CVT transmission - what is it, how does it work, what are the advantages?

What is a CVT gearbox , and how does it differ from a traditional transmission? This question may be of interest to both existing car owners with this type of torque transmission and future ones. This type of gearbox implies the absence of fixed gear ratios.

This gives a smooth ride and also allows you to use the engine in optimal modes. Another name for such a box is a variator. Next, we will consider the pros and cons of the CVT gearbox, the nuances of its use, as well as reviews from motorists who already own cars with a continuously variable transmission.

We'll consider:

Definition

The abbreviation CVT (Continuously Variable Transmission) translates as “continuously variable transmission”. That is, its design implies the possibility of smoothly changing the transmission coefficient between the driving and driven pulleys.

In fact, this means that the CVT gearbox has many gear ratios within a certain range (the boundaries of the ranges set the minimum and maximum diameters of the pulleys). Operating a CVT is in many ways similar to using an automatic transmission.

You can read about their differences separately.

Today there are the following types of variators:

CVT operation

- frontal;

- conical;

- ball;

- multi-disc;

- end;

- wave;

- disc ball;

- V-belt.

The CVT box (variator) is used not only as a transmission for passenger cars, but also for other vehicles - for example, scooters, snowmobiles, ATVs, and so on.

The most common type of CVT gearbox is a friction V-belt variator. This is due to the relative simplicity and reliability of its design, as well as the convenience and possibility of use in automobile transmissions.

Today, the vast majority of automakers producing cars with a CVT gearbox use V-belt variators (the exception is some Nissan models with a toroidal-type CVT gearbox).

Next, let's look at the design and operating principle of a V-belt variator.

Operation of the CVT box

The V-belt variator consists of two main parts:

- Trapezoidal timing belt. Some automakers use a metal chain or a belt made of metal plates instead.

- Two pulleys formed by cones with their points pointing towards each other.

The closer the coaxial cones are to each other, the diameter of the circle that the belt describes decreases or increases. The parts listed are CVT actuators. And everything is controlled electronically based on information coming from numerous sensors.

The principle of operation of the variator

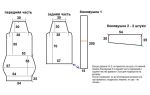

Continuously variable CVT transmission device

So, if the diameter of the driving pulley is maximum (its cones will be located as close to each other as possible), and the driven pulley is minimal (its cones will diverge as much as possible), then this means that the highest gear is engaged (corresponding to the 4th or 5th transmission in a traditional transmission). And vice versa, if the diameter of the driven pulley is minimal (its cones will diverge), and the diameter of the driven pulley is maximum (its cones will close), then this corresponds to the “lowest gear” (first in a traditional transmission).

To drive in reverse, the variator uses additional solutions, usually a planetary gearbox, since the traditional approach cannot be used in this case.

Due to the design features of the design, the variator can only be used on relatively small machines (with an engine power of up to 220 hp). This is due to the large forces that the belt experiences during operation.

The process of operating a car with a CVT transmission imposes some restrictions on the driver. Thus, you cannot suddenly start from a standstill, drive for a long time at maximum or minimum speed, tow a trailer, or drive off-road.

Pros and cons of CVT boxes

Like any technical device, CVTs have their advantages and disadvantages. But in fairness, it must be taken into account that currently automakers are constantly improving this transmission, so over time the picture will probably change, and CVTs will have fewer disadvantages. However, today the CVT gearbox has the following pros and cons:

| Advantages | Flaws |

| The variator ensures a smooth acceleration without jerks characteristic of a manual transmission or automatic transmission. | Today the CVT is installed on cars with engine power up to 220 hp. This is due to the fact that very powerful motors put excessive stress on the variator drive belt (chain). |

| Higher efficiency. Thanks to this, fuel is saved, and engine power is transferred to the actuators faster. | The variator is very sensitive to the quality of transmission oil. As a rule, it is necessary to buy only original high-quality oils, which are much more expensive than their budget counterparts. In addition, the oil must be changed more often than in a traditional transmission (approximately every 30 thousand kilometers). |

| Significant fuel savings. It is the result of high efficiency and a smooth increase in engine speed and speed (in a traditional transmission, significant overshoot occurs during gear changes). | The complexity of the variator device (the presence of “smart” electronics and a large number of sensors) leads to the fact that at the slightest breakdown of one of the many components, the variator will be automatically switched to emergency mode or disabled (forced or emergency). |

| Highly environmentally friendly, which results from lower fuel consumption. This means that cars equipped with a CVT meet modern high European environmental requirements. | Difficulty of repair. Often, even minor problems with the operation or repair of a variator can lead to a situation where it is difficult to find a workshop and specialists to repair this unit (this is especially true for small towns and villages). And the cost of repairing a CVT is much higher than traditional manual or automatic transmissions. |

| The electronics that control the variator always select the optimal operating mode. That is, the transmission always operates in the most gentle mode. Accordingly, this has a positive effect on the wear and service life of the unit. | A car with a CVT cannot tow a trailer or other vehicle. |

A car equipped with a CVT transmission cannot be used to tow a trailer or other vehicle. Also, you cannot tow the car itself if its engine is turned off. The exception is if you hang the drive axle on a tow truck.

Possible operational problems

In practice, owners of cars equipped with a CVT transmission face three main problems.

- Cone bearing wear. The reason for this phenomenon is trivial - wear products (metal shavings) or debris get onto the working surfaces. The car owner will be told about the problem by the sound of a hum coming from the variator. This can happen at different mileages - from 40 to 150 thousand kilometers. According to statistics, the Nissan Qashqai is very guilty of this. To avoid such a problem, it is necessary to regularly change the transmission oil (in accordance with the recommendations of most automakers, this should be done every 30...50 thousand kilometers).

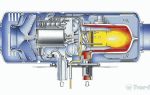

Reducing pump and valve

- Failure of the oil pump pressure reducing valve . This will be indicated to you by jerking and twitching of the car both during starting and braking, and during calm, even driving. The cause of the breakdown will most likely lie in the same wear products. Due to their appearance, the valve jams in intermediate positions. Consequently, the pressure in the system begins to jump, the diameters of the drive and driven pulleys become out of sync, and because of this, the belt begins to slip. During repairs, the oil and belt are usually changed, and the pulleys are ground. Prevention of malfunction is the same - change the transmission oil and filter on time, and also use high-quality oils. Remember that CVT type transmission oil must be filled into the variator (it provides the necessary viscosity and “stickiness”). CVT oil is distinguished by ensuring stable operation of the “wet” clutch. In addition, it is more sticky, which ensures the necessary adhesion between the pulleys and the drive belt.

- Problems with operating temperature . The fact is that the variator is very sensitive to the range of operating temperatures, in particular to overheating. A temperature sensor is responsible for this, which, if a critical value is exceeded, switches the variator to emergency mode (sets the belt to the middle position on both pulleys). For forced cooling of the variator, an additional radiator is often used. To avoid overheating the variator, try not to drive at maximum or minimum speed for a long time . Also, do not forget to clean the CVT cooling radiator (if your car has one).

Additional information about the variator

Many experts believe that the CVT gearbox (variator) is the most advanced type of transmission today. Therefore, there are all the prerequisites for the CVT to gradually displace the automatic transmission, just as the latter confidently displaces the manual transmission over time. However, if you decide to buy a car equipped with a CVT, then you need to remember the following important facts:

- the variator is not intended for an aggressive driving style (sharp acceleration and deceleration);

- In a car equipped with a variator, it is strictly not recommended to drive for a long time at extremely low and extremely high speeds (this leads to significant wear of the unit);

- the variator belt is afraid of significant shock loads, so it is recommended to drive only on a flat surface, avoiding country roads and off-road conditions;

- In a variator, it is imperative to change the transmission oil in a timely manner (and use only high-quality original oil).

Before purchasing a car with a CVT gearbox, you need to be prepared for its operating conditions. It will cost you more, but it is worth the pleasure and comfort that the CVT provides. Thousands of motorists today use a CVT transmission, and their number is only growing.

Reviews about CVT gearbox

Finally, we have collected for you real reviews from car owners whose cars are equipped with a CVT. We present them to your attention so that you have the clearest possible picture of the appropriateness of your choice.

| Positive reviews | Negative reviews |

| You need to get used to the variator. I had the subjective impression that as soon as you let go of the gas, the car stops much faster than with an automatic transmission (most likely this is because engine braking occurs). This was unusual for me, I like to drive to a traffic light. And on the plus side, the dynamics on the 1.5 engine are amazing (not compared to the Supra, but compared to regular cars with 1.5) and fuel consumption is low. | Everyone who praises the CVT, no one can sanely explain why it is better than the modern, also smooth 6-7-speed real hydromechanics, i.e. the answer is simple: nothing, even worse (written above in the article). It’s just that these people bought a CVT not because it is better than an automatic, but because the car they decided to buy did not come with a real automatic. |

| A CVT is more economical than an automatic (I compare it not with a Selick but with any other car with a 1.3 engine | The CVT does not inspire hope. An interesting development, of course. But, given that the entire global auto industry is moving away from improving the reliability of modern units, you can’t expect anything from variable speed drives (as well as from robots). Unless we switch to a consumer attitude towards a car: I bought it, drove it for 2 years under warranty, drained it, bought a new one. Which is exactly what they are leading us to. |

| Pros - faster and more confident acceleration compared to automatics and manuals (unless you are a master of sports in auto racing with a manual). Economical (Fit-5.5 l, Integra-7 l, both on the highway) | Why do you need a CVT when a “classic” automatic was invented long ago - smooth and super reliable? Only one option arises - to reduce reliability and make money on the sale of spare parts. And so, like, 100 thousand. The car has passed - that’s it, it’s time to go to the trash heap. |

| Last winter I drove a Civic with a CVT and had no problems on ice. The CVT is really more economical and dynamic than the automatic. The main thing is that you get it in good condition. Well, a little more expensive service is the price to pay for driving pleasure. | In short, CVT = hemorrhoids, a marketing cartoon for disposable cars. |

| Seventh year on the CVT - excellent flight! | The old machine gun is as reliable as an AK47, nafik these variks |

As you can see, most people who have tried driving a CVT at least once, if possible, do not refuse this pleasure further. However, it is up to you to draw your own conclusions.

Results

The variator, although more complex and expensive to maintain, is still by far the best transmission for cars with an internal combustion engine.

And over time, the price of cars equipped with it will only decrease, and the reliability of such a system will increase. Therefore, the described restrictions will be removed.

But today, do not forget about them, and use the car in accordance with the manufacturer’s recommendations, and then the SVT box will serve as faithfully for a long time as the car itself.

Did not find an answer to your question?

Ask in the comments. We will definitely answer!

Source: https://etlib.ru/blog/587-korobka-peredach-cvt—chto-eto-takoe

CVT (CVT)

Author: Vladimir EgorovSource: icarbio.ru310932There are a large number of workable variator designs, but only V-belt and toroidal ones are used in the automotive industry.

CVT (from Latin variātor “changer”) is an automatic transmission capable of smoothly changing the gear ratio within a certain range. The informal name is a variable speed transmission or automatic transmission variator.

CVT is a generally recognized worldwide abbreviation for variator from the English continuously variable transmission (translated as a constantly changing transmission).

Modern V-belt variatorCurrently, the V-belt variator is most widely used. The Variomatic CVT V-belt variator was first introduced in 1958 on the DAF passenger car.

Its successor, the Transmatic variator, began to be installed on Fiat and Ford cars in 1984. The V-belt CVT is a standard automatic transmission for many automakers, produced under their own names:

- Autotronic from Mercedes-Benz;

- Ecotronic, Durashift CVT from Ford;

- "Lineartronic" from "Subaru";

- "Multidrive" from Toyota;

- "Multimatic" from "Honda";

- "Multitronic" from "Audi";

- "Xtronic", "Hyper" from Nissan.

V-belt variators are also installed on some models of Chrysler cars (Dodge, Jeep), Fiat, Mini, Mitsubishi, Opel, Peugeot, etc.

In addition, analogues of the Variomatic continuously variable transmission are used in modern scooters (scooters), being their standard element since about the 80s of the 20th century.

The variator is installed on scooters with the most popular engine sizes (50, 70 and 125 cm3) from companies such as Malossi, Polini, Doppler, etc.

The most famous toroidal variator is produced by Nissan under the name “Extroid”.

CVT device

The variator as a gearbox includes the following elements:

- a mechanism that transmits torque and disconnects the gearbox and engine (neutral position);

- the variator itself;

- a mechanism that ensures reversing (reverse);

- Control block.

To transmit torque and decouple the variator from the engine, the following can be used:

- centrifugal automatic clutch (“Transmatic”);

- electronically controlled electromagnetic clutch (“Hyper”);

- multi-plate wet clutch with electronic control (“Multitronic”, “Multimatic”);

- torque converter (“Autotronic”, “Ecotronic”, “Extroid”, “Lineartronic”, “Multidrive”, “Xtronic”).

The last option is the most popular, because the hydraulic converter ensures smooth operation of the mechanism when transmitting torque, which results in a longer service life of the variator.

Automotive CVT transmissions use electronic control, the main functions of which are:

- changing the gear ratio of the variator in accordance with engine operating modes;

- torque converter/clutch control;

- ensuring the operation of the planetary gearbox.

The driver directly controls the variator using the selector lever. The control modes are similar to those of a conventional automatic transmission. Also, the CVT can implement the ability to select fixed gear ratios (analogous to the “Tiptronic” function).

The presence of this function, first of all, allows us to overcome the negative perception by many drivers of a constant engine speed during acceleration. A number of manufacturers call this function differently: “Sportronic” for Mitsubishi, “Autostick” for Chrysler.

V-belt variator design

A V-belt variator usually consists of one, less often two, belt drives. The transmission includes two pulleys connected by a V-belt.

The pulley is formed by two conical disks that can move or move apart, thereby changing the diameter of the pulley. Hydraulic pressure, centrifugal force, and spring force are used to bring the cones closer together.

The conical disks have an inclination angle of about 20°, which ensures that the belt moves along the pulley surface with the least resistance.

Scheme of operation of a V-belt variatorOn early V-belt variators, the belt was made of rubber (as on modern scooters), which made it short-lived (about 50,000 km) and not flexible enough (bending radius of at least 90 mm). Poor flexibility resulted in a narrow control range.

The vast majority of modern CVT gearboxes use a flexible V-shaped pusher belt made of several steel belts (about 10 - 12) and associated “butterfly” shaped plates.

The transmission of torque is carried out due to the friction forces between the pulleys and the side surface of the belt. This design provides high strength, durability, flexibility (minimum bending radius 30mm) and low noise level.

It was the advent of the metal V-belt that made it possible to widely use the variator on cars, since it could transmit significant torque.

Source: http://icarbio.ru/articles/variator-cvt.html

Features of the device and operation of the variator

Increasingly, cars are aggregated on the assembly line with CVT gearboxes.

But how is this justified and do the pros really outweigh the cons? Let's look at how a variator works, its internal structure and principle of operation.

We hope that the considered disadvantages and advantages will help you make the right choice in the future between CVT, DSG, robotic gearbox and automatic torque converter type gearbox.

CVT gearbox design

Structurally, the variator consists of the following components:

- mechanism that acts as a clutch. Allows you to transmit torque and, if necessary, disconnect the gearbox from the power unit;

- CVT transmission;

- planetary gearbox with a clutch package, allowing the vehicle to move in reverse;

- electronic control system.

There are a large number of CVT transmissions, but V-belt CVTs are the most widely used in cars. The mechanism consists of a belt, output and output pulleys, as well as mechanisms that change the diameter of the pulleys in the working area of the belt.

The first versions of CVTs were equipped with a rubber belt, but this design is extremely unreliable. Modern units use either a flexible metal belt or a chain. In a V-belt variator, torque is transmitted due to a friction pair: the side part of the belt is the working surface of the pulleys. The chain is in contact with the conical surface of the pulleys with the end part.

The advantage of a wedge-chain variator is flexibility (has a smaller bending radius) and lower mechanical friction losses. The chain works due to point contact with the surface of the cones, so there is a very high mechanical load at the points of contact. To increase wear resistance, pulley cones are made of high-strength steel alloys.

Principle of operation

Why are CVT transmissions called continuously variable? Only because the change in gear ratios between the output and drive pulleys occurs so smoothly that it is impossible to notice a distinct transition boundary.

To achieve direct transmission, at which the rotation speed of the input and output pulleys will be the same, we need to equalize the diameters of both pulleys. If we increase the diameter of the driven pulley, and leave d of the driving pulley the same, we will get a reduction gear.

The driven shaft rotates more slowly than the drive shaft, thereby increasing torque. It is in the downshift mode that a car with a CVT starts moving. To increase the speed of the machine, a reverse change in the diameters of the pulleys occurs.

This is precisely what the operating principle of the variator (Continuously Variable Transmission) is based on.

Clutch mechanism

In the process of developing the variator device, manufacturers used different types of mechanisms, including:

- automatic centrifugal clutch (common on scooters, motorcycles);

- electronically controlled electromagnetic mechanism;

- multi-disc clutch. It has an operating principle similar to that used to block individual rows of the planetary gear of a torque converter-type automatic transmission.

- Also, the operation of a multi-plate wet clutch is used to lock differentials and intelligently connect all-wheel drive. The “wet” clutch on the DSG works on the same principle;

- torque converter. We hope you are familiar with the design and principle of operation of a torque converter type automatic transmission, so we will not consider the design.

The use of a torque converter can significantly reduce the load on the variator when starting from a standstill. Slipping until the torque converter locks increases the life of the working surface of the cones and reduces belt/chain stretching. It was this decision that for the first time allowed a car with a CVT to endure off-road travel relatively painlessly.

Reverse gear

The drive and driven shafts in the variator rotate strictly in the direction of rotation of the engine crankshaft. Therefore, the only rational way to implement reverse gear is a planetary gearbox. When the main and sun gears are locked, the input shaft rotates in the same direction as the input pulley, which is connected to the carrier.

If you block only the main gear, the carrier, and with it the input pulley, will rotate in the opposite direction. For a visual representation of the design and operation of the planetary gearbox in a variator, we suggest watching the video.

Control system

The principle of operation of the variator in reverse gear mode is possible thanks to the use of 2 clutch packs.

One of them, if necessary, blocks the main and sun gears (forward movement), and the second – the variator housing and the ring gear (reverse gear).

The steel and friction discs are compressed by oil pressure, which is pumped into the system by an oil pump and supplied to the corresponding channels through the valve body (mechatronics).

Oil pressure is also used to move the moving part of the pulley, which allows you to adjust its diameter. For the correct operation of the CVT gearbox, it is extremely important that the change in diameters occurs as synchronously as possible. Therefore, designers pay great attention to the performance of the oil pump of CVT gearboxes.

Redirection of the oil flow to the appropriate channels is carried out by solenoids, which, at the command of the electronic variator control unit, open or close. To control the operation of the gearbox, the ECU uses data from speed sensors, mass air flow sensor, throttle opening sensor, and DTOZH.

What's good about CVT?

- No losses in acceleration dynamics due to gear shifting. When a car with a CVT accelerates intensively, the tachometer needle hangs in one place - in the zone of maximum engine power. Thus, overclocking is most effective.

- Reduced fuel consumption. If you are moving at a constant speed and accelerating moderately, the variator sets the minimum engine speed by selecting the gear ratio. This type of engine operation not only increases acoustic comfort in the cabin, but also reduces fuel consumption.

- Reducing harmful emissions into the atmosphere.

- Smooth movement. Thanks to a linear rather than stepwise change in gear ratio, the car maintains a smooth ride both during acceleration and braking.

- Compactness. The small dimensions allow the installation of CVTs on both all-wheel drive and front-wheel drive vehicles.

The pros are clear, but how serious are the cons?

Unfortunately, like many devices in the world of technology, CVTs are not without their drawbacks. The CVT was originally conceived as a transmission for subcompact cars, hatchbacks, mid-size sedans and small crossovers.

V-belt and even V-chain variators tolerate sudden changes in driving modes extremely poorly. Constant alternations of dynamic acceleration, deceleration and slipping of the drive wheels lead to damage to the surface of the cones and stretching of the chain/belt.

Scuffing causes twitching and accelerated wear of the belt/chain. Also, a drop in oil pressure leads to interruptions in the operation of the variator and loss of service life. Because of this, the friction packs begin to slip.

As a result, the oil ages very quickly, and the valve body becomes clogged with suspension from the friction linings (dust that gets into the ATF fluid).

Is it worth buying or is it better to choose a car with automatic transmission, DSG, manual transmission?

It is impossible to reliably say which is better: a CVT or an automatic transmission. Not a single continuously variable transmission can come close to the reliability of archaic torque converter automatic transmissions. But many modern automatic machines also cannot compete with them in this regard, let alone the operating features and problems of DSG and Power Shift.

Therefore, we recommend taking into account that there are different models and types of variators. When buying a car, be sure to study owner reviews, the real pros and cons of a specific gearbox model. Many manufacturers have learned to make durable CVTs that, with proper maintenance, can easily cover 150 and even 200 thousand km.

To avoid widespread malfunctions, CVTs are installed mainly on cars with low-power engines. But Audi, and more recently Nissan and Subaru, use CVT gearboxes in quite heavy and powerful cars.

Which in no way pushes you to choose a used car with a CVT. Much also depends on the driver’s driving style and approach to maintenance. Many people ignore the fact that the variator vitally needs proper heating in winter.

Also, to extend the service life, it is necessary to periodically change the ATF fluid and flush the cooling radiator.

Source: http://AutoLirika.ru/teoriya/variator.html

What is a CVT and how to drive a CVT correctly? Basic principles of variator operation: video

What is a variator gearbox? Basic principles of variator operation. Subtleties of operation of variator device elements: video. How to drive a CVT correctly?

Every car enthusiast knows how an automatic transmission differs from a manual one. And the dispute over the merits and demerits of both has not faded away between drivers for many years. Not only the technical characteristics of each device and their impact on the process of driving a car are mentioned, but also such points as fuel consumption, reliability, convenience and durability.

But few car owners know what a CVT is . Some believe that it is no different from an automatic transmission, while others distinguish it as a special type of gearbox. So who is right? And what is the secret of the variator? It’s not easy to figure this out, so you should start with the most basic operating parameters of this device.

This device is also called a continuously variable transmission . Its main difference from mechanical and automatic is precisely the absence of sharp shifting between gears. The number of “speeds” of the variator is unlimited, it is impossible to count them. What is the secret of this device? Fundamental difference from other boxes?

Of course, it all depends on how the variator works . The gearbox itself necessarily contains the following elements :

- the variator itself;

- control system;

- a mechanism that transmits torque and ensures separation of the engine and gearbox;

- a mechanism that allows you to move in reverse.

Typically a variator consists of one belt drive , but there are also models with two. The traditional model of the device consists of two pulleys that are connected using a V-belt. It is worth noting that the pulleys themselves are capable of changing their diameter .

This result can be achieved by the design of the elements themselves : they are formed by two conical disks. The discs move, increasing the diameter, and move apart, reducing it.

The belt moves over the surface of the pulleys , thereby increasing or decreasing the gear ratio.

The first models of variators were used on sewing machines and weaving machines, but then the belt was made of rubber and, accordingly, had low strength.

It was suitable for machine tools, but the car needed something more durable and wear-resistant. CVTs came to the automotive industry relatively recently.

It can be said that this technology took years to find the right material to create a CVT transmission for a car.

Modern devices are equipped with a flexible belt made from metal parts. Several (10 to 12) steel strips are interconnected to ensure not only durability and reliability of the structure, but also good rotation transmission . High flexibility and wear resistance allow the variator to operate for many years without breakdowns or adjustments.

If you want to know what a CVT gearbox is, then pay attention to the electronic control system that these models are equipped with. A large number of sensors measure all the necessary vehicle readings, transmitting information to the on-board computer .

A person does not need to worry about changing gears at the right moment; the variator itself will select the best gear ratios. How is this possible? All data from the sensors allows the device to change the diameter of the pulleys in time to accelerate the car to the desired speed and maintain the selected pace.

For example, the beginning of a machine’s movement is characterized by the smallest diameter of the drive pulley, but the maximum diameter of the driven pulley. As the speed increases, the first one begins to decrease in diameter, and the second one begins to increase.

Thus, the variator changes the gear ratio and accelerates the car, not allowing it to exceed the recommended values.

It is for this reason that many drivers do not like the sound of the CVT. The thing is that it does not allow excessively high speeds. This means that the car will not “roar” during the start and when you sharply press the gas pedal.

Some car enthusiasts consider moderate and even too low noise that a car makes to be “provoking.” The psychological problem is that a driver who does not hear the growling sounds of the engine assumes that the car is moving too slowly.

And this can lead to violation of the speed limit. But this drawback of the CVT gearbox is entirely subjective.

If you want to learn more about the operating principle of a variator , the video will help you understand all the intricacies of this device, examine each element and learn all the advantages and disadvantages of this gearbox.

Knowing what a CVT is is useful, but not enough. A good car owner must understand how to drive such a transmission in order to avoid costly repairs.

Firstly, you should avoid starting with a cold engine . In winter, all drivers try to give the car the opportunity to warm up to operating temperature; by this time the oil should enter all channels of the system, ensuring a safe start .

But if owners of cars with a manual transmission can afford to start the car and immediately hit the road (not recommended, since it increases wear on parts), then owners of cars with CVT gearboxes cannot do this.

The transmission oil must warm up ; if some elements work without lubrication, they will very quickly become unusable. But repairing a variator is a troublesome and very expensive task.

Secondly, the driver must constantly monitor the transmission oil level . If it is below the minimum, then the box is at risk. In addition, the quality of the consumable material itself must be at its best. The variator will not tolerate bad oil . But even high-quality and expensive material may not be suitable, so carefully read the instructions for the car.

Third, avoid off-road driving . The variator is not designed for such “problematic” terrain. It is also worth refusing to tow the vehicle itself or other cars.

Source: http://tvoe-avto.com/12887-chto-takoe-variator-na-mashine.html

What is a CVT on a car and how does it work?

In the modern automotive industry, various types of gearboxes are used. Famous concerns compete with each other all the time. And in the context of rising fuel prices, as well as increasing requirements for efficiency and reducing the amount of harmful emissions into the atmosphere, manufacturers have to use more and more new types of developments.

At the same time, using colossal financial resources. And the end consumer is always looking for a car whose consumption will be lower. Today, CVT gearboxes combine many of the requirements.

What is a CVT on a car?

A variator is a type of transmission system whose task is to transmit torque from an internal combustion engine to the wheels of a car.

A special feature of this gearbox is the ability to smoothly change the gear ratio. This can happen either manually or automatically.

This transmission device is characterized by the following features:

- produces low noise level during operation;

- lack of fixed gear stages;

- high smoothness of torque transmission, and as a result - smooth acceleration;

- low fuel consumption;

- faster car acceleration;

- increasing the service life of transmission elements;

- lower wear of engine parts.

The device of a CVT transmission in itself is not complicated and consists of the following elements:

- Pulleys with the ability to move apart, which are located on the shaft.

- Design for rotating the wheels and setting the gear selector to the neutral position.

- A mechanism that ensures switching to the “reverse movement” mode.

- Control block.

Types and principle of operation of the variator

Since the CVT, as a transmission device, came into the mass automotive industry not so long ago, it is worth noting that manufacturers are constantly trying to produce and improve the design of CVTs.

Therefore, every modern auto concern strives to develop more and more new methods of continuously variable transmission of torque. Today there are several types of variable gearboxes.

These include the following variators:

- V-belt;

- Toroidal.

V-belt

This is a type of CVT transmission in which torque is transmitted through two pulleys and a belt with a trapezoidal cross-section. Pulleys consist of two cone-shaped disks, between which a belt is located.

In this case, changing the gear ratio is carried out by changing the distance between two such disks. This process is traditionally carried out on both pulleys. This ensures maximum efficiency in torque distribution.

Some car manufacturers may use a chain instead of a belt. The operation of each of them is controlled by an electronic system, which does this through nearby sensors with servo drives and a central control unit. By changing the proximity of the disks, the friction force also changes, which, in turn, affects the change in torque.

Pulleys are divided into:

- the drive is a pulley to which the rotation of the crankshaft is transmitted;

- The driven one is a pulley to which torque is transmitted from the driver.

It got its name from the V-belt because of the belt, which acts as a wedge, located between the cone-shaped discs.

Toroidal

The toroidal type of gearbox is characterized by a different type of both the mechanism itself and the way in which it transmits torque. It looks like a pair of wheels with a sphere-shaped surface, between which there is a roller.

Pairs of wheels are divided into:

In this case, the change in gear ratio occurs due to a change in the friction force that occurs between the roller and the wheels. If the position of the roller changes relative to the transverse plane, the friction force and, accordingly, the gear ratio change.

How to use this device correctly?

When starting to drive, you need to do the same steps as on vehicles with an automatic transmission. When driving, intervention in the operation of the variator is not required, except when the manual gearbox control mode is selected. The specific operating mode of the variator is selected by moving the gear selector knob.

To start moving forward you need to:

- start the engine;

- move the gear selector knob to the forward position (D);

- by pressing the gas pedal, start moving.

After setting the handle to “D” (Drive) mode and starting to move, there is no need to take additional actions. During a short stop, switching to other modes is not required.

In case of a long stop, for example in a parking lot, you should change the mode to “P” (Parking). To avoid damage to the gearbox, switching to “P” mode is carried out after the vehicle has come to a complete stop.

To move backwards you need:

- move the handle to the “R” (Reverse) position;

- Having looked around, start moving, smoothly pressing the gas pedal;

- Having completed the maneuver, you must stop before moving the selector knob to another mode.

The neutral position “N” can be used in case of a long stop, but provided that the need to move will not arise soon. Overall, this is the familiar neutral gear. When it is turned on on the variator, as on any other gearbox, the power unit is disconnected from the gearbox.

Position “P” (Parking) is used when parking the vehicle. By moving the handle to this mode, the driven shaft of the variator is blocked with a pin. This method eliminates the possibility of rolling the car yourself.

Essentially, this is the same as setting the speed in a manual transmission. In some vehicles, to set the lever to this position you must:

- Depress the brake pedal.

- Tighten the handbrake.

- Move the handle to the “P” position.

To switch to the movement mode, it is necessary to carry out all manipulations in the opposite direction.

Manual control mode can be used to obtain a more complete driving experience when driving. Since the device itself does not provide for gears, all switching is conditional.

The variator changes the gear ratio to a certain value, thereby creating an imitation of switching. You need to understand that such switching is possible conditionally and if the engine speed changes, the variator will independently select gear ratios.

This is necessary to ensure the functionality of the variator itself.

There may also be other operating modes of the variator, such as:

- S – Sports mode. Necessary for a sharper response when pressing the pedal. The purpose of this mode is to drive in a more aggressive and harsh style.

- E - economy mode. The necessity and essence of this mode is contained in its name - the use of such settings for the gearbox operation, which will achieve maximum savings when driving.

- L – mode of bad weather conditions. Used for off-road driving, towing a trailer or car. In this mode, the variator directs the maximum amount of traction force to the wheels of the car.

CVT operating mode in winter

When operating a car with such a gearbox, you must know and adhere to the operating rules and recommendations provided by the manufacturer.

Also, understanding the design of the variator is necessary:

- Do not start driving immediately after starting the engine.

- There is no need to rush to press the gas pedal after switching to drive mode.

- Do not neglect bad weather conditions.

Should I buy a car with a CVT?

When purchasing a car with this type of gearbox, you need to remember that an aggressive driving style will lead to the fastest possible wear of gearbox parts.

In this connection, their replacement or replacement of the entire gearbox as a whole will be required. This is a rather expensive procedure. Therefore, for those who prefer a measured driving style and want to save on consumption, this type of gearbox will be more comfortable.

Pros and cons of a variator

Like any device, a variator has its pros and cons. For some, the advantages are more important than the negative, but for others, the negative points will not be acceptable.

Pros:

- low fuel consumption;

- low level of emissions into the atmosphere;

- improved acceleration dynamics;

- high smoothness;

- are more reliable than automatic transmissions;

- have relatively low weight;

- simple unit design;

- low noise level.

Minuses:

- not suitable for high power engines;

- it is not advisable to drive in an aggressive mode;

- the presence of a large number of sensors;

- expensive lubricant;

- rarely repaired.

Which is better - CVT or automatic?

It is difficult to answer what is better, because each type of checkpoint has its supporters and fans. The answer to this question is purely personal and individual.

After all, to understand and determine which is more suitable, you need to try driving in parallel in cars with different types of gearboxes. Only in this way can you determine a more convenient type of gearbox for yourself.

The CVT is the most progressive and convenient type of gearbox, the capabilities of which include reducing fuel consumption and emissions into the atmosphere. At the same time, it is categorically not suitable for operation in the mode of sudden acceleration and sudden braking.

This type is characterized by use in a measured style, where acceleration and braking are carried out smoothly.

Source: https://autopravilo.ru/sovety/variator-na-avtomobile-vidy-i-princip-raboty.html