Replacing antifreeze in Toyota Corolla

Japanese cars are very sensitive to the quality of technical fluids and the frequency of their replacement. Therefore, compliance or non-compliance with the manufacturer’s recommendations affects the service life of the main components of the vehicle.

It is difficult even for an experienced driver to visually determine the condition of the coolant and whether it needs to be replaced. Therefore, it is customary to focus on the mileage of the car and the duration of use of the coolant.

Despite the fact that modern coolants, according to the manufacturer, have a service life of 3 to 5 years, the Toyota Corolla manufacturer strongly recommends replacement once every 100,000 kilometers or after 1.5 years of mileage. If the refractometer readings are good, it is allowed to drain antifreeze from the Toyota Corolla after 3 years. Which, in fact, coincides with the recommendations of the coolant manufacturer.

Choosing antifreeze for Toyota Corolla

The consumer is asked to choose antifreeze based on the year of manufacture of the car.

For older models, in the cooling system of which steel, aluminum, brass, and copper were used, inorganic antifreezes are used. They are classified under the index G11.

The service life of G11 is only 2-3 years. When using this type of antifreeze, a protective film is formed on the internal surfaces.

A more modern version of coolant G12, G12+, G12++. It belongs to organic antifreezes of the “Long Life” type.

Liquids are based on a completely different principle of protecting internal metal surfaces from corrosion. It prevents the formation of oxides and has a longer service life.

This type of antifreeze is not recommended for use in cooling systems that contain copper-based metals.

When choosing, you should not focus only on color, since a mixture with the G11 index can be red, green, yellow. Not everyone knows what kind of antifreeze is best to pour into a Toyota Corolla.

Before 2005, the manufacturer recommended using Long Life Cooliant (LCC) type G11 (replacement interval is 40 thousand kilometers), after 2005 - Super Long Life Cooliant (SLLC) type G12+, G12++ (replacement interval is 100 thousand kilometers).

kilometers). Mixing G11 and G12+ with each other is strictly prohibited.

Coolant volume in Toyota Corolla

The volume of Toyota Corolla coolant depends on the type of engine and installed gearbox. For the 1ZZ-FE power drive, which was equipped with all-wheel drive versions of the 120 series, 6.5 liters are enough. For the front-wheel drive version - 6.3 liters. Exact information about how many liters of antifreeze is needed in a Toyota Corolla can be found in the car’s operating instructions.

Replacement procedure

If you switch to a new type of antifreeze or if it is impossible to determine what is in the system, experts recommend flushing. To do this, place the car on a level surface and prepare:

- container for waste liquid;

- funnel for filling;

- distilled water at the rate of 6-8 liters per wash.

Then drain the coolant.

- Unscrew the expansion tank cap and the filler cap on the radiator.

- After this, put a hose with a diameter of at least 8 mm onto the drain fitting located at the bottom of the radiator, unscrew the fitting and drain the coolant.

- There is a coolant drain plug located near the oil filter in the engine block.

- Unscrew the drain plug with a 14 mm wrench, first placing a container for technical fluid.

Fill flushing fluid through the filler hole on the radiator. The fluid level should correspond to the Full mark on the expansion tank. Based on the color of the drained liquid, be guided by the number of cycles; check the volume of antifreeze in the Toyota Corolla. - After filling in the flushing fluid, start the engine.

Experienced auto mechanics do not use drain holes specifically designed for this purpose. They disconnect the cooling system pipe located at the bottom of the engine. In order to replace the coolant, remove the plastic protection elements.

You should not warm up the engine before draining the coolant in a Toyota Corolla. When filling the radiator with coolant, start the engine, while turning the heater to the maximum heating position. Check the opening of the thermostat and, if necessary, add technical fluid to the Full level.

If the material was interesting or useful for you, publish it on your social network page:

Source: http://jrepair.ru/to-toyota/zamena-antifriza-v-toyota-corolla

Repair of the Toyota Corolla cooling system (Toyota Corolla)

The full range of vehicle technical support processes at RS Auto Service also includes repair of the Toyota Corolla cooling system.

The professional equipment of RS Auto Service allows you to effectively carry out all stages of this procedure. The replacement of a Toyota Corolla heating radiator (Toyota Corolla), replacement of a Toyota Corolla pump (Toyota Corolla) or replacement of a Toyota Corolla heater radiator (Toyota Corolla) by our specialists ensures uninterrupted operation of the entire cooling system.

The cooling system operates in conjunction with the central device of the machine - the engine. When the components of the cooling system operate efficiently, the engine performs its functions in the required thermal conditions. A breakdown of the cooling system makes the operation of the engine and the entire car vulnerable.

Price for repairing the Toyota Corolla cooling system in St. Petersburg

You can avoid more dangerous failures and costs by monitoring changes in the operation of the cooling system.

Signs of a malfunctioning cooling system:

- excessive engine heating;

- excessive engine cooling;

- cooling fluid leak;

- evaporation of coolant when the engine is running.

The above signs are a signal to immediately contact professionals who will accurately determine the presence of a breakdown and the reasons that caused it.

They will also repair the Toyota Corolla engine cooling system.

Basic procedures for repairing the cooling system

Work on setting up the cooling system includes checking and repairing its components.

High-quality repair of the Toyota Corolla cooling radiator allows you to preserve the functions of the engine. This procedure may include repairing the honeycomb core, plastic tanks, or completely replacing the device.

Repair of a Toyota Corolla heating radiator may include replacing a section, sorting out connections, flushing the radiator and other procedures. RS Auto Service specialists recommend repairing heating radiators at the beginning and end of the winter period.

Repairing the Toyota Corolla heater radiator also becomes relevant with the arrival of cold weather and may involve repairing the heater tap, metal pipe and other parts.

Designed to pump liquid into the engine jacket, the pump requires constant repair and diagnostic maintenance. Professional repair of the Toyota Corolla pump allows you to avoid engine malfunction.

Replacing the Toyota Corolla thermostat is an operation in which the qualifications of the performer are of great importance. Our technical center specialists quickly restore the operation of the thermostat to control the flow of antifreeze between the internal combustion engine and the radiator.

The above work must be carried out only on specialized equipment and only parts recommended by the manufacturers must be installed in such work as replacing a Toyota Corolla radiator.

The car owner must remember the interaction of the cooling system with the car engine and repair the Toyota Corolla radiator only in a specialized service center.

The secret of Toyota Corolla success

Toyota Corolla was recorded in the Book of Records as the best-selling vehicle. Entering the market in the late 60s, the car tried all sorts of variations: hatchbacks, sedans, station wagons, liftbacks.

To date, Toyota Corolla has retained its exemplary appearance and technical features at a high level. These include a reliable anti-corrosion coating and an excellent installation method.

Also, Toyota Corolla collects decent reviews based on the results of system security checks.

The RS service station repairs the Toyota Corolla cooling system quickly and at an excellent price. A friendly group of skilled craftsmen will give you the opportunity not to worry about your car and the outcome of the manipulations.

We provide a guarantee for all work and parts purchased in our center.

We will be glad to welcome you to our car service center in Kupchino!

For any questions, please call +7(812)6122842

Source: http://rsservicespb.ru/remont-sistemy-ohlazhdeniya-toyota-corolla

Repair and service of passenger cars

________________________________________________________________________________________

________________________________________________________________________________________

Cooling system 4A-FE, 5A-FE, 4A-GE, 7A-FE

Toyota 4A-FE, 5A-FE, 4A-GE, 7A-FE engines have a closed-type liquid cooling system with forced circulation of coolant and a thermostat with a bypass valve in the coolant inlet pipe.

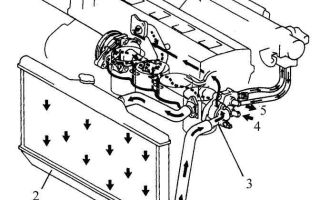

Fig. 186. Diagram of the cooling system of engines 4A-FE (AE101 and AT190), 5A-FE and 7A-FE of Toyota Corolla, Corona, Toyota Carina E, Carib, Toyota Sprinter, Kaldina cars

1 – thermostat, 2 – coolant inlet, 3 – (from the radiator), 4 – coolant outlet, 5 – (to the radiator), 6 – coolant pump, 7 – (from the heater), 8 – (to the heater ), 9 – coolant supply tube to the pump, 10 – (from the throttle valve heater), 11 – (to the throttle valve heater), 12 – radiator.

Fig. 187. Diagram of the 4A-GE engine cooling system (AE92, AW11 and AT160)

1 – thermostat, 2 – coolant inlet pipe, 3 – (from the radiator), 4 – (to the radiator), 5 – coolant pump. The cooling system includes: a cooling jacket (in the cylinder block and in the cylinder head), radiator, coolant pump, thermostat, electric cooling fan, connecting hoses and other elements. The coolant, heated in the cooling jacket, is forced by a liquid pump into the radiator, where it is cooled by a fan and the oncoming air flow that occurs when the car is moving. The coolant is then returned to the cooling jacket by a pump and cools the engine. The cooling system jacket of Toyota 4A-FE, 5A-FE, 4A-GE, 7A-FE engines is a network of channels for the passage of fluid. These channels are formed by the spaces between the cylinder liners in the cylinder block and communicate with the channels in the cylinder head. The movement of the liquid is organized in such a way as to ensure the most effective cooling of those engine elements that heat up the most during its operation (in particular, the upper belt of the engine cylinders and combustion chambers). Radiator The Toyota 4A-GE, 4A-FE, 5A-FE, 7A-FE radiator is located in the front of the car and is designed to cool the coolant coming from the cooling jacket.

The radiator consists of the right and left tanks and the radiator core, which connects the two tanks.

In the upper tank there is an inlet pipe through which coolant flows from the cooling jacket, as well as a hose for bypassing excess coolant or steam.

In the lower radiator tank there is a coolant outlet through which it enters the coolant pump, as well as a drain valve through which the coolant is removed.

The core of the radiator of Toyota 4A-FE, 5A-FE, 4A-GE, 7A-FE engines of Toyota Corolla, Corona, Toyota Carina E, Carib, Toyota Celica, Sprinter, Kaldina cars has many finned tubes through which the coolant flow passes from the upper tank into the bottom, as well as cooling fins for more efficient heat dissipation into the environment.

The coolant, heated as it passes through the cooling jacket, is cooled in the radiator by the air flow drawn in by the electric fan, as well as by the counter flow of air that occurs when the car is moving.

Models with automatic transmission have a special automatic transmission fluid cooler, which is located in the lower radiator reservoir. An electrically driven fan is located behind the radiator to facilitate air flow through the radiator. The fan turns on only if the coolant temperature reaches the operating value. This reduces the power required to drive the fan and prevents engine overcooling.

Features of the radiator for Toyota AW11 (MR2) models

The Toyota 4A-FE, 5A-FE, 4A-GE radiator for the MR2 model differs from the radiators of other models in that the coolant flow in it passes in a horizontal direction from one side of the car to the other. The radiator has two side tanks and a core that connects them.

The inlet pipe through which coolant enters the radiator from the cooling jacket and the faucet for draining the coolant are located in the left tank. The coolant outlet and air drain valve, which facilitates filling the engine with coolant, are located in the right tank.

The fluid cooler for models with automatic transmission is located in the radiator core and uses part of its tubes. The radiator cap has a conventional design, but is located on a separate pipe.

The radiator plug is a sealing type, it must seal the radiator and withstand the increased pressure resulting from the thermal expansion of the coolant. The increased pressure in the radiator prevents the coolant from boiling even at temperatures above 100°C.

The radiator cap has a steam (dump) valve and an air valve (vacuum valve). At a coolant temperature of 110-120°C, the excess pressure inside the radiator, caused by thermal expansion of the liquid, reaches 0.3-1.0 kg/cm2 or 30-100 kPa.

If the specified limit is exceeded, the steam valve opens under pressure and steam is removed through the steam pipe.

The air valve opens under the influence of vacuum that forms inside the Toyota 4A-GE, 4A-FE, 5A-FE, 7A-FE radiator of Toyota Corolla, Corona, Toyota Carina E, Toyota Sprinter, Caldina after stopping the engine and reducing the coolant temperature.

Opening this valve allows the coolant in the expansion tank to return to the cooling system. The expansion tank is designed to accumulate excess volume of coolant, which is obtained as a result of its volumetric expansion when heated. When the coolant temperature drops, it returns from the expansion tank to the radiator.

This way, the radiator is always filled with coolant without unnecessary coolant loss. To make sure it is necessary to add coolant, you need to check its level in the expansion tank. The water pump provides forced circulation of coolant through the cooling system.

It is installed in the front of the cylinder block and is driven from the crankshaft by the alternator drive belt. The thermostat is installed on the inlet pipe of the cooling circuit. It has a wax bypass valve and an automatic valve controlled according to the coolant temperature.

The automatic valve closes when the coolant temperature drops, thereby preventing coolant from circulating through the engine, speeding up the engine warm-up process.

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

Source: http://autozapchastiremont.ru/dvs_toyota_4a_fe_5a_fe_sistema_ohlazhdeniya.html

Toyota Corolla E150 (2010+). ENGINE COOLING SYSTEM DESIGN 1ZRRFE, 1NRRFE, 4ZZZFE

The engine cooling system is liquid, closed type, with forced circulation of liquid. The system consists of a cooling jacket, radiator with electric fan, expansion tank, water pump, thermostat and hoses. The circulation of liquid in the system is created by a water pump.

From the pump, the liquid is supplied to the engine cooling jacket, washes the cylinders and combustion chambers and then, depending on the position of the thermostat valve, returns to the pump through the bypass channel (at low temperatures) or through the radiator (at high temperatures).

The engine cooling system also includes a cabin heater radiator and heating channels for the throttle body of the power system.

Radiator with horizontal fluid flow, tubular-tape aluminum core and plastic tanks. The radiator tanks contain inlet and outlet hose pipes to the engine water jacket. A tap is installed in the left tank to drain coolant from the system.

The expansion tank serves to compensate for the changing volume of coolant depending on its temperature. It is made of translucent plastic. The filler neck of the tank is closed with a plastic plug with two valves: inlet and outlet.

The exhaust valve opens at a pressure of 78.5–122.7 kPa (0.80–1.25 kgf/cm2), ensuring an increase in the boiling point of the coolant and preventing intense vaporization. When a liquid cools, its volume decreases and a vacuum is created in the system.

The inlet valve in the plug opens at a vacuum of about 7 kPa (0.07 kgf/cm2).

NOTE

The serviceability of the plug valves is very important for the normal operation of the cooling system.

However, when problems arise (for example, boiling coolant), car enthusiasts pay attention only to the operation of the thermostat and forget to check the valves.

Leaking of the exhaust valve leads to a decrease in the boiling point of the coolant, and its jamming in the closed state leads to an emergency increase in pressure in the system, which can cause damage to the radiator and hoses.

A centrifugal water pump provides forced circulation of liquid in the cooling system.

It is located on the front surface of the cylinder block and is driven from the crankshaft pulley by a poly-V belt, common with the generator and air conditioning compressor.

The pump has sealed bearings that do not require replenishment of lubricant. The pump cannot be repaired, therefore, if it fails (liquid leakage or bearing damage), it is replaced as an assembly.

A thermostat with a solid heat-sensitive filler maintains normal operating coolant temperature and reduces engine warm-up time. The thermostat is installed in a housing mounted on the cylinder head.

At a coolant temperature of up to 77 °C, the thermostat is completely closed and the liquid circulates through a small circuit, bypassing the radiator, which speeds up engine warming up.

At temperatures above 80 °C, the thermostat begins to open and at 95 °C it opens completely, allowing fluid to circulate through the radiator.

The electric fan of the cooling system (with a plastic multi-blade impeller is used for additional cooling of the radiator; it is turned on and off by a signal from the electronic unit of the cooling system.

Moreover, depending on the intensity of the thermal regime and the operating algorithm of the air conditioner, the electric fan can rotate at low or high speed. The electric fan assembly with casing is mounted on the radiator of the cooling system.

The system is filled with liquid (antifreeze) Toyota Super Long Life Coolant (red), which does not freeze at ambient temperatures down to –40 °C.

WARNINGS

It is not recommended to fill the cooling system with water, since antifreeze contains anti-corrosion and anti-foaming additives, as well as additives that prevent scale deposits.

Coolant is toxic! Avoid inhalation of its vapors and contact with skin. Correct any leaks in the cooling system in a timely manner to prevent coolant vapors from entering the vehicle interior during operation.

Your health is more valuable than a new cooling system pipe or a tube of sealant!

POSSIBLE MALFUNCTIONS OF THE COOLING SYSTEM, THEIR CAUSES AND REMEDIES

| Cause of malfunction | Remedy |

| The engine gets very hot | |

| Reduced coolant level in the radiator | Add coolant |

| Thermostat is faulty (valve stuck in closed position) | Replace Thermostat |

| Water pump is faulty | Check the pump and replace if faulty |

| The tension of the accessory drive belt is loose | Check and replace the belt if necessary |

| The radiator core is clogged with dirt and insects | Clean the outside of the radiator core |

| Radiator tubes, hoses and engine cooling jacket are clogged with scale and silt deposits | Flush the cooling system and fill with fresh coolant |

| The electric fan does not turn on due to a broken electrical circuit, failure of the temperature sensor, fuses, additional resistance, relay or fan motor | Check and restore electrical circuits. If necessary, replace fuses, resistance, relay or electric fan assembly |

| Damage to the valve in the radiator cap (constantly open, due to which the system is under atmospheric pressure) | Replace the radiator cap |

| The engine overheats, cold air comes from the heater | |

| Excessive reduction in coolant level due to a leak or damage to the cylinder head gasket, causing vapor locking in the engine water jacket | Repair coolant leak. Replace damaged cylinder head gasket |

| The engine does not warm up to operating temperature for a long time, the thermal regime is unstable while driving | |

| Thermostat is faulty (valve stuck open) | Replace Thermostat |

| Constant decrease in coolant level in the expansion tank | |

| Radiator leaking | Replace the radiator |

| Expansion tank leaking | Replace expansion tank |

| Coolant leaks through leaky connections of pipes and hoses | Replace hose clamps |

| Damaged water pump seal | Replace the water pump |

| The cylinder head mounting bolts are not tightened sufficiently (on a cold engine during long-term parking, a coolant leak appears through the joint between the cylinder head and the cylinder block, in addition, traces of coolant may appear in the engine oil) | Tighten the cylinder head bolts to the required torque (see “Replacing the cylinder head gasket”, page 72) |

| Heater radiator leaking | Replace the heater core |

Source: http://zinref.ru/avtomobili/Toyota/002_00_Toyota_Corolla_Auris_2007_2011_remont_bez_problem_kopia/095.htm

4. Cooling and heating systems

Service and operation

Manuals → Toyota → Corolla (Toyota Corolla)

Cooling system design 1. Pump 2. Radiator 3. Inlet pipe 4. From heater 5. To heater Heater unit, fan unit and air conditioner mounted under the front body panel 1. Air conditioning control panel 2…

Opening pressure of the radiator cap valve 0.6 - 0.85 kgf/cm2 Thermostat response temperature 83 - 94 oC Type of refrigerant in the air conditioning system: - in cars before 1993 release R -12 - in cars after 1994 release ..

.

Warning Do not allow antifreeze to come into contact with skin or painted body parts. If antifreeze comes into contact with your skin or eyes, rinse immediately with plenty of cold water. Antifreeze is highly toxic, making it dangerous if it enters the esophagus.

Do not leave antifreeze in an open container or spilled on the floor in the form of puddles. Children and animals are attracted...Warning Until the engine has completely cooled down, do not unscrew the radiator cap, remove the thermostat or drain the coolant from the cooling system. Check PERFORMANCE ORDER 1.

Before jumping to the conclusion that the main cause of abnormal operation of the cooling system is a faulty...Warning Do not work in close proximity to the fan blades to avoid injury.

The fan may turn on spontaneously! Location of the main engine relay, air conditioner relay and fan relay in the main relay block A. Air conditioner relay B. Fan relay N3 ...Removal and installation PERFORMANCE ORDER 1. Disconnect the battery from ground. 2. Drain the liquid into a vessel (see subsection 2.8.4). 3.

Disconnect the upper and lower radiator hoses. 4. Disconnect the reservoir hose from the filler...Coolant pump. Three small arrows indicate the holes for the mounting bolts, and two large arrows indicate the inspection holes. Check PERFORMANCE ORDER 1. Failure of the coolant pump entails...

Warning Proceed to work only after the engine has completely cooled down. Check PERFORMANCE ORDER 1. In case of sensor failure, first check the fuses (see subsection 12.1). 2. If a short time after launching...

Check PERFORMANCE ORDER 1. The fan unit is located in the passenger compartment, above the right footwell. If the fan does not turn on, check the reliability and cleanliness of all connections, as well as the serviceability of the fuse. Make sure the battery is fully charged. 2…Warning The vehicles in question are equipped with airbags.

At any time when the battery is connected, the pillow (which has a rigid structure) can unfold (inflate). To prevent accidental airbag deployment (and possible injury) when performing any work near airbag components, turn the ignition key to position...

(Category). See the list of materials inside...

Removal ORDER 1. Depressurize the air conditioner and remove the refrigerant at a Toyota service center or a specialized workshop. 2. Remove the decorative grille (see subsection 11.26). 3. Disconnect...Removal ORDER 1. Depressurize the air conditioner and remove the refrigerant at a Toyota service center or a specialized workshop. 2. Disconnect the battery from ground. 3. Remove the belt from the compressor (see subsection 2...Removal PROCEDURE 1. Depressurize the air conditioner and remove the refrigerant at a Toyota service center or a specialized workshop. 2. Remove the radiator (see subsection 4.9). 3. Remove the decorative frame...Parts, which must be removed when dismantling the evaporator 1. Glove box 2. Air duct 3. Front door sill trim 4. Cooling unit Removing the evaporator 1. Air conditioning amplifier and interconnections 2. ...

Source: http://automn.ru/toyota-corolla/autocategory-2524-10.html