil in the crankcase.

In conclusion, a few tips . After 50 thousand kilometers or after two years of operation, the coolant needs to be changed. Use only proven branded fluid, as there are many fakes now and the “left” fluid will kill the pump or deposit scale everywhere.

When changing fluid, thoroughly flush the cooling system. If there is a fluid leak, after eliminating the malfunction, add only coolant to the system, and not water, otherwise you will ruin what is left in the system. When traveling, especially after repairs, check the temperature gauge more often.

Source: http://suvorov-castom.ru/sistema-oxlazhdeniya-dvigatelya-i-eyo-neispravnosti/

Engine cooling system - types of malfunctions and ways to eliminate them. Knowledge base of STO "Techcentrik"

There is a widespread belief among owners of new and used BMW cars that their powertrains are prone to overheating.

However, as practice shows, in most cases the cause of engine overheating is trivial and is typical not only for BMW cars, but also for any other liquid-cooled cars.

The root of the problem is a malfunction of the engine cooling system (ECS), which can only be eliminated, and life will regain its former bright colors. Let's try to understand the main types of SOD problems in modern internal combustion engines and talk about ways to eliminate them.

Often the cause of engine overheating is a malfunction of the ODS.

Liquid cooling: what is it?

In order to understand the reason for the malfunction of the cooling system, it is worthwhile to familiarize yourself in more detail with the design and operating principle of this important component of a modern internal combustion engine. The main components of a liquid cooling system are:

- a pump that circulates coolant in the system;

- a radiator, passing through which the heated coolant is cooled by the flow of oncoming air;

- radiator fan, which provides cooling when the car is stationary or moving slowly;

- a thermostat designed to ensure optimal temperature conditions by regulating the operation of the pump and the amount of coolant passing through the radiator;

- expansion tank, which compensates for the volume of coolant that expands as the temperature rises;

- heater radiator, which is part of the vehicle interior heating system;

- coolant temperature sensor designed to control heating of the working environment.

Immediately after starting the power unit, the pump, which is rotated by the crankshaft, begins to pump liquid, forcing it to circulate through the channels of the cooling system. As long as the engine is cold, the coolant moves around a small circle of the cooling system, bypassing the radiator.

When the engine reaches the required operating temperature, the thermostat opens and fluid begins to flow into the radiator. In older BMW engines, switching occurs at a temperature of 90-95° C; in new units, a controlled thermostat is installed that opens at 120° C.

Signs of a faulty ODS

According to statistics, problems with ODS are in the top five among all reasons for contacting service centers.

It is important to note that the car owner’s inattention to the engine cooling system can lead to much bigger problems, including complete failure of the power unit.

Therefore, it is important to know the main signs indicating that the SOD is not working properly. These include:

- Motor overheating. The cause may be either coking of the radiator with deposits and dirt, or a lack of coolant in the system. In the first case, cleaning the radiator, repairing it or replacing it will save you. In the second, it is enough to add or replace coolant. Therefore, before calculating how much a service call will cost you, take a look at the expansion tank; perhaps everything is not as bad as it seems.

- Coolant boiling. The reason for this may be a lack of coolant, a malfunction of the water pump, a failure of the radiator, as well as a host of other problems and malfunctions. And only competent diagnostics will reveal the true cause of coolant boiling.

- The engine overheats immediately after starting to move. In most cases, the cause is a pump failure, although other faults cannot be ruled out. The pump operates in conditions of elevated temperatures, so the seals often simply “shrink out”, as a result of which the mechanism begins to undermine. Moreover, this problem is typical for both the main and additional pumps.

- Antifreeze is leaking. Does a pool of coolant form under the car when parked? There can be a lot of reasons for this - from banal wear and cracking of pipes, to a malfunction of the pump or a violation of the integrity of the radiator.

- Engine hypothermia. Yes, yes, it can not only overheat, but also overcool. As a rule, replacing the thermostat is required to correct the situation.

- The interior does not warm up. The heating radiator is located under the front panel. When the heater is turned on, the heated coolant passes through the radiator and gives off heat, thereby heating the interior. If no heat is supplied, then most likely the heating radiator is to blame.

If one or more symptoms occur, the first thing we recommend doing is checking the antifreeze level. This can be done not only using the coolant level indicator, especially since it can also fail, but also visually.

To do this, just look into the expansion tank, which should be half full. It is also worth inspecting the engine compartment for signs of coolant leaks. But more serious diagnostics are best carried out at a service center.

The most common malfunctions and their elimination

Water pump. We will not consider it in detail, since everything is already clear here. As a rule, the reason lies in the fact that the plastic impeller rotates, having lost contact with the metal shaft.

Another possible option is a faulty pump bearing. In this case, specific scraping sounds may be heard, indicating that the fan blades are touching the diffuser.

However, whatever the reasons for the breakdown, there is only one treatment - replacing the unit.

Leaking cooling system. In this case, during heavy traffic, boiling of the coolant is inevitable. If the load is low, overheating may not occur. But the cooling system will constantly lose antifreeze, which means there will be a need to constantly top it up.

The cause of leakage may be small cracks in the tubes that drain coolant from the cylinder block, damage to plastic radiator fittings, loose clamps, etc. It is quite possible to visually identify such a malfunction, since the location of the damage is usually marked by a wet spot. Another issue is the integrity of the radiator.

If the tightness of the connection between the aluminum case and the plastic containers is broken, the only solution to the problem is to completely replace the radiator.

Often the cause of loss of tightness is a plastic valve designed to bleed air from the radiator.

For example, the design features of M40 engines are such that the valve is located near the filler neck. When pressed with a screwdriver, the plastic head often breaks off.

And since there is a sealing ring under it, the tightness of the system is broken.

The plastic radiator fittings we mentioned above can be repaired. However, it must be done on time. The main danger for the joint is that under the influence of antifreeze the walls of the fitting become thinner and the crack grows quickly.

If the damage is not repaired, sooner or later part of the fitting will break off and the hose will slip off. As a result, all the coolant ends up on the road, and the engine overheats, which almost inevitably leads to damage to the cylinder head.

It should be noted that it is impossible to quickly cool the power unit even if you have a spare canister of coolant, since when poured, the liquid boils and forms vapor locks that do not allow antifreeze to penetrate deep into the engine.

Visually, damage to plastic fittings can be determined by the presence of a light white coating. Be careful and periodically inspect the engine and engine compartment, without taking it to extremes.

On cars with mileage of 80-100 thousand km. The thermostat may contribute to engine overheating. It is quite simple to identify the malfunction - just touch the radiator pipes on a warm engine.

If the bottom one is cold and the top one is hot and the radiator is slightly warm, it means that the coolant is circulating through a small circuit. And this means only one thing - the thermostat does not work: it has stopped opening and does not let antifreeze into the radiator. There can only be one solution here - replacement.

Moreover, it must be done as soon as possible, since otherwise a lot of much larger malfunctions are inevitable, which can lead to engine overheating.

Determining a thermostat malfunction is quite simple.

Thermal coupling. It should be noted that due to the simple design of the thermal coupling, its incorrect operation is often a consequence of some other malfunction. There is simply nothing to break in the thermal coupling (the exception is the bearing, but its failures are extremely rare).

Therefore, before calculating the cost of repairs, you should make sure that there are no other factors that can affect the performance of the coupling. So, for example, the cause of failure may be a low level of antifreeze.

If there is not enough coolant in the radiator, then the air passing through the honeycomb does not heat up, therefore, the bimetallic plate does not heat up either. As a result, the clutch is fully operational, but does not engage. Another reason for this behavior of the thermal coupling may be corrosion and accumulated dirt.

In this case, the rod is constantly pressed due to deposits that have formed between it and the plate.

To summarize, we can say one thing - if suddenly the cooling system suddenly starts to work incorrectly, it is necessary to carry out systematic diagnostics to identify faults that can be removed without the involvement of car service specialists.

The first step is to check the coolant level, the second is to check the tightness of the system. If you cannot identify the damage yourself, you should immediately contact service.

And it’s better to do this as soon as possible, without waiting for the engine to overheat and the problems associated with this event.

Yuri Gulyaev

Source: http://texcentrik.ru/baza-znanij/sistema-oxlazhdeniya-tipichnye-problemy-i-puti-ix-resheniya

Basic malfunctions of the cooling system of a car engine. How to check system status and troubleshoot problems

In this article, we will look at the main malfunctions of the car cooling system and how to eliminate them if detected.

The cooling system is designed to maintain the engine operating temperature in the range from 95 to 105 degrees, which is necessary for its stable and economical operation. Operating the engine at a low coolant temperature leads to increased fuel consumption and the possibility of it getting into the oil.

How to check the condition of the cooling system

Before the trip, you need to inspect the condition of the cooling system: there are no leaks and the level of coolant in the expansion tank, which on a cold engine should be between the “maximum” and “minimum” marks.

You only need to add fluid of the brand that is used in the cooling system - coolants from different manufacturers are often incompatible with each other. As a last resort, you can add distilled water in an amount of no more than 0.5 liters. It must be remembered that the freezing point of the coolant will increase by about three to five degrees.

You should be especially careful when opening the expansion tank cap on a warm engine - there is a high probability of getting burned by hot liquid. You need to cover the plug with a thick rag and unscrew it slowly, releasing the pressure.

Basic cooling system malfunctions

The most common malfunctions of the cooling system: overheating (the engine “boils”), the engine does not warm up to operating temperature, the system is not sealed.

The cause of engine overheating may be a clogged radiator, a broken or weak cooling system pump belt, a broken belt or a faulty fan motor, a faulty expansion tank plug, or a faulty thermostat.

The expansion tank plug is equipped with air and steam valves. The air valve is used to admit air into the expansion tank when the engine is turned off and cools down.

The steam valve maintains the increased pressure in the cooling system during engine operation, which is necessary to ensure that the coolant does not boil.

The easiest way to check the radiator cap is to replace it with a cap from a known good car.

The thermostat distributes the flow of coolant in the cooling system using its valve. To check the thermostat, you need to start the engine and warm it up to operating temperature.

If the radiator and inlet pipe (upper) are cold, the thermostat is faulty. A removed thermostat can be checked by placing the thermostat in a container of water, gradually heating it and controlling the temperature.

The valve of a working thermostat should begin to open at a temperature of 78 - 85 degrees.

The causes of system leaks are often loose clamps on the connecting hoses. Less commonly, cracks in hoses, damage to gaskets and seals of the cooling system pump.

It is better to look for leaks with a warm, running engine, since the leaking coolant quickly evaporates. Of course, the inspection must be performed carefully, being careful of moving engine parts.

Engine cooling system - video:

Now you know what the main malfunctions of the cooling system are and you can eliminate them.

(No one has rated it yet. Be the first!)

Loading…

Source: http://avto-i-avto.ru/diagnostika-neispravnostej/neispravnosti-sistemy-oxlazhdeniya-avtomobilnogo-dvigatelya.html

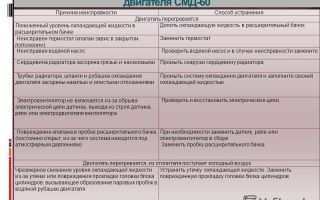

Possible malfunctions of cooling systems, causes,

Signs and ways to eliminate them

Coolant leak

Cause of malfunction:

– loosening the nuts (bolts) securing the cylinder heads;

– loosening of hose clamps and pipes;

– damage to hoses, pipes and sealing gaskets;

– wear of the water pump seals.

Signs of a leak may include:

– fluid leaks on the engine, radiator, pipes, hoses and instruments;

– frequent need to add fluid to the system.

To troubleshoot the problem you must:

– tighten fastenings and replace faulty parts.

Engine hypothermia

Causes of malfunction

– the blinds or radiator curtains are not covered;

– the hood is not insulated;

– the thermostat is faulty;

– the fan drive fluid coupling switch is faulty or incorrectly turned on.

Symptoms of a problem

– decrease in coolant temperature below 70°C;

– excessive fuel consumption, loss of power.

To troubleshoot the problem you must:

– close the curtain or radiator blinds;

– replace the faulty thermostat;

– check the installation of the fluid coupling switch and adjust it if necessary.

Engine overheating

Causes of malfunction:

– insufficient amount of fluid in the system;

– the blinds are closed;

– the fan and liquid pump drive belts are loose;

– the radiator is clogged;

– large scale deposits in the cooling jacket;

– the thermostat or the fan drive fluid coupling switch is faulty.

Symptoms of a problem

– high coolant temperature (above 100 °C);

– the hazard warning light is on;

– power drop;

– intensive release of steam through the steam outlet tube.

To troubleshoot the problem you must:

– add coolant to normal;

– open the blinds;

– adjust the fan and liquid pump drive belts;

– flush the cooling system and replace the thermostat.

Coolant entering the lubrication system

Causes of malfunction:

– damage to the cylinder head gasket;

– damage to the cylinder liner seals.

Signs of malfunction:

– increased oil level in the crankcase;

– a decrease in the level of coolant in the system without visible signs of leakage;

– when starting the engine after stopping it, the oil in the sump becomes whitish in color.

To troubleshoot the problem you must:

– replace faulty seals;

– change the oil in the lubrication system.

Chapter 6. Lubrication system

Purpose, characteristics and general structure

Lubrication system

The lubrication system serves to supply the required amount of oil to the rubbing surfaces of engines, as a result of which friction between mating parts is reduced, they are cooled and wear products are removed from the friction surfaces.

Depending on the operating conditions of the engine components and mechanisms, lubricant can be supplied to them in several ways, structurally combined into a single lubrication system.

In modern engines, due to the presence of various methods of supplying oil to the rubbing surfaces, the lubrication system is called combined.

It uses the following lubrication methods: pressure, drop (sprayed oil) and oil mist.

The main elements of any lubrication system are: an oil pump, oil filters and an oil cooler. The operating principle of the lubrication system of most engines is as follows.

The oil from the lubricant reservoir is pumped into a full-flow fine filter, from which it is supplied to the main line, made on both sides of the cylinder block in the form of longitudinal (main) lubrication channels, from where the oil is discharged through transverse channels to the bearings of the crankshaft and camshaft and further to other lubrication points.

Date added: 2016-09-26; views: 1143;

Source: https://poznayka.org/s62551t1.html

Basic cooling system malfunctions

⇐ PreviousPage 10 of 21Next ⇒

Coolant leakage can occur as a result of damage to the radiator, hoses, gaskets and seals.

To eliminate the malfunction, it is necessary to tighten the clamps securing the hoses and tubes, and replace the damaged parts with new ones. If the radiator tubes are damaged, you can try to patch holes and cracks, but, as a rule, everything ends with replacing the radiator.

Engine overheating occurs due to insufficient coolant level, weak fan belt tension, clogged radiator tubes, or a malfunctioning thermostat.

To eliminate engine overheating, you should restore the fluid level in the cooling system, adjust the fan belt tension, flush the radiator, and replace the thermostat.

Often, engine overheating occurs even when the elements of the cooling system are in working order, when the car moves at low speed and heavy loads on the engine.

This happens when driving in difficult road conditions, such as country roads and boring city traffic jams.

In these cases, you should think about the engine of your car, and about yourself too, by taking periodic, at least short-term, “breathes”.

Be careful while driving and do not allow the engine to run in emergency mode! Remember that even a one-time overheating of the engine disrupts the structure of the metal, and the life expectancy of the “heart” of the car is significantly reduced.

Cooling System Operation

When operating your vehicle, you should periodically look under the hood. A timely detection of a malfunction in the cooling system will allow you to avoid major engine repairs.

If the level of coolant in the expansion tank has dropped or there is no liquid at all, then first you need to add it, and then you should figure out (on your own or with the help of a specialist) where it went.

During engine operation, the liquid heats up to a temperature close to its boiling point. This means that the water contained in the coolant will gradually evaporate.

If over six months of daily use of the car the level in the tank has dropped slightly, then this is normal. But if yesterday the tank was full, and today there is only the bottom in it, then you need to look for a coolant leak.

Leakage of fluid from the system can be easily identified by dark spots on the asphalt or snow after a more or less long period of parking. By opening the hood, you can easily find the location of the leak by comparing wet marks on the asphalt with the location of the cooling system elements under the hood.

The fluid level in the tank must be monitored at least once a week. If the level has noticeably decreased, then the reason for its decrease must be determined and eliminated. In other words, the cooling system must be put in order, otherwise the engine may become seriously ill and require “hospitalization.”

Almost all domestic cars use a special low-freezing liquid called Tosol A-40 as a coolant .

The number 40 shows the negative temperature at which the liquid begins to freeze (crystallize).

In the conditions of the Far North, Antifreeze A-65 , and accordingly it begins to freeze at a temperature of minus 65°C.

Antifreeze is a mixture of water with ethylene glycol and additives. This solution combines a lot of advantages.

Firstly, it begins to freeze only after the driver himself has already frozen (just kidding), and secondly, Antifreeze has anti-corrosion, anti-foaming properties and practically does not produce deposits in the form of ordinary scale, since it contains pure distilled water . Therefore, only distilled water can be added to the cooling system.

When operating a car, it is necessary to monitor not only the tension, but also the condition of the water pump drive belt, since its breakage on the road is always unpleasant. It is recommended to have a spare belt in your travel kit. If not you yourself, then some kind person will help you change it.

The coolant can boil and cause engine damage if the fan motor sensor fails. If the electric fan does not receive a command to turn on, the liquid continues to heat up, approaching the boiling point, without cooling assistance.

But the driver has before his eyes a device with an arrow and a red sector! Moreover, almost always when the fan is turned on, a slight additional noise is felt. There would be a desire to control, but there will always be ways.

If on the road (or more often in a traffic jam) you notice that the coolant temperature is approaching critical and the fan is running, then in this case there is a way out. It is necessary to include an additional radiator in the operation of the cooling system - the interior heater radiator.

Fully open the heater tap, turn on the heater fan at full speed, lower the door windows and “sweat” home or to the nearest car service center. But at the same time, continue to closely monitor the engine temperature gauge needle.

If it does enter the red zone, stop immediately, open the hood and “cool down.”

, the thermostat can cause trouble if it stops releasing liquid through a large circulation circle. Determining whether the thermostat is working is not difficult.

The radiator should not heat up (determined by hand) until the coolant temperature gauge needle reaches the middle position (thermostat closed). Later, hot liquid will begin to flow into the radiator, quickly heating it, which indicates the timely opening of the thermostat valve.

If the radiator continues to remain cold, then there are two options. Tap on the thermostat housing, maybe it will open after all, or immediately, mentally and financially, prepare to replace it.

Immediately “surrender” to a mechanic if you see droplets of liquid on the oil dipstick that have entered the lubrication system from the cooling system.

This means that the cylinder head gasket is damaged and coolant is leaking into the engine oil pan.

If you continue to operate the engine with oil half consisting of antifreeze, the wear of engine parts will become catastrophic.

The water pump bearing does not break “suddenly.” First, a specific whistling sound will appear from under the hood, and if the driver “thinks about the future,” he will replace the bearing in a timely manner. Otherwise, it will still have to be changed, but with the consequence of being late for the airport or for a business meeting, due to a “suddenly” broken down car.

Each driver should know and remember that when the engine is hot, the cooling system is under high pressure!

If your car’s engine overheats and “boils,” then, of course, you need to stop and open the hood of the car, but you cannot open the radiator cap or expansion tank. This will do practically nothing to speed up the engine cooling process, and you can get severe burns.

Everyone knows what a clumsily opened bottle of champagne means for smartly dressed guests. In a car everything is much more serious.

If you quickly and thoughtlessly open the cap of a hot radiator, a fountain will fly out, but not of wine, but of boiling Antifreeze! In this case, not only the driver, but also nearby pedestrians may suffer.

Therefore, if you ever have to open the radiator cap or expansion tank, you should first take precautions and do it slowly.

Lubrication system

The lubrication system is designed to supply oil to the rubbing parts and partially cool them, as well as to remove wear products.

Rice. thirty.

Diagram of the engine lubrication system: 1 – oil supply channel to the gas distribution mechanism; 2 – main oil line; 3 – oil supply channel to the crankshaft bearings; 4 – engine crankcase; 5 – filter element; 6 – oil filter housing; 7 – oil pump; 8 – oil receiver with strainer; 9 – oil pan; 10 – oil drain plug

The lubrication system consists of (Fig. 30):

– oil pan;

– oil pump with oil receiver;

– oil filter;

– channels for supplying oil under pressure drilled in the cylinder block, cylinder head and other engine parts.

The engine oil pan is a reservoir for storing oil. When you pour oil through the oil filler neck, it flows through the voids inside the engine and drains into the oil pan. The oil level in the sump can be measured with an oil dipstick through the hole in the cylinder block.

The oil pump (Fig. 31) supplies oil under pressure (through a filter and channels) to the rubbing parts of the crank and gas distribution mechanisms. The pump consists of two gears and is driven by the engine crankshaft. As the gears rotate, the teeth capture oil and force it into the main oil line.

Rice. 31. Oil pump operation diagram: 1 – oil pump gears; 2 – pressure reducing valve; 3 – spring

The pressure reducing valve (Fig. 31) serves to limit the pressure in the engine oil channel system. When there is excess pressure, the spring is compressed and some of the oil flows back into the engine sump.

The oil filter (Fig. 30) serves to clean the oil passing through it from mechanical impurities. It is installed immediately after the pump and passes through itself all the oil that enters the oil line. Most often, the filter has a non-separable design and must be replaced simultaneously with a scheduled engine oil change.

Engine crankcase ventilation (see Fig. 32) provides suction from the crankcase and discharge into the intake manifold of gasoline vapors and exhaust gases that enter the lower part of the engine.

During the compression and power strokes, these vapors and gases partially break through the cylinder walls into the engine crankcase, dilute the oil and are very aggressive towards the parts of the crank mechanism.

Rice. 32. Engine crankcase ventilation diagram: 1 – air filter housing; 2 – filter element; 3 – crankcase ventilation suction manifold; 4 – carburetor; 5 – inlet pipeline; 6 – inlet valve; 7 – crankcase ventilation hose; 8 – oil separator; 9 – oil separator drain pipe; 10 – engine crankcase; 11 – oil pan

Crankcase ventilation is carried out forcibly due to the vacuum that occurs in the air neck of the carburetor when the engine is running.

The air filter housing is connected to the engine crankcase using a hose, through which crankcase gases are directed first to the carburetor and then to the cylinders for afterburning.

Internal combustion engines use a combined lubrication system - pressure and splash. Oil is supplied to the most heavily loaded rubbing surfaces under pressure, and the remaining parts of the engine mechanisms are lubricated by oil splashes and oil mist.

Oil reaches the bearings of the crankshaft and camshaft through the channels of the system under pressure. Having done its job, that is, lubricated, cooled a little and taking wear products with it, the oil flows back into the engine sump.

When the crankshaft rotates, oil splashes from its connecting rod and main bearings onto the cylinder bore, pistons and piston pins. All moving parts of the crank and gas distribution mechanisms seem to be “bathed” in oil. This achieves high wear resistance of friction pairs.

Source: https://lektsia.com/3×1827.html