Air suspension for Gazelle - creating maximum comfort!

The auxiliary pneumatic system, which is installed on the car, is a popular option for tuning minibuses of Russian and foreign production and allows you to obtain a number of advantages as a result, the main of which are:

- minimizing risks when the body is heavily overloaded, for example, when transporting large quantities of various goods,

- the ability to constantly change the ground clearance and the degree of rigidity of the main suspension,

- more comfortable driving when driving on rough roads,

- significant reduction in overall wear of basic suspension elements,

- unloading springs and various fastening elements,

- increasing the level of vehicle stability, and in some cases, front traction, with front-wheel drive (with an air control system in the airbags).

Auto auxiliary pneumatic system

- They will protect the chassis and save you money, increasing ground clearance by 3 cm.

In addition to the listed advantages, a fairly quick return on investment should be noted. With the right approach to installation and selection of parts, such investments pay off within 30-40 thousand kilometers.

Among the disadvantages are the high price of some parts and the difficulty of installing pneuma with your own hands. This requires experience and knowledge in the field.

Installing a competent pneumatic system in the suspension from specialists will cost at least 30 thousand rubles, depending on the complexity of the system itself (is there air supply control, what parts are used, etc.).

Installing air suspension on GAZelle cars (in particular, Next) is recommended if:

- the machine is used for transporting various equipment (pneuma reduces the risk of damage to high-precision parts from constant oscillations and vibrations of an uneven road surface);

- you often transport heavy loads, the weight of which is comparable to the maximum load on a conventional leaf spring suspension;

- it is necessary to increase comfort and safety when transporting various cargoes.

If you decide to install air suspension on your truck, you need to understand that you will have to make changes to the standard design, which, with certain changes (for example, the use of welding), may result in the dealer refusing warranty service. As a rule, the main elements of the air suspension, in other words, airbags, are attached using special brackets, and the remote control system itself is installed inside the car.

Installing air suspension on a truck

In any case, the installation of air suspension on this car is not particularly different, and the main element of reliability is a high-quality air spring.

We recommend choosing only parts from trusted manufacturers. For GAZelle Next, you can safely use pillows from Dunlop, Factory, Firestone, etc.

In addition to the pillow, you will need to change the struts, stabilizers and other parts of the standard suspension.

When developing new air struts, it is necessary to take into account the fact that a serious change in standard struts using welding and other work can reduce the strength of the structure. Therefore, if you decide to install the pillows yourself, it is better to work without significant changes to the factory design. This will make it easy to replace the shock absorber or air spring if it fails.

Do-it-yourself air bags for GAZelle

Thus, the simplest but most effective way is to replace conventional steel springs with air springs. Springs should be selected based on the total weight of the vehicle and drive.

In the case of the GAZelle Next model, it is recommended to install bellows or sleeve type pneumatic springs on the rear axle with a diameter that depends on the frequency of loads.

In addition, you should take into account the type of air suspension, which can be double-circuit or single-circuit.

The dual-circuit system is installed on both axles, this is important for owners of GAZelle Next with a long wheelbase; in other cases, it is enough to install pneuma on the rear axle of GAZelle Next. To do this, you will need to purchase a set of parts and equipment, which should include:

- two air cylinders of identical diameter,

- adapter plates and plastic pneumatic tubes (fittings),

- mounting brackets and other fastening elements,

- when installing a control system, you will also need pressure gauges for each axle, wiring, buttons and other electrical equipment and equipment (compressor unit, etc.)

As a rule, high-quality kits are able to provide a constant load capacity of 1200 to 1400 kilograms, which is quite enough to transport most cargo.

It is recommended to install air springs on the rear axle without using a receiver, which increases the softness and smoothness of the ride.

When installing the cushions at a comfortable height, you should move them as far from the center as possible to avoid friction on the springs (when the cushions expand while driving). On the front axle, the cushions are installed either directly on the spring or behind the front beam in the very center.

Source: http://tuningkod.ru/tyuning-avtomobilej/tyuning-russkix-avto/tyuning-gaz/pnevmopodveska-gazel-sozdaem-maksimalnyj-komfort.html

DIY air suspension

Paying tribute to fashion, air suspension becomes one of the attributes of the car. The direction of stance is becoming more and more developed, in which, without having air suspension, but let’s say a coil suspension, using a car in everyday use becomes more difficult and uncomfortable.

Air suspension is installed not only by connoisseurs of new tuning trends, it can also be very useful in the everyday life of the average driver.

Let's look at the main advantages of air suspension:

- Ability to adjust ground clearance (you can improve the cross-country ability of your car despite its lower class)

- Handling and roll (it is worth noting that despite the smooth ride, unlike springs, you can change the behavior of your car in a matter of seconds by adjusting the pressure)

- Drawdown when loaded (you can adjust the height of the car regardless of how loaded it is)

The advantages include many more factors that satisfy the needs of the car owner.

The main disadvantages include:

- Initial installation costs (since your car was not previously equipped with this function, you will need to spend money on purchasing all the units)

- The service life of air suspension due to external factors (frost, reagents, etc.) is significantly less than that of springs.

Main types of air suspension:

- Dual-circuit - the ability to separately adjust the height of the front and rear of the car.

- Four-circuit - control of each air spring separately, while they are connected to each other via an electronic controller for dynamic and static control (this is a more expensive option).

As for air bags, there are also several types :

- A more expensive option is “donut” type cushions as they are more resistant to loads and provide better handling (suspension travel is stiffer)

The most common ones consist of two and three links. The three links respectively have a longer stroke, which will allow the car to be lifted higher.

- The “sleeve” type is the cheapest option; the suspension travel is softer and less resistant to loads and the environment.

Air suspension components

- Air bags (donuts or sleeves)

- Receiver (12 liters is optimal)

- Compressor (based on many reviews today, the Berkut r20 model is considered optimal)

- The control panel is a device with which you can raise and lower the vehicle's ride height; in other words, it is the head unit that is responsible for the functions of distributing signals to the valves. Today there are many choices of ready-made remote controls for both two and four-circuit suspension, with various functions from the simplest to more complex wireless

- Valve block - responsible for supplying and releasing pressure in the system. You can make it yourself or buy a ready-made kit.

- Pressure gauges - necessary to regulate the pressure in the system. There are single-hand and double-hand, and there are also electronic ones.

- A moisture separator is necessary to ensure that additional moisture does not accumulate in the system.

- Pressure switch

- Connectors and fittings

- Check valve

- Connecting tubes + Reinforced hose (for compressor) - available in 6, 8 and 10 mm.

The larger the diameter of the tube, the faster the pillows are inflated. 0.8mm tubes are optimal.

Manufacturing of air struts

Before manufacturing air struts, it is necessary to decide on the choice of pillows, based on the weight of the vehicle and the diameter of the springs.

You also need to take into account the location of the spring (separate from the shock absorber, or the shock absorber in the spring).

For a passenger car, the most common and universal air springs are Rubena 114x2, 114x3, 130x2 and 130x3.

For heavier vehicles, the Dunlop 152x2, 152x3 and Rubena 170x2, 170x3 models are suitable.

To make air struts, we will need machined flanges and brackets to mount the air spring.

Welding flange (for strut, shock absorber).

For sale on the websites there are ready-made flanges for the diameter of the air spring, as well as ready-made semi-kits. Flanges to match the diameter of your pillow and stand can be ordered from the dealer.

The bracket can be a blind type (photo No. 1) (if the shock absorber is located separately from the air cushion), or with a hole in the center (photo No. 2) for the shock absorber shank (if the shock absorber is located inside the air cushion).

photo #1

photo No. 2

The platform for the spring is cut off from the rack and a flange is welded to mount the pillow.

A brace is placed on the cushion.

And it is tightened to the welded flange on the rack using bolts.

A bracket is also put on the cushion from the top and bolted to the flange; a rubber seal is put on the rod from the top. Ready air strut.

Source: http://worldcustom.ru/pnevmopodveska-svoimi-rukami/

DIY air suspension installation

Air suspension kit

To install air suspension on a car with your own hands, you need to know the instructions and use the necessary tools. How to do this correctly in a garage and what you will need to do this in today’s material.

Tuning all cars, including domestic VAZs, usually involves changing the exterior or upgrading the body, but some car owners go further and install a modern air suspension with their own hands.

Creating an air suspension on a passenger car is not the most common modification of the VAZ. This is partly due to a misconception about the complexity of the work and not the highest reliability of the design. At the same time, practice shows that thinking through and installing air suspension yourself does not cause any particular problems.

to contents ↑

About the advantages of air suspension

Pillows

Initially, the French automaker Citroen began actively using this type of automobile suspension. The French appreciated the advantages of the structures, which include the following:

- High level of comfort. Installing air suspension on a VAZ yourself helps to obtain an optimal balance between comfort and rigidity, which is impossible when installing traditional shock absorbers on a car.

- Possibility of changing the ground clearance. This feature of air suspensions not only makes it possible to relate the ground clearance to the vehicle’s load, but also to reduce it for high-speed driving (helps lower the center of gravity).

- Overload resistance. The ability to adjust the stiffness of the suspension makes it possible to additionally load the car without fear of damaging the chassis elements and changing the car’s behavior on the roads.

to contents ↑

What is required for installation?

Berkut R20

So, to install an air suspension on a car, in particular a VAZ, you will need a kit with the main elements, namely:

- Compressor. The durability and performance of the system depends on it. Practice proves that the best options are the Berkut R20 and R17 models, as well as the Falcon.

- Four air bags. They vary, so choose one for your specific car model. For example, some VAZ owners use cushions from the cab of a truck tractor.

- Compressed air cylinder. The receiver can be made in the form of a spare wheel or made into a cylindrical shape that will fit in VAZ sedans.

- Four solenoid valves. They act as locking and access elements. Select valves that are designed for high pressure up to 25 atmospheres.

- Connecting tubes. Some make them from PVC pipes from truck brake systems.

- Pressure gauges that will be placed inside the car. You will need two pieces in total.

- Control block. It can be assembled independently, taking into account the separate inclusion of two circuits - front and rear. A special toggle switch is also required to control the compressor.

- As you assemble the air suspension yourself, you may need items such as wires with terminals, a flexible hose with a metal braid, a high-pressure rubber hose and fasteners.

You can buy all this for about 30-40 thousand rubles, depending on the equipment used.

to contents ↑

Installation of air suspension using the example of a VAZ

When creating an air suspension for a VAZ passenger car, the most difficult process is installing air bags instead of shock absorber struts. The best option is to use the original rack housing.

VAZ with air suspension

First, the front suspension is disassembled. To install the air cylinder, you may have to bore the body or adjust the cushions to the diameter of the glass using the same turning.

There is an option to create an adapter, where one part will fit tightly into the body in place of the shock absorber, and the other will become the basis for the air spring.

Determine all these operations locally, taking into account the specific car model and the type of cylinders used.

The air inlet connection must be properly protected when installed on the machine together with the rear cylinders.

At the next stage, tubes are laid and connected to the receiver and pneumatic cylinders. In the trunk we install the receiver itself with pressure gauges in the cabin.

Taking into account the high load on the front axle of the car at the front, the pressure must be set within 8 atmospheres, and at the rear it is usually enough to reach 6 atmospheres.

Secure the compressor well and lay out the electrical wiring, install toggle switches, unit switches, and fuses. Place all of the listed elements where it is convenient for you. The main thing is that you have the opportunity to constantly monitor the pressure in the system. If you plan to frequently change air suspension modes, consider the ability to control the compressor from a remote control.

to contents ↑

Precautionary measures

After installing the air suspension and during its further operation, pay special attention to the technical condition of the structure.

To do this, it is necessary to monitor the presence of air leaks in connecting places (adapters, valves and fittings). If the leak is severe, you will hear it, or you can use a regular soap solution.

Monitor the pressure gauges and monitor the rate of pressure drop in the pillows. Periodically check how the compressor is working.

Before operating a vehicle with newly installed air springs, make sure there are no extraneous vibrations, friction or noise. Mostly problems occur with the steered wheels. From time to time, check the hoses supplying air to the cylinders for chafing. Also check the condition of the fastening of the air tubes under the bottom.

Video: Air suspension: all about it / air suspension / pneuma / on pneuma.

Video: DIY air suspension 1

Video: How to make a VAZ pneumatic shock absorber. Do it yourself!

Video:

Video: Air suspension on a VAZ: Is it worth it or not? from Auto overhaul

Source: http://Driving24.ru/kak-sdelat-pnevmopodvesku-vaz-svoimi-rukami/

DIY air suspension, for VAZ, Gazelle, Mitsubishi Eclipse GTX 3.0TT AWD, reviews

The desire to change their car, adapt it to different operating conditions, give it a sporty spirit or turn it into an all-terrain vehicle forces car enthusiasts to undertake an unprecedented experiment - to install it with their own hands.

But how feasible is the idea? Is it really possible to do it using scrap materials and in your garage? Let's discuss these points in more detail.

Is it advisable to install air suspension on a car?

Let's figure out what air suspension is and whether it's worth spending money on it.

Air suspension is a shock absorption system that allows you to automatically change a car without the use of physical force.

This type of suspension is considered a universal option, which allows it to be mounted on both cars and trucks.

Installing air suspension guarantees a number of advantages:

- Changing the vehicle's ground clearance. To increase (decrease) the clearance, it is not necessary to change the springs or make major alterations. A few minutes of adjustment and the suspension sets the desired ground clearance.

- Smooth ride off-road. The disadvantage of spring shock absorbers is their sensitivity to uneven roads, which requires maximum attention from the person behind the wheel. With air suspension it is simpler - vibrations are compensated, which reduces vehicle shaking to almost zero.

- Comfort and controllability. Hard or soft springs have strengths and weaknesses. The former are suitable for asphalt roads, and the latter for off-road use. The advantage of air suspension is that it smooths out the disadvantages of different springs.

- No drawdown. The air suspension guarantees optimal ground clearance even at maximum load, as the ground clearance can be easily adjusted to the required value. So it doesn't matter how many passengers are inside the vehicle.

Before deciding to install such a suspension, it is worth considering a number of its disadvantages:

- The cost of air suspension is high, which discourages car enthusiasts. The money is used to purchase air bags, an air receiver, a compressor and other devices.

- Not maintainable. If any of the system elements fails, the entire unit will have to be replaced. This leads to additional costs, which not all car enthusiasts are ready for.

- Insufficient resistance to the negative effects of “chemicals” on the roads, frost, heat, and so on. Such factors lead to a decrease in the resource of the node. And if alcohol poured into a pillow can save you from the cold, then only the installation of original and expensive products will protect you from “chemicals” on the road.

The principle diagram of the air suspension looks like this.

Another scheme.

Installing air suspension on a VAZ 2110

Statistics show that car enthusiasts are more dissatisfied with the product of the domestic automobile industry. That is why the number of tuned “nines”, “tens” and other AvtoVAZ models is growing on the roads.

The principle of selecting components and installing air suspension for different VAZ models is almost identical.

For example, let's take the 2110 model.

So, to install the air suspension yourself, you will need the following material:

1. Racks.

Here it is allowed to use factory racks of the SAAZ type with oil filling. Purchase costs - 8 thousand rubles.

2. Air suspension cushions.

As an option, use pillows from Scania’s fourth generation, mounted under the cab of a truck. The issue price is 3 thousand rubles per piece. For example, these.

3. Receiver for air suspension.

A gas cylinder from the “nine” is suitable as a receiver. It has several advantages - the presence of a check valve, resistance to pressure up to 22 atmospheres, capacity up to 45 liters.

All these advantages indicate that the car will rise faster. The main disadvantage is the large mass.

As an alternative, a 25-liter cylinder from KamAZ can be used. The cost of purchasing a cylinder is 2.5 thousand rubles.

4. Valves.

To operate, you will need two pairs of solenoid valves. Pay attention to quality. Devices must withstand up to 25 atmospheres. Price - 350 rubles per piece.

5. Fittings and tubes.

The best option is the use of PVC pneumatic tubes used in the brake systems of trucks. Tubes are selected with a diameter of 6 and 8 mm. The first (at 6 mm) are mounted from the intake valves to the receiver, and the second (at 8 mm) - from the compressor to the receiver. The asking price is 35 rubles per meter.

6. Compressor.

An excellent option is to install a Berkut P 20 series compressor costing 4,950 rubles. Advantages: high pumping speed, reliability.

7. Management.

To control the valves, a special system was used, controlled by three toggle switches. The first starts and stops the rear circuit, the second the front circuit, and the third controls the compressor.

8. Pressure gauge.

A pressure gauge, as well as a moisture and oil separator, are installed between the receiver and the compressor. The installation location in the cabin is determined independently. The issue price is 80 rubles per piece.

Before starting work, it is worth considering the following points:

- To manufacture the body, you will need the help of a specialist turner. Without this, it will not be possible to fit the pillow (has a diameter of 4.5 cm) tightly onto the car body. In addition, you will have to make several sealing washers;

- On the boots at the front of the car, you will have to remove the spring cups. In this case, the springs installed at the rear are first lowered until the body touches the 15″ wheel, and then cut off.

The air suspension installation algorithm is as follows:

- Install racks. There are two options - make new holes or use existing ones (the second method looks preferable).

- Remove the rubber bands and thread the oxygen tubes. Next, secure them to the body part using clamps. To avoid drilling the body, you can use drainage holes;

- Next, we secure the tubes with clamps;

- Place the rear contour over the beam at the back of the car, and then pull along it;

- Mount the gas equipment valve, which is necessary to bleed air and reduce the vehicle's ground clearance, onto a special bracket for fixing the fuel tank. Remember that you need extra space for the tube, which will be required when raising or lowering the vehicle's ride height. The tube will be flexible, so it is fixed using clamps;

- Installing the front circuit takes more time because the tube has to be routed through the entire machine. The main difficulty is in fastening. Here you will have to stretch your brains and find a suitable place to fix it;

- Guide the tubes from the airbags installed at the front along the steering rods. Afterwards, bring them into the engine compartment, install the crosspiece, route the pipes, install a relief valve and a valve;

- We connect relays, toggle switches, fuses with wires; here you will need electrical knowledge;

- It remains to check the operation of the mechanism. Here you need to fill the system with air (up to eight atmospheres), close the garage and listen to the system for leaks. If the ear does not detect anything, then it is worth checking the joints with a soap solution.

Finally, it is worth noting the following points:

- The pressure in the system should be maintained at 8 atmospheres for the front airbags and 6 atmospheres for the rear airbags. During the inflation stage, it is worth monitoring the compressor to prevent it from overinflating the air suspension. Otherwise, negative consequences for the system are likely - damage to fittings, swelling of hoses and other problems;

- The wheel alignment of the air suspension should be left at the usual level. Adjustment is required only in the position that is most needed (at mid-height).

It should turn out like this.

Installing air suspension on a Mitsubishi Eclipse GTX 3.0TT AWD

There is a lot of speculation on the Internet that installing air suspension on a Mitsubishi Eclipse often leads to a number of problems. But that's not true.

https://www.youtube.com/watch?v=nBfaisAhqp4

If you organize the process correctly and strictly follow the technology, the result will please even demanding car enthusiasts.

Another option is to install ready-made equipment from K-Sport or other brands.

But this approach is not rational for the following reasons:

- Costs turn out to be higher than planned;

- The reliability of such a system is minimal;

- You have to wait several weeks, or even months, for the necessary repair kit.

Thus, self-assembly of component materials is preferable. Moreover, the market is saturated with everything necessary for work.

So, to install the air suspension you will need five high-quality struts.

Many people recommend installing Rubena products, but they have a number of disadvantages - difficulty in choosing spring stiffness, problems in selecting a design for the rear suspension, minimal service life.

To avoid problems and additional costs in the future, you should give preference to original spare parts for air suspension of Audi, Volkswagen, Mercedes and others.

Here it is better to consult a specialist.

You will also need a Berkut type compressor (it is affordable and has a maximum service life).

The work begins with installing the rear pillars and drilling several holes in the body under the spare tire.

New holes are required to install adapter fittings for air lines.

What does the valve block look like?

Next, the pneumatic line is connected to the compressor and pumped up to 7-8 atmospheres. A few seconds and the car jacked itself up to the required height.

All that remains is to check the system for leaks. If there are obvious “spikes”, it is worth checking the joints and the quality of tightening of the fittings.

The last stage is removing the jacks and testing the car.

If the work is done correctly, the machine becomes soft and problems with overcoming high obstacles are eliminated.

When falling into a hole, the air suspension behaves with dignity and withstands the test.

One likely problem is proximity to the tire. In such a situation, a spacer will need to be installed.

A separate point is the body level sensors. They have to be completed separately and even have special brackets welded in for subsequent installation.

Sensors from Land Rover are excellent.

When connecting sensors, it is recommended to use high-quality factory wiring that has native insulation.

Wheel alignment in the middle position of the suspension will not hurt, after which the swing goes away, speed bumps go over more smoothly, small holes are “swallowed” and are almost inaudible in the cabin.

Installing air suspension on a Gazelle

To install the air suspension on a Gazelle, you will need the following material:

- Single-cylinder compressor (it’s worth taking water-cooled products), for example, from PAZ 3205.

- A water separator is a device that is useful for removing moisture.

- Solenoid valves are available in a wide range. Here, give preference to products from famous brands.

- Receiver. The option with a new or used device is allowed. The main requirement is performance.

- Valves for separating circuits. Another option is to purchase a 4-circuit valve.

- Floor level tap. The recommended option is Wabco. The asking price is 6.5 thousand rubles.

- Air bags. There are several options - Ruben 170*3 (7-8 thousand rubles), Atego (4-5 thousand rubles). The characteristics of these units are almost identical. Air springs ROR 21222663 (2b220, 113002, FIRESTONE: W01M586887) performed well.

- Brackets for fixing pillows.

- Control system - buttons, pressure gauges, toggle switches, joysticks and others. The “brain” of the system is the ECAS unit, which will cost a pretty penny.

The greatest difficulty during the installation process is the fastening of the air springs. It is this moment that we will pay attention to.

The algorithm is as follows:

- A cross member is welded in with stops installed on it for installing pneumatic cushions. It is not difficult to weld the cross member - use the 16th channel;

- Prepare a platform for the pillow. If the springs sag, then the car should be raised using jacks;

- Installation starts from the top. First, the top is fixed, then the cushion swings and after the studs are joined, the holes are drilled. Please note that the work should be performed at working height. Also make sure the pillows are as far from center as possible. This is necessary to prevent friction of the products against the springs under load;

- Installation of airbags on the front axle is not required if the vehicle has a short wheelbase. If the base is long, then you cannot do without performing such work.

- Installation of pillows is done in two ways - above the springs (in the central part of the beam) or directly to the spring. Both options have disadvantages. So, if you install it behind the beam, then when you unscrew the steering wheel, it is possible that the newly installed unit will touch. If you place the structure closer to the central part of the beam (above the springs), then the front part of the car lifts up;

- A brand is screwed to the Gazelle frame, and a special channel structure is provided above the springs. So you will have to work on welding to eliminate possible risks for the air suspension;

- The cushions on the front and rear axles are installed from above, and then inflated to the desired height. Once the position of the holes is determined, drill the holes and install the pillow.

See the photo for more details.

The result of the work is a rigid front suspension. To add softness, it is worth placing receivers using thick tubes in parallel to the pillows.

Reviews

The results of installing the air suspension can be judged by the reviews of motorists who have successfully completed the process:

1. Egor, Ford Fiesta.

“Great thing. If the price of the factory version were not so high, then it would take less time to install the air suspension. But in any case, I’m happy as an elephant. The car has become softer, “eats” potholes better, and passes speed bumps without problems.

2. Igor, VAZ-2110.

“I had a hard time installing the air suspension, but I was satisfied with the result. Now on the highway I lower the ground clearance, and when driving off-road I raise it to the maximum. The result was an explosive mixture of an all-terrain vehicle and a sports car.”

3. Alexander, Mitsubishi Lancer.

“I spent several weeks and almost 50 thousand on installing the air suspension. The result was amazing and I don’t regret for a second that I decided to do it. The car has become soft, it takes turns better, and it has become much more comfortable inside. So the installation of air suspension justified itself 100%.”

Bottom line

Of course, having studied the material presented above, it is difficult to immediately install air suspension on a car with your own hands; the work is complex and requires certain qualifications in electrical, mechanical, and welding work.

You also need to choose the right components (and here you need expert advice) and think outside the box.

But if you have a great desire to improve the suspension of your car and the cost of such work does not stop you, then you will definitely achieve your goal and truly experience all the delights of driving a car with air suspension.

And we hope that we have given you the right direction of action.

We invite you to watch the video.

Source: http://PortalVAZ.ru/pnevmopodveska-svoimi-rukami-na-vaz-gazel-mitsubishi-eclipse-gtx-3-0tt-awd-otzyvy/

DIY air suspension

Do-it-yourself air suspension was conceived a long time ago. The obstacles to its installation were financial difficulties and technical issues. But they were finally overcome.

The air suspension was installed with my own hands on a Moskvich-2140 produced in 1986, in the SL configuration.

Air suspension diagram

The air suspension on the car is built according to a four-circuit design with 8 valves, 2 valves per cushion - one valve for air supply, the second for return. The scheme will allow you to effectively control each air spring: lower the left side, raise the right side or vice versa, lower the front of the car and raise the rear, etc.

Fig.1 Moskvich-2140

Fig.2

Air suspension components

Unfortunately, they do not produce ready-made air suspension kits for domestic cars, so I assembled the air suspension with my own hands. The main components of the air suspension are air springs from America . Having studied the range of produced airbags, taking measurements with a ruler so that the air pillows would fit in place of the springs and not rub against the lower arms, an order was made.

Also, solenoid valves were delivered from America. In addition to all of the above, we purchased: fittings, tees, nipples, etc., a compressor from a car store, an oxygen hose from the construction market.

For the front suspension, RE-5 air springs from the American company Slam Specialties were chosen. The outer diameter, depending on the load and pressure, is 130-139 mm.

If the diameter was larger, the air bags rubbed against the sides of the lower arm. In addition, the RE-5 has built-in bump stops, so the car's standard bump stops are not needed.

For the rear suspension, Dominator 2500 cushions were purchased.

Fig.3 PP

Air suspension valves

The electromagnetic type valves for the air suspension were controlled under a voltage of 12 volts.

The valves have a flow area of 15 mm and this allows them to pass a huge amount of air through themselves, which will make it possible to very quickly pump and bleed air from the air bag.

With these valves, the Mosvich will rise and fall in one second. The valves are connected with 0.5 inch plumbing threaded fittings.

Fig.4 Air suspension components

At the very beginning, the Berkut R17 compressor was used for the air suspension, but its performance was rather weak. Therefore, it was replaced by the Berkut R20 compressor, which is half the price of a similar design Viair 400P.

Fig.5 Berkut R20

Receiver

The receiver for the air suspension is an air cylinder with a volume of 20 liters from the brake system of a KAMAZ vehicle. Some modifications were made: the U-shaped supports were welded, cut from a channel and painted. It has 5 holes - two at each end, and one for draining condensate.

Fig.6 Receiver

Installing air springs on the front axle

The main feature of the front axle of cars from the 60s to the 80s is the placement of shock absorbers inside the springs. Therefore, we had to place the shock absorber differently. We also had to move the brake lines. The PP fastenings were made using metal pads 3 mm thick. The upper one is attached to the cross beam and the lower one to the lower arm.

Fig.7 Front axle

Fig.8 Disassembled front suspension

Fig.9 Air bags

Fig. 10 Shock absorber on a new mount

Fig. 11 Front axle with air spring

Fig.12 Front air suspension

Installing air springs on the rear axle

A 5 mm thick corner was attached to the spar, which served as an upper support for the Dominator 2500 PP. The lower mount of the PP was made of several plates, which were secured between the springs and spacers. Spacers were needed so that in the lower position the body would lower onto the bump stops. The spring leaves were reduced to 3 pieces, and the stepladders were replaced from IZH-2715, since they are longer.

Fig.13 Details

Fig.14 Rear inflated PP

Fig.15 Rear air suspension

Air suspension control

The air suspension is controlled by yourself using a wired remote control G1910 from Gainta with 8 buttons. You can control either one airbag or separately the front or rear suspension and left or right side.

Fig.17 Remote control

Fig. 18 PD diagram

Source: http://vsepoedem.com/story/pnevmopodveska-svoimi-rukami

Installing air suspension on a Gazelle with your own hands

Are you interested in information on how to install air suspension on a Gazelle yourself? Then you should take a closer look at the services provided by our company. We produce ready-made kits with which you can install air suspension on a Gazelle with your own hands.

We are talking about both mass production and custom production. Our products are distinguished by a well-thought-out design and configuration, so every car enthusiast can handle installation without any problems.

When installing air suspension on a Gazelle yourself, you do not need to make structural changes to the main components of the car.

DIY air suspension for Gazelle

Installing air suspension on a Gazelle with your own hands will help to significantly improve the performance characteristics of your car, in particular its load capacity, softness of the suspension, the ability to adjust ground clearance, and so on.

The cost of modernization depends solely on the configuration and functionality. You can assemble all the necessary components yourself or purchase a ready-made kit from us.

Traditionally, this kit includes the following components:

- air bags that perform the main function;

- a compressor responsible for pumping pneumatic elements;

- flanges, bolts and other fastening elements with which the main air system and other components are fixed;

- control unit with sensors that greatly simplify the use of this equipment;

- pressure gauge;

- receiver to expand the capabilities of the system.

Do-it-yourself installation of air suspension on a Gazelle is much easier using our instructions, which can be found in each kit.

How to install air suspension on a Gazelle yourself

Installing a pneumatic system on a Gazelle with your own hands is a profitable opportunity that will not only allow you to get a quality improvement for your car, but will also help you save money.

When installing air suspension on a Gazelle with your own hands, you need to follow the standard logic that is inherent in the design of each car. We are primarily talking about the following stages:

- placing your minibus on a lift or jack;

- removing the bump stops from the frame;

- preparing fastening elements for installation;

- installation of air bags in place of bump stops;

- installation of the main air system and compressor;

- installation of a receiver and additional options;

- installation and configuration of the control unit

Source: https://a-ride.ru/pnevmopodveska_dlya_gaz_gazely_-_opisanie_foto_ustanovka

How to make and install air suspension with your own hands

You can argue about pendants endlessly. Some people speak out for modern “pneumatics”, while others speak for spring “classics”. However, all car enthusiasts agree that air suspension really gives the car additional stability and maneuverability. Some of them, if desired and have basic skills, can make and install it on a car with their own hands.

What is air suspension

Air suspension is a type of suspension that can adjust the vehicle's ground clearance. In this case, the adjustment is made either automatically or forcefully, but the driver’s physical force is not required.

Initially, air suspensions were used only to equip trucks to give them additional stability and increase ground clearance.

However, recently, suspensions of this type have begun to be installed on passenger cars.

Shock absorbers acquire more substantial dimensions and weight

Structurally, air suspension differs from conventional spring suspension in that it contains several auxiliary elements:

-

compressor for pumping air;

-

a receiver containing compressed air;

-

systems for air flow distribution.

The operation of the air suspension in a car is organized as follows: first, the compressor pumps the required amount of air into the receiver. After this, air under a certain pressure is removed from the receiver through the valves. The amount of air and the degree of its compression, as well as the diameter of the valves for each car model are selected individually.

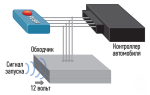

Four racks, compressor, receiver and controller

The main advantage of air suspension is that it makes the car more stable both when driving on uneven roads and when cornering at high speed..

In addition, the driver can adjust any height and stiffness of the suspension, that is, provide a smoother ride on any surface.

In addition, the use of air suspension allows you to experience other advantages of such equipment:

-

optimization of vehicle control;

-

availability of independent adjustment of the suspension depending on road conditions and driver habits;

-

personalization of the car - you can raise the body to the maximum height or lower it below the level recommended by the manufacturer;

-

practicality - even in cold weather, the performance characteristics of the air suspension remain at the usual level.

Today, the cost of cars with air suspension is higher than cars that are equipped with spring modifications. However, reliability in use and a number of advantages speak in favor of modern air suspensions.

Does it make sense to change the spring suspension to pneumatic?

Available statistics indicate that most owners of budget vehicles are dissatisfied with the handling and stability of their cars when cornering. Replacing a conventional spring suspension with a pneumatic one can immediately change ordinary movement indicators:

-

create the required ground clearance;

-

increase smoothness by increasing sensitivity;

-

make car trips more comfortable;

-

eliminate body sagging even at maximum load.

However, before changing a conventional suspension, for example, on a VAZ, it is recommended to calculate all the disadvantages of such a replacement:

-

high cost of assembled air suspensions;

-

if any of the suspension elements fail (for example, a valve, compressor or receiver), you will have to change the entire system - replacement for spare parts will not be possible;

-

Unlike spring suspension, air suspension reacts worse to changes in temperature conditions and reaction with road chemicals.

Features of using hydro, pneumatic and conventional suspension

Do not forget that modern cars can be equipped with a hydraulic suspension, which works thanks to a special fluid. Hydraulic suspension is considered more reliable than pneumatic suspension, as it provides a service life of up to 400 thousand kilometers. However, hydraulic elements are sensitive to the level of lubrication and, if they dry out, fail.

A conventional spring suspension has minimal cost and is easy to repair or replace.

When both hydraulic and air suspensions are expensive, and in the event of damage to any element, the entire unit immediately loses its functionality.

However, when comparing hydraulic and air suspensions, most drivers choose “pneumatic” due to its greater availability and wider range of settings.

How to make an air suspension with your own hands and install it

The key to the success of this enterprise is the correct selection of materials and preparation of tools. So, for work you will need standard equipment that almost every driver has:

-

angle grinder (grinder);

-

metal brush;

-

hammer;

-

knife;

- sealant.

The choice of materials will require special ingenuity from the master, since sometimes affordable elements can be used instead of expensive recommended products. To make your own air suspension, you will need to buy:

-

racks included (regardless of the reliability of the existing racks, you will need to purchase a new pair);

-

air suspension cushions (the most budget option is from a Scania car of the fourth generation);

-

receiver (you can save significantly on the purchase of this element if you have a gas cylinder from a VAZ 2109. The cylinder already contains a valve mechanism for “return” and is resistant to high air pressure);

-

two pairs of solenoid valves (the best option is valves with a pressure of up to 25 atmospheres);

-

several different PVC pipes and fittings to connect them. It is important to select tubes with a diameter of 6 mm and 8 mm - they are mounted in different parts of the system;

-

The compressor is one of the main elements of the pneumatic system; its choice should be taken as responsibly as possible: it is better not to skimp on quality;

-

control unit - any simple unit will do, the main thing is that it is equipped with three toggle switches;

-

pressure gauge - it is recommended to buy two devices at once (one is mounted between the compressor and the receiver, the other - in the cabin at the driver’s request);

-

moisture and oil separator - any.

Having prepared all the necessary material and tools, you can begin assembling the air suspension.

Manufacturing procedure

The front struts with pneumatics are made according to a more complex design than the rear struts. Therefore, we present two technologies.

Assembling the front struts

-

Knock off the cap from the stand and use a grinder to clean off the paint layer.

-

Press the adapter onto the stand; to ensure maximum softness, spacer rings can be added under it.

-

Fittings or tubes with a small diameter can be connected to the air supply holes in the adapter.

-

A pneumatic cushion is installed on the rack. It is necessary to calculate the height of the bump stop in advance, otherwise if there is a strong impact on the road, the spring may fail.

-

To seal the connection, a copper press washer and sealant are used.

-

Next, the support bearing is attached to the rack. It must be fixed in such a way that when the steering wheel is turned, the rod does not turn inside the shock absorber.

-

The air tube is connected to the cushion socket.

-

The pneumatic front strut is ready to be installed on the machine. The second rack is made using the same principle.

Rear strut assembly

-

Trim the spring cup a little and clean it of paint.

-

Cut threads for pneumatics to the end of the strut rod.

-

Before putting the air spring on the rod, we install a press washer for sealing.

-

The bump stop can be omitted, in which case the rear of the car will be lowered very low and at the same time create a unique smoothness of movement.

-

The air spring must be pressed onto the shock absorber completely.

-

After this, you can add air.

Video: how to assemble a rear pair of shock absorbers with air springs

Installation procedure

To install new suspensions, you will first need to remove the struts from the car. Even a novice driver can cope with this procedure - just jack up the car. After which the work will need to be carried out in the following order:

-

Install the rack into an existing hole (the option of creating new holes is allowed).

-

Remove the rubber bands and stretch the air supply tubes. Secure the tubes with clamps to the car body.

-

The cylinder (receiver) is mounted on a special bracket, which is located next to the gas tank.

-

The tubes from the airbags are routed through the steering rods. They will need to be brought into the engine compartment and routed to the relief valve and the valve that is installed on the receiver.

-

Next, the pneumatics are connected to the toggle switches of the control unit.

-

After which the installation is considered complete.

Video: installation

How to check

Immediately after installing homemade pneumatics on the shock absorbers of the car, you will need to make sure that the system is working. To do this, pressure is pumped up to 8 atmospheres. You should make sure by ear that there are no leaks in the system (no characteristic hissing of air can be heard).

After which it is necessary to set the pressure in the system for the front airbags to 8 atmospheres, for the rear ones - 6. The first time it is better not to rush into pumping air, since the compressor can pump over the system.

Next, it is recommended to adjust the vehicle's wheel alignment.

Air suspension control

The control unit is responsible for controlling the air suspension. Usually there are up to 8 buttons on it, each of which allows you to adjust both one specific strut and all shock absorbers in the complex.

To do this, a controller is installed in the car interior, which transmits indicators from each airbag to the driver.

Depending on the road situation, the driver can either increase or decrease the air pressure in the airbag, while the vehicle’s ground clearance will be increased or decreased.

Convenient display shows the pressure in each pillow

In order to turn off the air suspension, just press the corresponding button on the controller. Immediately after turning off, the system will set the average ground clearance, and the pillows will begin to work like regular shock absorbers on springs.

Recommendations for use

For daily use in a wide variety of conditions, air suspensions demonstrate amazing durability and practicality. Regardless of the characteristics of the road surface, the driver feels the smoothness and softness of the car.

However, pneumatic shock absorbers have two weak points - low temperatures and sand. Therefore, if you have to operate the car in severe frost (-35 degrees), it is recommended to reduce the ground clearance to a minimum.

This measure will protect the rubber elements from ruptures and ensure stability. In off-road conditions, where the vehicle is exposed to dirt and sand, the airbags can quickly fail.

There is only one way to prevent malfunctions: use high-quality pneumatic systems to equip the machine.

Thus, to assemble an air suspension and install it on a car, it requires not only a lot of time and effort, but also minimal experience. A beginner is unlikely to be able to make pneumatics on his own. However, even if you have experience and special knowledge, it is better not to neglect the advice of experienced car enthusiasts and use only expensive and reliable components.

Source: http://autoclub.su/kak-sdelat-pnevmopodvesku-svoimi-rukami/