Injector: device, principle of operation and repair possibilities

Over time, the basics of the automotive industry changed and became more and more distant from their origins. Thus, the fuel system of vehicles was subject to constant modernization until a universal injector appeared, which is used in the design of most gasoline cars today.

Injection feeding a motor with fuel, in fact, does not have any special intricacies or difficulties, however, to understand the principles and meaning of its functioning, it would not be amiss to familiarize yourself with it in more detail. It is the standard design and operation of modern injectors that will be discussed in today’s material.

Interesting? Be sure to “scroll” the page below.

A little history

Despite its popularization only in the mid-80s of the 20th century, the fuel injector appeared much earlier. According to official data, the first engine fuel injection systems began to be tested and used in the early 30s of the last century.

In those days, the design and operation of the injector were painfully primitive, so these components were used only on relatively unpretentious units from the field of military aviation.

In general terms, the fuel distribution mechanisms of those years were a completely mechanical design and performed the functions assigned to them quite well.

Note that the first purpose of the injectors was not to reduce the amount of fuel consumed by vehicles or improve the environmental friendliness of exhaust gases, but to increase engine power.

In part, injection systems justified themselves in this regard, but in the early 40s, jet engines began to be actively used in the military sphere, so the former instantly lost their relevance.

On top of that, the operation of mechanical-type injectors did not allow obtaining maximum efficiency from aircraft engines, because carburetors at that time were more flexible in terms of adjustment to the operating mode of the engine.

However, the “second life” of the injector-based fuel system began in the mid-80s, and they gradually became regulars in the automotive industry. The big role here was played not by the unique design of the unit, but by the possibility of reducing the emission of harmful substances in the exhaust gases when using it.

By the way, old mechanical injectors lagged far behind existing carburetors in all respects, so automotive engineers were forced to radically redesign the injection power system.

Let us note that they succeeded, because it is not for nothing that injectors remain the main components of car fuel systems.

Design and principles of operation of the injector

An injector (from English - “injector”) - in a general concept, is a device in the form of a jet pump, which is designed to inject liquid, semi-liquid or gaseous masses into a certain container.

In the case of a car injector, there are no particularities in the interpretation of this concept. The only thing is that the injection unit in the design of the machine is understood not as a separate pump (injector), but as a combination of them together with other units that form a single fuel system.

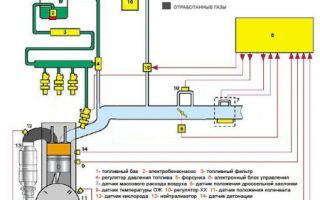

A typical design of an automobile injector corresponds to the following diagram:

A typical injector design as a single system involves the combined use of the following elements:

- nozzles and injector chambers connected to them (that is, several pumps noted above, combined into a synchronized system);

- control unit (the electronic brain of any injection system, which naturally controls the injector);

- catalytic converter (otherwise called an “afterburner”, which burns out all the fuel that did not burn out inside the engine and exited the combustion chambers along with the exhaust gases);

- additional components (wiring connecting the injectors and the control unit, fuel lines ensuring the delivery of fuel to the distribution mechanism, fuel pump, etc.).

As you can see, the operation of the injector is arranged without any particular difficulties. Of course, repairing such a fuel system is by no means easy, but you can understand the principles of its operation without any problems.

Types and technical characteristics of injection systems

Today, only two types of injectors are considered officially used in the automotive industry:

- Electronic injector. A node of this type works strictly according to the principle described above. That is, fuel is delivered to the injectors, and then, through the use of an electronic control unit, it is correctly dosed and correctly supplied to the combustion chambers of the engine. The operation of electronic type injectors is most convenient for the trouble-free operation of any car, which is why they are used in the design of almost all modern cars;

- Mechanical injector. This same unit is deprived of head control in the form of an electronic “brain”. To be more precise, the operation of a mechanical injector is based on adjusting the fuel supply to the engine using its valves (dosage occurs by connecting the injectors to the valves with special tubes, the former, based on the degree of openness of the latter, supply the optimal amount of fuel to the engine). Units with such a device were considered some kind of innovation in the “injection” field, but in a short time they managed to prove their inconsistency and to this day are not used in the serial production of cars.

Regardless of the type of node, it is customary to highlight its main properties. Today, among the technical characteristics of the injector, it is worth highlighting one point, or rather, the method of injecting fuel into the engine.

Of course, the injectors in any injection system directly inject fuel into the cylinders (intake manifold), however, the principles of gasoline delivery may differ.

So, there are injectors:

- With single injection (central injection). In such systems there is only one nozzle, which supplies fuel to the engine. Today, single injection injectors are not used, so there is no need to focus on them;

- With distributed injection - the most used at the moment. Their design assumes that the injector consists of the nth number of injectors that supply fuel to each individual cylinder. Among injection systems with distributed injection, there are several subtypes, or more precisely:

- direct injection (often called direct) - fuel enters the combustion chamber directly;

- simultaneous injection - fuel is supplied synchronously by all injectors to each engine cylinder;

- pair-parallel injection - fuel is supplied according to a paired scheme of nozzle operation (that is, one pump works for “intake”, the other works for “exhaust”);

- phased injection - gasoline is supplied exclusively to the “inlet” in any operating mode.

It is worth noting that such a wide variety of injectors is only partly justified, since in the vast majority of cases systems with either direct or simultaneous injection types are used.

Advantages and disadvantages of injectors

At the end of today’s material, it would be useful to pay attention to what the injector is good for and what it can cause trouble for any motorist. Let's probably start with the advantages of injection systems, which include the following provisions:

- Economical. We can definitely say that injectors work exclusively for their “owner” in comparison with the same carburetors. Surprisingly, somewhat similar fuel distribution units under the same engine operating conditions supply less fuel to the engine. This is largely due to the well-thought-out design of the injector and the presence of electronic control;

- Getting more efficiency from the engine. Again, amazing. Despite the smaller amount of fuel supplied to the engine, when using an injector it is possible to achieve more power from the power unit. This is also due to the well-organized design of the unit, and especially its electronic component;

- Environmental friendliness. Everything here is extremely simple, because in the structure of any injector there is a catalytic converter, which makes it more environmentally friendly by burning out the fuel that has not burned out in the engine;

- Stability in terms of work. Let us repeat, due to a well-organized device, the injectors are completely independent in their functioning from weather conditions or similar issues.

Among the disadvantages of injection systems, only one aspect is worth highlighting, namely their repair and, to some extent, operation. In this regard, injectors are quite whimsical and inconvenient for their owners. In particular, if you want to successfully use a unit of this type, any motorist needs:

- be prepared for expensive repairs in case of breakdown;

- always use only high-quality fuel;

- ensure the availability of special instruments for diagnosing and repairing the injector.

With this, perhaps, the most important provisions on the “injection” issue have come to an end. We hope that the material presented above was useful to you and fully revealed the principles of operation of the injector. Good luck on the roads!

Don't forget to share this page with your friends and subscribe to our group

Source: https://SwapMotor.ru/ustrojstvo-dvigatelya/inzhektor.html

Operating principle and design of the injector

“Born” in 1951, the injector gradually replaced carburetors; read the article - carburetor or injector.

And this happened thanks to one of its most important advantages, which is to reduce the amount of fuel used.

In addition to which, experts also note better acceleration dynamics of injection cars, stable operation of such engines, as well as a reduction in the number of harmful emissions from their operation into the atmosphere.

Let's find out where such properties come from, and in general what is the principle of operation of the injector, but first I will briefly outline the main disadvantages of the latter, so that you do not consider it ideal:

- expensive repairs of components;

- the presence of elements that cannot be repaired;

- the need to use high-quality fuel;

- the need to use special equipment for diagnostics, repair and maintenance.

How does the injector work?

So, as you know, in modern cars the carburetor system has already been completely replaced by injection engines. The latter, unlike carburetor engines, increase the car’s power, improve its acceleration dynamics and environmental friendliness. Moreover, fuel consumption is reduced.

By the way, the injector maintains high environmental performance without various adjustments and settings. After all, there is self-tuning of the air-fuel mixture, which became possible thanks to the oxygen sensor installed on the exhaust manifold (lambda probe).

Injector device

Fuel is supplied to the injection engine by injectors, which can be located either on the intake manifold (mono-injection), or near the intake valves of the cylinders (distributed injection), or directly in the cylinder head - the cylinder head (direct injection - fuel is injected into the combustion chamber itself) , see how to wash the injectors with your own hands here.

In addition to the injectors, the injector includes the following actuators:

- ECU (controller) - processes data from sensors and controls fuel supply and ignition systems;

- fuel pump (electric) - it supplies fuel;

- various sensors: temperature, crankshaft, camshaft, detonation;

- pressure regulator - maintains the difference in air pressure in the intake manifold and injectors.

Also, all injection engines are equipped with a catalytic converter (catalyst) in the form of a “honeycomb”, on which an active layer is applied that promotes the burning of fuel remaining in the exhaust gases. However, refueling with leaded gasoline for a long time leads to certain breakdowns, due to which the catalyst loses this ability.

Oxygen sensor in the injector and its operation

The most famous type is the zirconium oxygen sensor; more details in the article - what is an oxygen sensor. It is a switch (by the way, one of the most important), which sharply changes its state at around 0.5% oxygen contained in the exhaust gases.

The sensor interface device looks like this: a heated sensor (300 degrees Celsius and above) with a rich mixture (oxygen content < 0.5%), as a weak current source, sets the output voltage from 0.45 to 0.8 Volts, and with a lean mixture (oxygen content > 0.5%) - from 0.2 to 0.45 Volts.

And it doesn’t matter what the exact voltage level is, only where it is located in relation to the center line is taken into account. That is, fuel is added when the ECU detects a lean signal, and reduced when it is rich.

Consequently, the fuel supply is adjusted depending on the practical results of combustion, which allows the system to adapt to different operating conditions.

It is known that this sensor works reliably only in a well-warmed-up state, therefore, the ECU TCCS system will notice its readings only if the engine warms up to the required level. However, not everyone is happy with this. Therefore, to speed up this process, an electric heater is often installed in the oxygen sensor.

TCCS system computer. Injector self-diagnosis

A modern injector has many sensors installed, this makes it possible to optimize its operation.

Operating principle of a mechanical injector

Although previously other designs of injection engines were used. For example, there is a known engine in which control occurs using mechanical devices.

The control here is the dosage of fuel volume using a special valve. The valve is controlled by a system of levers, which is activated by the air flow.

Today, mechanically controlled valves have become completely obsolete.

Currently, each injection system has a built-in self-diagnosis subsystem, which allows you to identify faults in components, sensors and actuators of the system. After self-diagnosis, the computer generates diagnostic codes.

They are extracted from the computer's memory and decrypted according to tables. Each manufacturer has its own option for retrieving these codes. You can find almost all of them freely available on the Internet; you can read more about diagnosing an injector with your own hands here.

In addition, I recommend reading the instructions on how to clean the injector.

Video

I recommend reading:

Source: http://autoepoch.ru/avtoazbuka/princip-raboty-i-ustrojstvo-inzhektora.html

The whole truth about how an injection engine works (fuel injection system)

In order to reduce harmful emissions and improve engine efficiency, the automotive fuel system has undergone significant changes in recent years. For example, in the USA they abandoned carburetors back in 1990. Fuel injection systems appeared in the middle of the twentieth century, and they began to be used on production cars of European manufacturers around the 1980s.

Today, all new cars are equipped with injection engines. In this educational article we will look at the principle of operation of the injector and its design. You can find out how fuel gets into the engine cylinder. The design of an engine with an injection system is a very relevant topic for the modern car enthusiast, so make yourself comfortable and let’s get started!

The carburetor is losing ground

After the advent of the internal combustion engine, the carburetor was used to supply fuel to the engine. This device is still used in equipment such as chainsaws and lawn mowers. But as the car evolved, it became more and more difficult for the carburetor to satisfy many operating requirements.

For example, catalytic converters (catalysts) were introduced to meet increasingly stringent environmental regulations. The catalyst is effective only if the air-fuel mixture is carefully controlled. Oxygen sensors (we have already written about how they are checked - http://avtopub.

com/proverka-kislorodnogo-datchika-lyambda-zonda-svoimi-silami/) are responsible for controlling the amount of oxygen in the exhaust gases. This information is also used by the electronic engine control unit (ECU) to adjust the air/fuel ratio in real time.

The result is a closed control system , which could not be implemented using carburetors. Electronically controlled carburetors were produced for a short period of time, but they were even more complex than purely mechanical devices.

Carburetors were first replaced by throttle body fuel injection (also known as single point injection or central fuel injection ). In them, the injectors were located in the throttle body. It was a simple solution to replacing the carburetor, so automakers did not have to make changes to engine designs.

Over time, as new engines were introduced, the central fuel injection system was replaced by a multipoint fuel injection system (also known as a sequential injection ).

These systems use a separate fuel injector for each cylinder. Typically they are positioned to spray fuel directly onto the intake valve. These systems provide more accurate fuel metering and faster response.

It's time to study in more detail the principle of operation of the injector.

When you step on the gas

The gas pedal in your car is connected to the throttle body. This is a valve that regulates the amount of air entering the engine. So the gas pedal is actually the air pedal.

When you step on the gas pedal, the throttle valve opens more, causing the engine to receive more air.

The engine control unit (ECU, the computer that controls all the electronic components of the engine) “notices” the open throttle and increases the fuel supply to create the optimal fuel-air mixture.

It is very important that the fuel supply increases immediately after opening the throttle. Otherwise, some air will end up in the cylinders without enough fuel.

Sensors monitor the oxygen content in the exhaust gases, as well as the amount of air entering the engine. The ECU uses this data to select the air/fuel ratio as accurately as possible. How does an injector work on modern cars?

Nozzle

The fuel injector (injector) is an electronically controlled valve. The fuel supply to this valve is provided by the fuel pump. The nozzle can open/close many times per second.

When the injector is energized, an electromagnet moves a piston, which opens a valve, causing fuel to be injected under pressure through a tiny nozzle. The nozzle is designed to spray fuel. A fine mist appears that burns easily.

The injectors are installed in the intake manifold in such a way that they spray fuel directly onto the intake valves. The tube that supplies fuel to each of the injectors at a certain pressure is called a fuel rail.

In order to determine the optimal amount of fuel, the engine control unit receives signals from many sensors. Let's look at the most important of them.

Injection engine design - main sensors

To select the optimal amount of fuel under various operating conditions, the engine ECU monitors the readings of various sensors. Here are just a few of the main ones:

- Mass air flow sensor (MAF). Tells the control unit the mass of air entering the engine.

- Oxygen sensor(s) (lambda probe). Controls the oxygen content in exhaust gases. Using the information received from it, the ECU can detect a rich or lean fuel mixture and make appropriate adjustments.

- Throttle position sensor. It monitors the position of the throttle valve (it affects the air supply to the engine), thanks to which the control unit can quickly respond to changes, increasing or decreasing fuel consumption as necessary.

- Coolant temperature sensor. Helps the ECU determine when the engine has reached optimal operating temperature.

- Voltage sensor. Monitors the voltage of the vehicle's on-board network. Depending on the sensor readings, the control unit can increase the engine idle speed if the voltage drops (this happens with high electrical loads).

- Manifold absolute pressure sensor. Analyzes the air pressure in the intake manifold. The amount of air entering the engine is a good indicator of how much power it produces. The more air entering the engine, the lower the manifold pressure. This indicator is used to determine the amount of energy produced.

- Crankshaft speed sensor. Crankshaft rotation speed is one of the factors influencing the calculation of the required pulse duration.

There are two main types of control for multiport injection systems : the fuel injectors can open simultaneously, or each of them can open only before the intake valve of the corresponding cylinder opens (this is called sequential multiport fuel injection).

The advantage of sequential fuel injection is that the system can respond to any driver input faster, since from the moment the action is performed, it only waits for the next opening of the intake valve. The system does not need to wait for the motor to rotate completely. We were able to figure out how the injector works, but who is in charge of all this?

Engine control

The algorithms that control the engine are quite complex. There are many requirements that a power unit must satisfy. For example, this concerns emissions indicators or fuel efficiency requirements.

The engine control unit uses a formula and a variety of lookup tables to set the pulse duration under certain operating conditions. The formula is a combination of many factors multiplied by each other.

We will look at a simplified formula for determining fuel injector pulse duration .

In this example, our formula will consist of only three indicators, while in reality over a hundred parameters are usually taken into account.

Pulse Width = (Base Pulse Width) x (Factor A) x (Factor B)

To calculate the pulse width, the electronics first looks up the base pulse width in the appropriate lookup table.

Base pulse width is a function of engine speed (RPM) and load (calculated from manifold absolute pressure).

For example, the engine speed is 2000 rpm, and the load indicator is 4. In the table, you need to find the number at the intersection of 2000 and 4. It turns out 8 milliseconds.

| Engine speed | Load | ||||

| 1 | 2 | 3 | 4 | 5 | |

| 1,000 | 1 | 2 | 3 | 4 | 5 |

| 2,000 | 2 | 4 | 6 | 8 | 10 |

| 3,000 | 3 | 6 | 9 | 12 | 15 |

| 4,000 | 4 | 8 | 12 | 16 | 20 |

In the following examples, A and B represent the parameters that the control unit receives from the sensors.

Let's say that A is the coolant temperature and B is the oxygen level.

If the coolant temperature is 100 and the oxygen level is 3, the lookup tables indicate that factor A = 0.8 and factor B = 1.0.

| A | Factor A | B | Factor B |

| 1.2 | 1.0 | ||

| 25 | 1.1 | 1 | 1.0 |

| 50 | 1.0 | 2 | 1.0 |

| 75 | 0.9 | 3 | 1.0 |

| 100 | 0.8 | 4 | 0.75 |

So, since we know that base pulse width is a function of load and engine speed, and pulse width = (base pulse width) x (factor A) x (factor B) , the total pulse width in our example is:

8 x 0.8 x 1.0 = 6.4 ms

This example shows how the control system makes adjustments. Since parameter B displays the oxygen content in the exhaust gases, according to the data in the table, it can be concluded that the exhaust gases contain too much oxygen, as a result of which the ECU reduces the fuel supply.

Real control systems take into account over 100 parameters, each of which has its own correspondence table.

Some parameters are even adjusted over time to compensate for changes in the performance of components, for example, the catalytic converter (read about checking the catalyst here).

And depending on the engine speed, the control unit can perform these calculations more than 100 times per second.

If you liked our article about how an injector works and what fuel injection systems exist, share the link with your friends on social networks using the appropriate buttons below. Thank you for your attention, stay tuned!

Source: http://avtopub.com/kak-rabotaet-inzhektornyiy-dvigatel/

Car injector: how it works and how it works

Hello, dear car enthusiasts! Just as “the iron horse replaced the country horse,” the fuel injection system also replaced carburetors in cars.

Let experts argue about the advantages and disadvantages of fuel supply systems, but the car owner’s task is to have an idea of what an injector is and how a car’s injector works.

And you don’t necessarily need the device and operating principle of the injector in order to repair it yourself. But you need to know how a car injector works and what it consists of. At least so that unscrupulous car service technicians do not try to “warm up” their hands on your ignorance of your car.

Injector as a revolution in the automotive industry

Injector and nozzle operation

What is a car injector? An injector (Latin injicio, French Injecteur, English Injector - I throw it away) is a nozzle, like a gas or liquid (fuel) atomizer in engines, or part of an injection system for supplying (injecting) fuel in internal combustion engines.

The year of birth of the injection system is considered to be 1951, when Bosch equipped the 2-stroke engine of the Goliath 700 Sport coupe with it. Then, in 1954, the Mercedes-Benz 300 SL picked up the baton.

Massive, serial introduction of fuel injection systems began in the late 70s of the last century. The operation of the injector, in its operational characteristics, was in many ways superior to the operation of the carburetor fuel supply.

As a result: the first decade of the 21st century has practically completed the displacement of carburetors. Modern cars are mainly equipped with distributed and direct electronic injection systems.

The principle of operation of the injector in the fuel supply system

Fuel Injection System (fuel injection system) supplies fuel through direct injection using a nozzle (injector) into the engine cylinder or into the intake manifold. Accordingly, cars equipped with such a system are called injection cars.

The classification of injection injection depends on the principle of operation of the injector, as well as on the location of installation and the number of injectors.

Central fuel injection (mono-injection) injects all engine cylinders using one injector. The injector is usually located on the intake manifold (in place of the carburetor). The mono-injection system is not popular among automakers today.

The bulk of modern production cars are equipped with a distributed fuel injection system. That is, a separate injector is responsible for its own cylinder.

The distributed fuel injection system is classified by type:

- simultaneous - all injectors of the system supply fuel simultaneously to all cylinders,

- pair-parallel - a type of injection when the injectors open in pairs: one opens before the intake cycle, the other before the exhaust cycle. It is characteristic that the pair-parallel principle of opening the injectors is used during engine startup, or in emergency mode when the camshaft position sensor malfunctions. And while driving, the so-called phased fuel injection is used,

- phased - type of injection when each injector opens before the intake stroke,

- direct - a type of injection that occurs directly into the combustion chamber.

The principle of operation of the injector is based on the use of signals from a microcontroller, which in turn receives data from sensors.

Injector operation diagram

If you don’t get into the jungle of the “electronic brain” of our car, then the injector operation diagram looks like this.

Numerous sensors receive information about: crankshaft rotation, air flow, engine coolant temperature, throttle valve, engine detonation, fuel consumption, speed limit, vehicle on-board voltage, and so on.

The controller, receiving this information about the vehicle parameters, controls systems and devices, in particular: fuel supply, ignition system, idle speed control, diagnostic system, and so on. The change in operating parameters of the injection injection system changes systematically, based on the data obtained.

The device of a simple injector

The injector includes such actuators as:

- fuel pump (electric),

- ECU (controller),

- pressure regulator,

- sensors,

- nozzle (injector).

Accordingly, the injector circuit: an electric fuel pump supplies fuel, a pressure regulator maintains the pressure difference in the injectors (nozzles) and the air in the intake manifold. The controller processes information from sensors: temperature, detonation, camshaft and crankshaft, and controls ignition systems, fuel supply, and so on.

The fuel injection system is good for everyone, but it is not without its own characteristics. Adherents of carburetors call them disadvantages.

The features of the injector can be safely named: the fairly high cost of the injector components, low maintainability, high requirements for the quality and composition of the fuel, the need for special equipment for diagnostics, and the high cost of repair work.

Now, let's move on from the story about how the injector works and looks like to a visual aid. You will see in the video the principle of operation of the injector, and everything that is written above will immediately become clear to you.

Source: http://CarTore.ru/241-inzhektor-avtomobilya-kak-ustroen-i-princip-raboty.html

Injection engine: design and principle of operation

The injection engine is a complex device that ensures maximum performance of the car.

Unlike carburetor models, the injector is more economical and easier to maintain.

Such engines are equipped with a fuel injection system, which increases the car’s power and, on the contrary, reduces fuel consumption. The operating principle of an injection engine is discussed in our article.

The use of devices with a similar operating algorithm initially affected aircraft manufacturing. Tightening environmental standards led many car manufacturers to abandon the use of carburetor engines, the further improvement of which did not lead to the desired result.

The fuel injection system is controlled by an automated system or on-board computer. The condition of the air-fuel mixture is checked and if it is correct, fuel is sequentially injected directly into the intake valve. This ensures more accurate consumption and faster fuel combustion.

The design of an injection engine can be characterized by the following sequence:

- Pressing the gas pedal opens the throttle valve. This ensures air flow into the engine.

- The computer analyzes the volume of incoming air (depending on the pedal pressure), and then gives a command to supply the optimal amount of fuel.

- A special sensor monitors the amount of oxygen entering the engine and its correspondence to the volume of fuel.

- The fuel pumps the required volume, after which it is injected under pressure. As a result, a fine mist is formed, which quickly burns, driving the rotation mechanisms of the moving parts of the motor.

Even a simplified diagram shows how complex the process of driving a car is. The operation of an injector engine is a closed system in which every detail matters.

If any component fails, a signal about this is sent to the electronic system, after which the computer itself makes a decision about the possibility of further movement.

This is both an advantage and a disadvantage of such a mechanism, because under changed working conditions it will not be possible to rock the system “manually”; you will have to seek qualified help.

What are the features of the device?

As the information provided shows, the main difference from older carburetor models is the automatic fuel supply. This is the key point that determines the advantages of using an injection device. In addition, there are several more points that distinguish the difference between an injector and a carburetor.

Key differences:

- Due to the fact that a certain level of pressure is created in a carburetor engine, allowing the air-fuel mixture to be sucked in, and it is supplied automatically to the injector, output power is saved. This allows an overall increase in vehicle performance by 10%. The indicator is small, but over long-term operation this is a significant fuel saving.

- Quick response to changing traffic conditions. The injector almost instantly increases or decreases the fuel supply. This allows you to maneuver on the road much faster.

- The fuel injection system ensures easy engine starting.

- The injection device is less sensitive to changing weather conditions. Fuel consumption will be saved due to the fact that long engine warm-up is not required.

- Also, such devices comply with more stringent modern environmental standards. The level of harmful emissions is usually 50-70% lower, which is simply necessary in the modern world.

Among the main disadvantages is the complete dependence of the system on the serviceability of all elements. The injector is equipped with several sensors that analyze fuel parameters and operating conditions. If electronics fail, expensive repairs may be required.

Also, when operating a car with an injection engine, it is necessary to carefully monitor the condition of the fuel used. The injectors that supply and atomize the air-fuel mixture often become clogged when using low-quality gasoline.

At the same time, this criterion is very difficult to control, especially during a long trip, when you have to refuel at unverified points. Disadvantages also include expensive repairs in case of breakdowns.

In practice, repairing the electronic part yourself turns out to be an unsuccessful solution and may lead to the need to restore the system, and this costs a lot.

ECU

The main control center of the injector is the ECU - an electronic control unit. Its tasks include direct control over the operation of all systems, fuel consumption and supply, as well as signaling possible malfunctions in the vehicle. Reports on possible system failures and an algorithm for correct operation are stored in special memory cells,

Depending on the model, there are usually three types of device memory:

- The PROM requires one-time programming, after which all action algorithms for controlling the system are stored. The chip is stored on the unit board and can be replaced if necessary. Information cannot be deleted in case of network failures and cannot be corrected.

- RAM is a random access memory device. Refers to temporary file storage. It also serves as a place for calculating and analyzing the information received. The RAM is located on the printed circuit board of the unit; in case of network failures, the information is erased.

- EEPROM is an electrically programmable memory device. Mainly used to store information for the anti-theft system (owner codes and passwords). If the data entry is violated, the engine will not start. Such storage does not depend on network data; information will be preserved in any situation.

Injectors

The valve that allows you to control the injection of fuel into the system is called an injector. Two types of fuel supply system are used. Single injection is now practically not used. With this arrangement of the injector, fuel is supplied regardless of the opening of the engine intake valve. In addition, such control is little controlled electronically.

The second type - distribution injection is represented by a more advanced system. Thanks to several nozzles located directly near each cylinder, fuel is directed toward the engine. Such a system clearly regulates the fuel supply and also increases engine performance.

The type of injector control is also determined by the ECU and can be point or sequential.

Catalytic converter

This element of the injection engine system is designed to control car emissions. For its operation, an oxygen content sensor in the exhaust gases (lambda probe) is required.

If the permissible values are exceeded, the fuel injection is adjusted, and the exhaust gas recirculation process is also carried out.

In addition, the system contains special catalysts that reduce the content of harmful impurities after fuel combustion.

Sensors

A complex electronic control system involves checking and adjusting several sensors. If at least one element fails, the ECU generates an error.

Main sensors of an injection engine:

- MAF (mass air flow sensor). Provides information about the mass of air entering the engine.

- Lambda probe (oxygen sensor). Determines the oxygen content in the air-fuel mixture. Using such information, the ECU can detect changes in the fuel mixture and adjust its values.

- Throttle sensor.

Controls the position of the throttle valve, according to which the control unit can react by increasing or decreasing the fuel supply as necessary.

- Voltage sensor. Monitors the voltage of the machine's on-board network.

The sensor readings, if necessary, force the control unit to increase the idle speed if the voltage is low (most often at high electrical loads).

- Coolant temperature control sensor. It gives a signal that the engine is warming up, after which the ECU starts the operation of other systems.

- Absolute pressure sensor.

Monitors the pressure indicator in the intake manifold. The amount of air that enters the engine changes the consumption of the fuel mixture. This indicator is also used to determine the performance of a car.

- Crankshaft rotation sensor.

The crankshaft rotation speed is one of the determining factors that influence the calculation of the required pulse duration.

The benefits of the injector have already been appreciated by many car enthusiasts. Fuel consumption is reduced, vehicle performance is increased, and the process of driving it is made easier.

The operation of the injection engine is ensured by direct injection of fuel into the system, based on analyzed data on the parameters of the fuel mixture and the operating mode of the engine. How an injection engine works, its advantages and disadvantages compared to a carburetor device are discussed in our article.

If the material was interesting or useful for you, publish it on your social network page:

Source: http://jrepair.ru/interesnoe-na-jrepair-ru/agregats/inzhektornyj-dvigatel