How to check the injector nozzle and its serviceability

How to check the serviceability of an injector nozzle

How to check the serviceability of an injector nozzle

Problems with injectors occur both on cars powered by diesel fuel and on gasoline-injected cars. An injector is a part responsible for injecting fuel under a certain pressure. It is useful to know how to check the injector nozzle if starting difficulties occur.

Causes and symptoms

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline! Read more"

Accurate metering of fuel, tightness of hoses and seals, activation of the injector at the right moment are prerequisites for stable and trouble-free operation of the engine.

If the injection part leaks, as they say, then the fuel atomization efficiency deteriorates, i.e.

, the shape of the flame is upset and the power unit smokes, either black or gray, it is difficult to start, consumption increases, power is lost.

“The injector is leaking” is an expression that means fuel is leaking at a time when it is not needed.

There are many culprits for poor performance. For example, a dirty filter, a non-working fuel pump or bad spark plugs. The same thing happens due to the fault of a failed reel or due to problems with the timing belt.

If it is pouring, the injector is leaking

The most important symptom of a non-working injector is difficulty starting the internal combustion engine. This is especially true for a “cold” engine. In addition, as mentioned above, symptoms include increased fuel consumption and unstable engine operation in idle mode. The last symptom generally resembles almost a tripping of the engine, as if one of the cylinders is not working.

As for the driving signs of a non-working injector.

- The car moves jerkily, especially when trying to accelerate. The accelerator pedal is dull.

- Jerking while driving, after changing gears or releasing the gas pedal.

- There is an undisguised fiasco in traction and aphasia of dynamics during acceleration or maneuver.

Defects in injection elements should be corrected immediately, otherwise it will negatively affect the service life of the engine and gearbox. Experts also do not recommend driving with a faulty injector, because it is simply dangerous. On steep climbs, when maneuvering and overtaking, a car with a failed injector can play a cruel joke on the driver.

How is diagnostics carried out?

You should know that car injectors are classified into several types. Today, two of them are in use: conventional and electric injection elements (magnetic).

Electric or, more correctly, electromagnetic injectors (EMF) are equipped with a special valve that supplies fuel. It, the valve, is controlled by the power unit ECU using sent pulses.

As for mechanical injectors, they open as the gasoline pressure in the injector increases, i.e., automatically.

On modern cars, the first variants of injectors are often installed - EMF.

Checking the injector itself without removing it

Injector testing can be done in several ways. However, the simplest of them is in use, and this is not surprising. It makes it possible to quickly test the injectors without even removing them from the car. The fundamental factor in such diagnostics is the analysis of the noise emitted by the motor during operation.

If a muffled high-frequency noise is heard from under the hood, this indicates the importance of cleaning the injectors or a problem with one of them.

Checking power supply

It is recommended to check how the power is going. This test option is carried out only when the injectors themselves are functioning flawlessly, but difficulties are observed with starting.

Here's how this kind of diagnosis is carried out:

- the block is disconnected from the injection system;

- two wires are connected to the battery, which are simultaneously connected at the other ends to the injectors;

- Now you need to start the engine and check the presence or absence of gasoline leakage.

According to the result, the following conclusions are drawn:

- if fuel leaks, it means there is a problem in the car’s electrical circuit;

- if not, then everything is fine.

Another test option involves using an ohmmeter. This method allows you to measure the resistance on the injectors, and draw conclusions accordingly.

This is done as follows.

- You need to find out the standard parameter of the injection elements of a particular car (for example, for a VAZ - 11-15 Ohms). Some foreign cars are of greater or lesser importance.

- Next, you need to disconnect the terminal from the battery, thereby de-energizing the system.

- Remove the electrical connector from the injector using a screwdriver with a thin pin. It will be enough to snap off the special clamp installed on the block.

- After this, connect the terminals of the device to the injection parts to measure the indicator.

In this way, you can measure the compliance of the resistance indicator with the required one. If deviations from the norms are noticeable, the faulty injector is removed from the vehicle and replaced with a known good one. After this, you can check the resistance again, and be sure to evaluate the operation of the motor. If everything was done correctly, the engine characteristics should change.

Analysis of the operation of injectors on the ramp

This method already involves dismantling the fuel rail. The injectors, of course, are removed along with the ramp. Then reconnect all electrical contacts to the ramp (after all, they are thrown off during dismantling). The negative terminal of the battery, which was removed earlier, also returns to its place.

Further:

- the ramp is placed in the engine compartment so that it is possible to place a container with a printed scale under the injectors;

- the fuel supply hoses are connected to the ramp (be sure to securely fix them at the ends);

- the engine is started by the starter (it is advisable to work together with an assistant);

- while the assistant rotates the starter, you need to test the operating efficiency of all injectors (gasoline must be supplied equally to all injectors);

- at the last stage of the procedure, the ignition is turned off, the level of gasoline in the containers is checked (obviously, the level should be the same).

Anyone can check the injector nozzle with their own hands. It is not necessary to go straight to a car service center if you encounter another problem. An experienced motorist should be able to do some repairs himself.

Tired of paying fines? There is an exit!

Forget about fines from cameras! An absolutely legal new product - NANOFILM, which hides your license plates from IR cameras (which are installed in all cities). More details at the link.

- Absolutely legal (Article 12.2.4).

- Hides from photo and video recording.

- Installs independently in 2 minutes.

- Invisible to the human eye, does not deteriorate due to weather.

- 2 year warranty

Source: http://ozapuske.ru/inzhektor/kak-proverit-forsunku-inzhektora.html

Instructions: how to check the injectors without removing them from the engine and clean them if necessary

The nozzle on a car's injection engine plays a decisive role in the stability of its operation. It is no less important than spark plugs or pistons, since without proper fuel injection it is impossible to detonate at a strictly specified moment.

The injector injects fuel into the combustion chamber of the engine in a certain volume, which allows you to maintain the most economical and productive operating mode of the internal combustion engine.

The vehicle's electronic control unit regulates the amount of fuel supplied by the injector.

Signs of a faulty injector

If problems arise with the stability of the engine, then it is impossible to say unequivocally that the injector or any other component is to blame. It is necessary to check the ignition coil, spark plugs, cylinder compression and other components that are responsible for detonation in the combustion chamber, including injectors.

Here are just a few of the problems that indicate faulty injectors:

- The car engine shows unstable operation at idle;

- Fuel consumption has increased significantly;

- There are problems starting the engine;

- The car has lost its dynamics, and when overtaking or sharp acceleration, you feel a lack of power and engine jerking.

If there are similar problems in your car, you can start diagnosing the engine by checking the injector. There are several methods for checking injectors without removing them from the engine, and they will be discussed below.

How to check injectors without removing them from the engine using a multimeter

The diagnostic device multimeter is a faithful assistant to any motorist. It allows you not only to check fuses or the battery, but also to diagnose injector malfunctions. To check the injectors with a multimeter you need to do the following:

- Remove the high voltage wires from the injectors and consult your vehicle's manual to determine whether your engine has high impedance or low impedance injectors - this will be necessary for accurate diagnosis;

- Set the multimeter to resistance measurement mode and connect the diagnostic wires to the injector terminals, then take the measurement;

- If your vehicle has high impedance injectors, the measured resistance should be between 12 and 17 ohms. In the case where low impedance injectors are used on a car, their resistance lies in the range from 2 to 5 ohms.

In a situation where the indicators differ from the recommended ones, you should remove the injector from the car and check it in more detail, and if necessary, replace it.

Checking the injectors without removing them from the engine by ear

If you consider yourself quite experienced in diagnosing car malfunctions, you can try to identify problems with the injector by sound.

With the engine running, listen carefully to the sounds coming from the cylinder block. A dull ringing sound indicates that there are problems with the engine injectors.

In such cases, it is recommended to clean the injectors.

Checking the mechanical properties of the injector

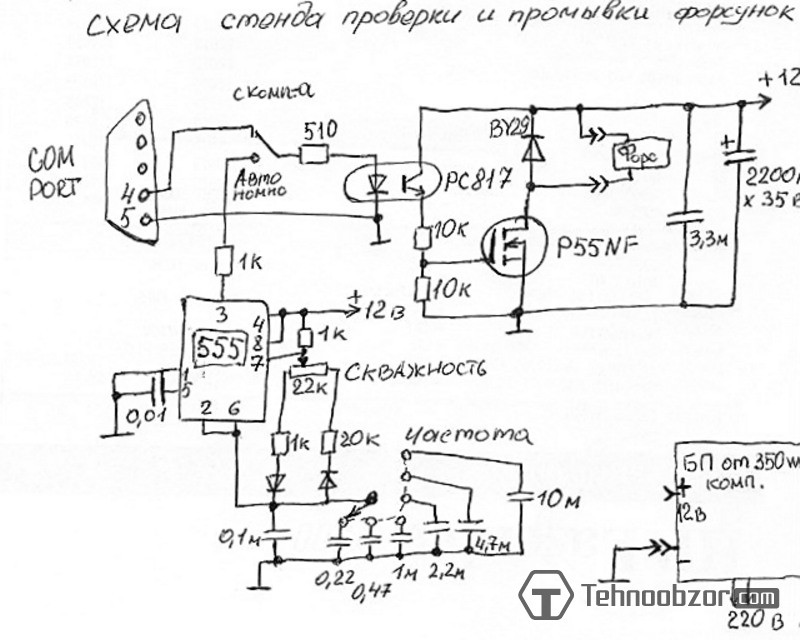

It is quite difficult to check the mechanical properties of injectors on your own, given the need for specific equipment to carry out such procedures. Many auto repair shops have special stands for checking the mechanical properties of injectors. With their help you can determine:

- What fuel flow passes through the injector when the engine is running;

- What does the “torch” of fuel spray from an injector look like when the engine is running. If the fuel is not flowing evenly through the injector, there is a good chance that it needs to be cleaned.

Checking the mechanical properties of the injector is the most accurate method for diagnosing this component of an internal combustion engine.

How to clean injectors without removing them from the engine

If a malfunction of the engine injectors is diagnosed, it is possible that they are dirty. To correct the situation without removing the injector from the engine, you can:

- Use specialized engine cleaning additives that are poured into the fuel tank;

- To keep engine injectors clean, experienced drivers recommend cleaning them monthly using pressure. To do this, you need to accelerate the car on a flat road to a speed of 120 kilometers per hour. In this mode, you need to cover 10-15 kilometers, after which you can slow down;

- If you do not have the opportunity to drive the car at high speeds, you can use another method of cleaning the injectors without removing them from the engine. It is necessary to maintain the vehicle idle speed at 4-5 thousand for 3 minutes. This method of cleaning injectors is less effective than the options listed above.

Experts recommend cleaning engine injectors every 30-35 thousand kilometers, even if there are no problems with the engine.

(326

Source: https://okeydrive.ru/forsunki-kak-proverit-i-ochistit-ne-snimaya-s-dvigatelya/

How to check injectors without removing them from the engine

Almost every car owner of a modern car with a fuel injection system sooner or later asks the question - how to check the injectors? If you notice that the car begins to jerk when accelerating, loses power and generally behaves inappropriately, these are signs of a faulty fuel injector.

Fuel injectors are present on both diesel and gasoline engines. The main purpose is to spray fuel into the inside of the cylinders, but in the event of a malfunction this process does not occur properly.

Signs of injector malfunctions

We have given the main signs of injector malfunction, which are relevant for most cars.

- The car jerks when accelerating

- Dips appear during engine operation. It feels like someone is holding the car.

- When driving a car, there is a persistent feeling of loss of power.

- An increase in fuel consumption of several liters for clogged injectors is a common occurrence

If such symptoms appear, or some of them, then there is a reason to think about diagnosing the injector.

What are the types of injector malfunctions?

On injection engines, two types of injectors are used - electromagnetic and mechanical.

The electromagnetic injector operates on the principle of a valve, which, depending on the signal from the vehicle's control unit, opens, injecting the required amount of fuel into the cylinder.

The mechanical nozzle opens under pressure. It is based on a spring and a needle. It works as follows: when fuel is supplied, a certain pressure is created, the needle rises and fuel is sprayed into the cylinder.

Nowadays, mechanical injectors are practically not used on modern cars, so we will talk about malfunctions of electromagnetic injectors.

Since the nozzle is a fairly simple part in its structure, it can have several faults:

- No signal from the control unit

- Internal winding break or other malfunction

- Contamination of fuel supply channels

As a rule, most often the injectors stop working as they should due to contamination.

If you suddenly suspect that the injectors are faulty, you can check them without removing them from the engine.

Checking for extraneous noise

This method requires some experience. You need to start the car and listen to whether the injectors make any unusual sounds. If you hear a distinct high-frequency noise from the area where the injectors are located, this means that cleaning needs to be done.

Checking injectors with a multimeter

The essence of this method is to measure the resistance on the injectors and compare it with the standard. Algorithm for checking resistance on injectors:

- We find out, either from technical literature or from Internet sources, what resistance is considered normal for an injector, and what the spread may be.

- We de-energize the car by removing the positive terminal from the battery

- We remove the connector from the injectors and check each one one by one with a multimeter in resistance measurement mode, comparing the resulting parameters with what they should be.

- If you find an injector whose parameters differ from the factory ones, then this is probably a faulty injector and needs to be replaced. If everything was done correctly, the problem will go away.

Checking the injector by applying voltage to it

The essence of this method is that you need to disconnect the power supply to the injector. Connect two wires in it and turn on the ignition. Next, connect these two wires to the battery terminals; if the injector begins to spray fuel, then everything is fine with it.

Checking the mechanical properties of injectors

Another method for checking injector nozzles is to diagnose mechanical properties.

Injectors have two main parameters that relate to mechanical properties. This is the amount of fuel sprayed, and the appearance of the spray pattern.

In order to check these properties, a special injector testing stand is required. The principle of operation of such a check is very simple. Each injector begins to pour fuel into its container at the same point in time. At the end of the test, it becomes clear which injector is not topping up, and which injector has an incorrect spray pattern.

This method gives the most accurate idea of which injector requires cleaning.

Repair and cleaning of injectors

There are several ways to clean injectors.

- mechanical method

- ultrasonic cleaning

- chemical cleaning

In garage conditions, you can clean it using chemicals. To do this, a special injector cleaner is poured into the fuel tank, which removes a significant part of the pollution during vehicle operation.

.

In order to clean injectors with ultrasound, you need a special stand. The essence of the method is that the nozzles are immersed in a special liquid, in which bubbles are formed under the influence of ultrasonic waves, thanks to which contaminants are removed.

This method is very difficult to implement in a garage, so you will have to go to a service station and pay money for this procedure.

Bottom line

Fuel injectors are the main element of the injection system. It is worth monitoring and maintaining them in working condition, preventing clogging and periodically doing preventive maintenance, which consists of driving at a speed of 100-110 km/h.

Source: https://djago.ru/dvigatel/kak-proverit-forsunki/

Do-it-yourself injector repair and fault diagnosis

For a long time, the carburetor engine was the most common power unit installed in passenger cars. The natural method of delivering the working mixture to the combustion chamber made it possible not only to produce relatively inexpensive engine models, but also to restore the car’s power system in a garage.

Symptoms of a problem

Injectors can be faulty not only on a gasoline injection engine, but also on diesel units. The main symptoms of failure of these parts are identical, therefore, regardless of the type of fuel on which the engine runs, the following signs may indicate a malfunction of this part:

- Increased fuel consumption;

- Unstable engine operation in idle mode;

- Difficulty starting, reminiscent of “overflow” of a carburetor engine;

- Jerks during uniform movement, and dips during sudden acceleration.

These are the main signs of a malfunction, but the injectors should be checked only after other possible causes of such manifestations have been completely excluded. The engine may operate unstably if the fuel pump malfunctions, when the hoses are leaking, or when the lumen of the pipe becomes clogged with various deposits.

A clogged fuel filter can also negatively affect engine performance. Jerking on a gasoline engine can also be caused by a faulty ignition system. All of the above options for engine breakdowns must be completely excluded before proceeding with a full diagnosis of engine injectors.

Injector diagnostics

Diagnostics of injectors depends on the type of this part. Currently, injection and diesel engines use two types of injectors - electromagnetic and mechanical.

- Electromagnetic - injection control occurs due to an electrical impulse emanating from the control unit;

- Mechanical - driven by the engine crankshaft using a transmission mechanism.

Many novice car enthusiasts are interested in the question: “How to check the injectors without removing them from the engine?”

With even a little experience, you can quite accurately determine the knocking of an injector. If fuel overflow occurs due to incomplete closing of the needle valve, then detonation and increased engine noise are also possible. Muffled high-frequency noise may also be observed in such a cylinder.

Malfunctions of electronic injectors can be determined with a multimeter; a pointer injector tester is also suitable for performing this operation. Diagnostics using an electrical measuring device is carried out in the following sequence:

- In the documentation for the car or for the installed injectors, you need to find the resistance value of this part;

- Turn off the ignition and remove the negative terminal of the battery;

- Using a thin screwdriver, disconnect the electrical connector of the injector;

- The multimeter or tester is switched to resistance measurement mode, and this parameter is measured between the contacts.

If the resistance values differ significantly from those indicated in the documentation, then the injector must be removed from the engine and it must be adjusted or replaced.

How to remove injectors

To remove the injectors you will need to prepare:

- Screwdriver Set;

- A set of keys;

- Pliers;

- Rags.

As a rule, the injectors on an injection engine are located on a special fuel rail, so finding them will not be difficult. To gain access to these parts, it is necessary to remove the air filter and various pipes, which can significantly complicate the removal process.

When carrying out dismantling work, you should also be careful. The fuel supplied to the injectors is under high pressure, which must be reduced.

For this purpose, the design of the injection engine has a safety valve, by pressing which you can reduce the fuel pressure to a safe value.

Then you need to disconnect the wires from each engine injector. These wires connect the control unit to the injector contacts.

The injector terminals have reliable spring clips that can be bent with a thin screwdriver, after which the control wire can be easily removed.

Next, unscrew the 2 bolts that secure the fuel rail to the engine and, using a pry bar, carefully separate the fuel rail from the intake manifold. When the injectors are removed along with the fuel rail, they should be carefully inspected.

If there are no sealing rings, they must be carefully removed from the manifold and installed back on the injectors, otherwise the functionality of this unit will be lost. At this point, the process of removing the injectors from the injection engine can be considered complete.

Removing diesel engine injectors

The process of dismantling a diesel engine injector may differ significantly from the process described above. The main difficulty of this operation lies in the more severe temperature conditions of the diesel engine, which can cause the injector to stick to the cylinder head.

To prevent thread failure, it is necessary to use special pullers that will avoid many troubles. Unskilled actions can lead to damage to the cylinder head, the repair of which will cost a very serious amount.

Damage to the injector itself is also undesirable; this engine element is expensive, so replacing the injector will also lead to unnecessary financial expenses.

How to check an injector

Injector malfunctions are not numerous, but any of the breakdowns can lead to unstable operation of the cylinder in which this part is installed. After removing the injector, it is necessary to carefully check and, if necessary, clean or replace the part that does not meet the conditions for uninterrupted delivery of fuel to the cylinders.

Correction of injection engine injectors consists, first of all, in eliminating tarry deposits in the area of fuel spray. Diagnostics and repair of parts installed on a diesel engine are carried out in a similar way. The diesel engine cylinder injector has a design that allows only the nozzle to be replaced.

If the injector is not dirty, but there is no fuel combustion in a given cylinder, then the injector winding may have burned out. A broken injector is a fairly rare malfunction, but if there is no other damage, it is necessary to measure the resistance between the contacts of this part using a multimeter.

If resistance is completely absent, then the faulty part must be replaced.

Plastic cups that are placed under the spray nozzle of each nozzle are ideal for this purpose.

Then you need to turn on the ignition and run the engine starter for 7 - 10 seconds. When performing diagnostics, you should pay attention to the quality of atomization of the fuel flowing from the injector.

If fuel flows from the nozzle in a straight stream, then this nozzle needs to be replaced or cleaned of carbon deposits formed on its nozzle. You should also pay attention to the amount of fuel in the containers that were placed under the injectors.

If, when performing diagnostics, there is a complete absence of fuel in any container, then there may be no power to the injectors. This problem can be caused by a lack of contact between the cable and the terminal, as well as a simple break in the wiring.

If the wiring is intact and there is good contact between the wire and the injector winding terminal, then the control unit of the vehicle's power system may be faulty. If the electronic control unit is faulty, then in order to continue diagnostic measures, it must be replaced with a known good part.

Checking the injectors yourself using this method allows you to fairly accurately determine the faulty parts of the car’s power system.

When performing such diagnostics, you should remember the heavy load on the battery when the starter is turned on, as well as the dangers of rotating the crankshaft without sufficient oil flow into the engine line, so it is advisable to carry out the diagnostics in one step. When the problematic injector is identified, you can begin to repair it.

Injector repair

Restoration of injectors is carried out in the following sequence:

- The battery is removed from the car and an adjustable adapter with a switch for autonomous control of the injectors is made from available unnecessary wires and parts;

- Purchase any spray to clean the carburetor, and make an adapter from the fuel hose from the canister pipe to the injector inlet.

To clean the internal tank of the injector, electricity is supplied through an adjustment switch from the battery to the injector terminals to open the needle valve. Simultaneously with the opening of the nozzle, the button on the can of cleaning liquid is pressed.

Setting up injectors in this way allows you to save a considerable amount of money, as well as gain invaluable experience in repairing an injection engine. During the injector cleaning procedure, it is necessary to pay attention to how the atomizing device passed fuel.

If fuel escapes from the nozzle in a direct stream, then disassembly and repair of this part will be required. How to disassemble the nozzle for repair will be described below.

Disassembling the nozzle

In most cases, injector repair can be done by replacing the filter, which is installed at the top of the injector where it connects to the fuel hose. To remove the filter, the main tool is to use a self-tapping screw, which is screwed 2-3 turns into the mesh filter and removed from the nozzle body.

Then, in place of the removed filter, a new mesh filter and o-ring are installed. In this way, it will be possible to ensure stable filling of the injector with clean fuel, which will have a positive effect on the operation of the injection engine.

Restored injectors can last for a long time, and if all cleaning and repair actions were carried out according to the rules, then the vehicle will be operated without serious deviations in the fuel supply system.

Source: https://SwapMotor.ru/ustrojstvo-dvigatelya/remont-forsunok.html

Checking and malfunctioning injectors on the VAZ-2114: signs of clogging

If, while driving, your car lost its dynamics, began to accelerate more slowly, and in general there were interruptions in its stable operation due to difficult starting and increased fuel consumption, one of the injectors installed on the engine may have failed. In this article we will tell you in detail how to check them, and what are the nuances in such work.

Step-by-step procedure for dismantling injectors

Despite the fact that many advise carrying out such work in the company of an assistant, it is difficult, but it is quite possible to do it alone, with your own hands.

- First of all, put the car on a flat surface and turn on the handbrake.

- We relieve the pressure in the fuel system: to do this, disconnect the terminal from the fuel pump and start the engine. When it has used up all the remaining gasoline, crank the engine with the starter a couple more times, thereby finally relieving the pressure in the fuel line. The arrow marks the location of the pump under the rear seat

- Next, open the hood and disconnect the negative terminal.

- After this, you need to turn off the fuel supply directly to the injectors by disconnecting the power supply.

- Then, using the key to “17”, we separate the fuel supply pipes and move them away from each other.

Unscrew the gasoline supply pipes

- We also disconnect the vacuum and air hoses.

- When nothing is stopping us, we take the hexagon and unscrew the 2 bolts that secure the ramp to the engine.

Use a screwdriver to unscrew the bracket on which the fuel pipes are attached.

- Now, nothing is holding the ramp, and by carefully pulling it, we remove the injectors from their seats.

Removing the fuel rail

Removing the injector from the VAZ-2114 fuel rail

Depending on which of the injectors has failed, the replacement process is absolutely identical.

- When the injector is on the ramp, press the spring retainer and remove the block.

As a rule, nothing prevents you from removing the lock.

- Next, remove the safety metal bracket.

The bracket will come out of place if you pry it with a screwdriver.

- After this, using a little force, remove the nozzle from its seat.

- We replace it with an identical spare part, and reassemble it strictly in the reverse order.

Step-by-step procedure for checking injectors

When nothing interferes with the operation of the dismantled ramp, we reconnect the power supply and gasoline supply pipes to it. Don't forget about the negative terminal of the battery.

- When everything is connected and ready for testing, we fix the ramp with the injectors so that four measuring containers of the same volume can be placed under them. This is necessary to ensure that the measurements are made as accurately as possible.

- Next, it is best to ask an assistant to sit in the driver’s seat, and if this is not possible, secure the ramp motionless and start the engine yourself.

- While the starter is “spinning” the engine, make sure that the injectors work in the same rhythm and the fuel is sprayed evenly. When carrying out such diagnostics, it is very clearly visible which of the four injectors is “snotty” or does not work at all.

It is noticeable how one of the injectors works differently than the other.

- When the measuring containers are filled to the required level, everything will become extremely clear and understandable. And if such facts are identified, the nozzle should be replaced, since washing it can only bring a temporary result, after which operational problems may occur again.

The check ends some time after the injectors are turned off.

- Also, after completing the diagnostics, wait a while to see how effectively the injectors maintain their tightness. This is important because when the car is idle, some of the fuel may simply drip into the cylinders, and its excess can negatively affect the condition of the engine as a whole.

- Inspect each injector for any external defects, the integrity of the o-rings and the power supply.

Procedure for checking injector power supply

- First of all, disconnect all the pads from the injectors.

- Then, we connect two wires to the pre-working block, the other end of which we bring to the “non-working” injector.

- Next, turn on the ignition and if the injector starts working, this means it is necessary to replace the non-working element of the electrical circuit - the block, and if not, then only the injector needs to be replaced.

Resistance faults

- In order to diagnose the injector windings, you must disconnect the negative terminal from the battery and all injector power connectors.

- Next, we connect the multimeter probes to the injector contacts and measure their resistance.

Values are within normal limits.

- Performance indicators should be from 11 to 15 Ohms; if they are significantly increased or decreased, the nozzle must also be changed.

conclusions

As you can see for yourself, in order to check the condition of the injectors on a VAZ-2114 with your own hands, there is nothing difficult. You just need to carefully read our article and strictly follow the order of actions.

Source: http://carfrance.ru/kak-svoimi-rukami-proverit-forsunki-na-vaz-2114/

Engine injector malfunctions, diagnostics and cleaning at home | AML

Owners of cars with injection-type engines sometimes face the problem of poor performance of some components.

Often the culprits of such problems are injector nozzles; their poor performance results in the inability to start the car and turns into an unwanted loss of time at the most inopportune moment.

But few people know how to check the injectors before a problem occurs. In this article you will learn how to identify the problem, as well as how to clean the injectors with your own hands and get rid of temporary problems.

From the first lessons of driving school (and maybe earlier) we know that the injection system of injection engines differs from carburetor engines.

Faced with a problem, many drivers rush straight to auto repair shops or service stations.

The problem is not always so serious, and it is quite possible that it can be solved even by a person with basic knowledge, which you can acquire by reading this material.

Injector malfunctions are very similar in symptoms to those of spark plugs.

Symptoms of a faulty injector

To begin with, it should be noted that such a complex mechanism as a car engine (especially in modern models) requires accuracy in definition.

It often turns out that with absolutely similar symptoms characteristic of malfunctioning injectors, for example, difficult starting of the engine on “cold traction” or increased fuel consumption, the reason is not in them, but in the spark plugs that need to be replaced.

Before establishing the exact cause and taking any action to eliminate them, you should very carefully check and make sure that the “diagnosis” is correct.

The following factors are the most common symptoms of faulty engine injectors:

- there are jerks when driving;

- loss of dynamics during acceleration;

- the engine stalls when switching, or when decelerating;

- fuel consumption increases.

If you notice any of the problems just mentioned, you need to do a spot check of the injectors as soon as possible. Otherwise, the car may fail at the most unnecessary moment (for example, when overtaking, or in other situations).

As a rule, injectors fail one at a time, so you need to check everything.

How to determine if an injector is not working on a running engine

Let's say you found a sign of a faulty injector and now want to know how to check your engine injectors? I would like to immediately note that the injectors themselves come in several types (mechanical and electromagnetic) and their design has significant differences, which means their testing methods should also differ. You can check injectors using several methods: checking injectors without removing them from the engine, checking removed injectors, checking injectors at home, checking gasoline or diesel injectors, etc. We will analyze the most popular methods:

Source: https://automotolife.com/services/neispravnosti-forsunok-dvigatelya/

How to check injectors?

Every car enthusiast should know how to localize and eliminate the most common car faults. If the engine is difficult to start, if jerking or stalling occurs when the engine is under increased load, if the engine idles unstably or develops insufficient power, the problem may be hidden in the injectors. How to check injectors?

Brief educational program

An injector is a device that supplies certain doses of fuel to the engine; injectors can be mechanical or electromagnetic.

Mechanical ones open under pressure and do not do any dosing; they simply spray fuel by opening and closing the spray hole.

Electromagnetic injectors are a controlled valve that opens and closes under the influence of an electronic control unit. Electromagnetic injectors are installed on central and distributed injection systems.

In central injection, fuel is supplied by a single injector, which is installed in front of the throttle valve. With multipoint injection, fuel is supplied through separate injectors, supplied to the intake manifolds of each cylinder. The central injector has a low winding resistance (4-5 Ohms), while the distributed ones have a high winding resistance (12-16 Ohms).

Diagnostic principles

Checking the injector of modern imported cars requires a special test bench. Domestic cars are less whimsical. How to check the injectors of a VAZ, for example? To do this, you need to remove the fuel frame, disconnect the electrical connector and the bracket securing the fuel pipes to the receiver and check the functionality of the injectors.

Checking the injectors yourself does not take much time. First, check the injector nozzle winding with a tester - the resistance should be 11-15 Ohms. Connect the fuel pipes to the rail and connect the electrical harness connector of the injectors, placing the bulbs under them.

Crank the engine with the starter and watch the fuel jets - they should be of the same shape. Crank the engine for several minutes and check whether the bulbs under the injectors are filled evenly. Ideally, the amount of fuel should be the same.

To check the quality of fuel atomization, disconnect the electrical connector from the injector and apply 12 V voltage from the battery, then turn on the ignition and observe the jet. Injection nozzles should create four jets. Any deviation from the norm leads to a malfunction.

If the injector has different resistance, flame shape, number of jets and fuel flow rate, it needs to be cleaned or replaced. When reassembling the injectors, make sure that the rubber O-rings are not frayed, torn or cracked, otherwise they will need to be replaced.

Causes and troubleshooting

Now that you know how to check the operation of the injectors, a logical question arises: what causes their operation to be disrupted? Most often, the cause of injector malfunction is simple contamination.

Under the influence of high temperatures, the injector becomes coked with resins that are present in low-quality fuel. Hard deposits form on the nozzle, blocking the spray holes and impairing the tightness of the needle valve.

This problem can be solved in several ways:

- Fuel additives (the method is preventative and is only suitable if you use it regularly. When old deposits appear, it leads to the opposite result).

- Washing without dismantling using flushing fuel (solvent).

- Washing on an ultrasonic stand is an extreme, but quite effective measure for removing hardened deposits.

Source: https://elhow.ru/tehnika/avto/remont-avtomobilja/kak-proverit-forsunki